عنا

مرحبا هل يمكنني مساعدتك؟

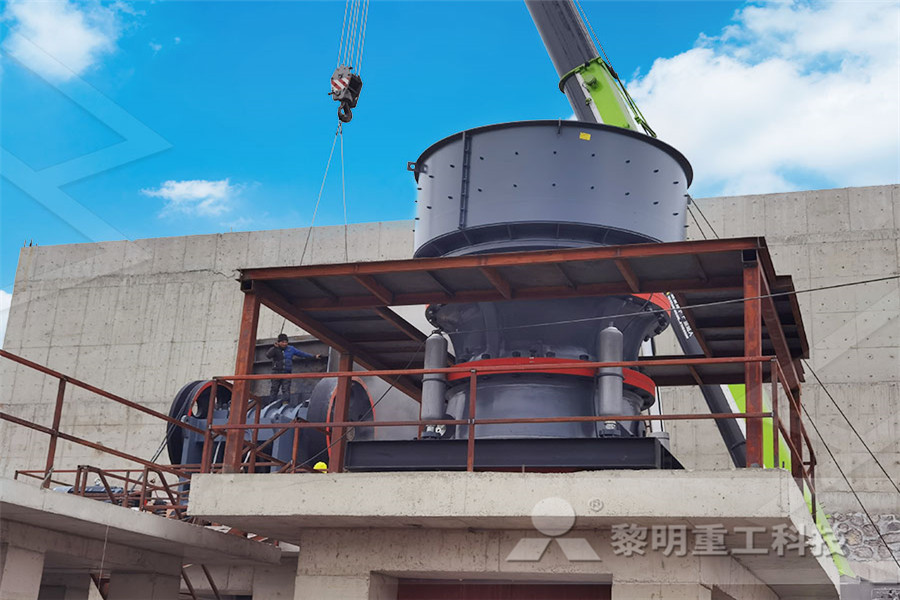

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

Coal Mine Blasting Design

2019-08-23T20:08:18+00:00

coal mine blasting design

Computer aided blastinground design in an arctic coal mine Design of blastingrounds in surface coal mines is dependent on physical properties and structural characteristics of the overburden material Design of blastingrounds in surface coal mines is dependent on physical properties and structural characteristics of the overburden material In the absence of any theoretical formula to design blasting rounds, mines have adopted a “trial and error” approach to optimize their blasting puter aided blastinground design in an arctic Casting design for bench blasting in surface coal mines is a new focus and a fairly recent success This study aims at the development of a model to predict the throw of overburden material based on geological conditions of a bench and charges in blast holesBlast round design and casting in surface coal mining

coal mine blasting design mojursuspl

coal mine blasting design Coal mining Britannica Coal mining Coal mining extraction of coal deposits from the surface of Earth and from underground Coal is the most abundant fossil fuel on Earth Its predominant Inquiry Online Mine Ventilation virtualminexpo SURFACE COAL BLASTING DESIGN Cast blastin g is being applied with great succe ss in coal mines in South Africa, United States, Australia and Ca nada The method may be defined as the use of explosi(PDF) A Dynamics Model of Surface Coal Blasting has yet to create a blast design method specifically tailored for large surface coal mine bench blasting This research examines the typical scale of bench blasting at large surface coal mines, develops a new method of design tailored for these operations, and tests the new method against two widely accepted traditional blast design methods NovelA novel powder factor based bench blast design method

Blasting in Underground Coal Mines miningst

Blasting in Coal Mines •Modern mechanised coal mines use machines and longwall mining methods to cut solid coal and convey the broken coal out of underground workings •Continuous mining equipment has escalated coal production and introduced The system named 3DBlasting Information and Judgment System (3DBIJS) can be used to predict mine after blast and help the decisionmaker to guide the practical production View Show abstract(PDF) Elements of drillandblast design and three The systematic planning and design process for underground coal mining operations – from inception to closure 1 PHASE 1: INVESTIGATIVE STUDIES 11 Market analysis The mine planning and design process for any new coal mining operation commences with the identification and analysis of specific market needs and requirements These needs andGUIDELINES FOR THE INTEGRATED PLANNING AND

Case Study Cast Blasting Orica Mining Services

Four seams of coal ranging from 1 metre to more than 43 metres thick are mined individually The coal from each seam is hauled by truck from the pit and stockpiled individually The coal then is crushed, sorted and washed Wilkie Creek mine has two active pits, namely A and B The blasting activities take place in Pit B in a hard has yet to create a blast design method specifically tailored for large surface coal mine bench blasting This research examines the typical scale of bench blasting at large surface coal mines, develops a new method of design tailored for these operations, and tests the new method against two widely accepted traditional blast design methods NovelA novel powder factor based bench blast design method This study addresses the effects of rock characteristics and blasting design parameters on blastinduced vibrations in the Kangal openpit coal mine, the Tülü openpit boron mine, and the Kırka openpit boron mine In this study, multiple vibration measurements have been conducted, and the related data have been analyzed and evaluatedInvestigation of the effects of blasting design

