عنا

مرحبا هل يمكنني مساعدتك؟

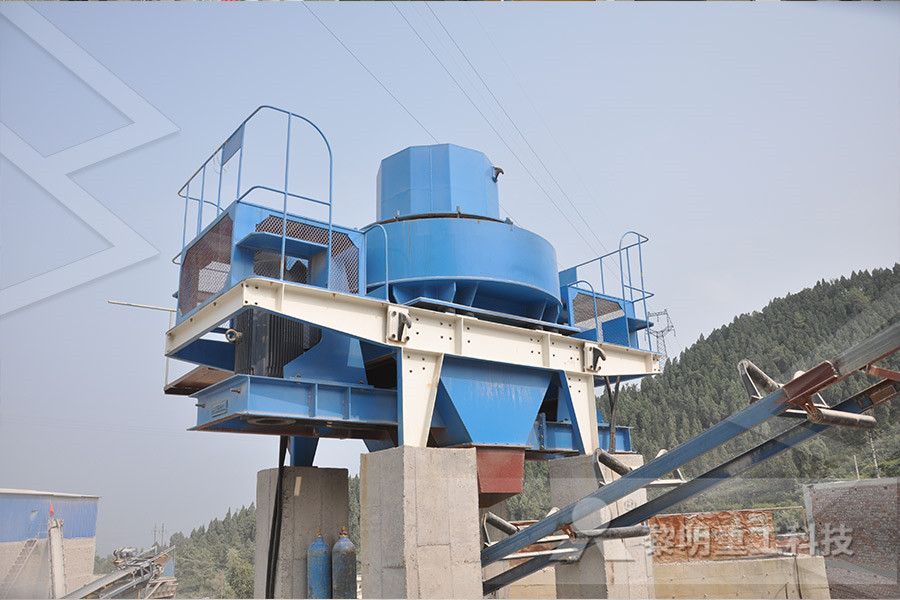

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

maintenance in clinker crusher

2021-02-10T11:02:34+00:00

Clincker Impact Crusher Operation And Maintenance

Maintenance In Clinker Crusher Maintenance in clinker crusher maintenance in clinker crusher in clinker cooling both mechanically and process wise it generates a uniformly distributed clinker bed just before the clinker reaches the mobile grate by evenly spreading the clinker and transporting the nes to the upper layer uniform clinker bed improved recuperation lowmaintenance in clinker crusher CMS (Crusher Machine Sale 54 dry clinker grinder unitedconveyor ;54'' and model 1370 for the international market with the drive and routine maintenance components designed to meet Read moreMaintenance In Clinker CrusherThe largest crusher in operation currently achieves a throughput of 13,000 tpd The service life of the special CLAUDIUS PETERS crushing rings can be extremely extended by suitable maintenance measures, so that today the recommendation for the roll crusher is based on the following features: Longer service life; Reduced dust generationClaudius Peters Clinker Crushers Claudius Peters

preventive maintenance plan jaw crusher SlideShare

Maintenance jobs of Jaw Crusher, Kiln, Clinker Cooler Cement Mill Crushing Plant Design and Layout Considerations More attention is being paid to the impact on crushing circuit design caused incorporated in the early planning stages at much lower cost Clinker Hammer Crusher At the CEMEX plant, bearing failures can lead to a halt in cement production To maintain continuous operation, it is critical for the bearings to operate smoothly As part of the predictive maintenance program, vibration analysis is used to monitor the condition of the crusherWear Debris Analysis Case Study Machinery A patented roll shaft arrangement offers efficient clinker crushing by our HeavyDuty Roller Breaker Modular Frame (HRB MF) Robust crushing rolls can handle large particles, clinker clumps and pile ups with an interlocking function to prevent Crush your clinker with our roller crusher I

HRB MF clinker breaker

An optimal crusher solution can help keep a kiln and cooler operating at peak efficiency The HRB MF (heavyduty roll breaker modular frame) sets the standard in clinker breakers and is ’s standard recommendation for the important task of crushing clinker at busy cement plants Using a grinding rather than strikingA hammer clinker crusher breaks down large clinker pieces before they are ground into cement in an enormous ball mill – with the aid of optibelt SK S=C Plus installed with a tight length tolerance without the need for measuring In the last step, the cement is packed and stacked on palletsPower and durability thanks to Optibelt drive solutionsIn maintenance welding the base metals are unknown, welding conditions are less than ideal and repairs often are carried out on rusty and dirty parts 1 Quarries • Shovel loader • Bulldozer • Drilling equipment • Reclaimer • Tractor • Truck • Funnel • Dragline excavator • Conveyor belt • Scalper • Cone crusher • Hammer crusherWelding Brazing Solutions for Maintenance Repairs in

United Conveyor Corporation Unveils Improved 54” x

Release Summary United Conveyor Corporation has released an improved 54” x 43” EXCENCRUSHER for reducing clinker size in wet/dry applications in industrial power plant and utility operationsMaintenance in clinker crusher maintenance in clinker crusher in clinker cooling both mechanically and process wise it generates a uniformly distributed clinker bed just before the clinker reaches the mobile grate by evenly spreading the clinker and transporting the nes to the upper layer uniform clinker bed improved recuperation lowClincker Impact Crusher Operation And Maintenance crusher for cement clinker and brokener for cement clinker Operation and maintenance of the mill in order to ensure the normal operation of the crusher for cement clinker, must make each member close cooperation and ensure Maintenance In Clinker Crusher

