عنا

مرحبا هل يمكنني مساعدتك؟

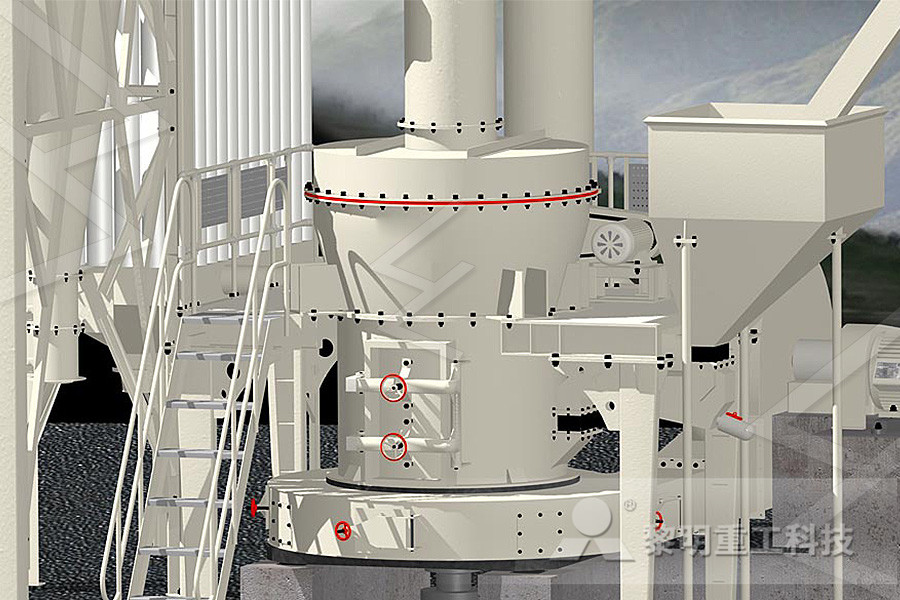

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

cement plant electrical preventive maintenance of ma

2020-08-13T20:08:48+00:00

ore cruser: cement plant electrical preventive maintenance

cement plant electrical preventive maintenance of machines Ali Hassan على حسNov 12, 2012 cement plant electrical preventive maintenance of Operation Maintenance Engineer, Cement Plant: Resume Preventive Maintenance Checklist for Machine Operators In manufacturing plants, machine »More detailedpreventive maintenance checklist for a cement plant cement plant electrical preventive maintenance of Operation Maintenance Engineer, Cement Plant: Resume Preventive Maintenance Checklist for Machine Operators In manufacturing plants, machine »More detailedpreventive maintenance checklist for cement plants

PS ManualPreventive and Predictive Maintenance

Preventive and Predictive Maintenance 700ZB00102 42 Preventive/Predictive Maintenance The guiding principle of PPM is the regular and systematic application of engineering knowledge and maintenance attention to equipment and facilities to ensure their proper functionality and to reduce their rate of deteriorationTherefore ACC cement plant, taken as a case study represents that cement plants are facing big challenges on reducing both energy and maintenance costs In orde r to improve the maintenance in the ACC plant, auditing of the existing maintena nce system had been conducted, since this step is essential in improving any mai ntenance systemMAINTENENCE IN CEMENT INDUSTRY PROJECT Technology cement plant electrical preventive maintenance of machines Ali Hassan على حسore cruser: cement plant electrical preventive maintenance

PS ManualPreventive and Predictive Maintenance

Preventive and Predictive Maintenance 700ZB00102 42 Preventive/Predictive Maintenance The guiding principle of PPM is the regular and systematic application of engineering knowledge and maintenance attention to equipment and facilities to ensure their proper functionality and to reduce their rate of deteriorationOct 15, 2013 concrete batch plant maintenance and lubrication schedule october 15, 2013 should be completed by a qualified electrician compare amperage draw on each leg of 3 phase power should be completed by a qualified electrician to reduce your maintenance time – keep your plant CONCRETE BATCH PLANT MAINTENANCE AND LUBRICATION SCHEDULECement plant in India Needed preventive maintenance, system health diagnosis, process parameter tuning and patch management We met that need with Performance Improvement Increased productivity through usability and efficiency optimization of equipment and processes Customer Benefit: More quality production Equipment covered: ABB Expert OptimizerINDUSTRIAL AUTOMATION ABB Cement Care

Preventive Maintenance: An Overview Reliable Plant

Of facilities that implement a maintenance strategy, 78 percent are switching to preventive maintenance, compared with 61 percent that still rely on reactive maintenance, according to a Plant Engineering maintenance study Preventive maintenance tools like a − Preventive maintenance to avoid unplanned downtime The plant, for the Thang Long Cement Joint Stock Company, a joint venture of the Vietnamese companies Lilama and Regenerative braking Braking energy is fed back into the plant electrical network Reduced utility bills Dynamic torqueLow voltage AC drives Complex cement challenges made CONECO 237 N 13th Street Blair, NE 68008 4024264181 FOR PARTS CALL 18006562651 OR coneco ®CONECO, the CONECO logo and other designated trademarks,Batch Plant and Central Mixer Operations Manual

(PDF) OCCUPATIONAL HEALTH AND SAFETY IN CEMENT INDUSTRY

Tomar, MK 2014, 'Study of Occupational Health, Safety and Environmental Aspects in Major Cement Manufacturing Industry (Ultratech Cement Limited)', Journal of Environment and Earth Science, Vol Good predictive and preventive maintenance practices give you: Improved operator and equipment safety – Potential problems can be caught and fixed before they can cause a dangerous situation; Improved equipment efficiency – Normal wear and tear reduces equipment efficiency Proper maintenance optimises working conditions and improves the life span of the equipmentCement mining maintenance training Strategic Maintenance Specialist with over 18 years of experience in Electrical / Cement industry Configuration, Testing, Commissioning and Troubleshooting of ABB protection Relays REF542Plus, REF615 and REF630 with ABB Configuration Tool REF542 Plus Configuration Tool PCM600Pervaiz Sajjad Assistant manager electrical DG cement

