عنا

مرحبا هل يمكنني مساعدتك؟

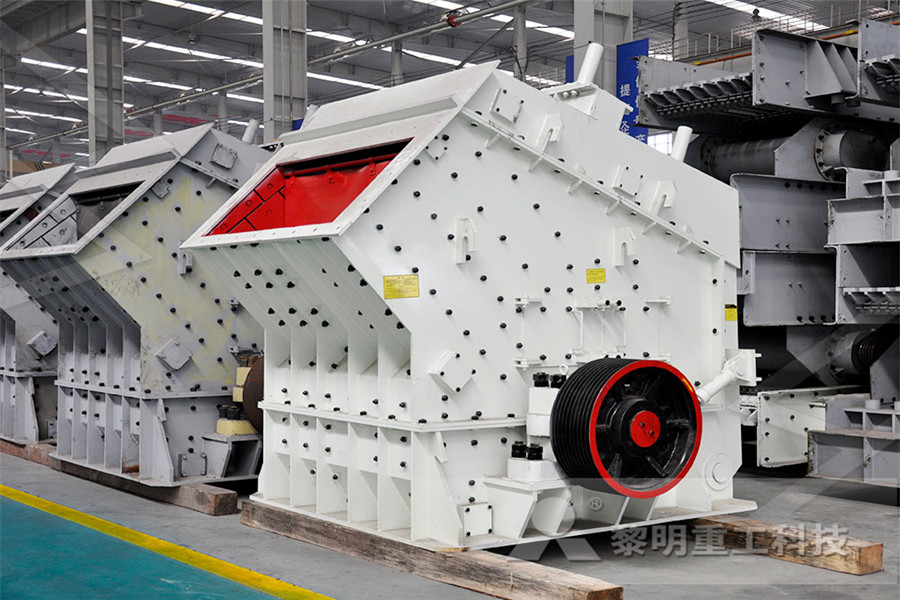

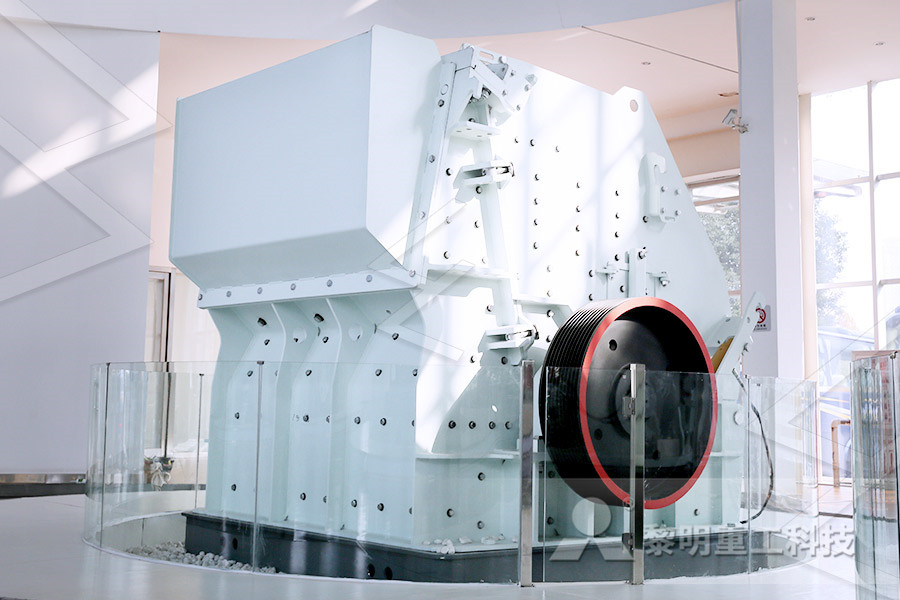

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

working principle of three roller mill

2019-04-22T13:04:07+00:00

Traditional Triroller mill working principle/technical

Working Principle The equipment consists of three rollers fixed on the frame and driven directly by the motor The rotation direction between rollers is generally different, the former roller rotates forward, rear roller rotates backward The speed of former roller is quick, while speed of rear roller vertical roller mill working principle india vertical roller mill working principle india Promac has successfully executed modern cement plants in India and There are many different kinds of forging processes available however they can be grouped into three main classes Drawn out length increases crosssection decreases Inquiry Onlineworking principle of three roller mill mojursusplHigh Speed Three Roll Mill For Paint , Golden Triple Roll Mill Working Principle High Speed Three Roll Mill For Paint , Golden Triple Roll Mill Working Principle Main feature 1 High precise (minimum 1μm, depend on materials) 2 Easycleaning roller 3 Variable speeds 4 Hopper(optional) 5 Adjust the gap between two rolls by single hand,High Speed Three Roll Mill For Paint , Golden Triple

