عنا

مرحبا هل يمكنني مساعدتك؟

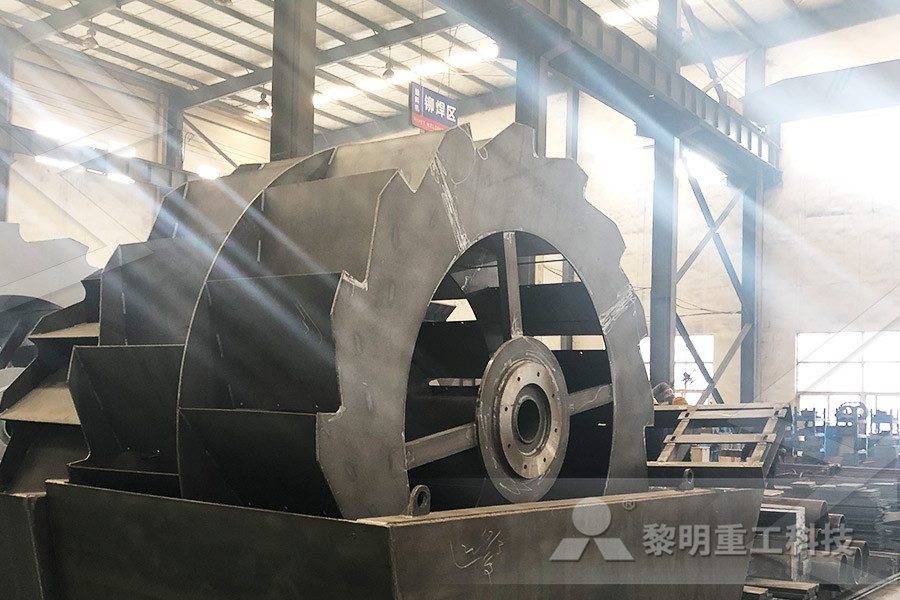

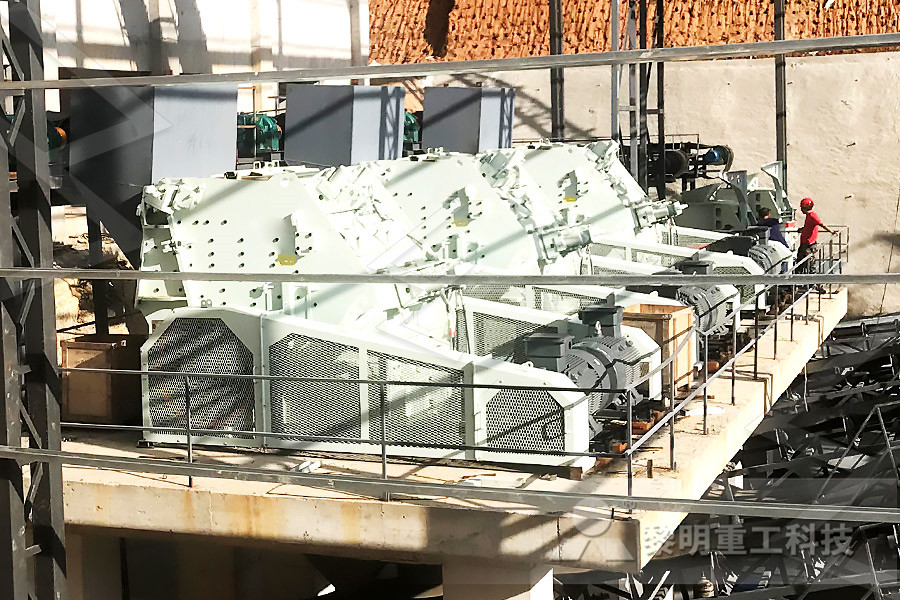

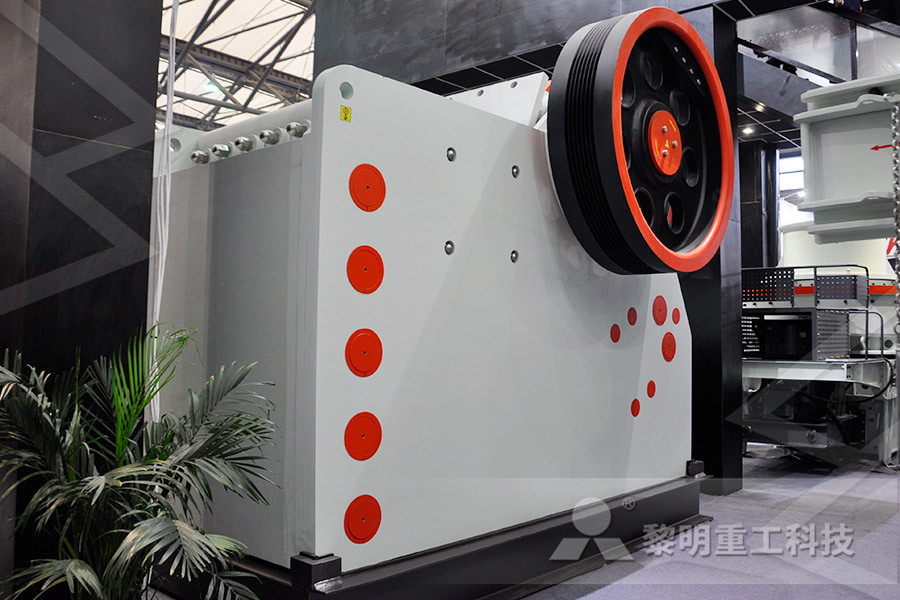

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

separation of gold from titanium

2021-08-14T16:08:30+00:00

Separation of gold and other rare materials from an

The three diamagnetic samples, namely, bismuth, graphite and gold, were cut from synthetic blocks with high purities (>9999%) by using a titanium knife to avoid contaminations of small A simple and sensitive solid phase extraction method was developed for simultaneous separation and preconcentration of gold and palladium ions with N(4methylphenyl)2{[(4phenyl5pyridine4yl Determination of gold by nanometer titanium dioxide Selective extraction and separation of titanium from vanadium slag and preparation of TiO 2 Shiyuan Liu , 1 , 2 Xiaobo He , 3 Shun Wu , 1 Yahui Liu , 2 Lijun Wang , * 1 and KuoChih Chou 3 1 Collaborative innovation center of steel technology, University of Selective extraction and separation of titanium from

Separation and Purification of Value Metals from

Abstract The demand for elements such as nickel, cobalt, titanium and gold in various applications has increased significantly Innovation to recover these elements now plays a major role in metallurgical processes as established technologies have challenges in treating the types of ores that are available while meeting the increasingly stricter environmental regulations Two cathode materials were used for the experiments of gold electrorecovery: 18 cm 2 vitreous carbon and titanium flat plates The electrochemical cell reactor is also comprised of a DSA® type (TiO 2 ) 07 /(RuO 2 ) 03 oxide anode and a Nafion® 450 membrane for the separation of the cathodic and anodic chambersSelective electrochemical recovery of gold and silver Sand Ltd, 1999) In some plant operations, dry magnetic separation is employed, particularly for recovering of titanium bearing minerals such as ilmenite and leucoxene from heavy mineral concentrates (Stradling, 1991) However, flowsheets for the recovery of titanium bearing minerals from beach sands differ withRecovery of titanium from beach sand by physical

