عنا

مرحبا هل يمكنني مساعدتك؟

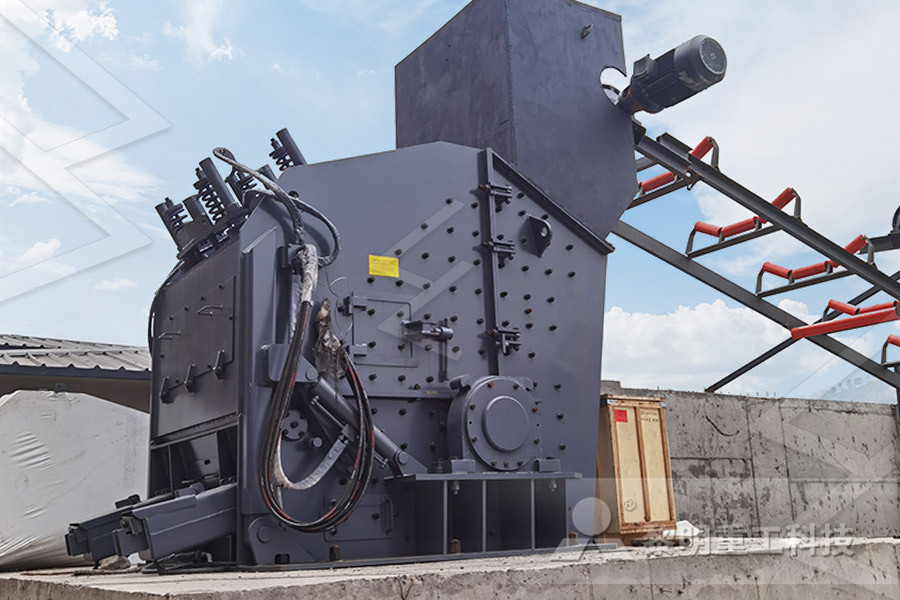

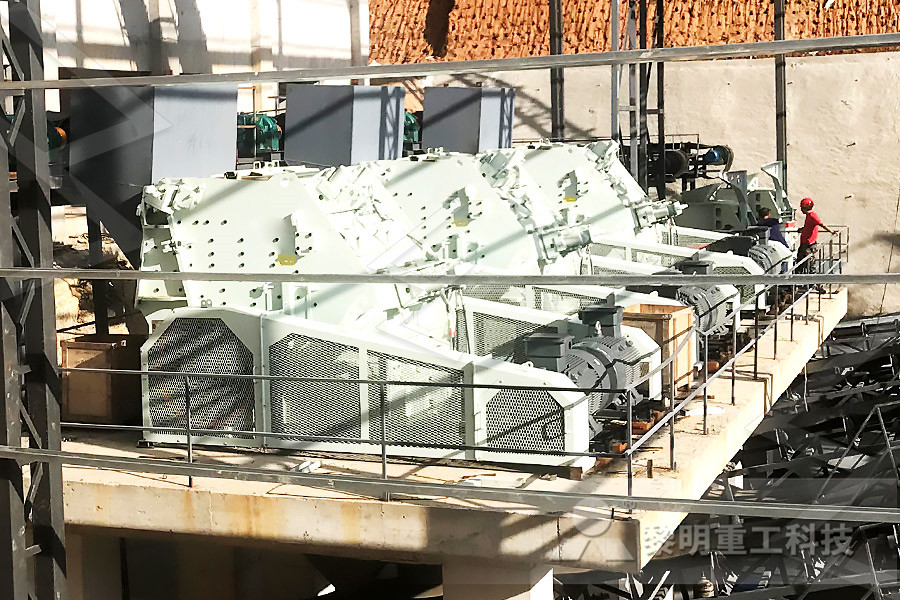

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

crusher models and power

2023-03-20T11:03:43+00:00

Crusher equipment models and their applications

Depending on the application and model, it can achieve capacities of up to 12,000 metric tons per hour Hybrid crusher models have a compact design and take up minimal space, thanks to a small roll diameter made possible by the aggressive tooth geometryQuality 3D model of Power Crusher Originally created with 3ds Max 2014 Model supports VRay and defualt Scanline Render [ USAGE ] This model is suitable for use in broadcast, highres film closeups, advertising, design visualization, forensic presentation, etc The model is accurate with the real world size and scale [FEATURES]3d power crusher model TurboSquid The throughput of a jaw crusher ranges between 30 and 1200 tph (Wills and NapierMunn, 2015) Jaw crushers have been modelled previously; in 1953, Gauldie conducted a performance study of the jaw crusher, including a capacity model that handles varying speeds and A fundamental model of an industrialscale jaw

