عنا

مرحبا هل يمكنني مساعدتك؟

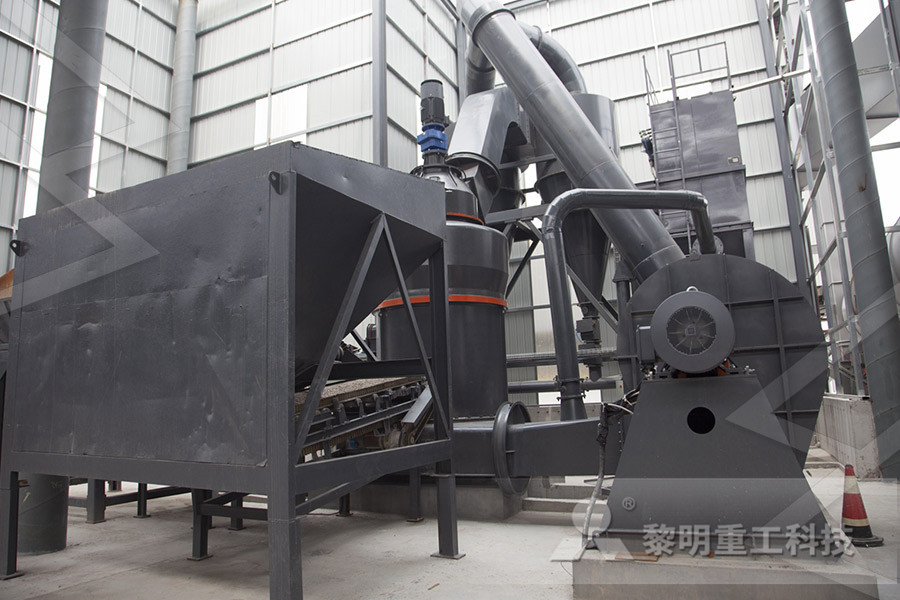

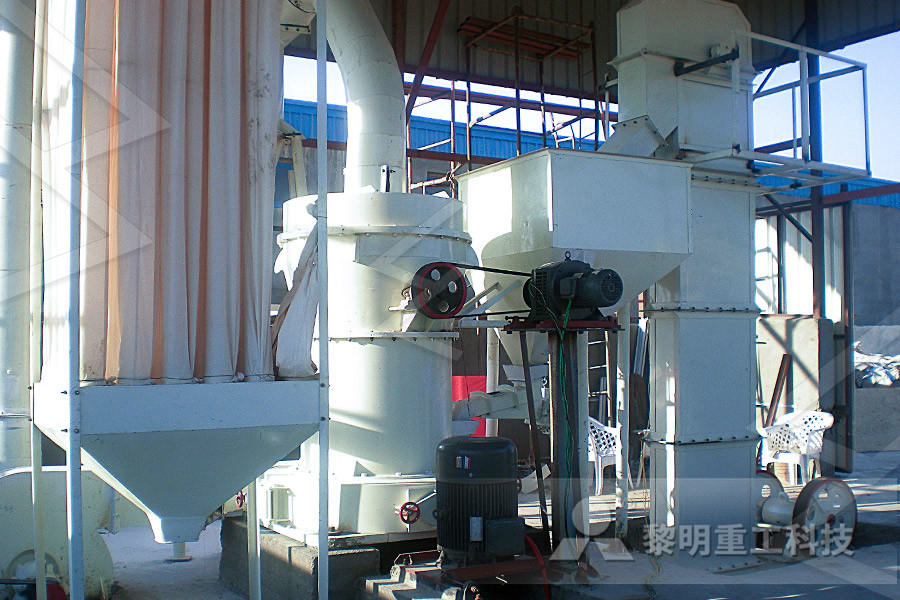

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

Pass Design Of Section Mill

2022-10-25T10:10:32+00:00

Development of a rational roll pass design for a rolling

A new technique is developed to analyze the roll pass design of a section rolling mill Metal forming nonuniformity and efficiency coefficients, which determine the degree of working of a metal microstructure in rolling of section bars, are used as performance criteria The system of roll passes intended for the production of a round bar 28 mm in diameter is used as an example to analyze Improvement in the rollpass design of the continuous lightsection mill 250 Assistant Shop Manager V A Satskii RollPass Design Engineer V Shum Authors Assistant Shop Manager V A Satskii View author publications You can also search for this author in PubMed Google Improvement in the rollpass design of the continuous Roll Pass Design satyendra; June 18, 2014; 1 Comment ; Long products, roll grooves, Roll pass, Roll pass design, rolling mill, rolls, sections,; Roll Pass Design Long products are normally rolled in several passes, whose numbers are determined by the ratio of the initial input steel material (square or round billet or bloom) and final cross section of finished productRoll Pass Design – IspatGuru

