عنا

مرحبا هل يمكنني مساعدتك؟

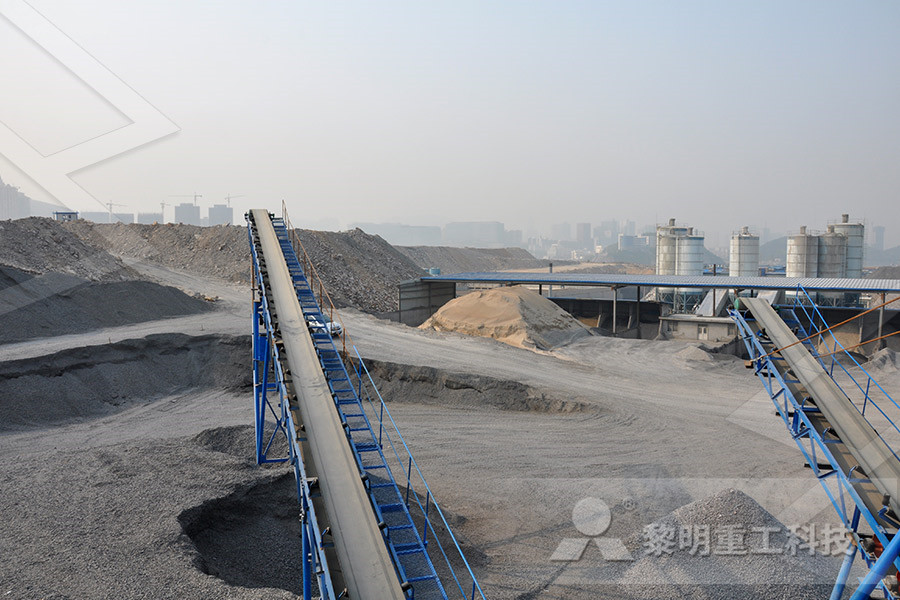

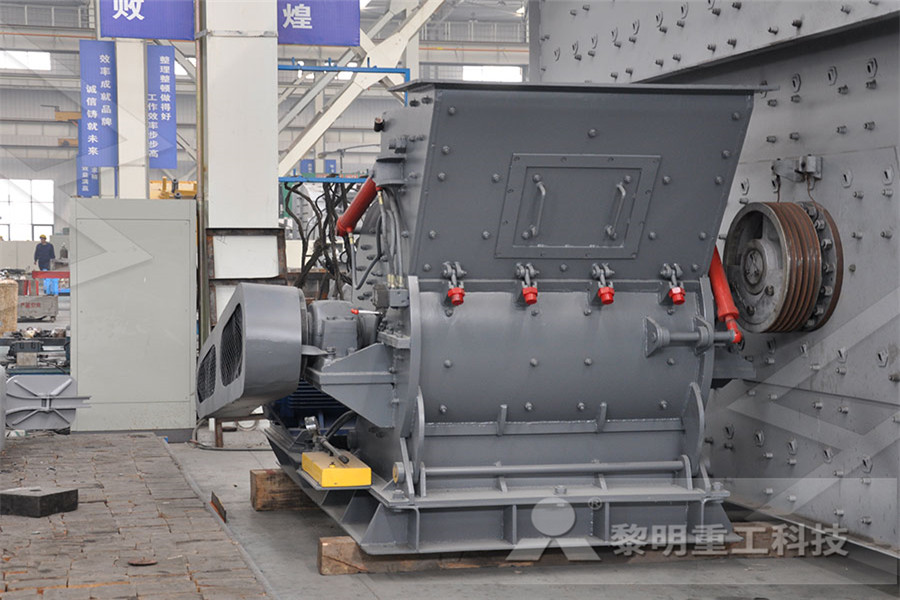

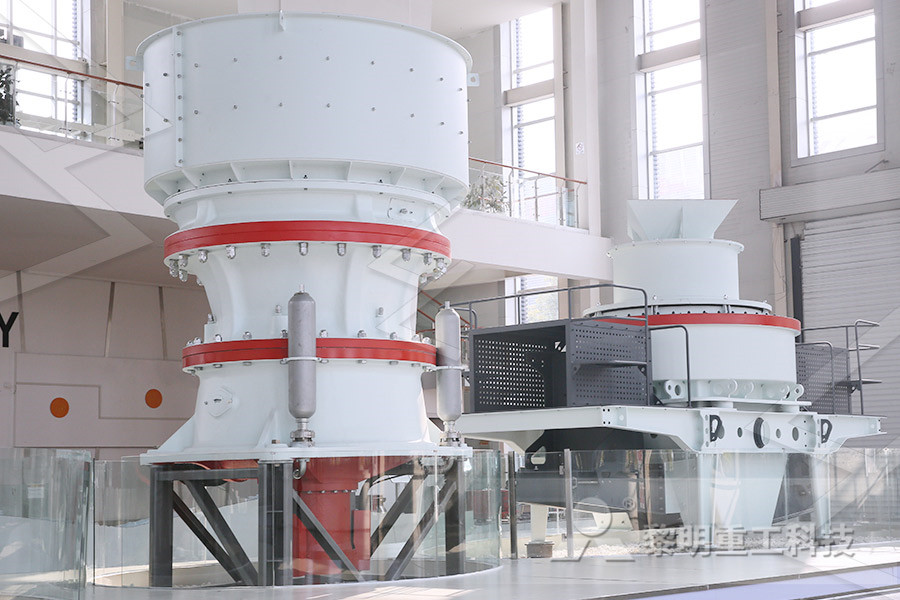

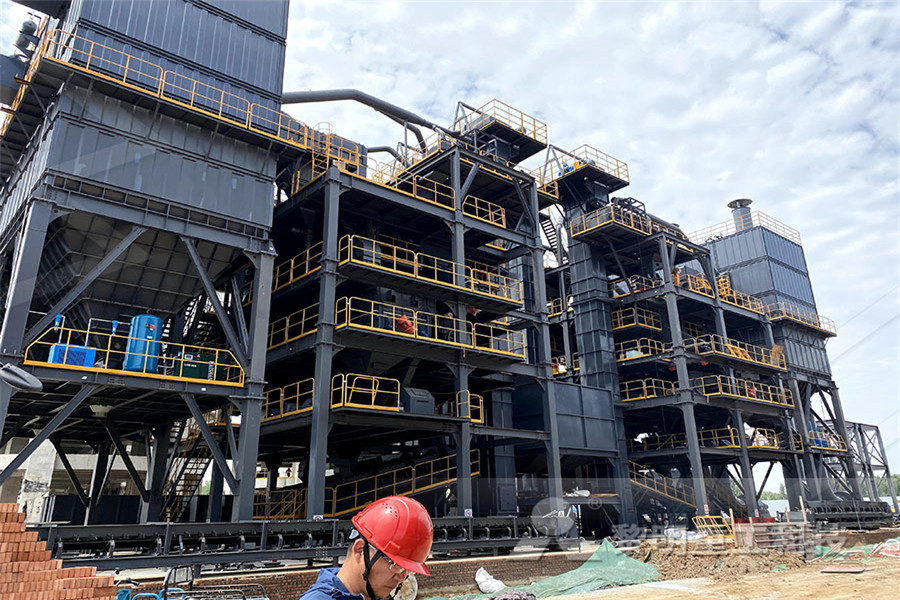

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

Reflux Classifier For Iron Ore

2020-12-16T01:12:50+00:00

The use of a Reflux Classifier for iron ores: Assessment

In the iron ore industry, the recovery of fine particles is an important concern in terms of process performance and production costs and perennial efforts are devoted to increase the efficiency in handling these fines The Reflux Classifier (RC) is a relatively new technology that is mainly used in the coal and minerals industriesAmariei et al (2014) investigated the application of the REFLUX™ Classifier at laboratory and pilot scale on two iron ore feeds, one having The purpose of this study is to examine the The use of a Reflux Classifier for iron ores: Assessment The REFLUX Classifier requires only minimal operator input, with just one operational control required Capacities up to 430 tph in coal and up to 500 tph in iron ore Nominal capacities range from 20 tonnes per hour (tph) to 430 tph in coal (200 mm +0250 mm), and from 25 tph to 500 tph in iron ore REFLUX® Classifier for gravity separation

