عنا

مرحبا هل يمكنني مساعدتك؟

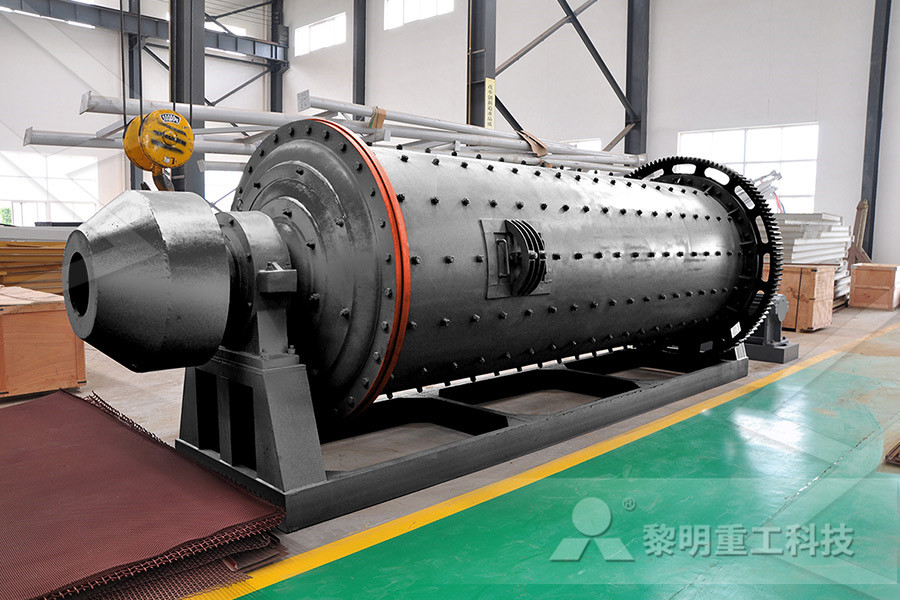

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

applied materials grinding system

2022-06-23T02:06:16+00:00

Applied Materials Grinding System High quality

Applied Materials Grinding System High quality Applied Materials Grinding System and turnkey system manufacturer from Taiwan Mill Powder Tech SolutionsApplied Materials Grinding System Prompt : Caesar is a famous mining equipment manufacturer wellknown both at home and abroad, major in producing stone crushing equipment, mineral separation equipment, limestone grinding equipment, etcApplied Materials Grinding System Mill Powder Tech Solutionsist Lieferant und Hersteller von Taiwan Applied Materials Grinding System mit mehr als 70 Jahren Erfahrung Seit 1940 bietet Mill Powder Tech unseren Kunden auf dem Markt für Mühlen und Pulvermischer einen hochwertigen Produktionsservice für Schleifsysteme für Applied Materials Grinding System Hochwertiges

applied materials grinding system quartzcrusher

Applied Materials Grinding System • Fineness:10~325Mesh (Due to different characteristics, the data is for reference only and would be varied) • Capacity: More detailsAbstract: In order to decrease the development costs, shorten the developing cycle, improve the overall performance and reduce the environmental pollution of the wafer precision grinding machine, the structure, transmission, movement of grinding system for wafer precision grinding machine is analyzed based on mechanical system mechanics, the threedimensional model of the grinding system is Grinding System Manufacturer: AMAT / APPLIED MATERIALS Model: Reflexion Category: WAFER GRINDING, LAPPING POLISHING CAE has broad access to semiconductor related equipment direct from fabs, often unavailable through other sources CAE finds the best deals on used AMAT / APPLIED MATERIALS Reflexion CAE has 23 wafer grinding, lapping polishing currently AMAT / APPLIED MATERIALS Reflexion (WAFER

AMAT / APPLIED MATERIALS Reflexion LK used for

Base system: Reflexion LK: 4head, 3platen, polishing system Dry in, dry out Polisher skins: Dark P1, P2, P3, P4; 4910 compliant Gap wash: 120° nozzles Load cup wafer exchanger: enhanced counter balance springs Nova 3090 ready: none Monitor 1 location: cart Monitor 2 CMP System, 8" Technology: CMP Oxide Wafer shape: Flat / Notch Consumed process materials: Polish slurry Platen 1 pad: IC1010 Platen 2 pad: IC1010 Platen 3 pad: IC1010 Pad conditioner: Diaphragm Pad conditioner head: DDF3 Pad conditioner holder Factory interface options: Cleaner type: MESA (Converted from reflexion) Megasonics Robot type: AMAT / APPLIED MATERIALS Insitu removal rate monitor: Full scan SECS GEM Interface Cassette tank Cassette type: SMIF Open cassette Integrated system AMAT / APPLIED MATERIALS Mirra Mesa used for sale CAE has broad access to semiconductor related equipment direct from fabs, often unavailable through other sources CAE finds the best deals on used AMAT / APPLIED MATERIALS Reflexion CAE has 23 wafer grinding, lapping polishing currently availableAMAT / APPLIED MATERIALS Reflexion (WAFER

