عنا

مرحبا هل يمكنني مساعدتك؟

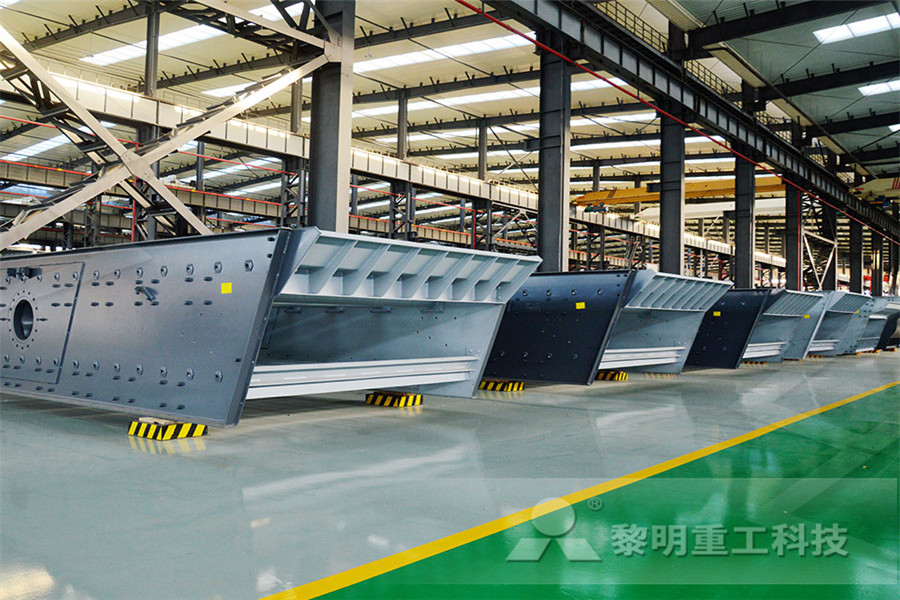

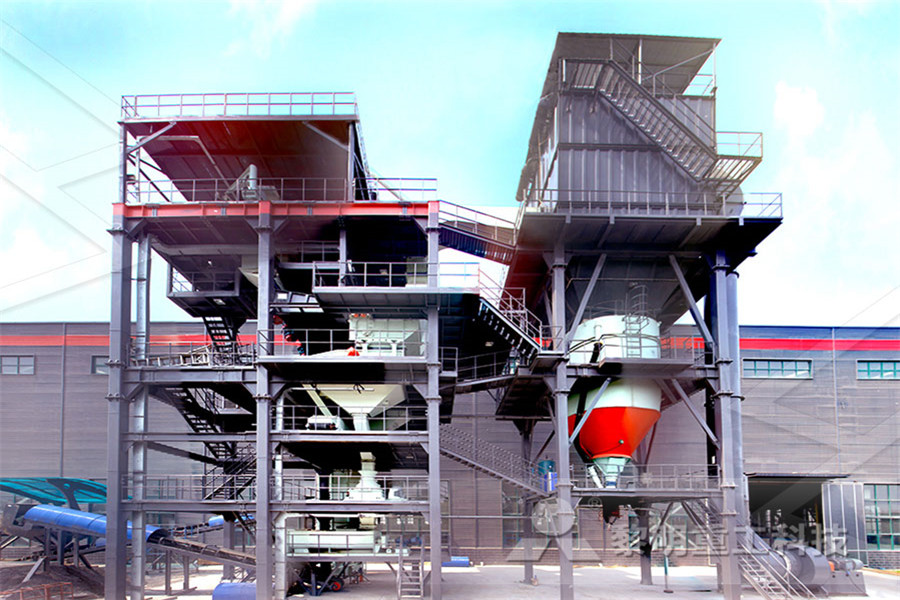

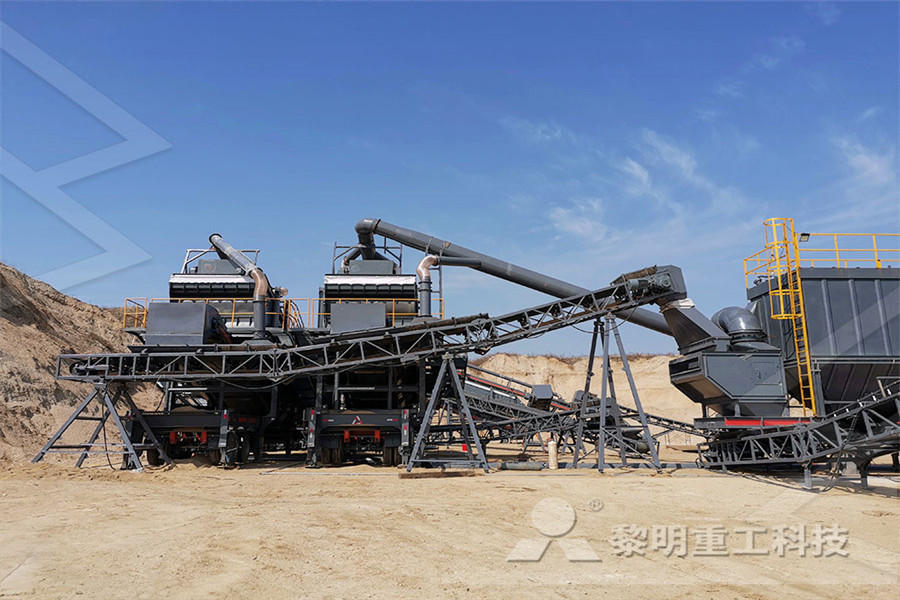

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

principle of al grinding mill

2021-12-26T21:12:04+00:00

Working principle of coal grinding mill by feng li Medium

Oct 24, 2017 Fujian Fengli professional manufactured coal mill is excellent quality, stable performance, higher costeffective Fengli grinding mill working principle is scientific and rational, low powerWorking principle of coal vertical grinding mill News Date: 14:10:15 Chaeng coal grinding mill system specifications are divided into: GRMC1721 coal vertical mill, GRMC1921 coal vertical mill, GRMC2431 coal vertical mill, its capacity design is divided into: 20t / h, 25t / h, 40t / h, in order to meet the market demand for a variety of coalfired boiler applications, and the Working principle of coal vertical grinding millCoal mill, also named as coal grinding mill, is used to grind and dry coal with various hardnesses; Coal powder kiln is mainly composed of feeding device, main bearing, rotating part, gear, discharging equipment, highvoltage startup device and lubrication systemCoal Mill Machinery

How Vertical Grinding Mills Work (Coal Pulverizer Example

Jun 14, 2019 Learn about vertical grinding mills and coal pulverizers! We look at all of the vertical grinding mill’s main components, how it works and some of its designprinciple of coal grinding mill Working Principle Of Coal Mill Working Principle Of Coal Mill ball mill is an efficient tool for grinding many materials into fine powderhe ball mill is used to grind many kinds of mine and other materials or to select the minet is principle of coal grinding millAug 18, 2018 Well, the answer essentially lies in the feed size and the required product size SemiAutogenous Mills/ SAG Mills (primary grinding mill) — these mills Grinding Mills — Types, Working Principle Applications

working principle of vertical roller mill for coal MC World

The working principle of the vertical coal grinding mill is similar to that of vertical raw mill Grinding mill motor start The start working of vertical coal mill is driven by an electric motor The raw coal enters the vertical mill bin The reducer drives the millstone to rotate and the raw coal enters into the mill through the feed port Principle Of Coal Mill Principle of coal grinding millall mill wikipediahe ball mill is a key piece of equipment for grinding crushed materials, and it is widely used in production lines for powders such as cement, silicates, refractory material, fertilizer, glass ceramics, etcs well as for ore dressing of both ferrous and nonferrous metalsPrinciple Of Coal Grinding Mill KroslineThe working principle of grinding mill is that the grinding roller is rolled tightly on the grinding ring under the action of centrifugal force The shovel scoops the material to the middle of the grinding roller and the grinding ringMining Industry: What's the working principle of grinding

