عنا

مرحبا هل يمكنني مساعدتك؟

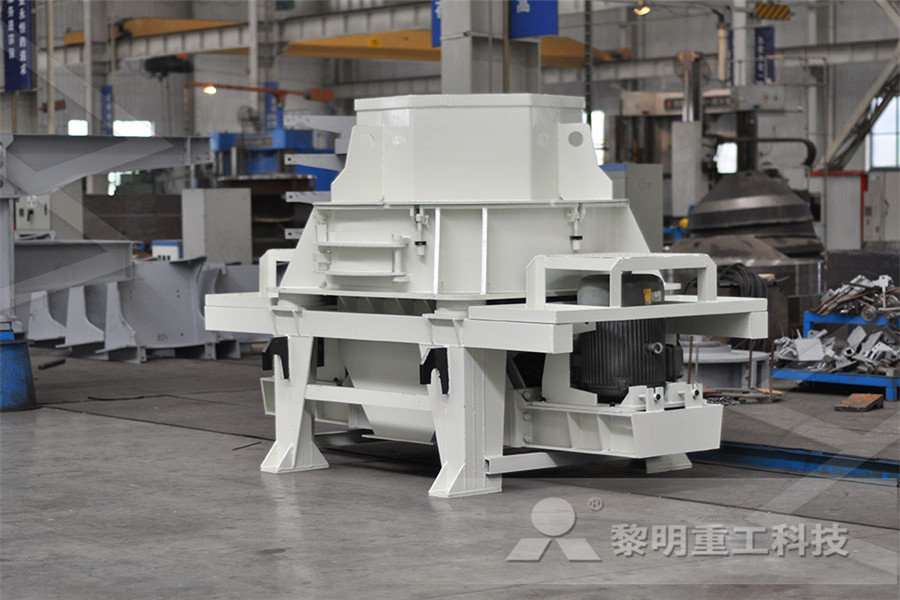

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

how to run wet process ball mill

2020-09-17T15:09:14+00:00

Wet ballmilling process? ResearchGate

2 using a wet ball milling, so how may I know the concentration of powder in the dispersion media ( how many grams of powder in milliliter, g/ml) is there a standard equation 3 the most Ball Mill Loading (wet milling) When charging a ball mill, ceramic lined mill, pebble mill, jar mill or laboratory jar use on a jar rolling mill it is important to have the correct amount of media and correct amount of product Charging a Wet Mill – The general operation of a grinding mill Ball Mill Loading Wet Milling Paul O Abbe In the production of ethanol, wet ball milling is the process used, because of its versatile process It produces more products than dry ball milling, but in terms of efficiency, capital, and operating cost, most ethanol plants in the USA prefer to use dry ball milling process In other words, dry ball Wet Ball Milling Vs Dry Ball Milling Orbis Machinery,

Wet Milling Process Custom Milling Consulting

Wet milling, also called wet media milling, is a process in which particles are dispersed in a liquid by shearing, by impact or crushing, or by attrition A mill is charged with media (small beads or spheres) and activated by a highspeed agitator shaft to separate the individual particlesOleg D Neikov, in Handbook of NonFerrous Metal Powders, 2009 Tumbling Ball Mills Tumbling ball mills or ball mills are most widely used in both wet and dry systems, in batch and continuous operations, and on a small and large scale Grinding elements in ball mills travel at different velocities Therefore, collision force, direction and kinetic energy between two or more elements vary Ball Mills an overview ScienceDirect Topics ball milling 3060 min Ar S F Nielsen, O Axelsson, Synth Commun 2000, 30, 3501 B(OH) 2 + Br Ac KFAl 2O 3/ Pd(OAc) 2 ball milling Ar c Franziska Schneider, Org Proc Res Develop, 2009, 13,44 Up to 96% yield Entry Rpm T (min) Yield% 1 400 10 92 2 800 5 94Ball Milling University of Massachusetts Boston

Grinding in Ball Mills: Modeling and Process Control

charge in the mill and a different impact of the milling bodies on the ground material The grinding process can also take place in dry or wet conditions depending on whether wetting agents are added to the starting material Some important characteristics of dry and wet BALL MILL METHOD FOR DETERMINING THE DISINTEGRATION OF FLEXIBLE BASE MATERIAL TXDOT DESIGNATION: TEX116E CONSTRUCTION DIVISION 3 – 5 LAST REVIEWED: SEPTEMBER 2014 water for one hour If 2 L (05 gal) of water do not fully cover the sample, use the smallest amount of water possible to do so Note 1—Use the dry sieve analysis as a rough check for BALL MILL METHOD FOR DETERMINING THE For cleaning the balls in ball mill process, I'm doing ultrasonic cleaning with DI water, Acetone, and IPA (1 hour each) consequently Whats the standard cleaning process? also the balls are Agate What is the cleaning process for balls in Ball mill

Ball Mill Maintenance Installation Procedure

Metallurgical ContentBall Mill Maintenance ManualOn Mill Installation and MaintenanceBall Mill Concrete FoundationsGrinding Mill FOUNDATIONGROUTINGBall Mill Sole Plate Am sure your Ball Mill is considered the finest possible grinding mill How to choose a right ball milling method for your material?1Definition of wet milling method and dry milling method2It is the key to choose the right ball milling method3Precautions in the process of selecting a grinding method4Wet ball mill is more economical and practical than dry ball millSolutions to Raise the Efficiency of Wet Ball Mill Fote Ball milling technique, using mechanical alloying and mechanical milling approaches were proposed to the word wide in the 8th decade of the last century for preparing a wide spectrum of powder materials and their alloys In fact, ball milling process is not new and dates back to more than 150 years It has been used in size comminutions of ore, mineral dressing, preparing talc powders and many Ball Milling an overview ScienceDirect Topics

