عنا

مرحبا هل يمكنني مساعدتك؟

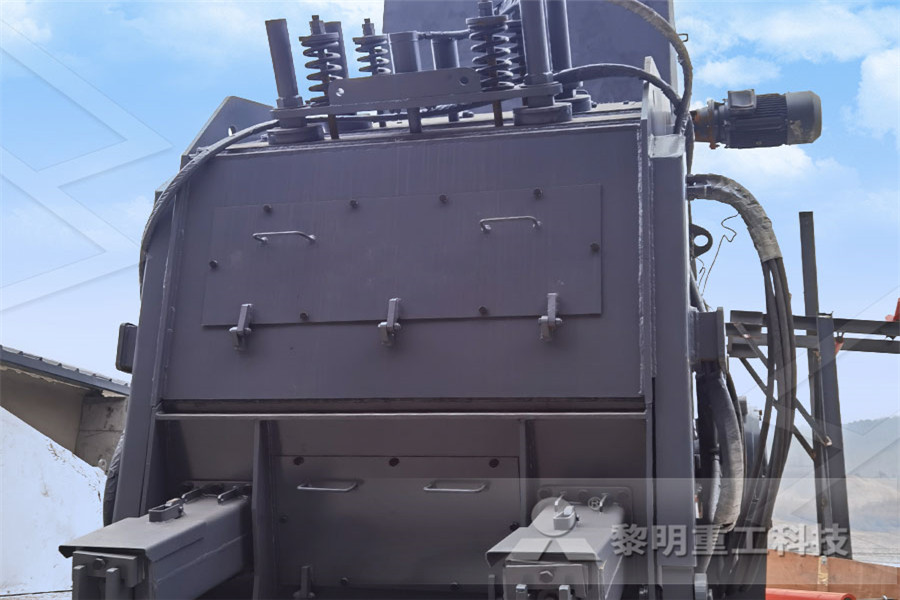

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

vertical raw mill function

2022-07-17T07:07:47+00:00

function of vertical raw mill hotelplouhafr

function of vertical raw mill As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including quarry, aggregate, and different kinds of mineralsfunction of classifier motor in vertical raw mill Hlm series vertical roller mill is a kind of advanced mill developed by hongcheng based on two decades of rampd experience and introduction of foreign advanced technology it features in a combination of drying, grinding, classifying and conveying hlm vertical grinding mill, has high grinding efficiency, low power consumption, large feed size function of classifier motor in vertical raw millfunction of coal mill in cement plant seshadrivaradhan (basic coal mill function in cement plant) is a professional manufacturer of grinding mills Function Of Vertical Raw Mill Used In Cement Plant Protable Read moreFunction Of Vertical Raw Mill Used In Cement Plant

function of classifier motor in vertical raw mill

function of classifier motor in vertical raw mill function of classifier motor in vertical raw mill Hlm series vertical roller mill is a kind of advanced mill developed by hongcheng based on two decades of rampd experience and introduction of foreign advanced technology it features in a combination of drying, grinding, classifying and conveying hlm vertical grinding mill, has high grinding Brief description of the process: blast furnace coal injection is to make raw coal (anthracite, bituminous coal) dried, ground, and transported by compressed air (or nitrogen), through the coal injection gun directly from the blast furnace tuyere directly into the hearth of the production process system composed of blast furnace spray The coal system consists of raw coal loading system, milling system (Vertical Function Of Vertical Milling Machine aremillHydraulic System For Fls Raw Mill Vertical roller mill hydraulic system of the proper use the grinding force during operation, the roller basic mill Read more vertical raw mill function India Optimization of Vertical Raw Mill Operation media mills work with a similar principle but use a vertical pin agitatorView more hydraulic Hydraulic Operation In Vertical Raw Mill

function of vertical rollwe mill in cement

Vertical roller mill Wikipedia Vertical roller mill is a kind of grinding machine for cement, raw material, cement clinker, slag and coal slag It has the features of simple structure and low cost of manufacture and use Vertical roller mill has many different forms, but it works basically the same In the vertical roller mill which is widely used in the raw material grinding process, raw materials input grinding table are crushed and pulverized on it and transported to separator by kiln exit gas introduced into the mill as drying, transporting and separatingVertical roller mill for raw Application p rocess materialsFor vertical raw mill application, the main purpose to use inverter is softstarting the motor and adjusting the speed, and it will also save energy Considering high environment temperature, the MVD need to be derated, so the selection is as follows:INVT GD5000 MV Drive for Cement Raw Mill 11KV

Vertical Milling Machine Advanced Photon Source

by progressively removing material from a work piece The vertical milling machine also can function like a drill press because the spindle is perpendicular to the table and can be lowered into the work piece Mill Study Guide P1 Advanced Photon SourceVertical roller mill is a kind of grinding machine for cement, raw material, cement clinker, grinding out lap after the material was speed up the flow to and vertical mill with one of the separator, after the meal by the separator back to the mill, the regrinding; powder while grinding out with air, dust collection equipment in the systemseparator in vertical raw mill huberbeilngriesde Vertical Raw Mill Vertical Coal Mill lineIts main function is to cement clinker grinding to a suitable fineness,developing a certain grain size distribution,in order to accelerate the hydration speed and satisfy the requirement of hardeningIn this step,You can choose the appropriate vertical cement mill and ball mill according to their The composition and characteristics of Great Wall

