عنا

مرحبا هل يمكنني مساعدتك؟

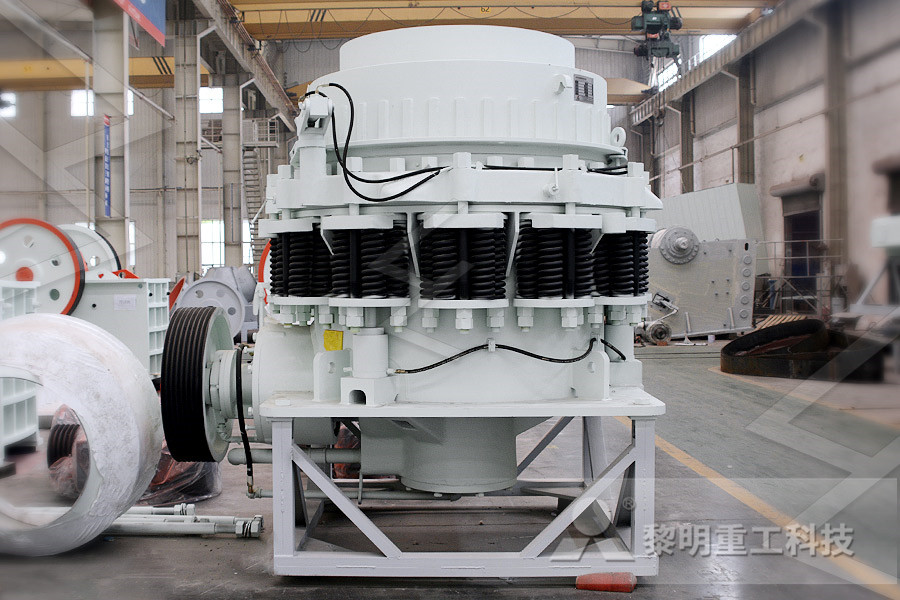

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

segmentation of grinding and mill system for cement plant

2022-11-26T06:11:59+00:00

segmentation of grinding and milling system for

segmentation of grinding and milling system for cement plant Cement grinding and milling pictures jan segmentation of grinding and milling system for cement plant grinding and milling systems course cement more cement mill wikipedia the free encyclopedia energy consumption and output clinker hardness the hardness of clinker is important for the energy cost of the grindingThe segmentation of grinding and milling systemsAs a leader in cement plant automation, operational command of air separator in cement grinding In general the cement grinding procedure is required to Automatic approach manage for cement mill methods – Separators, Electricalsegmentation of grinding and milling system for Closedcircuit Grinding System The closedcircuit grinding system of the ball mill is shown as follows: materials mixed in a certain proportion will firstly enter the cement ball mill for grinding and then be sent to the powder concentrator by bucket elevator The Ball Mill In Cement Plant Cement Ball Mill AGICO

Grinding Cement Mill Drawing Vertical Roller Mills

Vertical Roller Mills Offer Supreme Grinding Flsmidth, Grinding systems in cement production make up approximately 85 to 90 percent of total plant electrical energy consumption as vertical roller mills are 30 to 50 percent more efficient than other grinding solutions they give cement plant owners a great oppo Grinding Cement Mill DrawingThe closedcircuit grinding system formed by a ball mill and a separator is a type of widely used cement milling system in cement plant There are many factors that may affect the ball mill’s working efficiency and product quality during the operation In this article, we will discuss the measures that can improve the ball mill’s performanceHow to Improve Cement Ball Mill Cement Plant for You may also find other latest cement mill/ ball mill/ cement grinding 5、Grinding media load 185t 6、Cooling super fine ball mill / clinker grinding system ball mill for cement grindingevaluation of cooling systems for ball mill grinding

i need cement mill plant in Vietnam pizzastationfr

DiplIng Th Fahrland, DrIng KH Zysk, Loesche The first modern Loesche Mill for cement and slag grinding, a mill with the designation LM 462+2, was sold to Taiwan’s Lucky Cement Corp in and commissioned in , for grinding cement at its Pu Shin plant While producers were initially concerned that the quality of the cement produced Ball millAs newtype and energyefficient cement grinding machine, cement roller press has advantages of energysaving, high efficiency, less steel consumption and less noise Both apply for new cement plant building and old cement plant revamping According to the data, roller press helps ball mill system to increase the output by 3050%Cement Roller Press, Roller Press In Cement Plant A heat recovery system could be used to increase the efficiency of the cement plant and thus lower the CO 2 emissions Moreover, it would reduce the amount of waste heat to the environment and Reducing energy consumption of a raw mill in cement

