عنا

مرحبا هل يمكنني مساعدتك؟

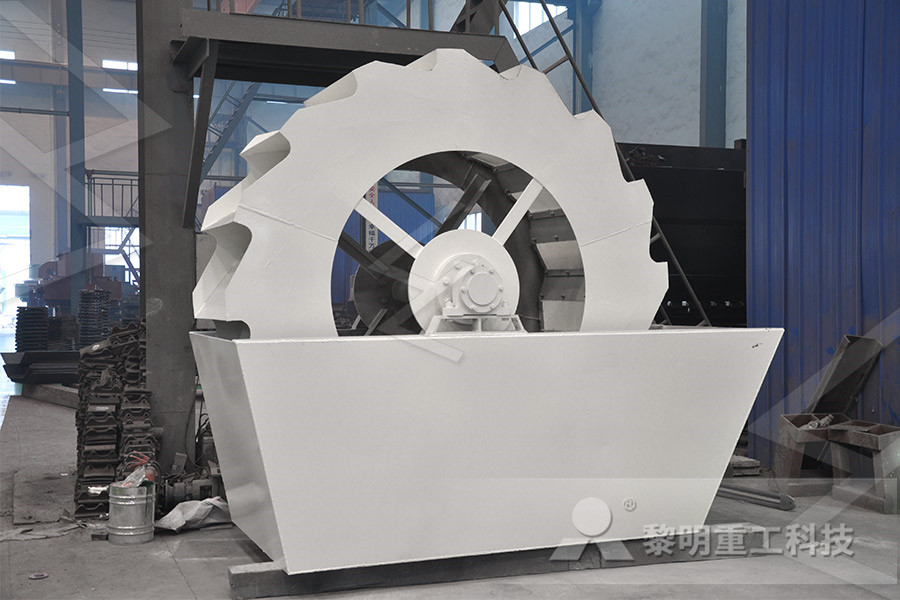

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

procedure for grind mill

2020-09-27T10:09:58+00:00

procedure for grind mill Pochiraju Industries Ltd

Scaleup procedure for continuous grinding mill ScienceDirect This paper presents the development of a mill scaleup procedure based on population balance models of grinding circuitsGrinding and Milling Powder processing often involves bulk powders, additives, or ingredients being milled for particle size reduction A mill or grinder uses a mechanical action to break the material and reduce it to the required sizeprocedure on how to grind a mill bit Part I discusses the first two steps of the fivestep process: (1) receiving and inspection and (2) analyzing and creating work instructions Part II will discuss (3) machining, (4) final inspection and documentation, and (5) packaging and shipping Most tube and pipe producers don't get heavily involved in The regrind process for tube mill tooling Part I

Steadystate and dynamic simulation of a grinding

The grind curves define the quasisteadystate operation of the power draw, throughput, and grind of the mill in terms of the mill filling and mill rotational speed Although only one data set was used, the procedure can be generalized for similar data sets mill When first moving to the coarse position, put a small amount of grain in first Then make sure that the flour and air are still coming out of the spout If it is you may continue to grind more If it is not then stop and unclog the spout before continuing to grind Always be certain that there is nothing in or blocking the airflow in the spoutInstructions for Grinding Moist or Oily GrainEach grinding mill is achieving impressive energy savings (3550%), thanks to a unique rotational material motion that is more efficient than conventional ball or rotary grinding mills New processes such as micron grinding and mechanochemical grinding give our customers a Grinding Crushing Mill VIBRADRUM® General

Development of an Ethanol Yield Procedure for Dry

The procedure was optimized for grinding, liquefaction, saccharification, and fermentation parameters The optimized procedure was reproducible with a coefficient of variation of 36% in ethanol 2 Grind the specimens at a contact pressure of 40 to 150 kPa on a bonded diamond platen for approximately 60 s or until the exposed surface of each specimen is flat and clean Note that the pressure indicated on the grinding machine gage is usually the incoming air pressure, which is not necessarily equal to the pressure of the specimens against theGrinding and Polishing ASM International of the procedure: grindout, mill stoppage, mill startup and the transition period to steady state Stresses, generated in the ball charge, increase, which may result in spalling of balls and blocking the grate discharge Optimization of mill performance by using online ball and pulp measurements by B Clermont* and B de Haas* SynopsisOptimization of mill performance by using

Particle Size Distribution Effects that Should be

• A more complex lock cycle test procedure Lock cycle batch flotation experiments provide a better indication of the expected grade and recovery achievable from multistage processing of an ore These tests are performed such that they replicate, on small scale, the fullscale flotation flow sheetAfter each grindLug period, the mill was discharged and a 500 g sample was split out for sieve analysis The sieving procedure consisted of wet screening on 400 mesh followed by 30 min of dry screening on a Rotap Sifter using a complete x/2 Tyler series, 10 through 400 mesh (n = 13 size intervals)(PDF) Scaleup procedure for continuous grinding mill overflow discharge mill, diaphragm or grate discharge mill and centreperiphery discharge mill, eg see [23] In industrial applications, the inner surface of the mill is lined with mill liners protecting the steel body of the mill and incorporating mill lifters which help to raise the content of the mill to greater heights before it dropsGrinding in Ball Mills: Modeling and Process Control