Dry bottom ash handling system Improving

require no maintenance, reducing its cost of ownership Fig 1 Overview of dry bottom ash handling system Boiler Transition hopper Seal Bottom valve Dry bottom ash conveyor Cooling air Precrusher Primary crusher Ochain Clinker cooling conveyor Secondary crusher Bottom ash bin ←Air transport system (Mixed into fly ash)Maintenance jobs of Jaw Crusher, Kiln, Clinker Cooler Cement Mill Crushing Plant Design and Layout Considerations More attention is being paid to the impact on crushing circuit design caused incorporated in the early planning stages at much lower cost than waiting preventive maintenance plan jaw crushermaintenance of ball mill – process crusher liming's training in maintenance procedures for vertical and ball mills will improve the availability of your mills and increase your plant openpit jaw crusherMaintenance Procedure Of Jaw Crusher Crusher

Wear Debris Analysis Case Study Machinery

Clinker Hammer Crusher At the CEMEX plant, bearing failures can lead to a halt in cement production To maintain continuous operation, it is critical for the bearings to operate smoothly As part of the predictive maintenance program, vibration analysis is used to monitor the condition of the crusher The clinker crusher is immediately blocked and the kiln becomes inoperable until engineers have cleaned the clinker crusher On average, a typical cement factory experiences over 9 kiln breakdowns per year because of this issue, resulting in more than 3 days of production downtime in total and accruing high maintenance overtime costsReduce kiln downtime with PdM Industrial AI and of the clinker bed and thus the clinker bed depth and clinker throughput are optimally controlled over the entire width of the cooler Implemented for the first time in a clinker cooler, this solution provides the best preconditions for consistent and uniform cooling of all grain size fractions Intermediate crusher conceptPOLYTRACK clinker cooler Polysius

Repair and Maintenance Solutions ESAB Welding

Our extensive portfolio features the top brands in welding consumables – including Stoody, EWAC, and ESAB – designed to extend component life, while equipment offers the performance and durability for demanding work environmentsRelease Summary United Conveyor Corporation has released an improved 54” x 43” EXCENCRUSHER for reducing clinker size in wet/dry applications in industrial power plant and utility operationsUnited Conveyor Corporation Unveils Improved 54” x Bearing Isolator Eliminates Clinker Grinder Maintenance JAMES LAUGHLIN 1112005 This particular plant uses four clinker grinders manufactured by Pennsylvania Crusher Co Each clinker Bearing Isolator Eliminates Clinker Grinder

Maintenance Procedure Of Jaw Crusher Crusher

maintenance of ball mill – process crusher liming's training in maintenance procedures for vertical and ball mills will improve the availability of your mills and increase your plant openpit jaw crusherrequire no maintenance, reducing its cost of ownership Fig 1 Overview of dry bottom ash handling system Boiler Transition hopper Seal Bottom valve Dry bottom ash conveyor Cooling air Precrusher Primary crusher Ochain Clinker cooling conveyor Secondary crusher Bottom ash bin ←Air transport system (Mixed into fly ash)Dry bottom ash handling system Improving Clinker Hammer Crusher At the CEMEX plant, bearing failures can lead to a halt in cement production To maintain continuous operation, it is critical for the bearings to operate smoothly As part of the predictive maintenance program, vibration analysis is used to monitor the condition of the crusherWear Debris Analysis Case Study Machinery

Claudius Peters Clinker Crushers Claudius Peters

The hammer crusher is the standard solution for crushing clinker CLAUDIUS PETERS has been supplying hammer crushers worldwide for capacities up to 6000 t/d since 1955 The hammers rotate at speeds of >300 rpmEXCENCRUSHER® Clinker Grinders are specifically designed for both wet and dry bottom ash applications, offering superior performance and highlevel reliability With decades of proven experience, UCC clinker grinders effectively reduce material size providing higher efficiency in pneumatic, hydraulic and mechanical bottom ash handling systemsEXCEN 18 Bottom Ash Crushers Wet Bottom Ash of the clinker bed and thus the clinker bed depth and clinker throughput are optimally controlled over the entire width of the cooler Implemented for the first time in a clinker cooler, this solution provides the best preconditions for consistent and uniform cooling of all grain size fractions Intermediate crusher conceptPOLYTRACK clinker cooler Polysius

Industrial Solutions polytrack clinker cooel r

Clinker bed height Installed Operation Grey and white cement, minerals 500 – 12,000 tpd 42 – 45 t/m 2/d 800 – 1,500 t/m/d ≥ 800 mm 20 – 22 Nm 3/kg cl 17 – 19 Nm 3/kg cl Hydraulics Stroke length Strokes /min 300 mm 3 – 5 normal 8 max Roller crusher Design Capacity Roller speed Drive Intermediate or end crusher 500 – 12,000 Our extensive portfolio features the top brands in welding consumables – including Stoody, EWAC, and ESAB – designed to extend component life, while equipment offers the performance and durability for demanding work environmentsRepair and Maintenance Solutions ESAB Welding Release Summary United Conveyor Corporation has released an improved 54” x 43” EXCENCRUSHER for reducing clinker size in wet/dry applications in industrial power plant and utility operationsUnited Conveyor Corporation Unveils Improved 54” x