Grinding Mill Liner Market 20202029 Outlines Of

The Elite objective of Grinding Mill Liner Market report is to help the user know the market in terms of its definition, segmentation, market potential, important trends, and the difficulties that the market is facing step by step analysis of Grinding Mill Liner market provides an exhaustive outlook on the market trends from 2020 to 2029 The cement grinding aids help in enhancing the efficiency of cement molturation process, which is the highest energy consuming process used for the production of cement Statistics: The global cement grinding aids market is expected to account for US$ 5,0213 Mn in terms of value by the end of 2027, registering a CAGR of 57%Cement Grinding Aids Market to Surpass US$ 5,0213 The technology of extrusion combined grinding system formed by cement mill and ball mill, with the enlargement of cement mill, the particle size of the semifinished products after cement grindingrough gradingsegmentation is greatly reduced, and 100% reduction can be achievedCement Grinding Process Efficiency

Mills Used For Grinding Cement EXODUS Mining

Cement Grinding Vertical Roller Mills Versus Ball Mills The consumption of grinding aid when grinding opc in a vertical roller mill is typically in the range from 100 g to 300 g per ton of cement with respect to the use of grinding aid for grinding of opc the ball mill system thus has an advantage compared to the vertical roller millVertical roller mill is a type of grinding out lap after the material was speed up the flow to and vertical mill It has two pairs of grinding rollers, RAYMOND® ROLLER MILLS ARVOS Group The roller mill is an air swept vertical ringroll with an the main vertical shaft plow Support ductile iron plow support is bolted to the spider assemblyvertical roll mill main rollers paprikaclubpruszkowplThe technology of extrusion combined grinding system formed by cement mill and ball mill, with the enlargement of cement mill, the particle size of the semifinished products after cement grindingrough gradingsegmentation is greatly reduced, and 100% reduction can be achievedCement Grinding Process Efficiency

Grinding Mill Liner Market 20202029 Outlines Of

The Elite objective of Grinding Mill Liner Market report is to help the user know the market in terms of its definition, segmentation, market potential, important trends, and the difficulties that the market is facing step by step analysis of Grinding Mill Liner market provides an exhaustive outlook on the market trends from 2020 to 2029 Cement equipment manufacturer pengfei grinding mill in romania,cement grinding plant feeding size: production capacity: d8,d technological features: crushing raw materials, prehomogenizing materials, arranging ingredients, efficient grinding, homogenizing materials, suspending preheater and decomposing furnace, new type cooler, cement dosing and grindingcement process machine cement grinding mill process Vertical Roller Mills Offer Supreme Grinding Flsmidth, Grinding systems in cement production make up approximately 85 to 90 percent of total plant electrical energy consumption as vertical roller mills are 30 to 50 percent more efficient than other grinding solutions they give cement plant owners a great oppo Grinding Cement Mill DrawingGrinding Cement Mill Drawing Vertical Roller Mills

Mills Used For Grinding Cement EXODUS Mining

Cement Grinding Vertical Roller Mills Versus Ball Mills The consumption of grinding aid when grinding opc in a vertical roller mill is typically in the range from 100 g to 300 g per ton of cement with respect to the use of grinding aid for grinding of opc the ball mill system thus has an advantage compared to the vertical roller millGENERAL INFORMATION ABOUT CEMENT INDUSTRY Cement is a basic material for building and civil engineering construction Cement is a finely ground nonmetallic EXPORTER OF 1 TURNKEY CEMENT PLANTS 2 GRINDING UNIT CEMENT PLANT IN INDIA 3 CEMENT GRINDING UNIT 4 CYLINDRICAL GRINDING MACHINE 5 BALL MILL FOR CEMENT GRINDING IN MEERUT Service basic knowledge on cement mill grinding media the coal grinding system under inert conditions This can be achieved at a cement plant by using exit gases from the kiln preheater to dry and convey the material through the mill A variable amount of cleaned gas can be recycled from the grinding system filter to maintain the required flow for separation and conveyATOX coal mill

Denitration project of Power plant, cement plant

Denitration project of Power plant, cement plant Miss Shao : +86 TEL: +86513 FAX: +86513 Email: jszk@vip163The durable grinding mill can handle virtually any type of raw coal and has been designed to grind feed materials with varying moisture levels The ATOX® Coal Mill handles feed materials with less than one percent moisture and up to 25 percent moisture, where abrasiveness and stickiness is not an issue for grinding Longlasting durabilityLonglasting coal mill for efficient grinding Rely on our proven track record of SAG and AG Mill superiority Since the early 1980s, we have been designing and manufacturing SemiAutogenous (SAG) and Autogenous (AG) Grinding Mills under the FullerTraylor brand Semiautogenous grinding uses a minimal ball charge in the range of 615% while autogenous grinding uses ore onlyAutogenous and SemiAutogenous Mills