Separation Of Titanium Ore From Magnetite

Separation Of Titanium Ore From Magnetite Wet drum magnetic separator for magnetite, limonite,hematite and titanium of iron ore chat online magnetite is sometimes found in large quantities in beach sand such black sands (mineral sands or iron sands) are found in various places, such as lung kwu tan of hong kong; california, united states; and the west coast of the north island of new The use of certified reference material, gold standard solutions and gold radioactive tracer 198 Au has shown that the separation efficiency of gold from iron is very high where the selective coefficient K Fe Au is found to be ≈64×10 11 Also, the resin capacity of gold tetrabromoaurate has been measured and found to be ≈12 m eq/1 g resinSelective separation of gold from iron ore samples To participate in the 911Metallurgist Forums, be sure to JOIN LOGIN Use Add New Topic to ask a New Question/Discussion about Gravity Separation/Concentration OR Select a Topic that Interests you Use Add Reply = to Reply/Participate in a Topic/Discussion (most frequent) Using Add Reply allows you to Attach Images or PDF files and provide a more complete input Use Add Comment = to Titanium Processing after Gravity Separation Gravity

extraction of titanium chemguide

Titanium extraction The overall process Titanium is extracted from its ore, rutile TiO 2 It is first converted into titanium(IV) chloride, which is then reduced to titanium using either magnesium or sodium Conversion of TiO 2 into TiCl 4 The ore rutile (impure titanium(IV) oxide) is heated with chlorine and coke at a temperature of about A new method has been developed for the determination of gold based on separation and preconcentration with a microcolumn packed with nanometer Determination of gold by nanometer titanium dioxide We present a facile twostep procedure for synthesizing spiky nanohybrids of titanium dioxide/gold (TiO 2 /Au) nanoparticles In this process, spiky TiO 2 is obtained using a hydrothermal method, followed by the introduction of plasmonic Au nanoparticles (AuNPs) via a photoreduction approach in which titanium fluoride and chloroauric acid tetrahydrate are used as raw materialsSpiky nanohybrids of titanium dioxide/gold

Constructing functionalized plasmonic gold/titanium

Constructing functionalized plasmonic gold/titanium dioxide nanosheets with small gold nanoparticles for efficient photocatalytic hydrogen evolution J Colloid Interface Sci 2019 Nov 1;555:94103 doi: 101016/jjcis201907060 A new twostep extraction procedure is proposed for separation and preconcentration of gold nanoparticles (AuNPs) from aqueous samples First, AuNPs are loaded onto a reversed phase C18 (RPC18) column, and then ligandassisted extraction into chloroform is performed 1Dodecanethiol (1DDT, 5 mM) was used as selective ligand for quantitative extraction under ultrasonic condition LigandAssisted Extraction for Separation and Solidphase extraction, separation and preconcentration of titanium(IV) with SSGV10 from some other toxic cations: a molecular interpretation supported by DFT June 2014 RSC Advances 4(64):3392333934(PDF) Solidphase extraction, separation and

Titanium Processing Equipment, Process Flow, Cases

Titanium can be alloyed with iron, aluminum, vanadium, and molybdenum, among other elements, to produce strong, lightweight alloys for aerospace (jet engines, missiles, and spacecraft), military, industrial processes (chemicals and petrochemicals, desalination plants, pulp, and paper), automotive, agriculture (farming), medical prostheses, orthopedic implants, dental and endodontic instruments To participate in the 911Metallurgist Forums, be sure to JOIN LOGIN Use Add New Topic to ask a New Question/Discussion about Gravity Separation/Concentration OR Select a Topic that Interests you Use Add Reply = to Reply/Participate in a Topic/Discussion (most frequent) Using Add Reply allows you to Attach Images or PDF files and provide a more complete input Use Add Comment = to Titanium Processing after Gravity Separation Gravity Titanium extraction The overall process Titanium is extracted from its ore, rutile TiO 2 It is first converted into titanium(IV) chloride, which is then reduced to titanium using either magnesium or sodium Conversion of TiO 2 into TiCl 4 The ore rutile (impure titanium(IV) oxide) is heated with chlorine and coke at a temperature of about extraction of titanium chemguide

