عنا

مرحبا هل يمكنني مساعدتك؟

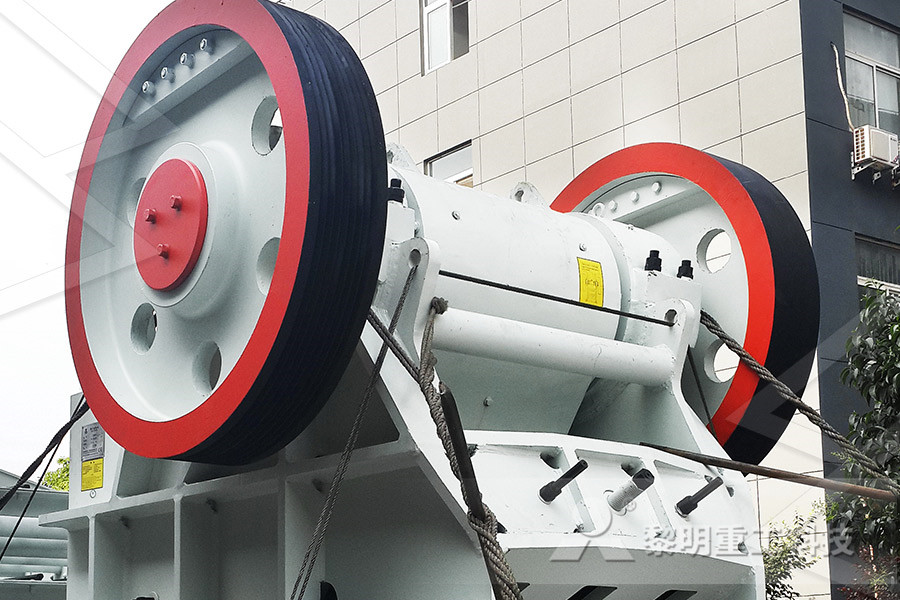

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

gypsum processing and use

2020-04-13T01:04:19+00:00

Gypsum processing and use Humanitarian Library

GYPSUM PROCESSING AND USE Gypsum is a particularly useful processed material Its main application is as a building material, mostly produced as socalled plaster of Paris for plastering walls and making decorative features in buildings However gypsum also has a diversity of Chemical gypsums are contaminated with the raw materials used in particular technologies, as well as the products of chemical processes These contaminants affect the properties of byproduct gypsum and subsequently formed binders The desulphogypsum produced by the wet process is highly pure calcium sulphate dihydrateProduction and use of byproduct gypsum in the Our pin mixers and disc pelletizers are frequently used to process gypsum into a premium pellet product Pin mixers are also ideal for use in dedusting applications, as well as a means of preconditioning gypsum for pelletization on a disc pelletizerGypsum Processing FEECO International Inc

(PDF) Gypsum Mining Production Processing and

Application of gypsum helps breakup hard soil, allows better aeration and water penetration and retention The processing of gypsum for use in the amendment of salinesodic soils involves crushing and 13 f grinding rock gypsum to 30 – 40 mesh size and loose or bagged product is transportedGypsum Processing for Wallboard Gypsum is a soft sulfate mineral composed of calcium sulfate dehydrate, with the chemical formula CaSO₄2H₂O It is widely used in a variety of applications and is the main ingredient in many forms of wallboard, block, and plaster products The traditional method of gypsum processing for stucco and plasterprocessing of gypsumgypsum mining processing lines gypsum is widely used in cement, paper making, painting materials, wall decoration and soil concentration, we need different processing technic to process gypsum, but the physical gypsum mining process is the sameirstly, gypsum quarry is exploded from gypsum mines exploding processhen it comes intoGypsum Mining And Processing haagdekode

1116 Gypsum Manufacturing US EPA

At some gypsum plants, drying, grinding, and calcining are performed in heated impact mills In these mills hot gas contacts gypsum as it is ground The gas dries and calcines the ore and then conveys the stucco to a product cyclone for collection The use of heated impact mills eliminates the need for rotary dryers, calciners, and roller mills Gypsum is a soft sulfate mineral composed of calcium sulfate dihydrate It forms as an evaporite mineral and as a hydration product of anhydrite It occurs chiefly in sedimentary deposits and is used to make plaster of Paris and fertilizers, as well as in the building industryWhat is Gypsum? Definition from CorrosionpediaGypsum Association – A notforprofit trade association founded in 1930, promoting the use of gypsum while advancing the development, growth, and general welfare of the gypsum industry in the United States and Canada on behalf of its member companiesGypsum Association – A notforprofit trade

(PDF) Gypsum Mining Production Processing and

The processing of gypsum for use in the amendment of salinesodic soils involves crushing and 13 grinding rock gypsum to 30 – 40 mesh size and loose or bagged product is transported • TREATMENT OF LOW QUALITY TUBEWELL WATER Many tubewells are pumping high sodium waters that make productive land unproductiveGypsum Processing for Wallboard Gypsum is a soft sulfate mineral composed of calcium sulfate dehydrate, with the chemical formula CaSO₄2H₂O It is widely used in a variety of applications and is the main ingredient in many forms of wallboard, block, and plaster products The traditional method of gypsum processing for stucco and plaster Gypsum Processing for Wallboard schenckprocess It is an important part of the Canadian economy, both from the side of extraction in the mining process to the final use after processing Today, nearly 75 percent of Canadian production of gypsum is based out of Nova Scotia Ontario, Manitoba and British Columbia also produce smaller amounts Uses in constructionWhat is Gypsum and How is it Used? — Bit Service