We should know the working principle of high

working principle of raymond roller mill working principle of three roller mill Working principle of Raymond roller mill The rollers tightly rolled on the ring under the effect of centrifugal force Shovel sends material between the roller and ring and the material is grinded into powder under the high pressure Then the Get Price See Details > Roller mill is a form of compression mill that uses a single, double, or triple cylindrical heavy wheel mounted horizontally and rotated about their long axis either in opposing pairs or against flat plates, to crush or grind various materialsRoller Mill: Components, Designs, Uses, Advantages Working principle of vertical roller mill is driven by motor reducer rotating disc, and the hot air from the air inlet into the vertical mill, the material from the feed opening falls on the disc center, due to the centrifugal force, the material is moved from the The working principle of vertical roller millITPUB博客

The Structure and Working Principle of High Pressure

The structure of high pressure grinding roller mill The structure of high pressure grinding roller mill is various, but its principle is basically similar The roller press is mainly composed of feeding device, material position control device, a pair of sticks, rotating device (motor, pulley, gear shaft), hydraulic system, and horizontal leakage prevention deviceFive and sixroller mills Sixroller mills have three sets of rollers When using this type of mill on grain, the first set of rollers crush the whole kernel, and its output is divided three ways: Flour immediately is sent out the mill, grits without a husk proceed to the last roller, and husk, possibly still containing parts of Roller mill Types, Gristmill conversion, Other Working Principle of Flour Milling Machine HOME > News Flour milling machine rotary screen uses for grain grading, the machine produced simultaneously three tracks, feeding end is elliptic, middle part is circular and then through small oval transition to discharge end,the approximate linear reciprocating motionWorking Principle of Flour Milling Machine

Hydraulic system vertical roller mill operation

Hydraulic system vertical roller mill operation 1 The working principle of the hydraulic system vertical roller mill The hydraulic system ofvertical mill is an important system, the main function ofthe hydraulic system is to break the grinding roller, which is when the internal grinding cavity wear parts wear, can stop open on both sidesofthe grinding roller millThe following is the working principle drawing of symmetrical 3 roll bending machine Driven roller Ⅱ, Ⅲ is driven by motor and reducer, which rotates in the same direction at the same speed (or in the opposite direction) Because of the friction between the roller and the plate, the plate is driven forward and the roller 3 Roll Bending Machine (Working Principle and Abster Lab use three roller mill is widely applied in institute experiment and trail production of paint, dye, printing ink, cosmetics, rubber, soap, high viscosity pulp, agriculture chemicals, ceramic, adhesion and grinding paste slurry etc Laboratory three roller grinding mill is currently one of the most popular grinding mill for paint, UV ink productionCosmetic Three Roll Mill, Cosmetics Manufacturing

Threeroll mill selection tips Processing Magazine

A threeroll mill is used mostly for dispersion, but does some grinding as well It uses three rollers of different speeds and directions to cause the sheer force between them to disperse and grind particles The threeroll mill is used to disperse material within a media, which is usually some type of semiviscous material such as creamThree Roll Mill Triple Roller Milling Machine For Paint / Ink / Pigment; Single Handle 3 High Rolling Mill For Paint / Ceramic Paste Red; High Speed Three Roll Mill For Paint , Golden Triple Roll Mill Working PrincipleThree Roll Mill factory, Buy good quality Three Roll Zro2 Al2o3 Material Triple Roller Mill 0500rpm Ceramic Roll Speed High Precise Three Roll Mill Machine 150mm Roller Length 5140 Micron Epoxy Resin Material Planetary Centrifugal Vacuum Mixer 700ml Single Cup Laboratory 3 Roll Mill Mini Type Lab Triple Roller Mill Dc Motor Nanoscale Ceramic Handle Three Roll Mill For Cosmetics MaterialsQuality Three Roll Mill Triple Roll Mill factory from