DESIGN OF SURFACE BLASTS A COMPUTATIONAL

National Institute of Technology Rourkela CERTIFICATE This is to certify that the thesis entitled “SURFACE BLAST DESIGNA COMPUTATIONAL APPROACH” submitted by Sri Ashutosh Mishra, Roll No in partial fulfillment of the requirements for the award of Bachelor of Technology degree in MiningLong, mid and short term Geology Models from through seam blasting, productions designs and schedules to LOM and asset life models all reconciliations and variance is quantified Lifeofmine planning risk assessments on geological structure and risks to your sites coal mineVulcan Model Coal Mine Solutions AustraliaThe Blast Management and Design Course is intended for managers, engineers, supervisors and motivated shotfirers Participants for the management course will be assumed to have a working knowledge of explosives, blast design and total mine operation objectives, and preferably to have previously attended an Orica Safe Efficient Blasting courseSafe Efficient Blasting in Opencut Coal and

Optimization of Blasting Parameters in opencast Mines

CHAPTER 3: DRILLING AND BLASTING IN LARGE OPENCAST MINES 31 Drilling 32 Blasting 33 Recent Advancement in Drilling and Blasting Techniques 922 2329 3040 CHAPTER 4: REVIEW OF OPTIMIZATION TECHNIQUES 41 General 42 Optimization of Mine Production System through Operation Research Techniques 4145 45331 Improved Coal Control By significantly improving material fragmentation and accurately identifying coal seams, stratification can also reduce coal loss or dilution Improved Safety Since stratification can improve blasting performance and blastloading design, it can significantly reduce the amount of fly rock produced by explosivesAutomated Coal Seam Identification Improves Drilling PRINCIPLES OF BLASTING IN COAL Underground coal mining operations could be divided into two categories , namely, Development and Depillaring Both for bord andpillar as well as for longwall mining, driving galleries through coal seams are done there are two techniques employed for blasting in development galleries =>Blasting on precut face Explosives and blasting in underground coal mining

Blasting DEQ Wyoming Department of

Blasting The Land Quality Division (LQD) regulates blasting in surface coal mining in Wyoming, and has a Memorandum of Understanding (MOU) with Wyoming Mine Inspector for all other mining operations in the state The MOU can be downloaded by clicking HERE The LQD's regulatory duties include issuing Blaster Certifications, review of shot Blasting in Mines 56 likes This book teaches how various types of explosives are made and utilized for Mining Production It is a core undergraduate Mining Engineering subjectBlasting in Mines Science, Technology Engineering Computer aided blastinground design in an arctic coal mine Design of blastingrounds in surface coal mines is dependent on physical properties and structural characteristics of the overburden material In the absence of Read morecoal mine blasting design

A novel powder factor based bench blast design method

has yet to create a blast design method specifically tailored for large surface coal mine bench blasting This research examines the typical scale of bench blasting at large surface coal mines, develops a new method of design tailored for these operations, and tests the new method against two widely accepted traditional blast design methods NovelThis study addresses the effects of rock characteristics and blasting design parameters on blastinduced vibrations in the Kangal openpit coal mine, the Tülü openpit boron mine, and the Kırka openpit boron mine In this study, multiple vibration measurements have been conducted, and the related data have been analyzed and evaluatedInvestigation of the effects of blasting design A method for solid blasting in underground coal mines, which comprises drilling a plurality of shot holes in a development face in an underground coal mine and charging each of the said shot holes with airdecked explosive cartridges(l), characterized in that the said explosive cartridges being airdecked using spacers(2) between the said "A METHOD FOR SOLID BLASTING IN

Blasting Techniques Used in Underground and

2 天前 In underground coal mine the yield of coal on an undercut face is nearly 58 te per kg of explosive and 125 te per detonator but with solid blasting the figures are 18 to 27 te per kg of explosive and 08 to 135 te per detonator CHAPTER 3: DRILLING AND BLASTING IN LARGE OPENCAST MINES 31 Drilling 32 Blasting 33 Recent Advancement in Drilling and Blasting Techniques 922 2329 3040 CHAPTER 4: REVIEW OF OPTIMIZATION TECHNIQUES 41 General 42 Optimization of Mine Production System through Operation Research Techniques 4145 4548Optimization of Blasting Parameters in opencast MinesThe Blast Management and Design Course is intended for managers, engineers, supervisors and motivated shotfirers Participants for the management course will be assumed to have a working knowledge of explosives, blast design and total mine operation objectives, and preferably to have previously attended an Orica Safe Efficient Blasting courseSafe Efficient Blasting in Opencut Coal and

Blasting DEQ Wyoming Department of

Blasting The Land Quality Division (LQD) regulates blasting in surface coal mining in Wyoming, and has a Memorandum of Understanding (MOU) with Wyoming Mine Inspector for all other mining operations in the state The MOU can be downloaded by clicking HERE The LQD's regulatory duties include issuing Blaster Certifications, review of shot COAL MINE PLANNING DESIGNAVREDDY, ADDLMANAGER The Singareni Collieries Company Limited Mining Methods Generally Coal is being mined by two main methods 1 Surface or Opencast mining 2 Underground mining The choice of method is largely determined by the depth, thickness and no of coal seams, geology of the coal deposit and other factors MinePlanningDesignppt Coal Mining Blasting in Mines 56 likes This book teaches how various types of explosives are made and utilized for Mining Production It is a core undergraduate Mining Engineering subjectBlasting in Mines Science, Technology Engineering