عنا

مرحبا هل يمكنني مساعدتك؟

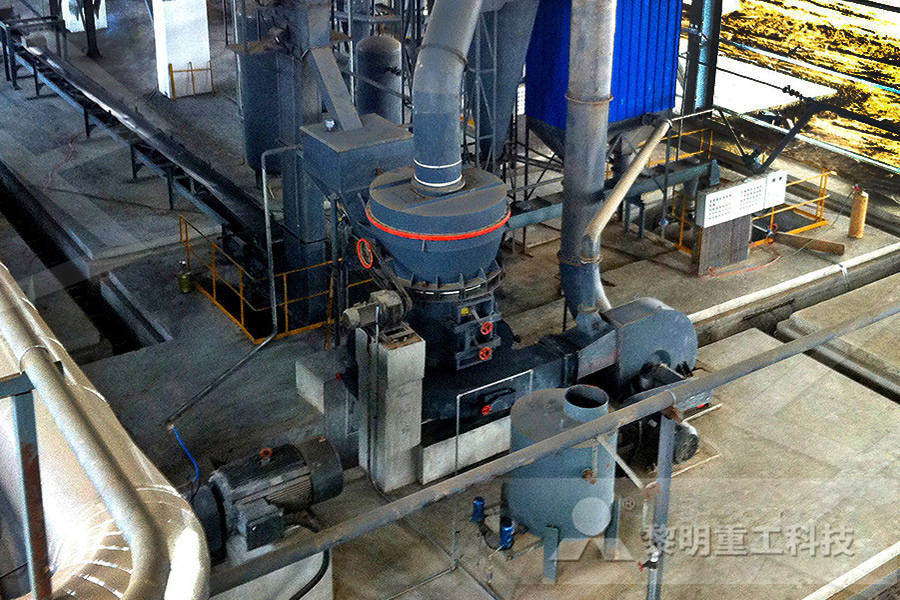

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

belt weigher measuring principle

2023-07-26T19:07:12+00:00

Belt Weigher Conveyor Belt Scale – Weighing

Conveyor Belt Scale or Belt Weigher Working Principle A typical conveyor belt scale or belt weigher system has a weigh bridge structure supported on load cells, an electronic integrator, and a belt speed sensor The load cells measure the material weight on the Operating Principle Belt Weighers are used to acquire continuous material flows of varying amounts Load cells acquire the weight of load on particular belt sections The longer the belt section is, the less the measuring result is affected by external influences In addition to belt load acquired by load cells, belt speed is measured by aMULTIBELT MultiIdler Belt WeighersToday’s belt weighing sytem consists of a weighing frame, load cells, a belt speed sensor and an integrator The weigh frame typically is made of a short section of steel channel with crossmembers and one or more sets of rollers on idlers that are designed specially for weighing How Modern Day Belt Weighers Work RTI Belt

MULTIBELT SingleIdler Belt Weighers

Belt Weighers are used to measure continuous material flows of varying amounts Load cells acquire the weight of load on particular belt sections A speed trans ducer measures the belt speed The product of these two variables is the current flow rate belt load q (in kg/m), the belt speed v (in m/s), the multiplication of q and v resulting in the actual mass flow (in kg/s) and the integration over time of the mass flow, resulting in the mass to be determined (in kg) Thus, belt weighers determine the total mass of a AUTOMATIC WEIGHING – PRINCIPLES, APPLICATIONS A typical belt scale system has a weigh bridge structure supported on load cells, an electronic integrator, and a belt speed sensor The load cells measure the material weight on the belt, and send a signal to the integrator The integrator also receives input in the form of electrical pulses from a belt speed sensorWT10 2010 en kap04 Belt Weighing

Accuracy Claims for Belt Weighers Control Systems

Also, the belt must pass through the weighing area in a straight line; this is essential to the principle that the belt weigher should be sensitive only to forces perpendicular to the belt One way to look at it is to say that the edge tension and the centre tension of the belt should be the sameThere are a lot of websites dedicated to belt weighers (BW) aka belt scales Most of those are featured the recommendations detailed or not so how properly to: (i) utilise belt weigher for commercial or technological needs, (ii) install it into belt conveyor, (iii) check its BWsite Belt Weigher Black White site MULTIBELT® SingleIdler Belt Weighers Continuous bulk solids measurement in belt conveyor systems Suitable for flow rates up to15,000 t/hr Accuracy up to ± 05 % Also legalfortradeversion Simple and quick installation Type BEM – designed modularly, suitable for any belt width Types BEP/BED – weighing platforms,MULTIBELT SingleIdler Belt Weighers

How Modern Day Belt Weighers Work RTI Belt

The modern day belt weigher is known by many names These include belt scale, weightomoter, conveyor scale, dynamic scale and inmotion weigher You will also find spelling variations on these such as beltweigher and beltscale Today’s belt weighing sytem consists of a weighing frame, load cells, a belt speed sensor and an integrator Operating Principle Belt Weighers are used to measure continuous material flows of varying Belt weigher of modular design, belt widths from 400 1400 mm BEP 400 1400 designed for measuring the belt speed of belt conveyor systemsMULTIBELT SingleIdler Belt Weighers The longer the belt section is, the less the measuring result is affected by external influences In addition to belt load acquired by load cells, belt speed is measured by a speed transducer The product of these two variables is the current flow rate Integration of flow rate determines the METAL SCANNING WEIGHER (4) METAL FEATURES