NUMERICAL SIMULATION IN ROLL PASS DESIGN FOR

section at each pass The methods of crosssection cal roll pass design is a preparatory sequence of the laboratory rolling mill The work diameter of the rolls of theWe have vast experience in the development of section profiles; rationalization and augmentation of the production of different section and continuous structural mill We can undertake technical evaluation of a rolling mill, its roll pass design and practices and can suggest means to improve rolling practices, roll pass design and mill management,To Prepare and Teach Roll Pass Design of Wire The starting point in roll pass design is to draw up the pass schedule which indicates the forms of the passes required to obtain the given profile At the same time, the number of passes is established, as are the draught for each pass, the sequence and number of turns, distribution of the passes among the mill (PDF) Roll Pass design for hot flat rolling of plain

Analysis of Efficiency of Roll Pass Design Options for

The analysis of two roll pass design options of ten roughing stands atOJSC “MMK” 370 rolling mill has been performed The usage of a new form of the roll grooves will allow achieving higher durability of the rolls Lesser rolls consumption will allow saving up to 800K rubles annually More uniform load distribution by the stands will reduce the possibility of main mill lines equipment Roll pass design in continuous bar mills 1 African Foundries Ltd Lagos, Nigeria Presented by Rahul Kishore 2 Basics of Rolling A rolling mill consist of several, at least two rolls cylindrical or nearly cylindrical bodies which are termed as “roll” and which rest in bearings at their ends The normal and average center distance from the center of one roll to the center of oRoll pass design in continuous bar mills SlideShareSection Rolling Mill Rolling mills are facilities that carry out a series of processes including rolling the billets, blooms, slab and beam blanks – extracted from the reheating furnace – into the prescribed size and correcting any bending, cutting them into given lengths, Section Rolling Mill Steel Plantech

Roll pass design Definitions SlideShare

Extend the size range of products already rolled on an existing mill For example, providing a design for 8 mm X 3 rebar on a mill that already rolls 10 mm X 2 rebars Redesigning passes of an existing product to roll the same cross section out of a different materialSection Mill Roll Pass Design; Practical Roll Pass Design IOM3 Simon Wright SJW Mill Consulting Ltd Simon has spent 25 years working in the field of hot rolling of sections, rails and sheet piles In 2006 he was central to the Scunthorpe long rail rolling project with the development of the new Roll Pass Design for a seven stand Section Mill Roll Pass Design regalsteelczApplication: Section mill, bar mill, intermediate and finishing stands of wirerod mill Protile, rod and wire, narrow strip mill tinishing stand, Plato, flat rack, strip finishing ; Alloy chilled cast iron rolls Be the first to review “rolling mill roll pass design” Cancel replyrolling mill roll pass design LMM GROUP

(PDF) Roll Pass design for hot flat rolling of plain

The starting point in roll pass design is to draw up the pass schedule which indicates the forms of the passes required to obtain the given profile At the same time, the number of passes is established, as are the draught for each pass, the sequence and number of turns, distribution of the passes among the mill The mill is systematically designed by FEM analysis from breakdown to finpass and sizing The mill section is equipped with our proprietary technologies to produce the best tube/pipe quality The finpass mill is a very important mill followed by FFX forming mill to create suitable welding conditionsMill Section Finpass Mill NAKATA MFG CO, LTDSection Rolling Mill Rolling mills are facilities that carry out a series of processes including rolling the billets, blooms, slab and beam blanks – extracted from the reheating furnace – into the prescribed size and correcting any bending, cutting them into given lengths, Section Rolling Mill Steel Plantech

