عنا

مرحبا هل يمكنني مساعدتك؟

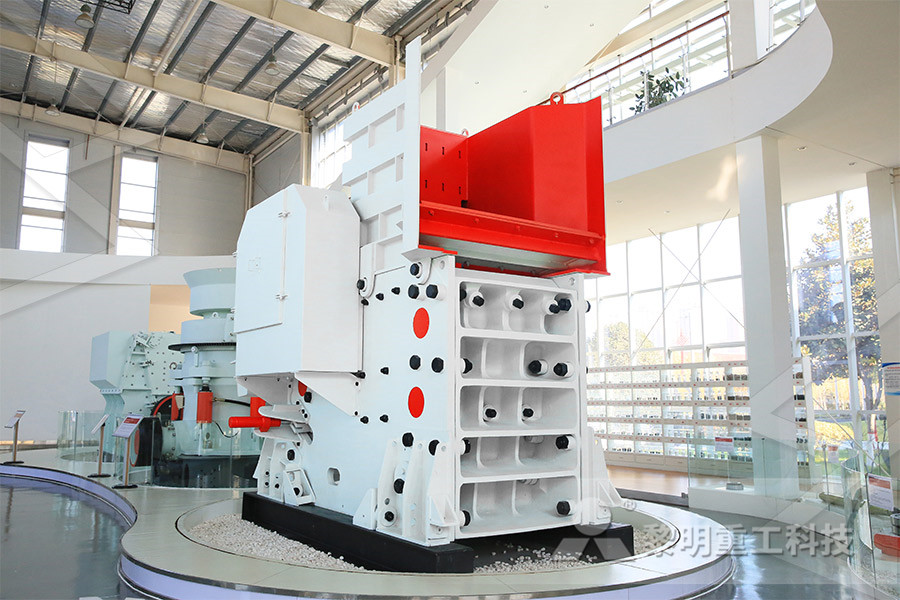

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

Cylindrical Grinding Skill

2023-08-07T18:08:04+00:00

Machining Level II Cylindrical Grinding Skills

Machining Level II Cylindrical Grinding Skills The National Institute for Metalworking Skills (NIMS) credentials are earned by students, trainees, apprentices, employees, and military personnel By earning NIMS credentials, these individuals demonstrate that their Credential: Machining Level II Cylindrical Grinding Skills Credentialing Agency: National Institute for Metalworking Skills, Inc (NIMS) The National Institute for Metalworking Skills (NIMS) credentials are earned by students, trainees, apprentices, employees, and military personnelMachining Level II Cylindrical Grinding Skills Cylindrical Grinding Fundamentals introduces learners to the components and operations central to the precision grinding of cylindrical, and even noncylindrical, workpieces Using animated demonstrations and other visual aids to break down Metal Cutting: Cylindrical Grinding Fundamentals

A skillformation model for grinding operations

Against such a background, this study takes up cylindrical plunge grinding, and presents a skillformation model based on the learning process similar to that in which a grinding operator acquires the performance of cylindrical grinding process by monitoring vital process signals like grinding power and infeed of axis The developed diagnostic system comprises of a powercell and LVDT Performance Enhancement of Cylindrical Grinding Process Cylindrical grinder, which includes both the types that use centers and centerless types A cylindrical grinder may have multiple grinding wheels Work piece holding by chucks and centers The work piece is rotated and fed past the wheel(s) to form a cylinder It is used to make precision rods, tubes, bearing races, bushings, and many other partsGRINDING PROCESS

Parishudh Cylindrical Grinding, Cylindrical Grinder

Lot of skill is required in repairing parishudh Cylindrical Grinding and lot of care has to be taken in fixing this machinery We use advanced methods and tools to repair this products These machines are highly useful in grinding of delicate work pieces and are popular for high degree of flexibility and productivityWhen you want to shape the outside of any object, then you need to use a cylindrical grinder Using this type of machine involves expert care and skill There are safety rules for using cylindrical grinder The practice of cylindrical grinding started more than a century ago14 Safety Rules to Follow While Using a Cylindrical Table 1: Process settings used in plunge grinding Machine Tool Angular wheelhead Workmaterial D2 steel (60 HRC) Wheel spec A 80 J 5 V Dresser spec Blade type Coolant type Emulsion type (4%) Operation Cylindrical plunge grinding Wheel speed 45 m/s Work speed 26 m/min Grinding length 10 mm Portable Diagnostic System for Grinding Process Evaluation Ramesh Babu et al, 1328 Performance Enhancement of Cylindrical Grinding

Dressing skill of grinding wheel

Most cylindrical grinders place parts and grinding wheels on a horizontal line The highest point of the outer circle of the part and the outer circle of the grinding wheel is called the contact point of the part/grinding wheel The dressing tool of diamond should be as close to the contact point of the part/grinding wheel as possible Credential: Machining Level II Cylindrical Grinding Skills Credentialing Agency: National Institute for Metalworking Skills, Inc (NIMS) The National Institute for Metalworking Skills (NIMS) credentials are earned by students, trainees, apprentices, employees, and military personnelMachining Level II Cylindrical Grinding Skills What is Cylindrical Grinding? Cylindrical Grinding is a process where you use a grinding wheel rotating in a horizontal axis to cut or grind a cylindrical workpiece mounted on a chuck or between centers rotating in an axis parallel to the grinding wheel axis, in the same plane Abrasive particles on the grinding wheel do the cutting of materialCylindrical Grinding Fine MetalWorking

