عنا

مرحبا هل يمكنني مساعدتك؟

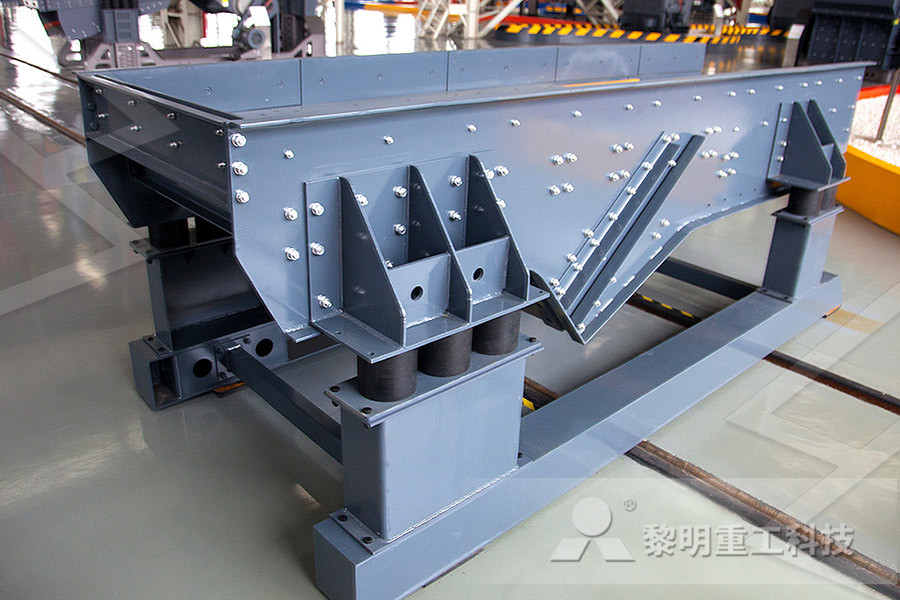

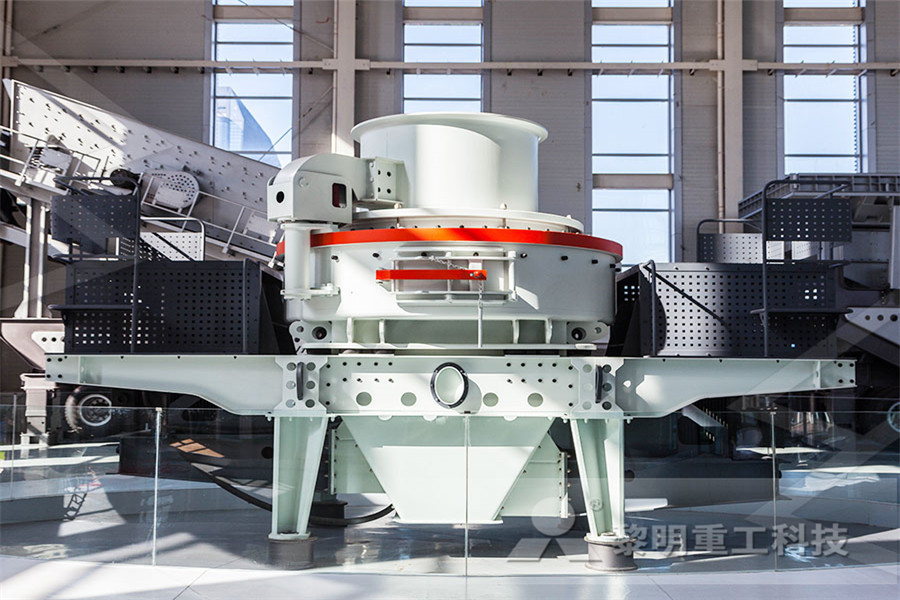

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

process for dry milling of aluminium flakes

2022-04-02T01:04:21+00:00

process for dry milling of aluminum flakes

process for dry milling of aluminium flakes Aluminum flake powder can be produced using aluminum foil scrap in the dry ball milling process During the ball milling the foil is laminated, microforged, cracked continuously, and then finally formed into a flake shape powder The size and shape of the flake powder produced depend on the ball milling conditions such as the ball size, the number of Process For Dry Milling Of Aluminium Flakes Manufacturing of aluminum flake powder from foil scrap by dry ball The aluminum flake powder produced by the dry ball milling of aluminum foil In the stamp milling method, aluminum powder is milled by a hammer in an airProcess For Dry Milling Of Aluminium FlakesProcess for dry milling of aluminium flakes ball mill metal flakes is one of the biggest manufacturers in aggregate processing machinery for the process for dry milling of aluminium flakes ball mill check price aluminum powders pastes and flakes market trends aluminum flakes are derived from aluminum powder by the dry ball milling processDry Ball Milling Process Of Aluminum Flake Powder In

