عنا

مرحبا هل يمكنني مساعدتك؟

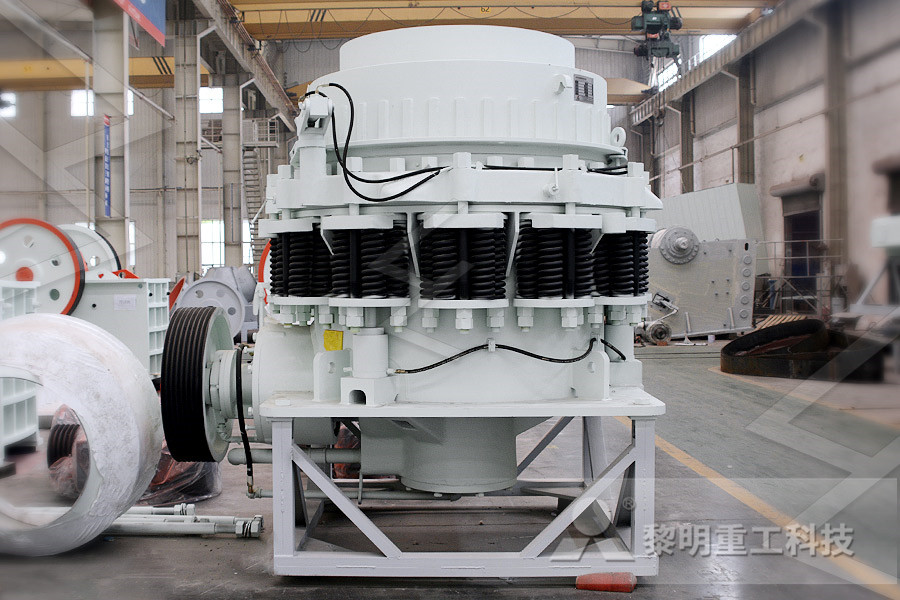

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

Hematite Iron Ore Revery Rates

2019-02-12T03:02:46+00:00

Recovery and separation of iron from iron ore using

The hematite ore is first heated to 700~800 °C in the heating zone, then falls into the reduction zone where flow rates of reducing gas CO and fluidizing gas N 2, on the recovery and separation Recovery and separation of iron from iron ore using innovative fluidized magnetization roasting and magnetic separation The goethetichematite iron ore contains more goethite and kaolinite mineral Optimum iron ore recovery of 786% was achieved with 637% Fe in concentrate when the jig was operated at medium (PDF) Recovery of iron from iron ore slimes by Iron ore is a mineral substance which, when heated in the presence of a reductant, will yield metallic iron (Fe) It almost always consists of iron oxides, the primary forms of which are magnetite (Fe3O4) and hematite (Fe2O3) Iron ore is the source of primary iron for the world's iron and steel industries It is therefore essential for the Hematite Fe2O3 PubChem

Flotation of silicates gangue from hematite containing

The gravity concentration allows obtaining of iron concentrate from the wellprepared feed (size fraction 53+20 micron) but with very low recovery Thus, the hematite concentrates with weak silica content and satisfactory iron recovery were obtained by reverse cationic flotation, when it was fed with iron preconcentrate produced by high gradientReverse flotation of silica from hematite is by far the most common route for the processing of iron ore containing silica gangue [1] In reverse flotation of iron ore, quartz, the major impurity Removal of hematite from silica sand ore by reverse Currently beneficiation of hematite ores is conducted using either direct flotation (hematite flotation) or indirect flotation (quartz flotation) techniques depending upon the nature of the available ore bodies In direct flotation, iron bearing mineral, mostly hematite, is floated using oleate as collecFLOTATION CHEMISTRY OF HEMATITE/OLEATE SYSTEM

Recovery and separation of iron from iron ore using

The rotary kiln generally handles hematite ores with a grain size of less than 30 mm [ 8]; however, the formation of clinker ring in the rotary kiln will affect the yield of iron resource [ 11 ] In the fluidized bed furnace, the hematite ore is shaken up by an upward current of gas which maintains the individual particles in suspension [ 12 13]Under these optimum conditions, iron concentrate with an iron grade of 5974% and iron recovery rate of 8631% were obtained by magnetic separation However, as the ore particle size became finer, it becomes difficult to capture the fine particles by magnetic separation, which would reduce the recovery rate of iron ore 33Strengthening iron enrichment and Abstract In the present investigation, fired pellets were made by mixing hematite iron ore fines of 100, 16+18, and 8+10 mesh size in different ratios and studies on their reduction kinetics in Lakhanpur, Orient OC2 and Belpahar coals were carried out at temperatures ranging from 850{sup o}C to 1000{sup o}C with a view toward promoting the massive utilization of fines in ironmakingStudies on the reduction kinetics of hematite iron ore

