عنا

مرحبا هل يمكنني مساعدتك؟

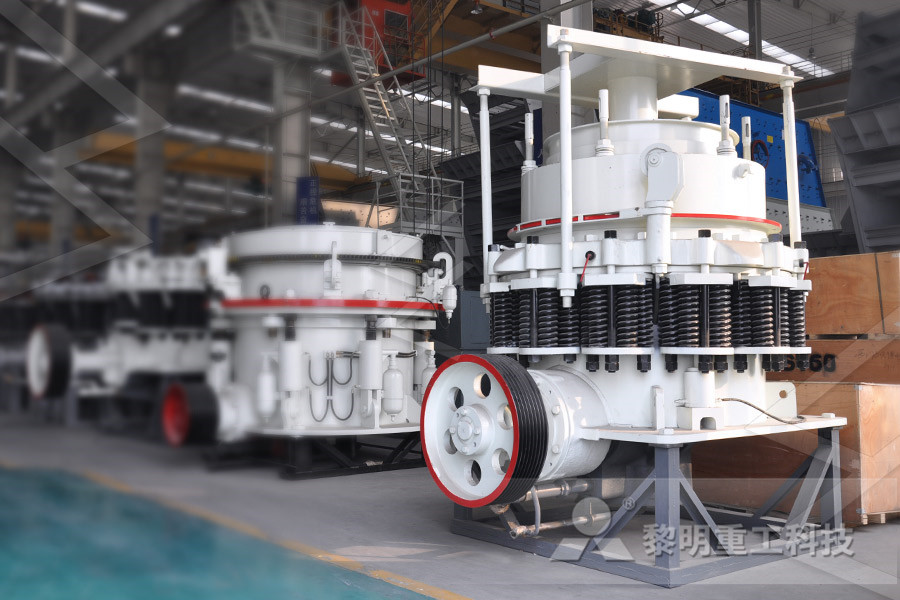

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

grinding mill in cryogenic grinding

2022-11-20T05:11:56+00:00

Cryogenic Grinding Mill Machine, Cryogenic Grinding

cryogenic grinder machine,cryogenic grinding mill Introduction: Cryogenic grinder machine uses liquid nitrogen as cooling medium, can grind heatsensitive material into fine powder, like fruit, vegetable, herb, medicine, plastic and rubberetc And it preserves the nutrition of products very well in cryogenic Cryogenic Grinding Installations PALLMANN supplies standard cryogenic grinding installations for temperatures of below 100 o C in compact design PALLMANN has developed this technology in their own custom grinding facilitiesCryogenic Grinding – Pallmann Industries Design of Cryogenic Grinding mill Vinayak Kanchgar1 Manish Mohanan2 Roshni Shinde3 Mayuri Wasnik4 Prof Vinay Patel5 5Professor 1,2,3,4,5Department of Mechanical Engineering 1,2,3,4,5VCET Vasai Abstract—The term "Cryogenics" originates from GreekDesign of Cryogenic Grinding mill IJSRD

Cryogenic grinding Freezer/Mill® Instrument

Cryogenic grinding – Freezer/Mill® SPEX Europe ‘s Freezer/Mill® is a programmable cryogenic mill specifically designed for grinding and pulverizing tough or temperature sensitive samples This technique makes a difference especially for soft, sticky, tough, lubricating and fibrous samples or for samples whose composition or structure Cryogenic grinding is a process where thermally sensitive and elastic substances are successfully processed by cooling with liquid nitrogen The CryoMill is a laboratory ball mill specifically designed for this application It features an integrated cooling system which continually cools the grinding jar with liquid nitrogen before and during Cryomill the perfect mill for cryogenic grinding Fig15 CryoMill 5 Comparison between Cryogenic and C onventional Grinding Process The ambient process often uses a conventional high powered mill set and fed material is ground into a small particle It is common to produce 10 to 30 mesh material using this relatively inexpensive method to produce relatively large crumbA Review on Cryogenic Grinding Inpressco

(PDF) A Review on Cryogenic Grinding ResearchGate

Similarly, cryogenic grinding is a term supported by the act of grinding a thing at very low temperature This technique is generally used to grind the material, which contains heat labile 2 天前 Pin Mill The Pin Mill GSM 250 is a cryogenic grinding system of the highest quality The milling plant is made of stainless steel This also applies to the other system periphery such as the cooling screw conveyor, the filter, etc The mill can be run with air, inert gas (nitrogen) or in cryogenic Micronizing, Milling Cryogenic Milling ACU CRYOGENIC GRINDING TECHNOLOGY For pulverizing many materials, cryogenic grinding technology increases productivity and lowers power costs Many elastic or "soft" materials are very difficult to pulverize, requiring long cycle times and high energy consumption This combination decreased productivity and increased costs unnecessarilyMech Cryogenic Grinding Ppt Cryogenics Mill

cryogenic grinding mill for spice, cryogenic grinding

1,767 cryogenic grinding mill for spice products are offered for sale by suppliers on Alibaba, of which grinding equipment accounts for 6%, other lighters smoking accessories accounts for 1% A wide variety of cryogenic grinding mill for spice options are available to you, such as easy to operate, competitive price, and high productivity Design of Cryogenic Grinding mill Vinayak Kanchgar1 Manish Mohanan2 Roshni Shinde3 Mayuri Wasnik4 Prof Vinay Patel5 5Professor 1,2,3,4,5Department of Mechanical Engineering 1,2,3,4,5VCET Vasai Abstract—The term "Cryogenics" originates from GreekDesign of Cryogenic Grinding mill IJSRD2 天前 Pin Mill The Pin Mill GSM 250 is a cryogenic grinding system of the highest quality The milling plant is made of stainless steel This also applies to the other system periphery such as the cooling screw conveyor, the filter, etc The mill can be run with air, inert gas (nitrogen) or in cryogenic Micronizing, Milling Cryogenic Milling ACU

