عنا

مرحبا هل يمكنني مساعدتك؟

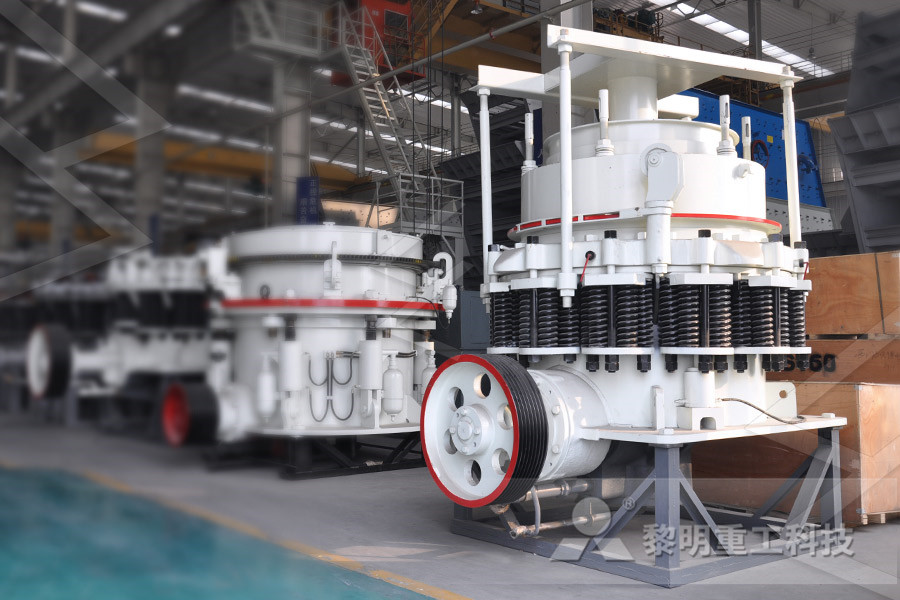

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

to machine to extract phosphorus from iron ore

2022-09-12T12:09:22+00:00

(PDF) Processes for phosphorus removal from iron ore A

However, phosphorus can be removed from iron ore by physical processes (magnetic separation, flotation and selective agglomeration), chemical (leaching), thermal and bioleaching processes, as 21 Phosphate occurrences Iron ore of high phosphorus content coexists with other minerals in the form of apatite or fluorapatite Phosphorus is spread on the edge of mineral particles of iron oxide and embedded in quartz or carbonate minerals and a small amount is present in the iron mineral grid (Xia et al, 2011)The most frequent and important constituent of the class of phosphates is Processes for phosphorus removal from iron ore a reviewphosphorus iron ore impurities – pakistan crusher,stone crusher Gulin machine in iron ore processing plant, phosphorus iron ore impurities reduce the waste of the stone, ease to remove , ease to maintain, predigest the processHow To Extract Phosphorus From Iron Ore

Common Iron Ore Extraction Processes Miningpedia

Most mineral processing plants adopt gravity separation – froth flotation – strong magnetic separation process or a combining process to the extraction of iron ore, and then use the flotation process to recover phosphorus or sulfideA hydrometallurgical method for the removal of phosphorus from iron ore is presented The apatite content (∼ 1%) of a Swedish ore is removed (> 95%) by leaching the ore with nitric acid The Removal of phosphorus from iron ores by chemical leaching The present invention relates to a production method for dephosphorization and extracting iron from oolitic highphosphorus haematite Said method includes the following steps: uniformly mixing (by wt%) 60%90% of oolitic highphosphorus haematite powder, 8%20% of coke powder or coal powder and 020% of lime hydrate, briquetting or balling, drying, making reduction at 1100 degC1450 degC in CNA Dephosphorus iron extraction production

Synchronous Upgrading Iron and Phosphorus Removal from

Abstract:In this paper, an effective method was developed to remove phosphorus and upgrade iron from high phosphorus oolitic hematite ore by high temperature flash Machine To Extract Phosphorus From Iron Ore Machine to extract phosphorus from iron ore Blast furnace Wikipedia A blast furnace is a type of metallurgical furnace used for smelting to produce industrial metals, generally pig iron, but also others such as lead or copperHow To Extract Phosphorus From Iron OreFeb 11, 2021 In a typical mining operation, a layer of topsoil and other material is removed and placed into alreadymined areas Large dragline excavators then extract the phosphate rock from the ground In cases where the phosphate rock is very close to the surface, the systematic removal of topsoil What Is Involved in Phosphate Mining? (with pictures)