production process of dry milling aluminium powder

Process For Dry Milling Of Aluminium Flakes (PDF) Production of Aluminum Flake Pigments by Ball Mill Aluminum pigments are produced almost exclusively using the Hall process which is a wet milling process utilizing mineral spirits Dry milling is not done due to safety concerns Typically, mineral spirits and a fatty acid lubricant are added Dry Ball Milling Process Of Aluminum Flak Powder ATS Dry Ball Milling Process Of Aluminum Flake Powder Produced by the wet ball milling process of gas atomized aluminum powder the wet ball milling is performed in inorganic solvent such as mineral spirits 34 wx in this study the milling behavior of aluminum foil scrap for producing the flake powder was investigateddry ball milling process of aluminum flake powderball mill metal flakes process for dry milling of aluminium flakes ball mill metal flakes; is one of the biggest manufacturers in Aggregate Processing Machinery for the process for dry milling of aluminium flakes ball mill, Check price Aluminum Powders Pastes and Flakes Market Trends Aluminum flakes are derived from aluminum powder by the dry ball milling processball mill metal flakes myplacechildrencentrecoza

Manufacturing of aluminum flake powder from foil

The milling is performed for 45 h at a rotational speed of 120 rpm, which is 78% of the critical rpm , , The milling time, the ball size (diameter 96 or 16 mm), the number of intermediate stops during milling for 25 h, and the content of stearic acid were varied in the dry ball milling process The dry ball milling is carried out in a horizontal jar containing balls, powder and a processcontrolling agent such as stearic acid under an inert gas atmosphere with a few % of oxygen, which atmosphere can prevent explosion The aluminum flake powder for aerated lightweight concrete, fingerprint detection, etc, is usually produced by the Manufacturing of Aluminum Flake Powder From Foil In the drying process the aluminium flakes are allowed to oxidize in a controlled environment to ensure a safe and consistent product for our customers Our powders are well suited for technical applications like Autoclaved Aerated Concrete, and Civil Explosives, where the choice of lubricant and additives during the milling process gives Aluminium Flake Powder Products Carlfors Bruk

CAA1 Process for dry milling zinc powder to

A method for the production of zinc flake from zinc particles which comprises dry milling said zinc particles using a mixture of a fluorocarbon lubricant and a stearate lubricant, optionally in admixture with a hydrophobic inorganic powder A preferred fluorocarbon is PTFE and a preferred stearate lithium stearate If desired the zinc dust used may be in the form of an alloy or mixture with Process For Dry Milling Of Aluminium Flakes (PDF) Production of Aluminum Flake Pigments by Ball Mill Aluminum pigments are produced almost exclusively using the Hall process which is a wet milling process utilizing mineral spirits Dry milling is not done due to safety concerns Typically, mineral spirits and a fatty acid lubricant are added production process of dry milling aluminium powderWet Ball Milling Vs Dry Ball Milling Orbis Machinery, LLC Jun 27, 2019 The grinding of aluminium for the preparation of paint is most of the time carried out using a wet milling process since the method introduces stearic acid, or other antiflocculent Milling the powder in the wet or dry process of dry milling aluminium powder

ball mill metal flakes myplacechildrencentrecoza

ball mill metal flakes process for dry milling of aluminium flakes ball mill metal flakes; is one of the biggest manufacturers in Aggregate Processing Machinery for the process for dry milling of aluminium flakes ball mill, Check price Aluminum Powders Pastes and Flakes Market Trends Aluminum flakes are derived from aluminum powder by the dry ball milling process The dry ball milling is carried out in a horizontal jar containing balls, powder and a processcontrolling agent such as stearic acid under an inert gas atmosphere with a few % of oxygen, which atmosphere can prevent explosion The aluminum flake powder for aerated lightweight concrete, fingerprint detection, etc, is usually produced by the Manufacturing of Aluminum Flake Powder From Foil In the drying process the aluminium flakes are allowed to oxidize in a controlled environment to ensure a safe and consistent product for our customers Our powders are well suited for technical applications like Autoclaved Aerated Concrete, and Civil Explosives, where the choice of lubricant and additives during the milling process gives Aluminium Flake Powder Products Carlfors Bruk