Gypsum Processing Enviro Grind Ltd

Gypsum Processing at Enviro Grind Statuary Regulations relating to the landfill disposal of Gypsum products including demolition plasterboard have enabled Enviro Grind to create innovative environmental solutions ahead of its competitors Enviro Grind’s Managing Director, Mr Martin Eves, is considered to be a World leading industry Gypsum is a very soft mineral composed of calcium sulfate dihydrate, with the chemical formula CaSO42H2O It is a byproduct of phosphate which is used as fertilizer This gypsum must be hauled from the phosphate field for further processing into wallboardGypsum processing technology trade information 1116 Gypsum Manufacturing 11161 Process Description12 Gypsum is calcium sulfate dihydrate (CaSO4 2H2O), a white or gray naturally occurring mineral Raw gypsum ore is processed into a variety of products such as a portland cement additive, soil conditioner, industrial and building plasters, and gypsum wallboard To produce plasters or1116 Gypsum Manufacturing US EPA

Handbook on Gypsum and Gypsum Based Products

Handbook on Gypsum and Gypsum Based Products (Mining, Processing, Transportation, Handling Storage, Gypsum Board, Plaster of Paris with Machinery Equipment Details) Gypsum is chemically known as calcium sulfate dihydrate and it contains calcium and Processing of gypsum permits the use of different techniques to produce a range of these products: pressing for blocks, rolling, extrusion for panels and boards, casting for decorative elements and foam gypsum products 25231 Wall blocksSustainability of gypsum products as a construction Gypsum is then passed through the processing plant to clean, crush and segregate it into different quality grades, dependent on the customer requirements The processing lines are controlled by an environmental permit which is issued and monitored annually by Newark and Sherwood District CouncilBantycock Quarry Extraction of gypsum British

used gypsum process

Gypsum as an Agricultural Amendment: General Use enced by the type of coal, scrubbing process, and sorbent used in the desulfurization process The FGD gypsum can have a purity as high as 996% (Table 12) Concentrations of other chemical elements in FGD gypsum from the W H Zimmer Station of DukeThe processing of gypsum for use in the amendment of salinesodic soils involves crushing and 13 grinding rock gypsum to 30 – 40 mesh size and loose or bagged product is transported • TREATMENT OF LOW QUALITY TUBEWELL WATER Many tubewells are pumping high sodium waters that make productive land unproductive(PDF) Gypsum Mining Production Processing and Gypsum Processing for Wallboard Gypsum is a soft sulfate mineral composed of calcium sulfate dehydrate, with the chemical formula CaSO₄2H₂O It is widely used in a variety of applications and is the main ingredient in many forms of wallboard, block, and plaster products The traditional method of gypsum processing for stucco and plaster Gypsum Processing for Wallboard schenckprocess

Gypsum Department for Energy and Mining

Gypsum used for plaster manufacture usually contains at least 90% CaSO 4 2H 2 O, a maximum of 002% NaCl (salt), and approximately 2% acid insolubles Another major use of gypsum is in the cement industry, where it is added at the rate of 2–5% to cement clinker prior to final grinding to retard the setting rate of concreteThe processing of gypsum depends on the end use There is little or no beneficiation Nearly allcommercial gypsum is calcined Generally gypsum is ground, calcined at 250oC for 2 hours and then at 300350oC, when it loses 75% of its water of crystallization and forms the hemihydrate (CaSO 4 ½ H 2O), known as plaster of Paris, stucco or GYPSUM IN SOUTH AFRICA The material is then conveyed to an enclosed processing area that separates the paper liner from the gypsum core The recycled gypsum is conveyed to drywall manufacturers, where it is blended with virgin or synthetic gypsum to make new wallboard The paper is further processed prior to recycling for use in a wide variety of applicationsRecycling Process New West Gypsum

What is Gypsum? Definition from Corrosionpedia

A typical mixture is 75% powdered gypsum (calcium sulfate), 20% granular bentonite and 5% sodium sulfate This mixture has a resistivity of 50 W cm and is suitable for use in high resistivity soils Gypsum/gypsum mortar attacks zinc and iron (steel) very strongly in combination with humidityGypsum as an Agricultural Amendment: General Use enced by the type of coal, scrubbing process, and sorbent used in the desulfurization process The FGD gypsum can have a purity as high as 996% (Table 12) Concentrations of other chemical elements in FGD gypsum from the W H Zimmer Station of Dukeused gypsum process The coprecipitation of selenium(IV) (Se) with iron(III) (Fe) is a widely practiced method for the removal of Se from mineral processing effluents, but the effect of gypsum as a major secondary mineral on the ironselenium coprecipitation process is still of concern In our work we first investigated the effects of pH, Fe/Se molar ratio and the neutralizing agent on the removal efficiency of Se The Effect of Gypsum on the Fixation of Selenium in

EMISSION FACTOR DOCUMENTATION FOR AP42

(SIC) for gypsum processing is 3275 The first six digits of the Source Classification Codes (SCC) identifying pollution sources in gypsum processing are 21 CHARACTERIZATION OF THE INDUSTRY1 Between 1983 and 1989, sales of gypsum products increased between 5 and 10 percent annually Address: Allsteel Gypsum Products, Inc 1250 NW 23 Ave Ft Lauderdale, FL 33311 Hours: MondayFriday: 6:00AM 4:30PM Saturday: 7:00AM 12:00PMAllSteel and Gypsum Products Serving Miami, Ft