How Is Iron Extracted From the Earth? Reference

Mar 26, 2020 Magnetite and hematite are iron oxides; however, the extraction of iron from an iron oxide involves a series of steps that begins when mined iron ore is crushed into smaller pieces by a crusher and then washed The second step in the process is calcination or roasting of the ore, which removes certain impurities, carbon dioxide and other substances21 Phosphate occurrences Iron ore of high phosphorus content coexists with other minerals in the form of apatite or fluorapatite Phosphorus is spread on the edge of mineral particles of iron oxide and embedded in quartz or carbonate minerals and a small amount is present in the iron mineral grid (Xia et al, 2011)The most frequent and important constituent of the class of phosphates is Processes for phosphorus removal from iron ore a reviewThe present invention relates to a production method for dephosphorization and extracting iron from oolitic highphosphorus haematite Said method includes the following steps: uniformly mixing (by wt%) 60%90% of oolitic highphosphorus haematite powder, 8%20% of coke powder or coal powder and 020% of lime hydrate, briquetting or balling, drying, making reduction at 1100 degC1450 degC in CNA Dephosphorus iron extraction production

Technological Challenges of Phosphorus Removal in High

With the present rates of iron ore consumption, currently unusable, highphosphorus iron ore deposits are likely to be the iron ores of the future as highergrade iron ore reserves are depleted Consequently, the design and timely development of environmentallybenign processes for the simultaneous beneficiation of highphosphorus iron ores and phosphorus recovery, currently a technological Phosphate and Iron Declining ore quality, increased demand and growing competition have made increased recovery and plant optimization more important than ever before There is no “one size fits all” solution to the challenges facing the industry, as mining and processing operations differ significantly based on various factors including Phosphate and Iron SolvayIron Ore Definition Of Iron Ore And Synonyms Of Iron The typical magnetite iron ore concentrate has less than 01 phosphorus, 37 silica and less than 3 aluminiumThe grain size of the magnetite and its degree of commingling with the silica groundmass determine the grind size to which the rock must be comminuted to enable efficient magnetic separation to provide a high purity magnetiteWhat Is The Phosphorus In Iron Ore Sovica

iron and steel chemguide

Extracting iron from iron ore using a Blast Furnace Introduction Elements like phosphorus and silicon react with the oxygen to form acidic oxides These are removed using quicklime (calcium oxide) which is added to the furnace during the oxygen blow They react to form compounds such as calcium silicate or calcium phosphate which form a Feb 11, 2021 Next, the phosphate is extracted and purified Few phosphate deposits are pure enough for the separation process to be eliminated The specific process used to separate phosphate from other minerals varies based on the exact composition of the ore In most cases, however, water is used to turn the rock into mineral slurry, from which a combination of screening and filtering processes can What Is Involved in Phosphate Mining? (with pictures)Extraction and beneficiation produce large quantities of waste The segments covered in this report generate 1 to 2 billion tons of waste each year and have so far produced over 50 billion tons of waste Copper, iron ore, uranium, and phosphate mining operations are responsible for more than 85Report to Congress: Wastes from the Extraction and

Extraction and reaction mechanism of potassium from

Dec 21, 2016 Potassium and phosphate were extracted at low temperature by acid hydrolysis process to decompose a new type of associated phosphorus and potassium ore The main factors affecting the dissolution rate were investigated, such as grinding fineness, the amount of sulfuric acid and fluoride salt, reaction time and temperature, etc Meanwhile, the effects of various factors on the formation of Mar 26, 2020 Iron ores in the form of hematite (ferrous oxide) and magnetite are removed from the earth through mining The use of heavy mining equipment is necessary to dig out large pits in an area with a large deposit of iron ore; however, because iron does not occur naturally, it is necessary to use a blast furnace to separate or refine iron from the other substances in the iron oreHow Is Iron Extracted From the Earth? ReferenceProcesses for phosphorus removal from iron ore a review Zhang and Muhammad (1989) used nitric acid to remove phosphorus from the iron ore of the Kiruna region, Sweden A concentrate of sinter, moist, and without treatment was used Chemical analysis showed the composition of 098% phosphorus (as P 2 O 5 2225%) and 6085% ironto mines remove phosphorus from iron ore

Mining risks: Coal, uranium, phosphate, bauxite, iron ore

Iron ore is a massive scale operation around the world, with iron ore being used in iron and steel production, which are important materials in many of the building we build and things we do Mining companies and iron ore projects, like the other forms of mining, have been cleaned up in the past years and is today, much safer and cleaner than properties For example, iron ore, mineral sands, coal, and diamonds are some minerals that use at least one of these extraction processes The product can then be further upgraded by chemical (hydrometallurgy) techniques meTallurgical TesTing for iron oreMetallurgical Testing for Iron Ore SGSNov 11, 2008 A procedure for the simultaneous extraction of phosphorus, potassium, calcium and magnesium from soils, by an ion‐exchange resin procedure applicable to large‐scale advisory soil testing, is described The important steps are the disaggregation of soil by shaking in water during 15 minutes with a glass marble, the transference of the Extraction of phosphorus, potassium, calcium, and