Gravity separation of ultrafine iron ore in the

The REFLUX™ Classifier is a recently developed waterbased gravity separation technology that is already being used worldwide to beneficiate particles above 0100 mm in size This paper reports tests performed on an ultrafine iron ore with nominal top size of 0106 mm, but with 59 wt% being below 0038 mm in size secures order for new REFLUX TM Classifier technology for treatment of iron ore fines in Norway Rana Gruber operating an iron ore mine and concentrator close to the Arctic Circle in Norway decided to order the two REFLUX TM Classifier RCTM3000HYSS units following successful pilot trials The new REFLUX TM Classifier technology is rapidly gaining popularity in coal and iron ore Order for new REFLUX TM Classifier Mineral Reflux classifier and iron ore,Our company is a largescale heavy enterprise that taking heavy mining machinery manufactory as main products and integrated with scientific research, production, and marketing We are concentrating on producing and selling machines such as jaw crusher, cone crusher, hammer crusher, ball mill, sand maker, mobile crushing plantReflux Classifier And Iron Ore westernriverranchmgde

Gravity separation of ultrafine iron ore in the Reflux

A major advantage of the Reflux Classifier technology is the achievement of simultaneous separation and desliming via a singlestage separation A series of continuous experiments using an iron ore feed with head grade of 35 wt per cent FeT and nominal top size of 0106 mm, with 59 wt percent being below 0038 mm in size including iron ore, chromite, manganese, and mineral sands The vast majority of the test data discussed in the following sections was obtained using the Lamella High Shear Rate REFLUX™ Classifier technology, utilizing 6 mm spacing between lamella channelsThe Lamella High Shear Rate REFLUX™ ClassifierFine Gravity Separation – REFLUX™ Classifier The primary purpose of this project is to use the REFLUX™ Classifier to process iron ore feeds in the 10 +0045 mm size range to produce a highquality freedraining iron ore product that is low in moisture content Continuous steadystate experiments were performed on a spirals feed sampleIron Ore Beneficiation University of Newcastle

REFLUX Classifier: Modular concept a proven success

REFLUX Classifier: Modular concept a proven success Jun 22, 2020 0 iron ore and mineral sand fines “On the back of our first RC modular plant installation and operation (which we did for three years as part of a BOOT contract also secured to treat PGM UG2 material to extract chrome), we were able to gain considerable learnings in how The Reflux Classifier as A Hematite Scavenger at Rana Gruber October 2019; Amine flotation is the natural choice in upgrading iron ore because of its selectivity and good flotation recovery (PDF) The Reflux Classifier as A Hematite Scavenger at The REFLUX™ Classifier is a recently developed waterbased gravity separation technology that is already being used worldwide to beneficiate particles above 0100 mm in size This paper reports tests performed on an ultrafine iron ore with nominal top size of 0106 mm, but with 59 wt% being below 0038 mm in sizeGravity separation of ultrafine iron ore in the REFLUX

Iron Ore Beneficiation University of Newcastle

Fine Gravity Separation – REFLUX™ Classifier The primary purpose of this project is to use the REFLUX™ Classifier to process iron ore feeds in the 10 +0045 mm size range to produce a highquality freedraining iron ore product that is low in moisture content Continuous steadystate experiments were performed on a spirals feed sampleRana Gruber operating an iron ore mine and concentrator close to the Arctic Circle in Norway decided to order the two REFLUX™ Classifier RCTM3000HYSS units following successful pilot trialsNew classifier technology recovers 20% iron otherwise including iron ore, chromite, manganese, and mineral sands The vast majority of the test data discussed in the following sections was obtained using the Lamella High Shear Rate REFLUX™ Classifier technology, utilizing 6 mm spacing between lamella channelsThe Lamella High Shear Rate REFLUX™ Classifier