Dynamic Modelling of Temperature in a Wet Ball Mill

Energy balance data is related to mill temperature where the latter is believed to be a primary indicator of inmill process dynamics [21, 12] It is a known fact that the biggest part of energy introduced in a ball mill is converted into heat, with only about 3 5% of this energy being used to grind the ore to the required fineness BALL MILL METHOD FOR DETERMINING THE DISINTEGRATION OF FLEXIBLE BASE MATERIAL TXDOT DESIGNATION: TEX116E CONSTRUCTION DIVISION 3 – 5 LAST REVIEWED: SEPTEMBER 2014 water for one hour If 2 L (05 gal) of water do not fully cover the sample, use the smallest amount of water possible to do so Note 1—Use the dry sieve analysis as a rough check for BALL MILL METHOD FOR DETERMINING THE Wet Grid Ball Mill Yantai Rhyther Mining Machinery Co,Ltd Capacity: 05500TPH Feed Size: ≤25 mm Grid ball mill is widely used in smashing all kinds of ores and other materials, ore dressing and national economic departments like building and chemical industries etc The size of ore shall not exceed 65mm and the best feed size is under 6mmWet Grid Ball Mill Yantai Rhyther Mining Machinery

wet ball mill machines globally

Mineral Beneficiation Process Xinhai provides 5 kinds of mineral dressing solution, such as magnetic separation, flotation separation, gravity separation, tailings dry stacking, etcAccording to the need of customers, ball mill can be either wet or dry designs Ball mills are designed in standard s izes of the final products between 0074 mm and 04(PDF) SIZE REDUCTION BY GRINDING METHODS size ball mill was used with ball media of sizes 10 mm, 20 mm and 30 mm respectively Quartz was the material used to perform the experiment and was arranged into 3 monosizes namely 8 mm +56 mm, 4 mm +28 mm and2 mm +14 mm for the experiment A mill run having a mixture of the 3 ball diameter sizes was also conducted It wasabeya and ototi, J ateria Sci ng , Journal of Material

(PDF) Phosphoric Acid Production Engr Sajid

Most of the old plants use dry grinding, and a majority of the new plants use wet grinding with a ball mill or ring roller mills having air classification Slurry containing 62 to 70% solid is produced Wet grinding requires about 30 to 40% less power and there is no atmospheric pollution by dustTo do otherwise—that is, to run both wet and dry—might result in shocking a hot tool with coolant, potentially accelerating tool failure If for some reason a part does calls for dry machining in one region of the part followed by wet machining in another, the shop is careful to insert a delay into the process to let the tool cool down Where Dry Milling Makes Sense Modern Machine Shop BALL MILL METHOD FOR DETERMINING THE DISINTEGRATION OF FLEXIBLE BASE MATERIAL TXDOT DESIGNATION: TEX116E CONSTRUCTION DIVISION 3 – 5 LAST REVIEWED: SEPTEMBER 2014 water for one hour If 2 L (05 gal) of water do not fully cover the sample, use the smallest amount of water possible to do so Note 1—Use the dry sieve analysis as a rough check for BALL MILL METHOD FOR DETERMINING THE

Ball Mill Design/Power Calculation LinkedIn

Ball Mill Power Calculation Example A wet grinding ball mill in closed circuit is to be fed 100 TPH of a material with a work index of 15 and a size distribution of 80% passing ¼ inch (6350 This machine run steadily and works reliably Ball mill is an efficient tool for grinding many materials into fine powder The Ball Mill is used to grind many kinds of mine and other materials, or to select the mine It is widely used in building Material, chemical industry, etc There are two ways of grinding: the dry process and the wet processBall Mill SlideShareMineral Beneficiation Process Xinhai provides 5 kinds of mineral dressing solution, such as magnetic separation, flotation separation, gravity separation, tailings dry stacking, etcwet ball mill machines globally

Vibration Feature Extraction and Analysis of Industrial

industrial wet mill varies due to its significant run length and the material characteristic changes due to pulp density variation The uses of sensors technology can benefit, but as per as the The mill product can either be finished size ready for processing, or an intermediate size ready for final grinding in a rod mill, ball mill or pebble mill AG/SAG mills can accomplish the same size reduction work as two or three stages of crushing and screening, a rod mill, and some or all of the work of a ball millAMIT 135: Lesson 6 Grinding Circuit – Mining Mill Consequently, efficiency in energy used can be as much as 40% – 45% less than a wet ball mill circuit – noticed with all power going into the comminution of the ore Smarter process control ensures consistent grinding to the correct size whilst the mill is in operationVertical roller mills: The new leader in grinding

Mill Speed Critical Speed Paul O Abbe

Mill Speed Critical Speed Mill Speed No matter how large or small a mill, ball mill, ceramic lined mill, pebble mill, jar mill or laboratory jar rolling mill, its rotational speed is important to proper and efficient mill operation Too low a speed and little energy is imparted on the productTo do otherwise—that is, to run both wet and dry—might result in shocking a hot tool with coolant, potentially accelerating tool failure If for some reason a part does calls for dry machining in one region of the part followed by wet machining in another, the shop is careful to insert a delay into the process to let the tool cool down Where Dry Milling Makes Sense Modern Machine Shop KOBELCO TECHNOLOGY REVIEW NO 29 DEC 2010 58 KOBELCO Pelletizing Process Shinichi YAMAGUCHI*1, Takeshi FUJII *1, Norihito YAMAMOTO , Tsutomu NOMURA*2 *1 Plant Engineering Department, Iron Unit Division, Natural Resources Engineering Business, *2 Technology Process Engineering Department, Iron Unit Division, Natural Resources Engineering BusinessKOBELCO Pelletizing Process