عنا

مرحبا هل يمكنني مساعدتك؟

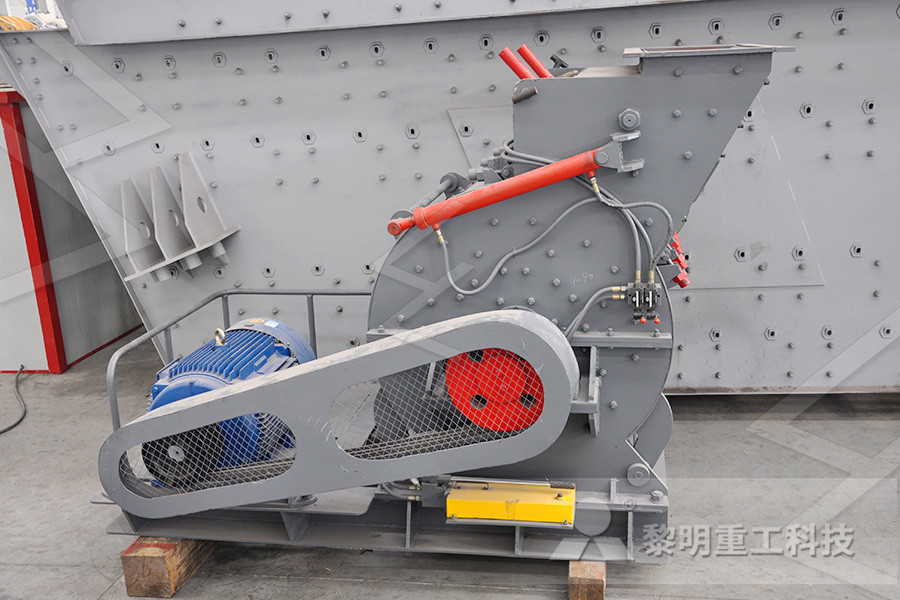

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

Friction In Cement Mill Grinding Media

2021-05-08T04:05:08+00:00

Grinding Media In Cement Mill Crusher Mills, Cone

grinding media in cement mill – Crushing project, Crusher grinding media in cement mill As a professional crushing and grinding equipments manufacturer, liming can supply you all kinds of machinery for you all over the worldCement Mill Grinding Media Page 1 of 1Nov 01, 2017 Cement Mill Grinding Media Dear Experts, I want to know about the GM size wise percentage distribution in Internal friction mill charge Figure: Grinding media Grinding Ball Charge in Mills: According to Levenson, the optimum grinding ball charge should be r The degree of ball charge cement mill grinding media in pdf help4helpngoCement Grinding Media Alumina Ball for Ball Mill This product are featured by high density and hardness, low wear lost, corrosionresistance etc They are the perfect highefficient grinding media for milling glaze/frit, pigment, ceramic materials, and various China Cement Grinding Media Alumina Ball for Ball

Cement Mill Grinding Media Page 1 of 1

re Cement Mill Grinding Media H there, These are just the basics if you want to accurately do it you have to fill it up to 80% BC and then do a longitudinal sieving and then correct the BC based on the results The biggest ball determination is explained 3 The friction force between the mill lining and the grinding ball 4Internal friction mill charge Figure 1 Grinding process inside horizontal mill [6] This work investigates the wear rate of grinding balls that are used in grinding mills for clinker to product the cement powder and study the effect of coating balls surface with layers of Wear Resistance Improvement for Grinding Balls of Grnding Media, Ball Mill Media, Grinding Media Balls manufacturer / supplier in China, offering Ceramic Grinding Balls Media for Cement, Mining Mill, Engineering Alumina Ceramic Tile for Stacker and Reclaimer Linings, Alumina Ceramic Tubes/Pipes for Thermal China Ceramic Grinding Balls Media for Cement,

