عنا

مرحبا هل يمكنني مساعدتك؟

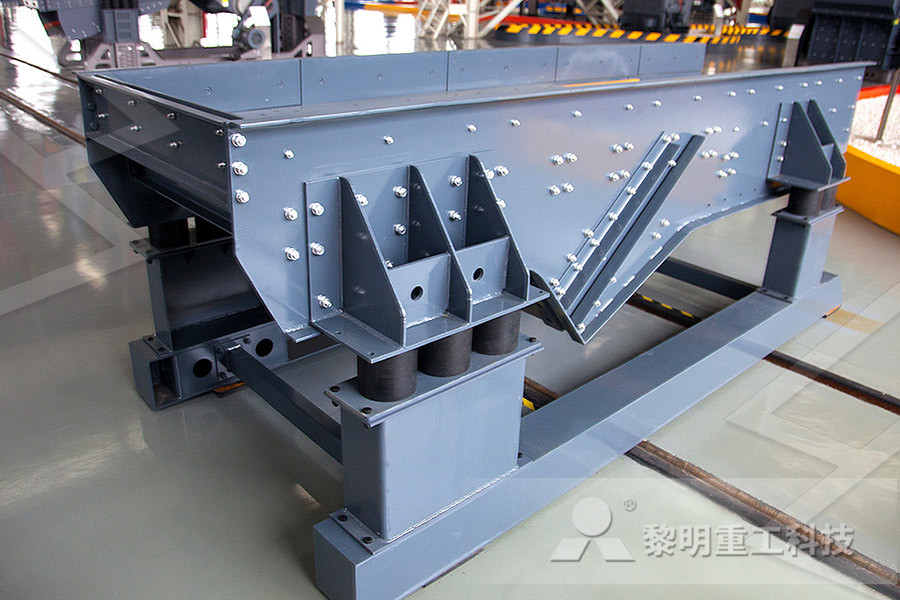

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

sand making dry process

2022-07-29T22:07:39+00:00

Wet Sand Making And Dry Sand Making Process LDHB

The dry sand making technology is later than the wet method and is further developed on the basis of the traditional wet sand making line This technique is relative to wet sand making, which does not require water during the sand removal process, and is therefore referred to as a dry sand production line Advantages and disadvantages comparison Dryprocess Sandmaking Plant Because there are many problems with conventional Sandmaking technique and equipment, such as the wetprocess sandmaking technique often cause dust pollution and lots of waste water and sludge, what’s more, due to the unreasonable gradation and flat strip shape of particles, the quality of the manufacutred sand is far from the requirements of modern Dryprocess Sandmaking Plant Shanghai It can produce higher quality manufactured sand with better grain shape In brief, dry sand making and wet sand making process both have its advantades Generally, dry sand making process is more suit for areas lack of water resources or use water with more difficulty while wet sand making process is suit for areas are rich in water resourcesThe comparison of Dry Sand Making and Wet Sand

Highlights of dry sand making processnicolepyChinaUnix博客

Highlights of dry sand making process Process of development of the sand are closely related with sand making equipment Sand production line equipment made by the combination of , and tape transfer machine and so on According to different processDry Sand Casting Process: A chemical or adhesive binder is mixed with unboned sand and then it is shaped in the form of the the mold or pattern It is then baked at a specific temperature Very intricate designs that are required for housing constructions and automotive parts can Dry Sand Casting, Dry Sand Casting Process, The system is a dry production process, and the produced aggregates have low moisture content of machinemade sand (generally less than 2%) There is no need to configure a dehydration device like the wet production processAggregate and sand making process without waste in

Sand Casting Process Basic Concept and Procedure

The dry sand core is mounted in position Now molten metal is poured through riser into mold cavity After pouring and solidification the part removed with require pattern shape Most important of sand casting advantages: The intricate shape can be made by this process because of The dry process, using preheaters and precalciners, is Grinding mill operations also result in particulate Cement plants are not normally designed to burn wastes Cement Plant Operations Handbook Dry Process Plants The manufacturing of the Sand process involves three stages These are crushing of stones in to aggregates by VSI, then fed to Rotopactor to crush aggregates into the sand to required grain sizes (as fines) Then, do the screening to eliminate dust particles and Washing of sand eliminates very fine particles present withinHow to Start Sand Manufacturing Business Process

Types of Moulding Sand in Casting Process

2 Dry Sand After making the mould in green sand, when it is dried or baked is called dry sand It is suitable for making large castings The moulds which is prepared in dry sand is known as dry sand moulds If we talk about the physical composition of the dry sand then it is same as that of the green sand except water 3 Loam SandWet Sand Making And Dry Sand Making Process LDHB Feb 19, 2019 In short, equipped with sand washing machine in sand production line to wash out the impurities and power, the method is called wet sanddry process sand production line mikadobestplSand Casting: The sand casting process also called as sand mold casting It is a common method for metal casting Almost 70% of metal casting of product follow by sand casting process The bonding agent (clay) is mixed with the sand The mixture is moisturized with water for develop strength and plasticity of clay to make moldSand Casting Process Basic Concept and Procedure