Roller Mill: Components, Designs, Uses, Advantages

Roller mill is a form of compression mill that uses a single, double, or triple cylindrical heavy wheel mounted horizontally and rotated about their long axis either in opposing pairs or against flat plates, to crush or grind various materials When looking at the working principle of the pendular roller mill it becomes apparent that the mill combines three unit operations in one process, namely a comminution process, a conveying process and a classification process Each individual process as well as their respective interactions need to be investigated and understood in order to Investigation of the comminution process in pendular Working Principle of Flour Milling Machine HOME > News Flour milling machine rotary screen uses for grain grading, the machine produced simultaneously three tracks, feeding end is elliptic, middle part is circular and then through small oval transition to discharge end,the approximate linear reciprocating motionWorking Principle of Flour Milling Machine

Roll Mill an overview ScienceDirect Topics

A paper roll mill in Paperie du Rhin in France installed an MBR process based on hollowfiber membranes (Table 192) The mill uses recycled (not deinked) paper as the raw material for the production of 40,000 tons of paper rolls annually The bioreactor (1500 m 3) is operated at an MLSS content of 12–16 g/L The wastewater from the mill is The machine can perform similar machinery tasks of homogeneous machine, ball milling, threeroller sharpening machine, bother maker and plasmgrinding machine Vitro Pharma Machinery is one of the leading colloid mill machine manufacturers in India Colloid mill working principle is on the basis of rotorstator Colloid mill machine suppliers Colloid Mill Machine Working Principle Manufacturers The following is the working principle drawing of symmetrical 3 roll bending machine Driven roller Ⅱ, Ⅲ is driven by motor and reducer, which rotates in the same direction at the same speed (or in the opposite direction) Because of the friction between the roller and the plate, the plate is driven forward and the roller 3 Roll Bending Machine (Working Principle and

Cosmetic Three Roll Mill, Cosmetics Manufacturing

Abster Lab use three roller mill is widely applied in institute experiment and trail production of paint, dye, printing ink, cosmetics, rubber, soap, high viscosity pulp, agriculture chemicals, ceramic, adhesion and grinding paste slurry etc Laboratory three roller grinding mill is currently one of the most popular grinding mill for paint, UV ink production2 ThreeHigh Rolling Mills: In this mill, the three rolls stand in parallel one by others The rolls are rotating in opposite directions In this mill, between the first and the second rolls, the material passes If the second roll rotates in a direction then the bottom roll rotates in another directionRolling Process: Working, Application, Defects, Type of Three Roll Mill Triple Roller Milling Machine For Paint / Ink / Pigment; Single Handle 3 High Rolling Mill For Paint / Ceramic Paste Red; High Speed Three Roll Mill For Paint , Golden Triple Roll Mill Working PrincipleChina Shenzhen ZYE Science and threerollmill

roller mill working operation Mining

5 roller trapezium roller mill operation principleShanghai JoyalTrapezium Mill,Trapezium Mill For Working Principle The operation principle of main unit of Trapezium mill is that main unit runs with the »More detailedRoller mill is a form of compression mill that uses a single, double, or triple cylindrical heavy wheel mounted horizontally and rotated about their long axis either in opposing pairs or against flat plates, to crush or grind various materialsRoller Mill: Components, Designs, Uses, Advantages Working principle of vertical roller mill is driven by motor reducer rotating disc, and the hot air from the air inlet into the vertical mill, the material from the feed opening falls on the disc center, due to the centrifugal force, the material is moved from the The working principle of vertical roller millITPUB博客

The Working Principle of Pharmaceutical Roller

Roller Compactor are utilized to induce fine powders involving two counter rotating sticks and presses on the raw materials into a good streamlined (powders, sheets, strips) Roll Compactor can also be known as dry Granulator Then, Roller Compactor Manufacturer tell you its working principle A roller compactor usually includes three main When looking at the working principle of the pendular roller mill it becomes apparent that the mill combines three unit operations in one process, namely a comminution process, a conveying process and a classification process Each individual process as well as their respective interactions need to be investigated and understood in order to Investigation of the comminution process in pendular A paper roll mill in Paperie du Rhin in France installed an MBR process based on hollowfiber membranes (Table 192) The mill uses recycled (not deinked) paper as the raw material for the production of 40,000 tons of paper rolls annually The bioreactor (1500 m 3) is operated at an MLSS content of 12–16 g/L The wastewater from the mill is Roll Mill an overview ScienceDirect Topics