Cement mill grinding media faq Mining Machinery

grinding media for cement mill about grinding media of cement mill grinding media for cement mills hackersgroupofindiacoin A cement mill or finish mill in North American usage is the equipment used to grind the hard nodular clinker from the cement kiln into the fine grey powder that is cement History Materials ground Temperature control Ball Tribological Processes in a Ball Mill for Ordinary Portland Cement The ball mill comprises of series of grinding balls charged into a cylindrical tube, power consumption, wear rate of grinding media and product quality are special steel balls of high strength charged into both first and second chamber of the by optimum mill speed, angle of repose and ball size distribution grinding media distribution chart of both chamber Cement Ball Mill Structure When Ball Mill is working, raw material enters the mill cylinder through the hollow shaft of the feed The inside of the cylinder is filled with grinding media of various diameters (steel balls, steel segments, etc); when the cylinder rotates around the horizontal axis at a certain speed, Under the action of centrifugal force and friction Ball Mill for Cement Grinding Process

Grinding Media Percentage In Graphite Mine Mill

Ball Millmill Cement Mill Grinding Media Wear Rate Cement Mill Grinding Media Pdf a comparison of wear rates of ball mill grinding media a comparison of wear rates of ball mill grinding journal of mining and metallurgy 52 a 1 2016 110 corresponding author ic get price friction in cement mill grinding media a cement mill is the equipment that Cement Grinding Media Alumina Ball for Ball Mill This product are featured by high density and hardness, low wear lost, corrosionresistance etc They are the perfect highefficient grinding media for milling glaze/frit, pigment, ceramic materials, and various mine ore powder, they are using ceramics, cements, paints, refractories, inorganic China Cement Grinding Media Alumina Ball for Ball grinding media in cement mill – Crushing project, Crusher grinding media in cement mill As a professional crushing and grinding equipments manufacturer, liming can supply you all kinds of machinery for you all over the worldGrinding Media In Cement Mill Crusher Mills, Cone

Wear Resistance Improvement for Grinding Balls of

3 The friction force between the mill lining and the grinding ball 4Internal friction mill charge Figure 1 Grinding process inside horizontal mill [6] This work investigates the wear rate of grinding balls that are used in grinding mills for clinker to product the cement powder and study the effect of coating balls surface with layers of Cement Ball Mill Structure When Ball Mill is working, raw material enters the mill cylinder through the hollow shaft of the feed The inside of the cylinder is filled with grinding media of various diameters (steel balls, steel segments, etc); when the cylinder rotates around the horizontal axis at a certain speed, Under the action of centrifugal force and friction force, the medium and the Ball Mill for Cement Grinding ProcessEFFECTS OF GRINDING MEDIA SHAPES ON BALL MILL EFFECTS OF GRINDING MEDIA SHAPES ON BALL MILL PERFORMANCE power plants cement production and pharmaceutical industries It is costly and an inefficient process in Considering that worn balls in an industrial mill charge constitute about 15 to 40 percent and that the highest difference in breakage rate observed being nine how to calculate grinding media charging

Oppsite classification of grinding media Page 1 of 1

Oppsite classification of grinding media Hello, We have got a strange phenomenan in one of our cement ball mill second compartment in checking we have observed that the grinding media had sorted and classified oppositely inside the second compartment as the following: 25 mm (near intermediate diaphragm), 30 mm, 40 mm and finaly 50 mm (near mill out let diaphragm) 2 Shape, size, and weight of the grinding media 3 Friction between the lining and the grinding media 4 Internal friction mill charge Figure: Grinding media 441 Grinding Ball Charge in Mills: According to Levenson, the optimum grinding ball charge should be r 016D The degree of ball charge varies with in the limit of 25 and 45%Cement mill notebook SlideShareA cement mill is a grinding machine that used to grind hard, nodular clinker from cement kiln into fine powder that is cement At present, most cement is ground in ball mills As the rapid development of construction, more and more cement are required AC can provide large capacity cement mill for the customers to use in the cement making plantLarge Capacity Cement Mill Used For Cement Making

