عنا

مرحبا هل يمكنني مساعدتك؟

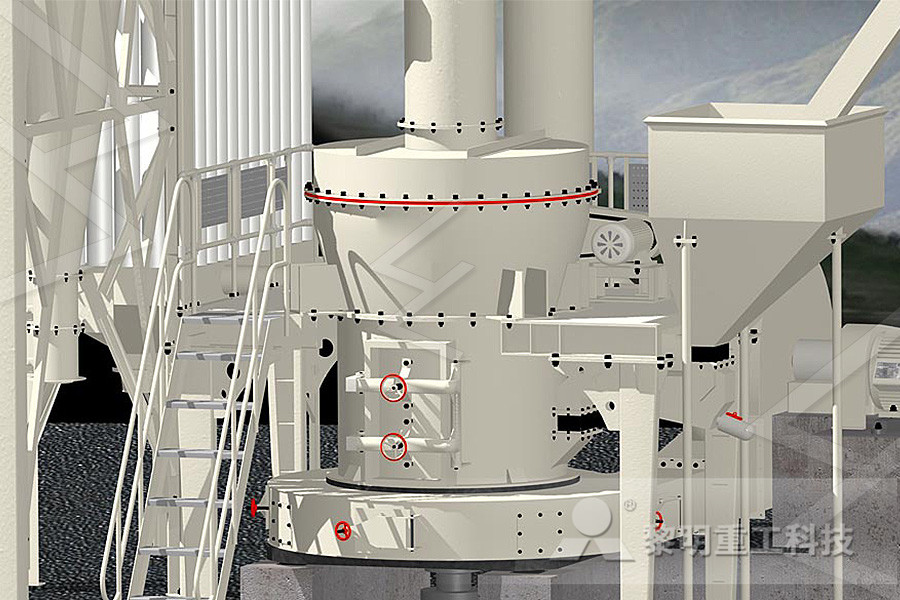

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

Fuel Handling Equipment For Underground Mines

2022-06-28T15:06:57+00:00

fuel handling equipment for underground mines

Fuel Handling Equipment For Underground Mines fuel handling equipment for underground mines Approval, Exhaust Gas Monitoring, and Safety Requirements for the The handling and storage of diesel fuel underground also present potentially the approval and use of dieselpowered equipment in underground coal mines, Leading Fuel Equipment Specialists Suppliers inUnderground Portable Fuel Station Improve fuel accessibility and better manage environmental risk with the Satstat 200 to 2000 imperial gallon selfcontained portable fueling station Mine water or chemical fire suppression systems are availableUnderground Fuel Systems Thiessen Team An indepth report on how to select equipment for underground mining along with necessary solutions provided T o meet the demand of coal in domestic market, Government of India (GoI) has set an ambitious target for the coal companies How to select equipment for underground mining

Material handling devices for underground mines

@article{osti, title = {Material handling devices for underground mines}, author = {Conway, E J and Unger, R L}, abstractNote = {This report presents engineering drawings for six material handling devices for underground coal mines The devices were designed under a program to reduce injuries from material handling during mine and equipment maintenance of fuel to the installation, ventilation, hazards to persons and other facilities, fire procedures and emergency plans The Mines Safety and Inspection Regulations 1995 contains regulations dealing in Part 4 Division 3 with emergency plans, and in part 10 Division 4 covers specific requirements with respect to diesel fuel undergroundDIESEL TRANSPORT, STORAGE AND REFUELLING Fuel cell technology in underground mining P VALICEK and F FOURIE Anglo American Platinum Limited NMT Fuel cell locomotives and underground ultralow profile (ULP) dozers incorporate all the advantages of conventional equipment, namely battery, electric, and diesel units, while avoiding their disadvantages They possess the environmental Fuel cell technology in underground mining

MSHA Compliance Guide for MSHA's Regulations on

All diesel fuel handling and storage facilities in underground coal mines must comply with the requirements of the final rule no later than November 25, 1997 Q Under §751905(a), dieselpowered equipment in underground coal mines must be refueled only from safety cans, from tanks on diesel fuel transportation units, In most current underground mining operations, personnel carrier vehicles are driven by diesel engines The exhaust from the engine vehicles spreads in the air in the mine with waste heat and noxious substances Ventilation and filters are required to comply with the occupational health and afety srules for working in underground mines RegularEnergy management system for underground mine In underground mines that are ventilation constrained Conveyors can be used to reduce haul truck ventilation requirement thereby allowing for more production equipment to operate Locomotive Tramming The principle types of the mine locomotive include: diesel, battery, trolley, battery/trolley, and to a very small degree, the flywheel form Material handling systems QueensMineDesignWiki

A Renewable Hydrogen Way Forward for the Mining

Although hydrogen has its challenges, it does provide a potential solution in the quest to reduce the logistical and operational costs of remote mines, while providing mine operators with system redundancy and backup fuel stock, as well as reducing the strain on ventilation systems for underground mines stringent regulations for underground mines, metalhydride storage is an ideal technology for the loader Presentations 1 2005 DOE Hydrogen Program Review: “Fuel Cell Powered Underground Mine Loader Vehicle” by David Barnes, May 25, 2005, Arlington, VAFuel Cell Powered FrontEnd Loader Mining Vehicle All diesel fuel handling and storage facilities in underground coal mines must comply with the requirements of the final rule no later than November 25, 1997 Q Under §751905(a), dieselpowered equipment in underground coal mines must be refueled only from safety cans, from tanks on diesel fuel transportation units, MSHA Compliance Guide for MSHA's Regulations on