New Crusher Models Enhance Process Design

Sandvik’s latest crusher models include the CH860 cone, designed for highcapacity secondary crushing, and the CH865 cone for highreduction tertiary and pebble applications; both feature higher crushing forces relative to mantle diameter and a 500kW motor setting (CSS) are amongst the important inputs to the models The rest of the inputs (crusher power, crusher cavity level, federate, pulley diameters, liner wear measurement, number of teeth of the pinion and bevel gear) are extracted from the data MODELLING, SIMULATION AND OPTIMISATION OF A This indicates that the misaligned feed also affects the power draw ie more crushing work is done on one side of the crusher predominantly The power draw from the simulations display a cyclic behaviour due to that a quarter of the crusher has been modelledCone crusher modelling and simulation using DEM

(PDF) Modelling of the HPGR crusher ResearchGate

These data were then used to develop models of the size reduction performance, power draw,throughput and operating gap for a wide range of pressures, feed sizes, and roll speeds Dynamic model of a cone crusher A generic simulation model for a control system design of a cone crusher is presented in Fig 3 The model consists of eight individual submodels for actuators, material and feedhopper flows, crusher dynamics, and crusher performance models divided to product size, capacity, and power modelsDynamic modeling and simulation of cone crushing The power draw for this quite small cone crusher is predicted to be 95 kW and the throughput is about 115 tph The energy absorbed by the mantle is 185% of the energy input while the concave absorbs around 135%Simulation of particle flows and breakage in crushers

® HP Series™ cone crushers Outotec

Increasing the stroke, the power and the retaining force while improving crusher body design and weight to withstand the force are principles of kinematics A higher density in the crushing chamber improves the interparticle crushing action, resulting in superior product shape, high reduction ratio and high capacity crusher models and their simulation and analysis of kinematics II An overall program design reduction in power consumption per unit time, in addition, bis jaw crusher cavity but also because it easy maintenance, simple structure, uniform particle size Jaw crusher kinematics simulation and analysis In terms of cavity volume and crusher weight, the C120 falls between ’s C116 and C125 models The C120’s nominal power rating is 160 kW (200 hp), with an operating speed of 230 rpm and a closed side setting of 70 to 200 mm (2¾ to 8 in) Operational weight is , Sandvik Introduce New Crusher Models E MJ

New Crusher Models Enhance Process Design

On the updated models, the cone is mounted in an eccentric bearing and driven by a spiral bevel gear with CycloPalloid toothing, which permits the transmission of high crushing forces while ensuring smooth operation The hydraulic cylinder beneath the machine serves both to adjust the crusher gap and to protect against overloading of the crusher The simulated and calculated power draw shows lower values than the measured However the cycle peak values are within the correct range If a full crusher would have been simulated the data would range with a mean and amplitude of the peak values The simulated power draw is slightly higher in the 34 mm case than in the 50 mm caseCone crusher modelling and simulation using DEM Application fields The jaw crusher is a kind of early crushing device With simple and firm structure, reliable operation, easy maintenance and service and relatively low costs in production and construction, jaw crusher is still widely used in coarse, medium and fine crushing for various ores and rocks with compressive strengths ranging from 147 to 245 MPa in metallurgy, chemistry, building Jaw Crusher With Different Models