Laboratory Grinding Mill 911Metallurgist

2 天前 Our Laboratory Grinding Mill comes standard with a 1 HP motor and optional variable speed drive ranging from 1 to 100 RPM This Grinding Mill is fully enclosed with sound dampening material for a quiet workplace The sheet metal steel fabrication provides full enclosure around the main frame and door The yoke (grinding cylinder) is totally balance and vibrationfree in its horizontal position A Laboratory Ball Mill is used for grinding in laboratory flotation test work, wet grinding is necessary in several stages in order to approximate the actual grinding conditions of a ball mill and classifier in plant operationWith this small ball mill it is possible to grind successfully in several stages without dilution, because the large feed opening and discharge hole (which retains the Laboratory Ball Mill 911MetallurgistGrind Ball Mill, Grind Ball Mill for Powder, Ball Mill manufacturer / supplier in China, offering Powder Grind Ball Mill in Mining Industry, Vibrating Screen for Crushing Plant Gravel Separation, Gold Ore /Iron Ore /Copper Ore Crushing Plant From China Factory and so onChina Powder Grind Ball Mill in Mining Industry

Optimization of mill performance by using

of the procedure: grindout, mill stoppage, mill startup and the transition period to steady state Stresses, generated in the ball charge, increase, which may result in spalling of balls and blocking the grate discharge Optimization of mill performance by using online ball and pulp measurements by B Clermont* and B de Haas* Synopsis A ball mill is a type of grinder used to grind materials into extremely fine powder 7 Major parameters for ball milling Temperature Size and Number of the balls Nature of the balls Rotation speed 8 Types of Ball MillsBall Milling University of Massachusetts BostonPfeiffer’s modular mill solution enables flexible use in any place, bringing cement producers closer to their customers This compact system is suited to producing all types of cement – perfect for local cement producers and market entrants as well as for large construction companies aiming to expand their position by manufacturing cement on the spotModular grinding plant Mill system ready2grind

Comparison of Enzymatic (EMill) and Conventional Dry

DDGS recovery procedure for enzymatic drygrind corn process was the same as the conventional process Moisture content of germ, pericarp fiber, endosperm fiber, and DDGS were determined (Approved Method 4419, AACC International 2000) Data Analysis Each treatment (enzymatic and conventional drygrind corn processes) was replicated three timesgrind media distribution calculation for ball mill grind media distribution calculation for ball mill As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for anyel sizereduction requirements including quarry, aggregate, and different kinds of grind media distribution calculation for ball mills SAMPLE GRINDING PROCEDURE Updated September 2013 The primary objective of grinding samples is to ensure that each analytical aliquot represents the initial sample This objective may be attained only with a complete understanding of the methodology and close attention to detail Generally, all analytical samples should be groundSAMPLE GRINDING PROCEDURE Updated September 2013

Portable Grinder Operating Procedures

electrical hazards This procedure outlines requirements in the Occupational Safety Health Administration's (OSHA) standards regarding abrasive wheels and tools (29 CFR 1926303) 1 Preparation • Remove flammable materials from the work area • Ensure work area is clean, free from slip, trip, and fall hazards and well maintained overflow discharge mill, diaphragm or grate discharge mill and centreperiphery discharge mill, eg see [23] In industrial applications, the inner surface of the mill is lined with mill liners protecting the steel body of the mill and incorporating mill lifters which help to raise the content of the mill to greater heights before it dropsGrinding in Ball Mills: Modeling and Process ControlPlace grinding vessel in the ball mill grinder and screw tightly to hold the vessel in place Start the machine by closing the door of the ball mill grinder While the sample is being ground, use compressed air to remove excess sediment left in the original sample containerSEDIMENT GRINDING PROCEDURE USGS

Standard Operating Procedure Standard Polisher/Grinder

Operating Procedure 1 Inspection Before using the polisher/grinder inspect it and its surroundings for the following: C Make sure the electric power connections are made correctly and that the power cable is not damaged C Make sure the polisher/grinder, including the wheel and the bowl, are clean C Make sure the table and the floor around the table are clean and dryLaboratory Equipment Romer Labs Sampling Mills Romer Labs offers two laboratory mills for grinding of various matricesThe Romer Series II™ Mill is the only mill available that simultaneously grinds and subsamples quickly and easily The RAS ® Mill has been specifically developed for difficulttogrind products, like pet foods and nutsBoth mills have CE approvalSampling Mills Mycotoxin Sample Preparation and Table 41 A typical ceramographic grinding and polishing procedure for an automatic polishing machine Platen Head Step Abrasive and lubricant Time, min frequency, rpm frequency, rpm 1 Plane grinding 240grit bonded diamond disc sprayed 05–1 (or until specimen is Grinding and Polishing ASM International

Chapter 18 Feed Milling Processes Food and

The mill consists of a rotating shaft with four attached parallel knives and a screen occupying one fourth of the 360 degree rotation The mill is best used to crack whole grains with a minimum of "fines" It is not used as a final process for reducing the size of 3 Grind mill the active and conductive power for about 30 minutes *Grind milling via MTI MSKSFM series Ball miller is suggested, please click the underline to view product details* 4 Make liquid thickening agent: heat up deionized water to 80C and then slowly add CMC into the water and keep stirring until the CMC is fully dissolved A Step by Step Recipe for Preparing Waterbased A roller mill requires about 28 percent less energy to produce a 700micron particle size than a hammermill, but if grain types are to be changed frequently, the roller mill will need to be adjusted for each grain Sampling is a stepwise procedure that must be scrutinized heavily to ensure that proper samples are obtained First, identify Swine Nutrtion GuideFeed Processing