Minerals Free FullText Recovering Iron from Iron

Iron ore tailings (IOTs) are a form of solid waste produced during the beneficiation process of iron ore concentrate In this paper, iron recovery from IOTs was studied at different points during a process involving preconcentration followed by direct reduction and magnetic separation Then, slagtailing concrete composite admixtures were prepared from highsilica residues Iron Ore Conference Perth, WA 1 Iron Ore 2011 Unlocking the value in waste and reducing tailings: suitable product grades and production rates could be achieved These test programs Hematite recovery cannot be practically improved and hematite as it is not magnetic and will decreaseErnest Henry Iron Ore 2011 Paper final IsaMillAbstract: There are two types of iron resources such as primary iron ore and iron sand In general, primary iron ores use as raw materials in iron and steel making and can reduce directly In Direct reduction process, Fe 2 O 3 (hematite) is converted to metallic iron by the removal of oxygen This work presents a heat transfer rate study for Hematite

SEPARATION EXPERTISE FOR YOUR SUCCESS IN THE

production rates, and minimize maintenance Now and for years to come Whether it’s reducing the amount even thickeners and plants for water recovery When the highest volumes are critical, our innovative With difficult hematite iron ore, it was also the very fine particle size distributionThe gravity concentration allows obtaining of iron concentrate from the wellprepared feed (size fraction 53+20 micron) but with very low recovery Thus, the hematite concentrates with weak silica content and satisfactory iron recovery were obtained by reverse cationic flotation, when it was fed with iron preconcentrate produced by high gradientFlotation of silicates gangue from hematite containing Iron (Fe) is a metallic element which constitutes about 5% of the Earth’s crust and is the fourth most abundant element in the crust Iron ores are rocks from which metallic iron can be economically extracted The principal iron ores are hematite (Fe 2 O 3) and magnetite (Fe 3 O 4) Hematite is an iron oxide mineral It is nonmagnetic and has colour variations ranging from steel silver to Iron Ore AIMR 2011 Australian Mines Atlas

Why iron ore grade is now more important than ever

In Australia, hematite has been the dominant iron ore mined since the early 1960s, accounting for about 96 per cent of the country’s iron ore exports Load Error The rotary kiln generally handles hematite ores with a grain size of less than 30 mm [ 8]; however, the formation of clinker ring in the rotary kiln will affect the yield of iron resource [ 11 ] In the fluidized bed furnace, the hematite ore is shaken up by an upward current of gas which maintains the individual particles in suspension [ 12 13]Recovery and separation of iron from iron ore using Abstract In the present investigation, fired pellets were made by mixing hematite iron ore fines of 100, 16+18, and 8+10 mesh size in different ratios and studies on their reduction kinetics in Lakhanpur, Orient OC2 and Belpahar coals were carried out at temperatures ranging from 850{sup o}C to 1000{sup o}C with a view toward promoting the massive utilization of fines in ironmakingStudies on the reduction kinetics of hematite iron ore

Ernest Henry Iron Ore 2011 Paper final IsaMill

Iron Ore Conference Perth, WA 1 Iron Ore 2011 Unlocking the value in waste and reducing tailings: suitable product grades and production rates could be achieved These test programs Hematite recovery cannot be practically improved and hematite as it is not magnetic and will decrease The concentration of low grade iron ore resources was evaluated by washing and reduction The advanced concentration methods for low grade limonite and hematite iron ores of South Eastern Anatolian resources required such specific methods The followed column flotation and magnetic separation, microwave radiated reduction of hematite slime and limonite sand orewere investigated on Concentration and Microwave Radiated Reduction of Abstract: There are two types of iron resources such as primary iron ore and iron sand In general, primary iron ores use as raw materials in iron and steel making and can reduce directly In Direct reduction process, Fe 2 O 3 (hematite) is converted to metallic iron by the removal of oxygen This work presents a heat transfer rate study for Hematite

SEPARATION EXPERTISE FOR YOUR SUCCESS IN THE

production rates, and minimize maintenance Now and for years to come Whether it’s reducing the amount even thickeners and plants for water recovery When the highest volumes are critical, our innovative With difficult hematite iron ore, it was also the very fine particle size distributionThe gravity concentration allows obtaining of iron concentrate from the wellprepared feed (size fraction 53+20 micron) but with very low recovery Thus, the hematite concentrates with weak silica content and satisfactory iron recovery were obtained by reverse cationic flotation, when it was fed with iron preconcentrate produced by high gradientFlotation of silicates gangue from hematite containing Iron Ore is a rock containing ironrich compounds and forms the basic raw material in the manufacture of steel and iron products There are many varieties of iron ore – eg: hematite and magnetite – mined throughout the world and shipped, especially in large vessels, to industrial regions worldwide in the form oi fines (dust) or in lumps; can be very dusty or, alternatively, attract Iron Ore HandyBulk

Why iron ore grade is now more important than ever

In Australia, hematite has been the dominant iron ore mined since the early 1960s, accounting for about 96 per cent of the country’s iron ore exports Load Error Flotation tests conducted on the two Iron Duke samples using oleate showed that the presence of goethite adversely affected the flotation response of the hematite but contact angle measurements showed a higher hydrophobicity for the sample containing 25% goethite Correcting the oleate addition for the changes in surface area still showed that the goethite reduced the flotability of the hematiteEffect of 25% Goethite on the Hydrophobicity and