Reflux Classifier extracts Clunies Ross science award

groundbreaking Reflux Classifier, or RC2020 The Reflux Classifier was first patented by Galvin and his team in 2000, and is presently responsible for around $15 The REFLUX classifier incorporates the new ‘laminar high shear rate’ mechanism: the latest in fine particle gravity based separation technology This, along with advancements in channel spacing and width mean that REFLUX classifiers are more efficient and more compact than competing fine coal and mineral processing equipment REFLUX® Classifier VideosExisting installations of the REFLUX™ Classifier have focussed on the beneficiation of particles in the 0250 to 20 mm size range Significant interest has emerged in the coal industry in the processing of particles up to 40 mm in size, with new research funding directed to the establishment of a fullscale facility (FIG 2), located at a plant just one hour from the UniversityBackground University of Newcastle

launches new, modular Reflux Classifier plant

Mia Breytenbach: The modular Reflux Classifier (RC) plant is an integrated engineered solution and is based on a fundamental component – ’s wellproven RC technology REFLUX Classifier: Modular concept a proven success Jun 22, 2020 0 iron ore and mineral sand fines “On the back of our first RC modular plant installation and operation (which we did for three years as part of a BOOT contract also secured to treat PGM UG2 material to extract chrome), we were able to gain considerable learnings in how REFLUX Classifier: Modular concept a proven successRana Gruber operating an iron ore mine and concentrator close to the Arctic Circle in Norway decided to order the two REFLUX™ Classifier RCTM3000HYSS units following successful pilot trialsNew classifier technology recovers 20% iron otherwise

The Lamella High Shear Rate REFLUX™ Classifier

including iron ore, chromite, manganese, and mineral sands The vast majority of the test data discussed in the following sections was obtained using the Lamella High Shear Rate REFLUX™ Classifier technology, utilizing 6 mm spacing between lamella channels groundbreaking Reflux Classifier, or RC2020 The Reflux Classifier was first patented by Galvin and his team in 2000, and is presently responsible for around $15 Reflux Classifier extracts Clunies Ross science award Highcapacity, compact design Easy to operate with only one control Capacities up to 200 tph in coal and 250 tph in iron ore Easy transport and installation Advanced fineparticle gravity separation The patented REFLUX® Classifier is one of our most advanced fine particle, gravitybased separators, offering significant advantages in capacity, adaptability and efficiencyGravity classifier REFLUX® DorrOliver

New classifier technology recovers 20% iron otherwise

Thursday, March 30th, 2017 secures order for new REFLUX™ Classifier technology for treatment of iron ore fines in Norway Rana Gruber operating an iron ore mine and concentrator close to the Arctic Circle in Norway decided to order the two REFLUX™ Classifier RCTM3000HYSS units following successful pilot trialsThe use of a Reflux Classifier for iron ores Assessment Jul 01 2014 0183 32 In the iron ore industry the recovery of fine particles is an important concern in terms of process performance and production costs and perennial efforts are devoted to increase the efficiency in handling these fin The Reflux Classifier RC is a relatively new technology that is mainly used in the coal and minerals classifiers use in the iron ore processingExisting installations of the REFLUX™ Classifier have focussed on the beneficiation of particles in the 0250 to 20 mm size range Significant interest has emerged in the coal industry in the processing of particles up to 40 mm in size, with new research funding directed to the establishment of a fullscale facility (FIG 2), located at a plant just one hour from the UniversityBackground University of Newcastle

launches new, modular Reflux Classifier plant

The modular Reflux Classifier (RC) plant is an integrated engineered solution and is based on a fundamental component – ’s wellproven RC technology