Online Detection of Belt Deviation of Belt Weigher Using

Online Detection of Belt Deviation Liang Zhu 1 Introduction Continuous weighing of bulk materials is the measurement equipment in respect of bulk materials trade, widely used in a variety of agricultural and industrial production and trading places The belt weigher (BW) is just one type of mass measuring instrument in the family ofIt is somehow reflected even in OIML and other sources where belt scale called as a belt weigher Intuitively the term “scale” has a higher status than the”weigher” has The term scale implies that it is a measuring instrument for a legaltrade operationBWsite Belt Weigher Black White site MULTIBELT® SingleIdler Belt Weighers Continuous bulk solids measurement in belt conveyor systems Suitable for flow rates up to15,000 t/hr Accuracy up to ± 05 % Also legalfortradeversion Simple and quick installation Type BEM – designed modularly, suit able for any belt width Types BEP/BED – weighing platforms, suitable for IEC belt widthsMULTIBELT SingleIdler Belt Weighers

MULTIBELT® MultiIdler Belt Weighers

The standard MultiIdler belt weigher comprises: Weighing platform for accommoda Operating Principle Belt Weighers are used to acquire continuous material flows of varying Load cells acquire the weight of load on particular belt sections The longer the belt section is, the less the measuring result is affected by external influences 1 load cell 1 theory of load cell 3 load cell 4 load cell 4 load cell application 4 load cell belt weigher 4 load cell junction box 4 load cell platform scale 4 load cell scale 4 load cell technology 4 load cells in parallel beam load cell theory beam load cell types bending beam load cell principle calibration of load cell theory capacitive load cell principle compression load cell principle 4 load cell belt weigher Archives Instrumentation ToolsBelt Scales The success of electromechanical belt scales is primarily determined by the environment where they are installed Primary areas of consideration are factors like belt tension variations, idler alignment, environmental factors such as wind and vibration, belt lift, length and angle of the conveyor and so forth Our belt scales are supplied with state of the art MCON 2000 and UCON Weighing Systems Belt Scales Industrial Scales

Accuracy Claims for Belt Weighers Control Systems

Providing accuracy guarantees on its calibration services and weighing equipment, with 30 years of market leading innovation Control Systems Technology, for when accuracy matters! Calibration, Service and Repair Of All Weighing Equipment All types of weigher servicing, repairs, calibrations and trade certifications LEARN MORE CST Belt Scales and Weigh Feeders Market leader in Conveyor Belt The longer the belt section is, the less the measuring result is affected by external influences In addition to belt load acquired by load cells, belt speed is measured by a speed transducer The product of these two variables is the current flow rate Integration of flow rate determines the METAL SCANNING WEIGHER (4) METAL FEATURES Operating Principle Belt Weighers are used to acquire continuous material flows of varying particular belt sections The longer the belt section is, the less the measuring result is affected by external influences In addition to belt load acquired by load cells, belt speed is measured by a speed Belt weigher with weighing platform MULTIBELT® MultiIdler Belt Weighers

Online Detection of Belt Deviation of Belt Weigher Using

Online Detection of Belt Deviation Liang Zhu 1 Introduction Continuous weighing of bulk materials is the measurement equipment in respect of bulk materials trade, widely used in a variety of agricultural and industrial production and trading places The belt weigher (BW) is just one type of mass measuring instrument in the family of Working Principle 31 Measuring Principle A belt weigher continously weighs the amount of material transported on a conveyor belt Belt Load The material is guided over a platform arranged below the belt and limited by one carrying idlersThe platform load applies a force on load L/C via weighed idler403表说明书百度文库Principle operation of a weightometer We offer two technologies for conveyor weighing namely ElectroMechanical E M type which employs load cell s to measure the loading on the belt and Gamma type which determines the load on the belt by measuring the absorption of gamma rays ElectroMechanical scales ElectroMechanical scales are available in many different formats All the E M scales employ principles of a conveyor weightometer

How to Measure Conveyor Belt Speed with Encoders

Direct Measurement Using an Encoder Measuring Wheel The third way to monitor conveyor speed is to attach an encoder to an encoder measuring wheel that rides on the surface of the belt or one of the rollers if the belt itself is crowded with product Typically, these wheels are 1 foot in circumference, which makes an easy conversion from RPM to FMS Belt Scales Operational Principle for Bulk Conveyors Constructive Design The FMS measuring roller has to be fixed between two stations of idle rollers under the belt The measuring roller whose shape corresponds to the shape of the belt is supported on both sides on FMS force measuring bearings The measuring bearingsBelt Scales for Bulk Conveyors Fatih Otomasyon SistemleriProviding accuracy guarantees on its calibration services and weighing equipment, with 30 years of market leading innovation Control Systems Technology, for when accuracy matters! Calibration, Service and Repair Of All Weighing Equipment All types of weigher servicing, repairs, calibrations and trade certifications LEARN MORE CST Belt Scales and Weigh Feeders Market leader in Conveyor Belt Accuracy Claims for Belt Weighers Control Systems

Check Weighing Solutions Penko

PENKO FLEX RANGE This allinone controller is available as MFL (MonoFiller) CHK (Check Weigher), BLT (Belt Weigher) and LIW (LossinWeight) for filling processes is suitable for trade (certified); in addition to 8 inputs it has 4 integrated set points which can be used for example for product supplyCookies are harmless text files that web servers can store on your computer's hard drive when you visit a website We only use functional cookies that are necessary for this site to function, including those that are necessary for Google Analytics to workConveyor Belt Scales, Weigh Feeders, Chute Detector,