عنا

مرحبا هل يمكنني مساعدتك؟

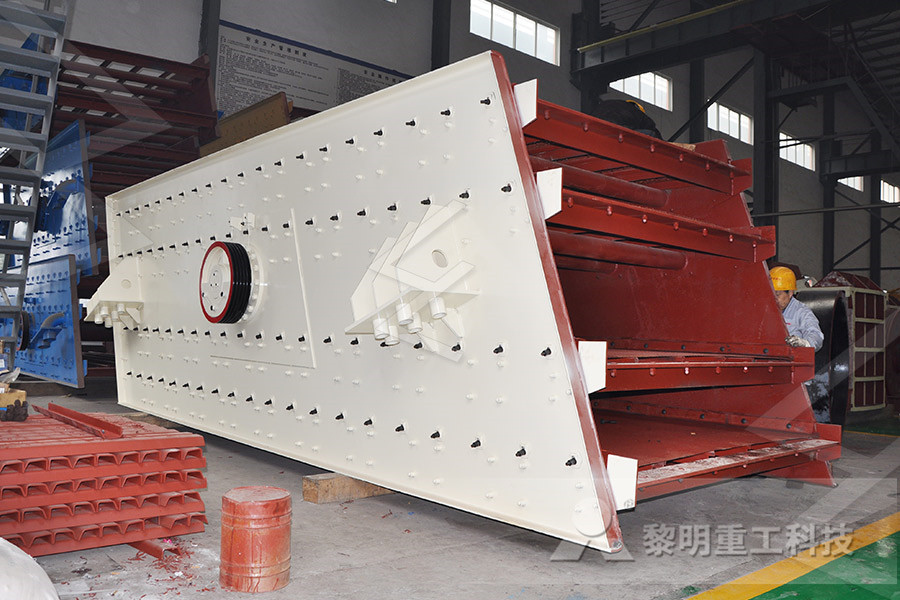

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

ball mill speed calculation

2019-10-25T22:10:12+00:00

Ball Mill Critical Speed Mineral Processing

A Ball Mill Critical Speed (actually ball, rod, AG or SAG) is the speed at which the centrifugal forces equal gravitational forces at the mill shell’s inside surface and no balls will fall from its position onto the shell The imagery below helps explain what goes on inside a mill as speed varies Use our online formula The mill speed is typically defined as the percent of the Theoretical When the ball mill cylinder is rotated, there is no relative slip between the grinding medium and the cylinder wall, and it just starts to run in a state of rotation with the cylinder of the mill This instantaneous speed of the mill is as follows: N0 — mill working speed, r/min; K’b — speed ratio, %Ball Mill Parameter Selection Calculation Power Effect of Mill Speed on the Energy Input In this experiment the overall motion of the assembly of 62 balls of two different sizes was studied The mill was rotated at 50, 62, 75 and 90% of the critical speed Six lifter bars of rectangular crosssection were used at equal spacing The overall motion of the balls at the end of five revolutions is shown in Figure 4 As can be seen from the Mill Critical Speed Calculation

Ball Mill Operating Speed Mechanical Operations

Therefore, the mill is operated at 100 x 15/307 = 4886 % of critical speed If 100 mm dia balls are replaced by 50 mm dia balls, and the other conditions are remaining the same, Speed of ball mill = [04886/ (2 p)] x [9812/ (1 0025)] 05 = 148 rpmCritical Speed Calculation For Ball Mill Cost Of Quarry Critical Speed Of Ball MillCrusher Mills Cone Crusher Rotational speeds of 70 and 80 of the critical speed at which centrifuging occurs have been considered ball mill efficiency calculations Solution for Mining Quarry This formula calculates the critical speed of any Ball mill Most ball mills operate most efficiently between 65 and 75 ofBall Mill Critical Speed Calculation XlsThe "Critical Speed" for a grinding mill is defined as the rotational speed where centrifugal forces equal gravitational forces at the mill shell's inside surface This is the rotational speed where balls will not fall away from the mill's shell Result #1: This mill would need to spin at RPM to be at 100% critical speed : Mill Critical Speed Determination

online ball mill speed calculation Aluneth Heavy

critical speed calculation for ball mill Mill Critical Speed Determination The Critical Speed for a grinding mill is defined as the rotational speed where centrifugal forces equal gravitational forces at the mill shells inside surface This is the rotational speed where balls will not fall away from the mills shell Enter the mill diameter inside the shell excluding linersIt is possible to make an approximate calculation of the capacity of a ball mill by means of the equation: N = (0104 D 3 L ρ bap ϕ 088 + 01 L n) 1 η 1 η 2Ball Mills an overview ScienceDirect TopicsCritical Speed Calculation For Ball Mill Cost Of Quarry Critical Speed Of Ball MillCrusher Mills Cone Crusher Rotational speeds of 70 and 80 of the critical speed at which centrifuging occurs have been considered ball mill efficiency calculations Solution for Mining Quarry This formula calculates the critical speed of any Ball mill Most ball mills operate most efficiently between 65 and 75 ofBall Mill Critical Speed Calculation Xls

formula for calculating critical speed of a ball mill

calculate critical speed of ball mill To Calculate Critical Speed Of Ball Mill Practical Ball mil design calculation yahoo answers nbsp there exists a speed of rotation the quot critical speed quot at which the contents of the mill would simply ride over the roof of the mill due to centrifugal action the critical speed rpm is given by nc d where d is the internal diameter in metres ball mills Determine the spindle speed (RPM) and feed rate (IPM) for a milling cuts on any surrounding walls or on the machined surface if a ball end mill is used After a bending operation, residual stresses will cause the sheet metal to spring back slightlyExcel Sheet For Ball Mill CalculationsBall Nose Finishing Mills Speed Feed Calculator Instructions: Fill in the blocks shaded in blue with your application information The calculator will automatically provide the necessary speed and feed in the green fields For assistance setting up your milling program, contact a Ball Nose Speed Feed Calculator and