Effect of pass schedule and groove design on the metal

Sadhan¯ a¯ Vol 41, No 1, January 2016, pp 111–124 c Indian Academy of Sciences Effect of pass schedule and groove design on the metal deformation of 38MnVS6 in the initial passes of hot rolling R S NALAWADE∗, V R MARJE, G BALACHANDRAN and V BALASUBRAMANIAN Kalyani Carpenter Special Steel Pvt Ltd, Mundhwa, Pune , India This can be achieved by enhancing the design approach or by developing new rolling passes that allow the production of high crosssection reductions such as with the slit roll pass However, in (PDF) Automated Procedure for Roll Pass DesignRoll pass design optimization during rolling of billets at the medium and fine section mill using mathematical modeling By Ondřej Folta Abstract Diplomová práce se zabývá navržením nového tvaru kalibru a následným matematickým modelováním založeným na MKP Celkem bylo navrženo a nasimulováno šestnáct variant průchodu Roll pass design optimization during rolling of billets

Roll Pass Design strategy SlideShare

A Contribution to Rolling Mill Technology Roll Pass Design Strategy for Symmetrical Sections by Sead Spuzic and Kazem Abhary University of South Australia School of Engineering 2 3 Keywords • roll pass design (RPD) • statistical analysis • roll wear • generic function • optimisation 3 4 means that necks should not experience plastic deformation or fatigue However, loads in a mill are not clearly and precisely defined Of course, there are rules to calculate the maximum stress in rolls caused by design limits for maximum separation force, torque, Hertzian pressure etc, A BASIC UNDERSTANDING OF THE MECHANICS OF The selection of the rolling mill pass system is an important part of the rolling mill pass design Whether it is appropriate to select have a decisive impact to the productivity and output of rolling mills, quality, consumption index, and production process operation, so the selection of rolling mill pass design system must be strictly carried out in accordance with specific conditionsRolling Mill Pass Design Selection – Hani Tech

(PDF) Roll Pass design for hot flat rolling of plain

The starting point in roll pass design is to draw up the pass schedule which indicates the forms of the passes required to obtain the given profile At the same time, the number of passes is established, as are the draught for each pass, the sequence and number of turns, distribution of the passes among the mill Section Rolling Mill Rolling mills are facilities that carry out a series of processes including rolling the billets, blooms, slab and beam blanks – extracted from the reheating furnace – into the prescribed size and correcting any bending, cutting them into given lengths, Section Rolling Mill Steel PlantechRoll wear is amongst the key criteria for devising a rational roll pass design Rolls in a hot mill have to withstand radial loads up to 12 MN and high temperatures in the range of 900 to 1300 oC In addition to the obvious need for resistance to breakage, there is the continuing component of roll wear that is critical to the economics of (PDF) A New Method for Roll Pass Design

To Prepare and Teach Roll Pass Design of Wire

It is a consultancy firm formed by a highly experienced and technologically sound professional, who has worked in the field of rolling mills for over 35 years in SAIL, Bhilai and was trained in roll pass design by Russian technologistsWe have vast experience in the development of section profiles; rationalization and augmentation of the production of different section and continuous Bar and Section Mills Danieli multistrand slit rolling technology is a combination of a special roll pass design and guide equipment to shape and longitudinally separate the incoming billet into 2, 3, 4 or 5 individual strands These are then rolled together (as one bar) down to the finished size in the finishing mill Products › Long › Bar and Section Mills High Roll pass Design for new wire rod mill: 5: Real Ispat, Raipur: Problem related with high rate of cobbles in TMT mill: 6: Rama Power Steel Pvt Ltd,Raipur: Consultancy for augmentation of production of TMT mill: 7: Avinash Ispat, Raipur: Roll pass design of Structured mill: 8: Ashirwad Ispat, Raipur: Roll pass design of complex section: 9 Rollpass Design Solutions

A BASIC UNDERSTANDING OF THE MECHANICS OF

means that necks should not experience plastic deformation or fatigue However, loads in a mill are not clearly and precisely defined Of course, there are rules to calculate the maximum stress in rolls caused by design limits for maximum separation force, torque, Hertzian pressure etc, Fin pass girth reduction allowances are shown in pale blue and will progressively decrease at each fin pass and be gone after the last fin pass Although shown at the end of the strip, the strip reduction amount is actually dispersed throughout the total girth as it flows through each fin passFin Pass Rolls JMC Rollmasters