عنا

مرحبا هل يمكنني مساعدتك؟

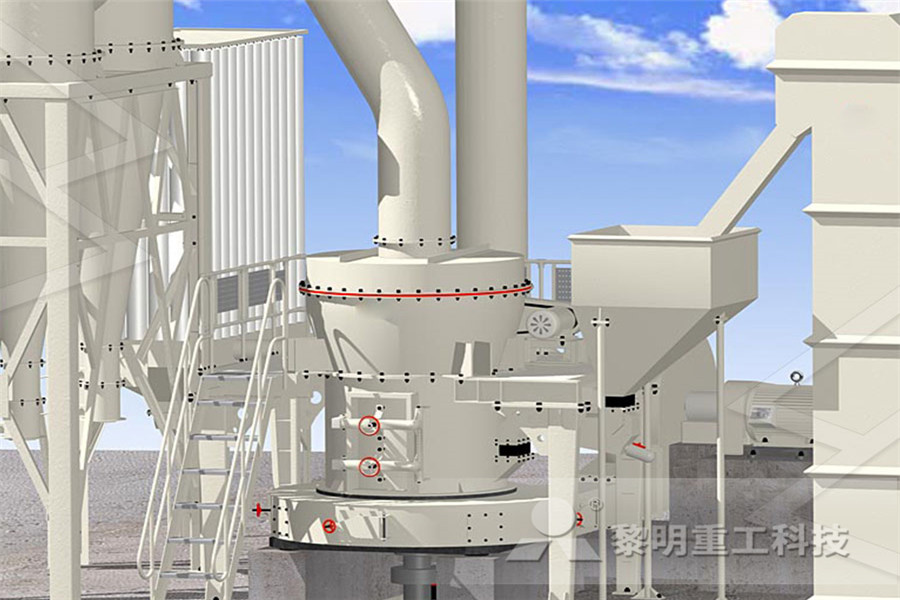

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

Carbon In Pulp Technology For The Extraction Of Gold Pdf

2022-10-16T22:10:38+00:00

carbon in pulp technology for the extraction of gold pdf

carbon in pulp technology for the extraction of gold pdf Carboninsolution for the recovery of gold from clarified solutions by j van deventer, jP wyethe, mH kotze, and j shannon synopsis testwork was done with two different adsorbents, dowexminix goldselective resin and activated carbon, to detemine their relative performances with regard to gold recovery from clarified lowgrade gold extraction after leaching by cyanide in aerated alkaline slurries The continuous processes of gold recovery by adsorption on activated carbon in agitated tanks, namely the carboninpulp (CIP) and the carboninleach (CIL) processes, have been widely used since the 1970s Due to the economic importance of these processes, their simulation hasDYNAMIC SIMULATION OF THE CARBONIN PULP AND 12 The Carboninpulp Process Process Chemistry and Unknown Areas 3 a; Leaching of Gold from the Ore 3 b) Adsorption of Aurocyanide onto Activated Carbon l c) Carbon Acid Washing and Elution 7 d) Gold Electrot'inning or Precipitation 8 e) Carbon Reactivation 8 f) THE CHEMISTRY OF THE CARBONINPULP PROCESS

(PDF) Gold CIP and CIL process optimization in a

The carbon in pulp (CIP) and carbon in leach (CIL) processes became firmly established in the gold mining industry in the 1980s, initially in South Africa and Australia, from where they spread Today’s gold mining operations optimize efficiency and output through the use of superior Haycarb gold recovery carbon technology Our high density carbons with particle to particle consistency in activity and shape is an ideal solution for applications in CIL (carboninleach), CIP (Carboninpulp) and CIC (carbonincolumn) processesActivated Carbon In Absorption Gold Extraction Gold process flow sheet development and test work has always been part of MINTEK’s technology service whilst MINTEK played a prominent role in establishing the CarbonInLeach (CIL) and CarbonInPulp (CIP) cyanidation technology, during the 1970’s to 1980’s international gold boomGold Group MINTEK MINTEK

(PDF) Gold Extraction and Recovery Processes For

Gold Recovery from Solution The common processes for recovery of the solubilized gold from solution are (certain processes may be precluded from use by technical factors) [5,6]: Carbon Adsorption MerrillCrowe process Electrowinning Ionexchange/Solvent Extraction (i) Carbon Adsorption The process known as carbon in pulp, or charcoal in pulp or Pdf Gold Extraction And Recovery Processes For Internal gold recovery from solution the common processes for recovery of the solubilized gold from solution are carbon adsorption merrillcrowe process electrowinning ionexchangesolvent extraction carbon adsorption the process known as carbon in pulp, or charcoal in pulp orcarbon loss gold extraction zazvorucinkycz recover the dissolved gold, such as cementation, adsorption onto activated carbon (carboninpulp and carboninleach) or onto a resin (resininpulp and resininleach), ionexchange chromatography, and solvent extraction4 Solvent extraction is an effective method for the separation and purification of precious metalsSolvent Extraction of Gold(III) with Diethyl Carbonate