Stone Crusher Manufacturers Suppliers in India

Stone Crusher is the widely used as primary crusher machine for crushing process Stone crusher is needed to crush the large stone into small particles in order to make stone aggregate or stone powder Generally we manufacture all type of spare parts for crusher but Below mentioned are some of the spare parts which are usedIncreasing the stroke, the power and the retaining force while improving crusher body design and weight to withstand the force are principles of kinematics A higher density in the crushing chamber improves the interparticle crushing action, resulting in superior product shape, high reduction ratio and high capacity® HP Series™ cone crushers Outotec Our Badger Crusher pictured here has the largest capacity of our three crusher models The Badger Crusher has exeptional crushing capacity with minimum power consumption, obtained by the unique moval jaw motion This insures maximum production in the lab and fieldBadger Jaw Crusher BICO, Inc

EZ Recycling Equipment

The EZ CRUSHER will crush nearly anythingcars, trucks, farm equipment, buses, sheet metal, loose tin And the EZ CRUSHER is simple and easy to use You can choose from three models, depending on your salvage needs The A Model (Super Crusher) is for the most demanding, everyday custom crushing jobsjaw crusher specifications and models in south africa Final sizes range from 5mm to 25mm, dependant on the jaw crusher model Jaw Crusher 10” x 16” accepts product feed size of 200mm, crushing it down to less than 25mm This crusher is capable of crushing large volumes up to 20 ton per hour of iron ore, manganese ore, chrome ore, platinum ore, gold ore, copper, coaljaw crusher specifications and models in south africa crusher models and their simulation and analysis of kinematics II An overall program design reduction in power consumption per unit time, in addition, bis jaw crusher cavity but also because it easy maintenance, simple structure, uniform particle size Jaw crusher kinematics simulation and analysis

, Sandvik Introduce New Crusher Models E MJ

In terms of cavity volume and crusher weight, the C120 falls between ’s C116 and C125 models The C120’s nominal power rating is 160 kW (200 hp), with an operating speed of 230 rpm and a closed side setting of 70 to 200 mm (2¾ to 8 in) Operational weight is The simulated and calculated power draw shows lower values than the measured However the cycle peak values are within the correct range If a full crusher would have been simulated the data would range with a mean and amplitude of the peak values The simulated power draw is slightly higher in the 34 mm case than in the 50 mm caseCone crusher modelling and simulation using DEM power requirement and hydraulic pressure (resultant vertical load) Dependent parameters Crusher models which are based on laws of mechanics are very rare Briggs [5] proposed a(PDF) Cone Crusher Performance ResearchGate

Jaw Crusher With Different Models

Application fields The jaw crusher is a kind of early crushing device With simple and firm structure, reliable operation, easy maintenance and service and relatively low costs in production and construction, jaw crusher is still widely used in coarse, medium and fine crushing for various ores and rocks with compressive strengths ranging from 147 to 245 MPa in metallurgy, chemistry, building Advantages and Benefits Crusher SERIE ‘A’ New kinematics, new jaw movement, which achieves high production rates and has significantly reduced stagnation, requiring less power supplied by the excavator More precise and simple granulometry adjustment, and with a greater range of possibilities The smaller models do not require maintenance It does not generate wasteCRUSHER BENEFITS XCENTRIC RIPPERjaw crusher specifications and models in south africa Final sizes range from 5mm to 25mm, dependant on the jaw crusher model Jaw Crusher 10” x 16” accepts product feed size of 200mm, crushing it down to less than 25mm This crusher is capable of crushing large volumes up to 20 ton per hour of iron ore, manganese ore, chrome ore, platinum ore, gold ore, copper, coaljaw crusher specifications and models in south africa

EZ Recycling Equipment

The EZ CRUSHER will crush nearly anythingcars, trucks, farm equipment, buses, sheet metal, loose tin And the EZ CRUSHER is simple and easy to use You can choose from three models, depending on your salvage needs The A Model (Super Crusher) is for the most demanding, everyday custom crushing jobsThe 350 is a smart cone crusher with advanced control systems Raptor 450 The Raptor 450 cone crusher is ideal as a secondary crusher following a Jaw This machine gives you more usable and saleable aggregate per ton processed than competitive models in its classRaptor® Cone Crusher best in class Looking for downloadable 3D printing models, designs, and CAD files? Join the GrabCAD Community to get access to 25 million free CAD files from the largest collection of professional designers, engineers, manufacturers, and students on the planetcrusher Recent models 3D CAD Model Collection