DON Civilian COOL Snapshot Machining Level II

Machining Level II Cylindrical Grinding Skills The Skill Level reflects the level, based on MOS training and/or experience, the Soldier should be the most prepared to successfully earn the credential See the Table Legend for details about each level Proponent FundedIf you operate a grinding shop, cylindrical grinding comprises one component of the many jobs you perform every day This is a precise form of grinding requiring great skill and focus The machinery, cylindrical grinders come in different types in order to address the specific demands of a product or jobCylindrical Grinding: Definition and Types skill of the operator This paper presents an approach to develop a diagnostic system that can enhance the performance of cylindrical grinding process by monitoring vital process signals like Performance Enhancement of Cylindrical Grinding Process

Cylindrical Grinding Process Strategy THORS

The THORS Cylindrical Grinding Process Strategy course expounds the factors that play a crucial role in cylindrical grinding and guides the learner to apply the principles to develop a grinding strategy This practical introduction, enriched with reallife examples, provides actionable strategies for better outcomes in cylindrical grindingFor over 60 years at HH Arnold, we have specialized in providing our customers with a singlesource solution for precision cylindrical grinding and machining Our ability to serve a broad customer base, in a highly competitive industry is a direct result of our commitment to customer service, and constant investment in the most advanced precision grinding equipment availableCylindrical, Centerless, Surface and Honing Grinding doi: 101016/jpromfg201608103 Performance Enhancement of Cylindrical Grinding Process with a Portable Diagnostic System R Vairamuthu1 Brij M Bhushan2 R Srikanth1 and Ramesh Babu N1 1Department of Mechanical Engineering, Indian Institute of Technology, Madras 2Graduate student, Massachusetts Institute of Technology, MAPerformance Enhancement of Cylindrical Grinding

GRINDING PROCESS

Grinding wheels Grinding wheels can sharpen knives and tools Grinding wheels are produced by mixing the appropriate grain size of abrasive with required bond and then pressed into shape The characteristics of the grinding wheel depends on number of variables Specified by dia of wheel, dia of spindle hole and face width of wheelErie Precision Grinding offers the latest machines in precision technology that have earned a reputation for reliability, durability, and overall quality We offer the latest in skill and precision technology Learn more about the machines we use below + Chevalier FSG 50”x120” Dual Column Surface Grinder + Studer S33 Cylindrical Our Machines Erie Precision Grinding Credential: Machining Level II Cylindrical Grinding Skills Credentialing Agency: National Institute for Metalworking Skills, Inc (NIMS) The National Institute for Metalworking Skills (NIMS) credentials are earned by students, trainees, apprentices, employees, and military personnelMachining Level II Cylindrical Grinding Skills

DON Civilian COOL Snapshot Machining Level II

Machining Level II Cylindrical Grinding Skills The Skill Level reflects the level, based on MOS training and/or experience, the Soldier should be the most prepared to successfully earn the credential See the Table Legend for details about each level Proponent Funded The THORS Cylindrical Grinding Process Strategy course expounds the factors that play a crucial role in cylindrical grinding and guides the learner to apply the principles to develop a grinding strategy This practical introduction, enriched with reallife examples, provides actionable strategies for better outcomes in cylindrical grindingCylindrical Grinding Process Strategy THORS If you operate a grinding shop, cylindrical grinding comprises one component of the many jobs you perform every day This is a precise form of grinding requiring great skill and focus The machinery, cylindrical grinders come in different types in order to address the specific demands of a product or jobCylindrical Grinding: Definition and Types

Performance Enhancement of Cylindrical Grinding Process

skill of the operator This paper presents an approach to develop a diagnostic system that can enhance the performance of cylindrical grinding process by monitoring vital process signals like doi: 101016/jpromfg201608103 Performance Enhancement of Cylindrical Grinding Process with a Portable Diagnostic System R Vairamuthu1 Brij M Bhushan2 R Srikanth1 and Ramesh Babu N1 1Department of Mechanical Engineering, Indian Institute of Technology, Madras 2Graduate student, Massachusetts Institute of Technology, MAPerformance Enhancement of Cylindrical Grinding CYLINDRICAL GRINDING OF RUBBER COATED ROLLERS MUST HAVE KNOWLEDGE OF USING MICROMETERS AND BASIC ENGINEERING SKILL ABILTY 18 20 Cylindrical Grinder Jobs March 2021 Indeed

traininggovau MEM07008D Perform grinding

Grinding operations and the processes and associated level of skill covered by this unit are often described in industry by the term '1st Class Machining' Where precision mechanical measurement is required, MEM12003B Perform precision mechanical measurement should also be consideredGrinding wheels Grinding wheels can sharpen knives and tools Grinding wheels are produced by mixing the appropriate grain size of abrasive with required bond and then pressed into shape The characteristics of the grinding wheel depends on number of variables Specified by dia of wheel, dia of spindle hole and face width of wheelGRINDING PROCESSThis cylindrical grinder is a type of grinding machine used to shape the outside and inside of an object The cylindrical grinder can work on a variety of shapes However, the object must have a central axis of rotation This includes, but is not limited to, such shapes as a cylinder, an ellipse, a cam, or a crankshaftRD Trinity Steel Private Limited Sri Lanka