عنا

مرحبا هل يمكنني مساعدتك؟

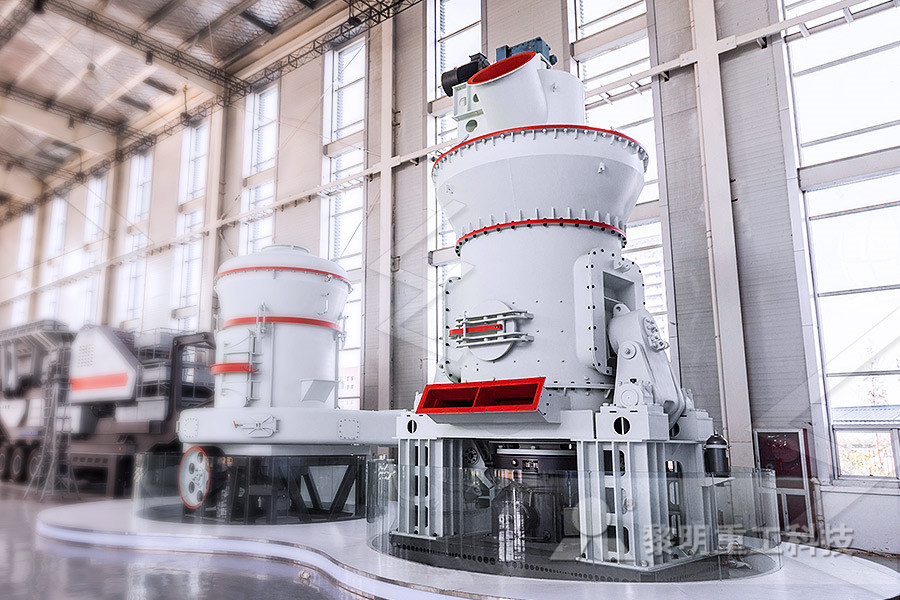

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

loss on ignition iron ore

2021-08-21T19:08:15+00:00

ISO 11536:2015(en), Iron ores ? Determination of loss

The measurement of loss on ignition (LOI) is a technique widely used in the iron ore industry Ignition loss is the sum of contributions from the mass loss of volatile compounds water vapour, carbon dioxide and sulfides (due to the decomposition of goethite and carbonaceous materials), and the mass gain due to oxidation [Fe (II) to Fe 2 O 3 ] Laserinduced breakdown spectroscopy (LIBS) and partial least squares regression (PLSR) have been applied to perform quantitative measurements of a multiplespecies parameter known as loss on ignition (LOI), in a combined set of runofmine (ROM) iron ore samples originating from five different iron ore depositsQuantitative Measurements of Loss on Ignition in Iron Loi loss of ignition iron ore The measurement of loss on ignition LOI is a technique widely used in the iron ore industry Ignition loss is the sum of contributions from the mass loss of volatile compounds water vapour, carbon dioxide and sulfides due to the decomposition of goethite and carbonaceous materials, and the mass gain due toLoss On Ignition Iron Ore Soby

method BSI Standards Publication loss on ignition

The measurement of loss on ignition (LOI) is a technique widely used in the iron ore industry Ignition loss is the sum of contributions from the mass loss of volatile compounds water vapour, carbon dioxide and sulfides (due to the decomposition of goethite and carbonaceous materials), and the mass gain due to oxidation [Fe(II) to Fe2O3] Its Quantitative Measurements of Loss on Ignition in Iron Ore Using LaserInduced Breakdown Spectroscopy and Partial Least Squares Regression Analysis Yaroshchyk, Pavel ; Death, David L ; Spencer, Steven J Abstract Publication: Applied SpectroscopyQuantitative Measurements of Loss on Ignition in Iron ISO 11536:2015 specifies a gravimetric method for the determination of the loss in mass of fullyoxidized iron ores, when ignited at 1 000 °C This method is applicable to a concentration range of 1,0 % (m/m) to 10,0 % (m/m) loss on ignition in natural iron ores, iron ore concentrates and agglomeratesISO ISO 11536:2015 Iron ores — Determination of

Study on kinetics of thermal decomposition of low LOI

Hydrated minerals in these hematite iron ores are kaolinite, gibbsite and goethite, which contribute to the loss on ignition (LOI) during thermal decomposition Experiments in fixed bed have been carried out at variable bed depth (16, 32, 48 and 64 mm), temperature (400–1200 °C) and residence time (30, 45, 60 and 75 min) for iron ore samples determination of Loss on Ignition (LOI) from raw iron ore samples by passing them through a number of furnaces with progressively higher temperatures The LOI is a measure of the water content of the ore and an important step in iron ore analysis When ore is fed into a blast furnace, the water contained in it will evaporateGeochemical Analysis or Iron Ore SGS Australia Iron ore samples with contrasting chemistry from two different origins of eastern and middle part of India were taken in the present investigation The Sample A represents 5447% Fe with 490% SiO2, 726% Al 2 O 3 and 857% loss of ignition (LOI)Mineralogy and textural impact on beneficiation of

Why iron ore grade is now more important than ever

The rest is impurities that require energy to remove them in the iron making process The main impurities in iron ore are silica and alumina, which have to be melted out in the blast furnace toQuantitative Measurements of Loss on Ignition in Iron Ore Using LaserInduced Breakdown Spectroscopy and Partial Least Squares Regression Analysis Yaroshchyk, Pavel Death, David LQuantitative Measurements of Loss on Ignition in Iron The loss on ignition is reported as part of an elemental or oxide analysis of a mineral The volatile materials lost usually consist of "combined water" (hydrates and labile hydroxycompounds) and carbon dioxide from carbonatesIt may be used as a quality test, commonly carried out for minerals such as iron oreFor example, the loss on ignition of a fly ash consists of contaminant unburnt fuelLossonignition chemeurope