CMP Applied Materials

To make sure material is removed evenly across an entire 300mm wafer, regardless of the incoming film uniformity and that the process stops at the right point to avoid grinding away the critical underlying features, Applied developed a sophisticated control system that continuously measures the film thickness at multiple points across the wafer AMAT / APPLIED MATERIALS CMP 3600 2002 vintage ID # Reflexion system, 12" General features: (4) Titan heads (3) Platen systems Operator interface with monitor and keyboard Windows NT based soAMAT / APPLIED MATERIALS CMP 3600 用 待售的 價格 CMP System, 12" (4) Titan head, (3) platen system Operator interface with monitor and keyboard Windows NT based software control Integrated electronics control cabinet Integrated Applied Materials factory interface on fourwide frame Integrated Mesa Cleaner including (2) brush scrubber modules and spin rinse dry module CDROM English language system manuals and schematics FI AMAT / APPLIED MATERIALS Reflexion 3600 benutzt

Semiconductor Wafer Polishing and Grinding

Semiconductor Wafer Polishing and Grinding Equipment Market 2021 Precise OutlookApplied Materials, Ebara Corporation, Lapmaster, Logitech, Entrepix, Revasum, Logomatic tanmay February 5, 2021 11Journal of Applied Materials Engineering The mechanisms, compared to other sintering techniques, advantages of this system, applied modifications and the history of the development of this technique are presented Spark Plasma Sintering (SPS) uses uniaxial pressing and pulses of electric current (the type of grinding wheel, granulation Journal of Applied Materials Engineering Most grinding mechanisms can be applied for both batch and continuous operations in principle but every mill is designed and operated preferably in either way For the continuous grinding systems, the separation mechanism is also important to obtain the product with required particle size 63 Open and closedcircuit grinding systemChapter 10 Selection of Fine Grinding Mills

A model for simulating the grinding and classification

These important parameters were applied in the model analysis, and the obtained simulation results were compared with the actual data collected from the industrialized production line Materials collected from grinding and classification cyclic system are shown in Fig 4 4 Results and discussion411 Working as senior engineer on 300mm wafer Chemical Mechanical Grinding System and Nano2000 Optical Metrology System in Customer Field 2 Provide technical support on Installation, Calibration, Process, Software and Hardware Issue; Provided basic 3Technical Product Support Engineer Applied Materials A series of controlled grinding experiments, utilizing loose or fixed abrasives of either alumina or diamond at various particle sizes, were performed on a wide range of optical workpiece materials [single crystals of Al2O3 (sapphire), SiC, Y3Al5O12 (YAG), CaF2, and LiB3O5 (LBO); a SiO2−Al2O3−P2O5−Li2O glass ceramic (Zerodur); and glasses of SiO2:TiO2 (ULE), SiO2 (fused silica), and P2O5 OSA Towards predicting removal rate and surface

Journal of Applied Materials Engineering

Journal of Applied Materials Engineering The mechanisms, compared to other sintering techniques, advantages of this system, applied modifications and the history of the development of this technique are presented Spark Plasma Sintering (SPS) uses uniaxial pressing and pulses of electric current (the type of grinding wheel, granulation In this article the selection of more appropriate raw materials applied to aluminoborosilicate glass system for vitrified cubic boron nitride (CBN) grinding wheels was investigatedRaw materials selection applied to glass bonding for CAE has broad access to semiconductor related equipment direct from fabs, often unavailable through other sources CAE finds the best deals on used AMAT / APPLIED MATERIALS Reflexion CAE has 22 wafer grinding, lapping polishing currently availableAMAT / APPLIED MATERIALS Reflexion (WAFER

Semiconductor Wafer Polishing and Grinding

Semiconductor Wafer Polishing and Grinding Equipment Market 2021 Precise OutlookApplied Materials, Ebara Corporation, Lapmaster, Logitech, Entrepix, Revasum, Logomatic tanmay February 5, 2021 930 AMAT / APPLIED MATERIALS Mirra Track 2000 vintage ID # CMP System, 8" Process: PCUD System controller Main system: Polisher Ontrak cleaner FABS Cassette system Missing / Faulty parts: PneutroAMAT / APPLIED MATERIALS Mirra Track benutzt zu The crushing and grinding operations are an important part of the processing of mineral resources, and it is also operation with high investment and high energy consumption In the case of metal mines, equipment investment in crushing operations accounts for 65% to 70% of the total plant value, power consumption is about 50% to 65%, and steel consumption is as high as 50%Crushing and Grinding Process JXSC Machine

Chapter 10 Selection of Fine Grinding Mills

Most grinding mechanisms can be applied for both batch and continuous operations in principle but every mill is designed and operated preferably in either way For the continuous grinding systems, the separation mechanism is also important to obtain the product with required particle size 63 Open and closedcircuit grinding system These important parameters were applied in the model analysis, and the obtained simulation results were compared with the actual data collected from the industrialized production line Materials collected from grinding and classification cyclic system are shown in Fig 4 4 Results and discussion41A model for simulating the grinding and classification Today, Applied unveiled a new version of its flagship Reflexion GT™ CMP system designed to planarize tungsten, which is used to connect transistors and memory cells together in advanced logic and DRAM chips You can read more how the new system will help chipmakers fabricate their latest and greatest devices on the Applied Materials website hereThe Unlikely Art of ChemicalMechanical Planarization

OSA Towards predicting removal rate and surface

A series of controlled grinding experiments, utilizing loose or fixed abrasives of either alumina or diamond at various particle sizes, were performed on a wide range of optical workpiece materials [single crystals of Al2O3 (sapphire), SiC, Y3Al5O12 (YAG), CaF2, and LiB3O5 (LBO); a SiO2−Al2O3−P2O5−Li2O glass ceramic (Zerodur); and glasses of SiO2:TiO2 (ULE), SiO2 (fused silica), and P2O5