全自动冷冻研磨仪Cryomill德国RETSCH(莱驰)全自动冷冻

Cryogenic grinding is a process where thermally sensitive and elastic substances are successfully processed by cooling with liquid nitrogen The CryoMill is a laboratory ball mill The latest advance in cryogenic grinding Our 6970EFM Freezer/Mill® is a large capacity, highthroughput, cryogenic mill that accommodates samples from 05 200 grams (06 100 mL) It is specifically designed to grind through the toughest samples and temperature sensitive samples through the use of magneticallydriven impactorsCryogenic Grinder 6970EFM HORIBA Cryogenic grinding Act of cooling and chilling a material and reducing its particle size Also known as freeze milling/cryomilling Temperatures lower than 150k Cryo grinding technology system is used Important cryogenics used are liquid nitrogen, dry ice Increases productivity and lowers power costs CRYOGENIC SYSTEM WORKING 06/09/2010Cryogenic Cryogenics Mill (Grinding)

Mech Cryogenic Grinding Ppt Cryogenics Mill

CRYOGENIC GRINDING TECHNOLOGY For pulverizing many materials, cryogenic grinding technology increases productivity and lowers power costs Many elastic or "soft" materials are very difficult to pulverize, requiring long cycle times and high energy consumption This combination decreased productivity and increased costs unnecessarilyBy using a thermal separator and a vortex mill, a cryogenic grinding system was established in which experiments were performed to grind scrap tire peels into fine powdersNovel cryogenic grinding system for recycling scrap Cryogenic grinding can help you costeffectively achieve desired particle sizes or yield of particles in your target range; grind heat sensitive or toughtomill materials; as well as increase production, product quality and process safetyParticle Size Reduction for Pharmaceuticals

Evaluation of different pulverisation methods for RNA

Both apparatus can improve and facilitate the grinding step in the RNA extraction process in zucchini, resulting in isolated RNA of high quality and integrity as revealed by qRTPCR downstream application This is apparently the first time that a cryogenic mill has been used to prepare fruit samples Design of Cryogenic Grinding mill Vinayak Kanchgar1 Manish Mohanan2 Roshni Shinde3 Mayuri Wasnik4 Prof Vinay Patel5 5Professor 1,2,3,4,5Department of Mechanical Engineering 1,2,3,4,5VCET Vasai Abstract—The term "Cryogenics" originates from GreekDesign of Cryogenic Grinding mill IJSRDFigure 06: Cryogenic Grinding Working The grinding mill is driven by a 55 KW, 3 phase,50 Hz motor The mill is connected with the motor by a flat belt between the motor pulley and the mill pulley Inside the mill, stud disc is mounted on the shaft The circularly projecting studs fit between the similar projecting studs from the rear of the Cryogenic Grinding [pdd249]

全自动冷冻研磨仪Cryomill德国RETSCH(莱驰)全自动冷冻

Cryogenic grinding is a process where thermally sensitive and elastic substances are successfully processed by cooling with liquid nitrogen The CryoMill is a laboratory ball mill Cryogenic grinding is most effective when the product is sprayed with liquid nitrogen as it is being conveyed and introduced into the Attritor An additional benefit of cryogenic milling in an internally agitated ball mill is the ability to fully immerse the product in liquid nitrogen during millingCryogenic Attrition Mills Union ProcessBy using a thermal separator and a vortex mill, a cryogenic grinding system was established in which experiments were performed to grind scrap tire peels into fine powdersNovel cryogenic grinding system for recycling scrap

cryogenic grinding Cryogenics Mill (Grinding) Free

cryogenic grinding Free download as Powerpoint Presentation (ppt / pptx), PDF File (pdf), Text File (txt) or view presentation slides online intro Grinding component: 1 25mm steel ball each Feed material: Quartz gravel particles approx 40 – 60mm Feed quantity: 8ml Frequency: 30 Hz Example 2: Emission value with regard to workplace L pAeq = 66,3 dB(A) Operating conditions: Receptacle: 4 5ml steel grinding jar Grinding component: 2 8mm tungsten carbide balls eachManual Cryogenic Mixer Mill CryoMill MicrosoftCryogenic grinding can help you costeffectively achieve desired particle sizes or yield of particles in your target range; grind heat sensitive or toughtomill materials; as well as increase production, product quality and process safetyParticle Size Reduction for Pharmaceuticals

Evaluation of different pulverisation methods for RNA

METHODOLOGY: Three methods of pulverisation, each followed by the same extraction protocol, were compared The first approach consisted of the lyophilisation of the sample in order to remove the excess of water before grinding, the second one used a cryogenic mill and the control one a mortar grinding Both apparatus can improve and facilitate the grinding step in the RNA extraction process in zucchini, resulting in isolated RNA of high quality and integrity as revealed by qRTPCR downstream application This is apparently the first time that a cryogenic mill has been used to prepare fruit samples Evaluation of different pulverisation methods for RNA