ISO/TR 18230:2015 Iron ores Determination of loss

ISO/TR 18230:2015 describes a gravimetric method for the determination of the loss in mass of nonoxidized iron ores, when ignited at 1 000 C This method is applicable to a concentration range of a mass fraction of −3,0 % to 7,0 % loss on ignition in natural iron ores, iron ore ISO 11536:2015 specifies a gravimetric method for the determination of the loss in mass of fullyoxidized iron ores, when ignited at 1 000 C This method is applicable to a concentration range of 1,0 % (m/m) to 10,0 % (m/m) loss on ignition in natural iron ores, iron ore concentrates and agglomerates The method is not applicable to the following:ISO 11536:2015 Iron ores Determination of loss on ISO 11536:2015 specifies a gravimetric method for the determination of the loss in mass of fullyoxidized iron ores, when ignited at 1 000 °C This method is applicable to a concentration range of 1,0 % (m/m) to 10,0 % (m/m) loss on ignition in natural iron ores, iron ore concentrates and agglomeratesISO 11536 European Standards

Geochemical Analysis or Iron Ore SGS Australia

determination of Loss on Ignition (LOI) from raw iron ore samples by passing them through a number of furnaces with progressively higher temperatures The LOI is a measure of the water content of the ore and an important step in iron ore analysis When ore is fed into a blast furnace, the water contained in it will evaporateNominal Chemical composition and loss on ignition of raw materials Iron Ore Source Chemical Composition ( weight percent on dry basis) Fe (Total) Fe 2 O 3 Al 2 O 3 SiO 2 TiO 2 MnO Loss on Ignition Orissa Mining Corporation (OMC) 6263 8956 409 380 011 001 243 Bentonite binder 396 5836 2114 675 212 BinderPAPER OPEN ACCESS Related content Characterization of For bulk weight loss of iron ore (or of any material in general) then, yes LOI (Loss on ignition) is usually measured at 1000C or 1100C However, in the Australian iron ore industry, typically 3 Please let me know the temperature required for the

A textural and mineralogical study of the relationship

Preservation of macroscopic features, such as mesobanding, and microscopic features, such as pseudomorphs, is compelling evidence of supergene enrichment which, together with residual upgrading by leaching of these ironformations, produces ores which typically assay 62 percent Fe, ignition loss of 4 to 6 percent, and >007 percent P The loss on ignition is reported as part of an elemental or oxide analysis of a mineral The volatile materials lost usually consist of "combined water" (hydrates and labile hydroxycompounds) and carbon dioxide from carbonatesIt may be used as a quality test, commonly carried out for minerals such as iron oreFor example, the loss on ignition of fly ash consists of contaminant unburnt fuelLoss on ignition Wikipedia of loss on ignition in iron ore 灼烧减量的测定 1 The paper introduced the background of this national standard about the determination of loss on ignition in iron ore by gravimetric method 介绍了我 灼烧减量的测定,determination of loss on ignition in iron ore

LossonIgnition Standard Operating Procedure

Loss on ignition as a method for estimating organic and carbonate content in Journal of Paleolimnology, 25: 101110 Most recent modification sequence: Nov 2013 J Heck modifications for use with an analytical database and S Rogers modifications to furnace instructionsNominal Chemical composition and loss on ignition of raw materials Iron Ore Source Chemical Composition ( weight percent on dry basis) Fe (Total) Fe 2 O 3 Al 2 O 3 SiO 2 TiO 2 MnO Loss on Ignition Orissa Mining Corporation (OMC) 6263 8956 409 380 011 001 243 Bentonite binder 396 5836 2114 675 212 BinderPAPER OPEN ACCESS Related content Characterization of In selecting iron ore for iron and steel industries, the properties which need to be considered are tumbler, abrasion and shatter indices, porosity, chemical composition, loss on ignition, reduction behaviour, thermal degradation, etc In the present investigation, 10 different types of hematite iron ore CHARACTERIZATION OF PROPERTIES AND REDUCTION

How can goethite iron ore properties be taken?

Goethitic ores generally have higher loss in ignition due to inherent chemically bonded water within it For drying process under 350 degrees Celsius, there will be no such effect on properties interest (iron, silica, manganese, phosphorus and alumina), loss on ignition, granulometry and rock types in an iron ore deposit Sampling information is available from a set of exploration drill holes The methodology considers the construction of multiple rock Ore Geology Reviews uchilecl combustion of carbon is the major contributing component of ignition loss [3] Although the allowable fly ash LOI depends on local practice, many countries have recently tended to institute more strict specifications for the limit on LOI (ranging from 3% to Effects of the Loss on Ignition of Fly Ash on the

Mineralogy and textural impact on beneficiation of

The effect of mineralogy and texture on the beneficiation of goethitic ores from two different origins is highlighted Sample A having 5447% Fe with 857% loss of ignition (LOI) indicates the presence of vitreous and ochreous goethite, martite and microplaty hematite as the major mineralsMicroscope studies of a wide range of ores and fresh, oxidized, or partly ironenriched, banded ironformation (BIF) have shown a consistent sequence of alteration of the primary constituents, chert, magnetite with or without hematite, carbonates, and silicates, leading to the formation of martite(hematite)goethite ores which form the bulk of the reserves of the Hamersley Iron ProvinceA textural and mineralogical study of the relationship 2 天前 Table of ContentsCharacteristic Data of Ores and AdditiveCharacteristic Data of the ExperimentsSinter OutputPhysical Quality and Structure The authors investigate the influence of the basicity index CaO/SiO2 on the sintering properties of hematite ore mixtures The experimentation was performed with three different mixtures of ores from Tazadit, Nimba, ManoRiver, Itabira, Marcona, Sintering Hematite Iron Ore