Stochastic Modeling of a Concrete Mixture Plant with

concrete mixture plant with constant failure and arbitrary repair rates of the subsystems and discussed the reliability modeling of concrete mixture plant with preventive maintenance using supplementary variable technique An attempt has also been made to discuss the availability of this plant with respect to different failure and repair ratesplant money in both repair costs and lost business due to downtime The way to keep your batch plant in good working condition is to set up and follow a regular maintenance schedule Because batch plants come in many different styles with various layouts and types of equipment, there is no one maintenance plan that can be used at every plantBatch plant maintenance Concrete ConstructionPerform preventive maintenance on a regular schedule for both High Tension and Low Tension transformers and motors Designing and making of general starters for light switching and motor starters Install and maintain wiring, control, and lighting systems Identify electrical JAPHETH OCHIENG Graduate Electrical Engineer Mombasa

Vibration Analysis in Preventive Maintenance in Industrial

Vibration analysis is an industrial engineer's tool that successfully diagnoses and pinpoints erratic operation conditions well in advance in order to prevent severe breakdowns The basic steps involved in implementing a vibration tracking tool are detection, analysis, and corrective action Trending data and summaries are usually taken by using vibration sensors arranged strategically on the scheduling system for which all maintenance activities will be performed It does not address followup work generated by preventive maintenance activities The adoption of other techniques must be implemented via a variance These other techniques must be consciously chosen, technically sound, effectively implemented, and properly documentedMaintenance Scheduling for Electrical EquipmentCONECO 237 N 13th Street Blair, NE 68008 4024264181 FOR PARTS CALL 18006562651 OR coneco ®CONECO, the CONECO logo and other designated trademarks,Batch Plant and Central Mixer Operations Manual

Preventative Maintenance (PM) Manual

Maintenance is work preformed on a routine basis to protect users of a building and to assure a long life for the building Its goal is a minimum of unexpected repairs for buildings, grounds and equipment A wisely implemented preventative maintenance program; designed to correctmaintenance and nonmaintenance related downtime Nonmaintenance related downtime may be attributed to lack of demand, an interruption in raw material supply or production scheduling delays beyond the control of the maintenance function Asset utilization is also a function of operating rate, quality and yield losses, etcKEY PERFORMANCE INDICATORS Plant MaintenanceGood predictive and preventive maintenance practices give you: Improved operator and equipment safety – Potential problems can be caught and fixed before they can cause a dangerous situation; Improved equipment efficiency – Normal wear and tear reduces equipment efficiency Proper maintenance optimises working conditions and improves the life span of the equipmentCement mining maintenance training

What is Planned Preventative Maintenance Why Does It

May 23, 2017 Planned preventative maintenance (PPM), also commonly referred to as planned or scheduled maintenance, is essentially a scheduled maintenance routine, set out to ensure machinery, services and equipment are all maintained at regular intervals electrical wiring consumer units;We are seeking to recruit Electrical Maintenance Supervisor for our Cement Plant in Çanakkale The position will report to Energy Production and Electrical Maintenance Manager and will proactively support the plant in all major maintenance activities especially troubleshootingAKÇANSA ÇİMENTO SANAYİ VE TİCARET AŞ Electrical Jan 17, 2014 breakdown, predictive maintenance, preventive maintenance, RCM, Maintenance Practices for Plant and Equipment Nothing lasts forever and all the equipment in a plant has associated with it some predefined life expectancy or operational life Maintenance is the work of keeping the plant and equipment in good condition for operationMaintenance Practices for Plant and Equipment – IspatGuru

Electrical Safety Audit Benefits Eco Energies Eco

Review of the earthing and lightning protection system implemented in plant to make sure the equipment and human safety To check earth resistance of earth pits and sockets on sampling basis Review of EPM (Electrical Preventive Maintenance) programme within the facility Review of the shutdown procedure, work permits, lockout tags etcMar 16, 2020 1 Preventive motor maintenance The objective of this kind of maintenance is to prevent operating problems and make sure that the motor continuously provides a reliable operation Usually, preventive maintenance is a scheduled part of maintaining a whole systemRegular Motor Maintenance To Avoid Failureconcrete mixture plant with constant failure and arbitrary repair rates of the subsystems and discussed the reliability modeling of concrete mixture plant with preventive maintenance using supplementary variable technique An attempt has also been made to discuss the availability of this plant with respect to different failure and repair ratesStochastic Modeling of a Concrete Mixture Plant with

UTL: Electroplating Fire FM Global

Electrical failure is one of the leading causes of fire A thorough electrical preventive maintenance program can help identify electrical equipment that may be prone to failure so that corrective action can be taken before it becomes an ignition source In the event a fire does occur, automatic sprinklers can help contain it, limiting the Preventive Maintenance Procedures 37 AIRFIELD PAVEMENTS (See checklist in Exhibit 45) The concept of preventive maintenance for GA pavements is very simple: if you have pavements in good condition, it is much more costeffective to maintain them in good condition than to allow them to deteriorate and then try to rehabilitate or even replace themChapter 4 Preventive Maintenance Procedures Preventive Nov 08, 2015 Preventive Maintenance of Transformers The objective of this section is to outline the recommended work practices that are usually performed for preventive maintenance of transformers The recommended procedures specified in this chapter do not pertain to the major overhaul and repair of a transformer However, many tasks performed during routine maintenance and major overhaul ofTransformers:Preventive Maintenance of Transformers