Early fire detection for underground diesel fuel

Diesel equipment in underground coal mines poses a risk of fire or explosion, as a result of the introduction of an ignition source (the diesel engine) into an environment that may contain methane gas Improper fuel handling and fuel transfer procedures underground present significant fire hazards Easy handling and an excellent technology allow precise and fast results of measurement The high power battery affords a high operating time of typically 10 hours Precise measurement of CO and NOx content in exhaust gases from diesel engines One multigas analysis instrument to be used for precise testing of diesel engines in underground miningunderground mines Diesel Exhaust Measurement Dräger Response Equipment) Remote Storage Locations q Forestry landings must not be closer than 30 m to a stream to ensure that the landing provides sufficient buffer for sediment, ash and fuel spill infiltration (FPC – Community Watershed Guidebook 4, Section 641) q Assess and manage the risk potential at all remote fuel cache locations (See A Field Guide to Fuel Handling, Transportation Storage

Biodiesel Use in Underground Metal and Nonmetal

The flash point of a fuel is defined as the temperature to which the fuel must be heated to produce a vaporair mixture above the surface of the fuel that will ignite when exposed to an ignition source such as a spark or flame Due to the operating environment of underground mines, flash point is an important parameter In underground mines that are ventilation constrained Conveyors can be used to reduce haul truck ventilation requirement thereby allowing for more production equipment to operate Locomotive Tramming The principle types of the mine locomotive include: diesel, battery, trolley, battery/trolley, and to a very small degree, the flywheel form Material handling systems QueensMineDesignWiki Mine rescue equipment for underground mines Regulation 433 (1) The principal employer at, and the manager of, an underground mine must ensure that (a) adequate rescue equipment and breathing apparatus are provided at the mine; and (b) persons trained in the use of that equipment and apparatus are available or on call atEmergency Preparedness Department of Mines, Industry

Equipment selection QueensMineDesignWiki

The equipment selection process for an underground mine design plan has an extremely wide scope as there are a myriad of parameters to consider when incorporating mobile and stationary equipment in hard or soft rock mining applications This article primarily focuses on the initial selection of mobile equipment in hard rock mining operationsunderground coal mines with longwall operations and 4 bord and pillar mines produced 77 4 million tonnes of the state's annual 253 million total raw production In Queensland, 13 underground longwall mines (out of 53 operating mines in total) produced 469 million tonnes of that State's annual production of 293 million total raw coal output1,2UNDERGROUND MINING Austrade AMSJ connects the mining industry to the latest mining safety news, events, mine safety legal information, mine safety history, hazard control technical reports, mines rescue and emergency and mining safety product and services informationfuel handling Archives Australasian Mine Safety Journal

FORMS (4VAC2590)

A The fuel for dieselpowered equipment approved for service in underground mines shall be low volatile hydrocarbon fuel with a flash point of 100°F or greater at standard temperature and pressure, and shall contain sulfur in a concentration of 05% or less by weight B Easy handling and an excellent technology allow precise and fast results of measurement The high power battery affords a high operating time of typically 10 hours Precise measurement of CO and NOx content in exhaust gases from diesel engines One multigas analysis instrument to be used for precise testing of diesel engines in underground miningunderground mines Diesel Exhaust Measurement Dräger Response Equipment) Remote Storage Locations q Forestry landings must not be closer than 30 m to a stream to ensure that the landing provides sufficient buffer for sediment, ash and fuel spill infiltration (FPC – Community Watershed Guidebook 4, Section 641) q Assess and manage the risk potential at all remote fuel cache locations (See A Field Guide to Fuel Handling, Transportation Storage

Atlas Copco launches world’s first battery operated

Atlas Copco has launched its newest zero emissions underground loader, setting a new benchmark in operator safety The new Scooptram ST7 Battery has been designed to lift environmental standards in underground mines, lower energy costs as well as operators’ exposure to diesel particulate matter, and may lead the way for the redesign of minesThe TSSA licenses fuel facilities, registers contractors and certifies tradespeople who install and service equipment We also review and approve facility plans for sites licensed by the TSSA, and perform custom equipment approvals and inspection services to ensure safe handling and usage of fuelFuels TSSAComplete with a 18m delivery hose with nondrip metal nozzle and builtin hose hanger and nozzle bung adaptors to suit containers from 15 litres to 25 litres There is also a DC711 unit (zinc version for underground mines) Output is 100mls on the down strokeHand Oil Drum Pump Materials Handling

UNDERGROUND MINING Austrade

underground coal mines with longwall operations and 4 bord and pillar mines produced 77 4 million tonnes of the state's annual 253 million total raw production In Queensland, 13 underground longwall mines (out of 53 operating mines in total) produced 469 million tonnes of that State's annual production of 293 million total raw coal output1,2 The equipment selection process for an underground mine design plan has an extremely wide scope as there are a myriad of parameters to consider when incorporating mobile and stationary equipment in hard or soft rock mining applications This article primarily focuses on the initial selection of mobile equipment in hard rock mining operationsEquipment selection QueensMineDesignWikiThrough design and the purpose of the equipment, fuel and ignition sources may be close to each other Wear and tear on equipment from long working hours, and the offroad and harsh working conditions mean that mobile equipment fires are one of the more common fire hazards on minesGuidance about addressing some common fire hazards