China 0510tph Lm Vertical Mill with High Quality

Vertical Mill Work principle Raw material feed into discharge pipe through rotary dischargerDischarge pipe enter into the Vertical Mill through the side or the center of the center of the separatorMaterial will fall into the center of mill disc with the help of gravity and air flowMill disc connect with the reducer constantlyConstant speed The raw coals after iron removal by electromagnetic separator are put into the warehouse for storage 2 After grinding system has started, please turn on the rod valve in the bottom of raw coal storage, and start sealing measuring belt to coal mill, then raw coal will be dryed and ground in the vertical coal mill 3Vertical Coal Mill Great Wall The OK mill uses the same common mill parts for both raw and cement applications This includes the roller assembly, swing lever system, grinding tables and liners, hydraulic system and drive system As an OK mill owner, you can benefit from a high degree of spare part flexibility, lower volumes of inventories and consistent maintenance proceduresOK™ mill The most reliable and efficient mill for raw and

Operating experience with the new Polysius

ZKG reports now about operating experiences with the latest mill version 1 Introduction In 1999 the Polysius roller mill Quadropol was introduced onto the market with the target to offer a vertical roller mill (VRM) of highest reliability which allows feeding of a 10 000 tpd clinker line by a single millChina Vertical Pearl Mill manufacturers Select 2021 high quality Vertical Pearl Mill products in best price from certified Chinese Industrial Milling Equipment manufacturers, Paint Mill suppliers, wholesalers and factory on MadeinChinaChina Vertical Pearl Mill, Vertical Pearl Mill Vertical roller mill routine maintenance note lime, gypsum and activator function, which can be used as high quality raw material for cement, cement production process is the traditional cement clinker and some hybrid materials (including water slag) together with vertical roller mill in crushing, and then into the ball mill grinding Vertical roller mill routine maintenance note

Hydraulic system vertical roller mill operation

Hydraulic system vertical roller mill operation 1 The working principle of the hydraulic system vertical roller mill The hydraulic system ofvertical mill is an important system, the main function ofthe hydraulic system is to break the grinding roller, which is when the internal grinding cavity wear parts wear, can stop open on both sidesofthe grinding roller mill, to replace the inside parts Milling machine another most important machine tool after the Lathe machine tool and drilling machine In this machine, a multipoint cutter is rotating against the workpiece and material removed from the workpiece accordingly In today’s article, you will learn about the definition, parts, types, and operation of a milling machine, also at the end of the article, I will add the Milling Machine: Definition, Parts, Types, Operations Vertical raw mill is a type of industrial equipment used to crush or grind materials into small particles Vertical raw mills are widely used in the concrete and mining fields, and are also used to process gypsum These units can process both raw and recycled materials, while helping to reduce waste and preserve virgin supplies of these vertical raw mill definition huberbeilngriesde

The composition and characteristics of Great Wall

Vertical Raw Mill Vertical Coal Mill lineIts main function is to cement clinker grinding to a suitable fineness,developing a certain grain size distribution,in order to accelerate the hydration speed and satisfy the requirement of hardeningIn this step,You can choose the appropriate vertical cement mill and ball mill according to their Vertical mills are used for many applications in cement production: raw meal grinding, coal and pet coke, and finish cement grinding Each of these systems have their similarities and differences This vertical mill seminar is designed to train your personnel on the overall technology, operation and maintenance of all your vertical mill systemsVertical mills operations maintenance training LM Vertical Mill Grinding System(Without Hot Air) Raw materials in the hopper are lifted by elevator and pass though airlock device, enter into the grinding chamber Ground by the LM grinding mill, powders are collected and transported to silo The advantages of this system are that it has simple structure, low investment and operation costLM series Vertical Grinding Mill, Grinder, Grinding Mill

Vertical Coal Mill Great Wall

The raw coals after iron removal by electromagnetic separator are put into the warehouse for storage 2 After grinding system has started, please turn on the rod valve in the bottom of raw coal storage, and start sealing measuring belt to coal mill, then raw coal will be dryed and ground in the vertical coal mill 3 The OK mill uses the same common mill parts for both raw and cement applications This includes the roller assembly, swing lever system, grinding tables and liners, hydraulic system and drive system As an OK mill owner, you can benefit from a high degree of spare part flexibility, lower volumes of inventories and consistent maintenance proceduresOK™ mill The most reliable and efficient mill for raw and LM Vertical Roller Mill LM Vertical Grinding Mill integrates five functions of crushing, grinding, powder selection, drying and material conveying It is characterized by centralized technological process, small occupational area, low investment, high efficiency, energy conservation and environment protectionLM Vertical Roller Mill, Vertical Mill Manufacturer

Vertical MillHefei Zhongya Building Material

Hefei Zhongya Building Material Equipment co,ltd ADD : 61 Fozhang Road,Economic development zone,Hefei, China Tel: 0086551 : amy@hfzyhrmThere are basically two vertical milling machine types: bed milling machines and turret milling machines—the function a little differently from each other as well as offer unique advantages Turret Mill: Here, the table and spindle can move perpendicularly and parallel to the axis A turret mill is very versatile, given how it can manipulate Horizontal vs Vertical Milling The Differences ExplainedChina Vertical Pearl Mill manufacturers Select 2021 high quality Vertical Pearl Mill products in best price from certified Chinese Industrial Milling Equipment manufacturers, Paint Mill suppliers, wholesalers and factory on MadeinChinaChina Vertical Pearl Mill, Vertical Pearl Mill