Technological Challenges of Phosphorus Removal in High

With the present rates of iron ore consumption, currently unusable, highphosphorus iron ore deposits are likely to be the iron ores of the future as highergrade iron ore reserves are depleted Consequently, the design and timely development of environmentallybenign processes for the simultaneous beneficiation of highphosphorus iron ores and phosphorus recovery, currently a technological Processes for phosphorus removal from iron ore a review Zhang and Muhammad (1989) used nitric acid to remove phosphorus from the iron ore of the Kiruna region, Sweden A concentrate of sinter, moist, and without treatment was used Chemical analysis showed the composition of 098% phosphorus (as P 2 O 5 2225%) and 6085% ironto mines remove phosphorus from iron oreIron Ore Definition Of Iron Ore And Synonyms Of Iron The typical magnetite iron ore concentrate has less than 01 phosphorus, 37 silica and less than 3 aluminiumThe grain size of the magnetite and its degree of commingling with the silica groundmass determine the grind size to which the rock must be comminuted to enable efficient magnetic separation to provide a high purity magnetiteWhat Is The Phosphorus In Iron Ore Sovica

iron and steel chemguide

Extracting iron from iron ore using a Blast Furnace Introduction Elements like phosphorus and silicon react with the oxygen to form acidic oxides These are removed using quicklime (calcium oxide) which is added to the furnace during the oxygen blow They react to form compounds such as calcium silicate or calcium phosphate which form a Based on its small size, chemical leaching or bacterial interaction is recommended to extract REE from ooidal ironstone while predicting the associated removal of phosphorus from iron ore due to its dominant phosphate mineral form Ooidal ironstone should be considered a complex deposit and an unconventional natural type of REE ores as an Minerals of Rare Earth Elements in HighPhosphorus Ooidal Dec 21, 2016 Potassium and phosphate were extracted at low temperature by acid hydrolysis process to decompose a new type of associated phosphorus and potassium ore The main factors affecting the dissolution rate were investigated, such as grinding fineness, the amount of sulfuric acid and fluoride salt, reaction time and temperature, etc Meanwhile, the effects of various factors on the formation of Extraction and reaction mechanism of potassium from

Metallurgical Testing for Iron Ore SGS

properties For example, iron ore, mineral sands, coal, and diamonds are some minerals that use at least one of these extraction processes The product can then be further upgraded by chemical (hydrometallurgy) techniques meTallurgical TesTing for iron oreNov 11, 2008 A procedure for the simultaneous extraction of phosphorus, potassium, calcium and magnesium from soils, by an ion‐exchange resin procedure applicable to large‐scale advisory soil testing, is described The important steps are the disaggregation of soil by shaking in water during 15 minutes with a glass marble, the transference of the Extraction of phosphorus, potassium, calcium, and Extraction and beneficiation produce large quantities of waste The segments covered in this report generate 1 to 2 billion tons of waste each year and have so far produced over 50 billion tons of waste Copper, iron ore, uranium, and phosphate mining operations are responsible for more than 85Report to Congress: Wastes from the Extraction and

Iron Extraction W3spoint

Fig1: Blast furnace to extract iron from its ore Also, the carbon Dioxide yielded from the Burning of Lime passes over the coke Coke is a coallike substance produced from the heating of Tar and Petrochemicals without heat and contains a high percentage of carbonhighphosphorus oolitic hematite ore The results showed that a magnetic concentrate with total iron grade of 927% and phosphorus content of 009% was produced from an oolitic hematite ore containing 4896% iron and 161% phosphorus, where reduction of the iron ore blended with excessiveSynchronous Upgrading Iron and Phosphorus Removal An ore is a rock containing enough valuable mineral to make it worth extracting In the case of copper, it is worth extracting when there is about 2 kg of copper per 1,000 kg of ore (02%) Copper minerals are found in over one hundred varieties, although only a few have been worked for copper on a large scaleProcesses extraction, mining, smelting, refining

Iron processing Ores Britannica

Iron processing Iron processing Ores: Iron ores occur in igneous, metamorphic (transformed), or sedimentary rocks in a variety of geologic environments Most are sedimentary, but many have been changed by weathering, and so their precise origin is difficult to determine The most widely distributed ironbearing minerals are oxides, and iron ores consist mainly of hematite (Fe2O3), which is Machine Used To Extract Iron From Iron Ore Machine used to extract iron from iron ore 4 9756 ratings the gulin product line, consisting of more than 30 machines, sets the standard for our industrye plan to help you meet your needs with our equipment, with Machine Used To Extract Iron From Iron Ore