Sand Making Plant Sand Production Line Artificial

Sand Making Plant Details 1 Output capacity 30500t/h 2 Raw materials for making artificial sand River pebble: it is high quality material for making sand Quartz stone: it can be crushed to make quartz sand or silica sand, which is even better than natural sand in terms of strength and shapeThe processing techniques used in mining silica sand are very important The techniques consist of both wet and dry processes, and at times, process combinations to produce an acceptable product In the common silica sand making process, jaw crusher is used as primary crushing machine and then goes through the secondary crushing plantSilica sand processing plant manufacturer from China The others with unsuitable size will be screened from vibrating screen, then will be transferred to the sandmaking machine, this forms a closed circuit manifold cycles Sizes of final products will be according to our customers' requirements If it is the dry process, the classifier and deduster will be attached according to you requirementSand Production Line, Sand Making Production Line,

Wet Frac Sand Processing AggNet

Three basic types of proppants are used: natural silica sand; resincoated silica sand; and ceramic beads The wet processing of frac sand involves taking natural silica sand proppants from the point of a quarried stockpile of silica sand through to the stockpile that feeds the dryer and final dry sizing process2 Dry Sand After making the mould in green sand, when it is dried or baked is called dry sand It is suitable for making large castings The moulds which is prepared in dry sand is known as dry sand moulds If we talk about the physical composition of the dry sand then it is same as that of the green sand except water 3 Loam SandTypes of Moulding Sand in Casting Process The cost of Sand Making Machine is relatively high, scientific and rational application of Sand Making Machine is economical Henan Mining Machinery Co, Ltd is a professional manufacturer and supplier of new sand making machine with advanced process, quality assurance, reasonable price and top service welcome customers both at home and abroad to consult and purchase!Procedure and problems of sand making machine

8 Different Types of Moulding Sand with Their

7 Parting Sand The parting sand is used to avoids sticking of green sand to the pattern And also it allows in easy removal of cope and drag This parting serves the same purpose as dust It is pure clay free silica sand 8 Core Sand The core sand is the sand for making cores It is also called oil sand because it is a mixture of silica cating process July 12, 2020 6The machining allowance provided to ferrous castings for making small and average sized casting is A)15mm B)3mm C)45mm D)6mm Answer is B)3mm Show Answer green sand B)dry sand C)loam sand D)wet sand Answer is D)wet sandcating process ~ Mechanical Engineering MCQWet Sand Making And Dry Sand Making Process LDHB Feb 19, 2019 In short, equipped with sand washing machine in sand production line to wash out the impurities and power, the method is called wet sanddry process sand production line mikadobestpl

New type dry cement process, New type dry cement

New type dry cement process from Henan Mining Machinery Co, Ltd High Quality New type dry cement process Manufacturing and Exporting supplier on Alibaba 4Drytype Sandmaking Technology Getting Favor by Enterprises Given the heavy demand for high quality machinemade sand in Hunan and the weaknesses brought by the wettype sandmaking system, sandmaking enterprises have started to search a new technology to replace itAnother High Quality Sand Production Line by Dry Artificial sand making machine production line sand production line dry method has several advantages compared to traditional wet compared to the production line : 1 , artificial sand production line of sand dry process production line – reducing production costs Traditional wet sand production line at the same time producing a large amount Artificial sand making machine production line dry

Coarse Material Washer Sand Making Plant HPOWER

The coarse material washer uses dry sand making process by separating sand and powder for quarry site HPOWER offers complete sand making line of crusher, screen and sand makerThe processing techniques used in mining silica sand are very important The techniques consist of both wet and dry processes, and at times, process combinations to produce an acceptable product In the common silica sand making process, jaw crusher is used as primary crushing machine and then goes through the secondary crushing plantSilica sand processing plant manufacturer from China Sand Making Plant Details 1 Output capacity 30500t/h 2 Raw materials for making artificial sand River pebble: it is high quality material for making sand Quartz stone: it can be crushed to make quartz sand or silica sand, which is even better than natural sand in terms of strength and shapeSand Making Plant Sand Production Line Artificial

Artificial Sand Making Machines, Jaw Crushers, Cone

Conventional Method for separating dust is only to be washed by water Akashganga invented a novel process for separating dust It is a dry Process requires no water This process is much economical and more efficient In Water Washing fine particles of sand are swept away, makes the sand inferior qualitySand Blasting: This is the process that also applied for removing the color and it is done at the dry condition of the garments This process is done by air flow gun with the help of sand The high pressure sand is applied on the specific area of the garments and eventually the color will reduce However, this process has some disadvantages ,so Denim Dry process SlideShare Quick Contact MY TRADING COMPANY 19, Rasika Society, RH No 54, MIDC, Chinchwad, Pune , Maharashtra, INDIA + 9198508 93570, 98500 87464Sand Making Machines, Vibrating Feeders, Dealer,