Mineral processing Concentration Britannica

Mineral processing Mineral processing Concentration: Concentration involves the separation of valuable minerals from the other raw materials received from the grinding mill In largescale operations this is accomplished by taking advantage of the different properties of the minerals to be separated These properties can be colour (optical sorting), density (gravity separation), magnetic The FoM of the TiN dimer exhibits a slow increase, and even a slight decline, with decreasing separation distance, which differs from the FoM performance in the Au nanosphere dimer This result is consistent with the trend of the absorption spectrum for separation gaps smaller than 5 nm (figures 1(b) and (c)) As the separation gap decreases New coupling mechanism of titanium nitride The three diamagnetic samples, namely, bismuth, graphite and gold, were cut from synthetic blocks with high purities (>9999%) by using a titanium knife to avoid contaminations of small Separation of gold and other rare materials from an

Separation Of Titanium Ore From Magnetite

Separation Of Titanium Ore From Magnetite Wet drum magnetic separator for magnetite, limonite,hematite and titanium of iron ore chat online magnetite is sometimes found in large quantities in beach sand such black sands (mineral sands or iron sands) are found in various places, such as lung kwu tan of hong kong; california, united states; and the west coast of the north island of new Visible‐Light‐Induced Electron Transport from Small to Large Nanoparticles in Bimodal Gold Nanoparticle‐Loaded Titanium(IV) Oxide † Dr Shin‐ichi Naya Environmental Research Laboratory, Kinki University, 3‐4‐1, Kowakae, Higashi‐Osaka, Osaka 577‐8502 (Japan)Visible‐Light‐Induced Electron Transport from Small USA USA USA USA US A US A US A US A US A US A US A US A US A US A US A US A Authority US United States Prior art keywords gold separating precious metals lead zinc Prior art date Legal status (The legal status is an assumption USA Process of removing gold, silver, copper,

Titanium Processing Equipment, Process Flow, Cases

Titanium can be alloyed with iron, aluminum, vanadium, and molybdenum, among other elements, to produce strong, lightweight alloys for aerospace (jet engines, missiles, and spacecraft), military, industrial processes (chemicals and petrochemicals, desalination plants, pulp, and paper), automotive, agriculture (farming), medical prostheses, orthopedic implants, dental and endodontic instruments We fabricated a ptype nickel oxide (NiO)/gold nanoparticle (AuNP)/ntype titanium dioxide (TiO 2) structure in which AuNPs are placed in the pn junction of TiO 2 and NiO The photoelectric properties of NiO/AuNPs/TiO 2 suggest that the main driving force of the hole separation from AuNPs to NiO is the local electric field of the depletion layer of the pn junction of TiO 2 and NiO rather Hotcarrier Separation Induced by the Electric Field of Mineral processing Mineral processing Concentration: Concentration involves the separation of valuable minerals from the other raw materials received from the grinding mill In largescale operations this is accomplished by taking advantage of the different properties of the minerals to be separated These properties can be colour (optical sorting), density (gravity separation), magnetic Mineral processing Concentration Britannica

extraction of titanium chemguide

Titanium extraction The overall process Titanium is extracted from its ore, rutile TiO 2 It is first converted into titanium(IV) chloride, which is then reduced to titanium using either magnesium or sodium Conversion of TiO 2 into TiCl 4 The ore rutile (impure titanium(IV) oxide) is heated with chlorine and coke at a temperature of about The FoM of the TiN dimer exhibits a slow increase, and even a slight decline, with decreasing separation distance, which differs from the FoM performance in the Au nanosphere dimer This result is consistent with the trend of the absorption spectrum for separation gaps smaller than 5 nm (figures 1(b) and (c)) As the separation gap decreases New coupling mechanism of titanium nitride The present study investigated the acid and flux fusion digestion techniques for complete dissolution of ilmenite and subsequent separation of iron and titanium by precipitation process Analytical results indicated that the Na 2 HPO 4 /NaH 2 PO 4 H 2 O, Na 2 B 4 O 7 and LiBO 2 flux fusion procedures were the most effective for complete Selective precipitation study for the separation of iron