(PDF) The extractive metallurgy of gold ResearchGate

Covered are the processes of cyanidation and alternative solvents for leaching gold and silver ores, heap and vat leaching, carboninpulp (CID), the technology of carbon adsorption and desorption The carbon in pulp (CIP) and carbon in leach (CIL) processes became firmly established in the gold mining industry in the 1980s, initially in South Africa and Australia, from where they spread (PDF) Gold CIP and CIL process optimization in a A process for adsorbing gold from a leach pulp by means of activated carbon is described in which the leach pulp (the leach solution together with the subdivided gold bearing ore) is diluted to a specific gravity of less than that of the activated carbon and is subsequently passed upwardly through a multistage liquid/solid contacting columnUSA Recovery of gold by a carboninpulp

Carbon and Resin Technologies for Gold Recovery

Carboninpulp The ore is crushed, finely ground and mixed with the cyanide leach solution to form a slurry in an agitation tank The activated carbon is introduced into the slurry and then removed by screening once it is fully loaded or “pregnant” with gold Carboninleach This process is very similar to the CIP process value of approx 2g of gold per tonne of solution a carbon loading of up to 15 kg gold per tonne of carbon is achieved leaving as little as 0,01g of gold per tonne of solution in the tailings There are essentially three process varieties that use carbon adsorption: The carbon in pulp (CIP) process, The carbon in leach (CIL) process andsketches tables UNIGE Figure 1 Using conventional technology,13 impure gold feed material is leached in hydrochloric acid under oxidising conditions Most base metals and PGMs are also solubilised under these conditions The leach solution is then purified by solvent extraction Gold is selectively extracted into the organic phase, while other solubleGold refining by solvent extraction—the Minataur™ Process

Gold recovery from cyanide solutions with a new

In a resininpulp process for the recovery of gold cyanide from a very dilute solution it is desirable that the resin should exhibit the ability to load gold at the natural pH of the leach liquor and be stripped by an aqueous alkali The present work describes the results of gold cyanide adsorption by new ionexchange hollow fibers prepared by the amination of sulfochlorinated polyethylene The CarboninPulp (CIP) gold processing technology has enabled a rapid, worldwide growth in gold production As a result, gold is one of the few winners for the mining industry in the 1980's The key step in the CIP technology is the adsorption of the gold(1) dicyanide ion, Au(CN)2, onto coarse carbon granulesChapter 32A process for adsorbing gold from a leach pulp by means of activated carbon is described in which the leach pulp (the leach solution together with the subdivided gold bearing ore) is diluted to a specific gravity of less than that of the activated carbon and is subsequently passed upwardly through a multistage liquid/solid contacting columnRecovery of gold by a carboninpulp process

THE CHEMISTRY OF THE CARBONINPULP PROCESS

12 The Carboninpulp Process Process Chemistry and Unknown Areas 3 a; Leaching of Gold from the Ore 3 b) Adsorption of Aurocyanide onto Activated Carbon l c) Carbon Acid Washing and Elution 7 d) Gold Electrot'inning or Precipitation 8 e) Carbon Reactivation 8 f) Pulp flow Figure 1: Schematic diagram of a carboninpulp or carboninleach plant with three tanks, showing basic carbon in pulp gold extraction diagram »More detailed Contact Supplier gold extraction processing plant from china Carbon In Leach Gold Extraction Process Carbon adsorption is increasing using in newer plants for gold recoverycarbon in pulp gold extraction process equipments Gold Recovery Via Activated Carbon from Cyanide Liquors Containing Cuprous Cyanocomplexes Activated carbon is widely used for gold recovery from cyanide leach liquors via carboninleach (CIL) or carboninpulp (CIP) technology From all the base metals cyanide complexes typicallyTECHNICAL PAPER Purolite

USA Recovery of gold by a carboninpulp

A process for adsorbing gold from a leach pulp by means of activated carbon is described in which the leach pulp (the leach solution together with the subdivided gold bearing ore) is diluted to a specific gravity of less than that of the activated carbon and is subsequently passed upwardly through a multistage liquid/solid contacting columnCarboninleach and carboninpulp are continuous processes that use activated carbon in a cascade of large agitated tanks, which have been widely used to recover or concentrate precious metals in gold extraction plants In the carboninpulp process adsorption occurs after the leaching cascade section of the plant, and in the carboninleach Dynamic simulation of the carboninpulp and carbon Similarly, pretreatment of the ore pulp with 35 lb chlorine per ton at 24° to 30° C and 15 hours reaction time resulted in 89pct gold extraction by subsequent cyaanidation Concomitant studies showed that electrolyzing the pulp prepared with a brine solution was equally as effective as electrolyzing hypochlorite and chlorine for oxidizing Download [PDF] The Chemistry Of Gold Extraction

Gold refining by solvent extraction—the Minataur™ Process

Figure 1 Using conventional technology,13 impure gold feed material is leached in hydrochloric acid under oxidising conditions Most base metals and PGMs are also solubilised under these conditions The leach solution is then purified by solvent extraction Gold is selectively extracted into the organic phase, while other soluble