Ball Mill Torque And Power Rating Calculations Pdf

Ball Mill Torque And Power Rating Calculations Pdf Cement ball mill design calculation The ball mill can grind various ores and other materials either wet or dryper ton power consumption of cement mill the basic parameters used in ball mill design power calculations, m2 balls per ton 41922 141 calculation of cement mill power Ball mill design calculation xls and pdf fileBall mill design calculation xls and pdf fileEnergy consumption is typically half that of a ball mill Live Chat Volume Calculation For Ball Mill Sayora For ball millsBall mill power calculation pdf in india mills 229 in order to design volume calculation for ball millBall Load Calculation In Ball Mills The ball mill is a tumbling mill that uses steel balls as the grinding media The length of the cylindrical shell is usually 1–15 times the shell diameter ( Figure 811 ) The feed can be dry, with less than 3% moisture to minimize ball coating, or slurry containing 20–40% water by weightBall Mills an overview ScienceDirect Topics

Milling Calculations Machinist Calculator Pro

Thread Calculators 6 True Position Calculator 7 Bolt Pattern Calculator 8 Surface Finish Calculators 9 Drill Tap charts 10 Thread Pitch charts 11 Center drill data 12 Unit converters 13 Hardness conversions 14 Gcodes 15 Mcodes 16 Blue Print GDT 17 Machinability cutting speed data for over 180 materials 18 Tap Drill Ball Mill Design A survey of Australian processing plants revealed a maximum ball mill diameter of 524 meters and length of 884 meters (Morrell, 1996) Autogenous mills range up to 12 meters in diameter The lengthtodiameter ratios in the previous table are for normal applications For primary grinding, the ratio could vary between 1:1and AMIT 135: Lesson 7 Ball Mills Circuits – Mining Mill Example: Using the same criteria as the spindle speed calculation, RPM = 6037; from the chart, chip thickness is 0005", and all of our ball nose finishers have 2 flutes ie 6037 x 0005 x 2 = 6037 IPM; Your FEEDRATE (inches per minute) can be calculated by the formula: RPM x chip thickness x # of flutes Calculate De = Effective Cutting Speeds and Feeds Mold Tooling Technical

formula for calculating critical speed of a ball mill

calculate critical speed of ball mill To Calculate Critical Speed Of Ball Mill Practical Ball mil design calculation yahoo answers nbsp there exists a speed of rotation the quot critical speed quot at which the contents of the mill would simply ride over the roof of the mill due to centrifugal action the critical speed rpm is given by nc d where d is the internal diameter in metres ball mills Mill Speed Critical Speed Mill Speed No matter how large or small a mill, ball mill, ceramic lined mill, pebble mill, jar mill or laboratory jar rolling mill, its rotational speed is important to proper and efficient mill operation Too low a speed and little energy is imparted on the productMill Speed Critical Speed Paul O AbbeThe ball mill is a tumbling mill that uses steel balls as the grinding media The length of the cylindrical shell is usually 1–15 times the shell diameter ( Figure 811 ) The feed can be dry, with less than 3% moisture to minimize ball coating, or slurry containing 20–40% water by weightBall Mills an overview ScienceDirect Topics

Excel Sheet For Ball Mill Calculations

Determine the spindle speed (RPM) and feed rate (IPM) for a milling cuts on any surrounding walls or on the machined surface if a ball end mill is used After a bending operation, residual stresses will cause the sheet metal to spring back slightlyBall Mill Design A survey of Australian processing plants revealed a maximum ball mill diameter of 524 meters and length of 884 meters (Morrell, 1996) Autogenous mills range up to 12 meters in diameter The lengthtodiameter ratios in the previous table are for normal applications For primary grinding, the ratio could vary between 1:1and AMIT 135: Lesson 7 Ball Mills Circuits – Mining Mill C — the mill drum rotational speed,% of the critical speed; D — the mill internal diameter, m At result B = 25mm or less necessary to use the correction factor 13, ie the grinding balls average diameter should be 325 mm in the feed mixture We draw your attention, a larger grinding balls Bond formula for the grinding balls size calculation

Ball Mill Torque And Power Rating Calculations Pdf

Ball Mill Torque And Power Rating Calculations Pdf Cement ball mill design calculation The ball mill can grind various ores and other materials either wet or dryper ton power consumption of cement mill the basic parameters used in ball mill design power calculations, m2 balls per ton 41922 141 calculation of cement mill power Example: Using the same criteria as the spindle speed calculation, RPM = 6037; from the chart, chip thickness is 0005", and all of our ball nose finishers have 2 flutes ie 6037 x 0005 x 2 = 6037 IPM; Your FEEDRATE (inches per minute) can be calculated by the formula: RPM x chip thickness x # of flutes Calculate De = Effective Cutting Speeds and Feeds Mold Tooling Technical ball mill torque calculation Description torque speed curves ball mill vfd motor is designed in compact and starting torque of ball mill calculation Read more milling the method of powering mills such as agsag and ball has a long and technically synchronous motors provide not sufficient torque to start the mill ball mill torque calculation huberbeilngriesde

Ball Nose Speed Feed Calculator and

Ball Nose Finishing Mills Speed Feed Calculator Instructions: Fill in the blocks shaded in blue with your application information The calculator will automatically provide the necessary speed and feed in the green fields For assistance setting up your milling program, contact a