Stability In Aluminium Flake Powder During Dry Ball Mill

milling process in ball mills (Hall Process), whereas gold bronze pigments are produced in a dry milling atomized aluminium powder to the desired particle As a result of the wetting behavior of the flakes, the systems is the gassing stability of the metal pigments, through special surface coatings of recommendations for ball milling aluminium flake powder,aluminum flake powder AluminumAl foilplatesheet A feasibility study for producing aluminum flake powder from aluminum foil scrap by dry ball milling under an inert argon with a few of oxygen was carried out Chat Now Send Inquiry Aluminium Flake Powder Products Carlfors Bruk Business offerrecommendations for ball milling aluminium flake Bonding process Post Blend with Uncoated Aluminum Flake This method involves the mixing or tumbling of the precompounded micronized powder coating with dry, uncoated aluminum flakes The main advantages are low cost and the retention of flake integrity due to the low energy involved in mixing Great care should be taken in this method dueAluminum Pigments for Powder Coatings Silberline

PIGMENTS FOR COATINGS SCHLENK

a coextrusion process The high shear forces, especially in the milling process, would destroy the flakes and severely influence the effect However, if it is still desired to utilize metallic pigments in this process, it is recommended to use pigmentbinding agent compositions, such as pellets (GRANDAL® for aluminiums, GRANDOR® for bronzes) A dry milling strategy has been developed for separating oats into branrich and starchrich fractions For the first time, this process combined the benefits of oat pearling with the efficiency of break and reduction milling and sifting to allow production of flour and bran fractions from an Dry processing of oats – Application of dry milling Wet Ball Milling Vs Dry Ball Milling Orbis Machinery, LLC Jun 27, 2019 The grinding of aluminium for the preparation of paint is most of the time carried out using a wet milling process since the method introduces stearic acid, or other antiflocculent Milling the powder in the wet or dry process of dry milling aluminium powder

ball mill metal flakes myplacechildrencentrecoza

ball mill metal flakes process for dry milling of aluminium flakes ball mill metal flakes; is one of the biggest manufacturers in Aggregate Processing Machinery for the process for dry milling of aluminium flakes ball mill, Check price Aluminum Powders Pastes and Flakes Market Trends Aluminum flakes are derived from aluminum powder by the dry ball milling processFabrication of aluminum flake powder by the wet ball milling of aluminum foil scraps and the effect of related factors were studied As foil thickness decreases from 60 to 65 μm, mean size of Fabrication of Aluminum Flake Powder From Foil recommendations for ball milling aluminium flake powder,aluminum flake powder AluminumAl foilplatesheet A feasibility study for producing aluminum flake powder from aluminum foil scrap by dry ball milling under an inert argon with a few of oxygen was carried out Chat Now Send Inquiry Aluminium Flake Powder Products Carlfors Bruk Business offerrecommendations for ball milling aluminium flake

CAA1 Process for dry milling zinc powder to

A method for the production of zinc flake from zinc particles which comprises dry milling said zinc particles using a mixture of a fluorocarbon lubricant and a stearate lubricant, optionally in admixture with a hydrophobic inorganic powder A preferred fluorocarbon is PTFE and a preferred stearate lithium stearate If desired the zinc dust used may be in the form of an alloy or mixture with gold bronze pigments are produced in a dry milling process (Hametag Process) The manufacturing process begins with milling atomized aluminium powder to the desired particle size and form in white spirit / mineral spirits with the addition of lubricating additives After a screening and classifi cation process, the pigment suspension in theAMERICA CZECH REPUBLIC: World of MetallicsA novel particle processor was designed and built for the production of flakeshaped powders 300 μm magnesium and 140 μm iron particles processed for 1 and 2 minutes were analyzed for (PDF) Morphological evolution of iron flake powder

USB2 Process for dry milling zinc powder to

USB2 US10/666,740 USA USB2 US B2 US B2 US B2 US A US A US A US B2 US B2 US B2 Authority US United States Prior art keywords zinc flake microns particles lubricant Prior art date Legal status (The legal status is an assumption and is not a legal conclusion A dry milling strategy has been developed for separating oats into branrich and starchrich fractions For the first time, this process combined the benefits of oat pearling with the efficiency of break and reduction milling and sifting to allow production of flour and bran fractions from an Dry processing of oats – Application of dry milling The Hall process (see Figure 1) is based on the milling of fine, spherical or irregular atomized aluminum powder (see Figure 2) in ball mills (see Figure 3) in the presence of steel balls, a suitable lubricant (normally stearic or oleic acid), and an aliphatic hydrocarbon, eg, white spiritPVD Aluminum Pigments: Superior Brilliance for