Progress with Grinding Aids for Vertical Roller Mills

The differential pressure between the inlet and outlet of the mill (ΔP mill) is an important process variable for the testing of grinding aidsΔP mill reflects the load and the filling level of the mill At unchanged separator settings, the increase of ΔP mill indicates more internal circulations and more fines As a result of the higher ΔP mill, the mill vibration increases (810mm/s The ball mill is a hollow drum closed with loading and unloading end caps, filled with grinding media and rotated around its axisThe drum of the ball mill (Pic 1) is a hollow cylinder of steel, lined inside with armor lining plates which protect it from impact and friction effects of the balls and the grinding materialHOW BALL MILL WORKS? energosteelCement Grinding Media Alumina Ball for Ball Mill This product are featured by high density and hardness, low wear lost, corrosionresistance etc They are the perfect highefficient grinding media for milling glaze/frit, pigment, ceramic materials, and various mine ore powder, they are using ceramics, cements, paints, refractories, inorganic China Cement Grinding Media Alumina Ball for Ball

miller grinding ballmiller grinding cement

friction in cement mill grinding media Mill (grinding) Wikipedia Ball mill A typical type of fine grinder is the ball mill A slightly inclined or horizontal rotating cylinder is partially filled with balls, usually stone or metal, which grind material to the necessary fineness by friction friction in cement mill grinding media 2When cement ball mill is running,grinding media loaded inside ball mill cylinder under the effect of centrifugal force and friction force rolls alongside the cylinder wall with crushed ore;when both of them are lifted to a certain height,due to gravity effect they fall and travels along the cylinder wall under the continuous comminution,crushing and grinding of grinding media,finally the cement ball mill Zao Mining MachineryEFFECTS OF GRINDING MEDIA SHAPES ON BALL MILL EFFECTS OF GRINDING MEDIA SHAPES ON BALL MILL PERFORMANCE power plants cement production and pharmaceutical industries It is costly and an inefficient process in Considering that worn balls in an industrial mill charge constitute about 15 to 40 percent and that the highest difference in breakage rate observed being nine how to calculate grinding media charging

Ball Mill for Cement Grinding Process

Cement Ball Mill Structure When Ball Mill is working, raw material enters the mill cylinder through the hollow shaft of the feed The inside of the cylinder is filled with grinding media of various diameters (steel balls, steel segments, etc); when the cylinder rotates around the horizontal axis at a certain speed, Under the action of centrifugal force and friction force, the medium and the I Moment of Inertia of the grinding media about ‘O’ Iarea Area moment of inertia of rotor Jassembly Mass polar moment of inertia of rotor and mill assembly Jmotor Mass polar moment of inertia of motor l Length of rotor L Length of the mill Lc Length of cable m Mass of grinding media in the mill N Normal reaction acting on the grinding mediaGRINDING MEDIA OSCILLATION: EFFECT ON TORSIONAL 2 Shape, size, and weight of the grinding media 3 Friction between the lining and the grinding media 4 Internal friction mill charge Figure: Grinding media 441 Grinding Ball Charge in Mills: According to Levenson, the optimum grinding ball charge should be r 016D The degree of ball charge varies with in the limit of 25 and 45%Cement mill notebook SlideShare

Large Capacity Cement Mill Used For Cement Making

A cement mill is a grinding machine that used to grind hard, nodular clinker from cement kiln into fine powder that is cement At present, most cement is ground in ball mills As the rapid development of construction, more and more cement are required AC can provide large capacity cement mill for the customers to use in the cement making plantThe ball mill is a hollow drum closed with loading and unloading end caps, filled with grinding media and rotated around its axisThe drum of the ball mill (Pic 1) is a hollow cylinder of steel, lined inside with armor lining plates which protect it from impact and friction effects of the balls and the grinding materialHOW BALL MILL WORKS? energosteelThe operating principle of the ball mill consists of following steps In a continuously operating ball mill, feed material fed through the central hole one of the caps into the drum and moves therealong, being exposed by grinding media The material grinding occurs during impact falling grinding balls and abrasion the particles between the balls Then, discharge of ground material performed The operating principle of the ball mill Primo Pizza