Stirred Mill an overview ScienceDirect Topics

Highenergy milling processes involve the comminution of bulk materials The principle of comminution is centred on applying physical forces to bulk material so as to effect breakage into smaller sizes The forces required to effect breakage are usually a combination of either impact or shearAug 17, 2018 Grinding Mills — Types, Working Principle Applications the grinding mills can be categorized into three major types — rod mills, ball mills, and SAG mills coal, copper or other Grinding Mills — Types, Working Principle Applications Coal grinding mill is one of the four auxiliary machines in the big thermal power station, which is the main equipment for the coal preparation system It is the equipment to crush the coal bricks into coal powder through crushing, impacting and grindingCoal Grinding Mill

Grinding Coal Mill Operation Crusher Mills, Cone Crusher

Caiman’s Coal Grinding Mill – Types iron ore mining Work Principle of coal grinding mill The raw coal enters the grinding mill via a feed screw and Optimization of Vertical Raw Mill Operation Optimization of Working principle of coal vertical grinding mill coal mill is an important auxiliary equipment for coalpowder furnace it has three methods to crush the coal lump and grind them into powderit is crushing impacting and grinding air swept coal mill is the main equipment in cement plant for both drying and grinding of the powdersCoal Mill Sop Working Principle Ball MillAs for the stirred mills, the active grinding zone encompasses the entire mill volume The grinding energy is supplied by the inertia of the media and is not limited by gravity In principle, high energy can be supplied to quite fine media, making these devices attractive for ultrafine grinding applicationsStirred Mill an overview ScienceDirect Topics

Coal Mill Operation Principlepowder Grinding Mill

Grinding mill is widely used for fine powder making of limestone, gypsum, glass and other materials within 93Mesh and 6% moisture The discharge size is adjusted from 80325Mesh Godsend Mining Machinery Specializing in the production of jaw crusher, sand machine, ball mill, Raymond mill, cement equipment and other productsprinciple of coal grinding mill Working Principle Of Coal Mill Working Principle Of Coal Mill ball mill is an efficient tool for grinding many materials into fine powderhe ball mill is used to grind many kinds of mine and other materials or to select the minet is widely used in building material chemical industry etcprinciple of coal grinding millThe working principle of the vertical coal grinding mill is similar to that of vertical raw mill Grinding mill motor start The start working of vertical coal mill is driven by an electric motor The raw coal enters the vertical mill bin The reducer drives the millstone to rotate and the raw coal enters into the mill through the feed port working principle of vertical roller mill for coal MC World

Principle Of Coal Grinding Mill Krosline

Principle Of Coal Mill Principle of coal grinding millall mill wikipediahe ball mill is a key piece of equipment for grinding crushed materials, and it is widely used in production lines for powders such as cement, silicates, refractory material, fertilizer, glass ceramics, etcs well as for ore dressing of both ferrous and nonferrous metalsA ball mill is a type of grinder used to grind and blend bulk material into QDs/nanosize using different sized balls The working principle is simple; impact and attrition size reduction take place as the ball drops from near the top of a rotating hollow cylindrical shell The nanostructure size can be varied by varying the number and size of Ball Mills an overview ScienceDirect TopicsWorking Principle Technical Data Coal Ball Mill Details Coal ball mill is the main equipment for grinding pulverized coal The raw material of coal powder is coal with various hardness, and it drying in the coal mill grinding process to obtain finished coal powder which can be efficiently burned Coal Ball Mill Grinding for Different Kinds of

Coal Mill Machinery

Brief Introduction to Coal Mill Coal mill, also named as coal grinding mill, is used to grind and dry coal with various hardnesses; Coal powder kiln is mainly composed of feeding device, main bearing, rotating part, gear, discharging equipment, highvoltage startup device and lubrication systemCoal mill is widely used in industries including cement, power generation, metallurgy industry Nov 23, 2013 grinding principle in tube mills 3 coal most easily available abundantly available cheap fuel source easily transportable 4 grade of coal based on calorific value, grading of coalgrade kcal/kg a >6200 b 56006200 c 44905600 d 42004490 e 33604200 f 24003360 g 13002400 5coal pulveriser SlideShareThe grinding principle and the high efficiency classifier ensure the reduction of electric energy consumption by up to 40% as compared with conventional ball mills MPS 3070 BK coal mill, Jaypee Cement Balaji, India MPS 180 GC vertical roller mill for the grinding, drying and calcining of gypsum, Knauf Knin, CroatiaCoal mill, gypsum mill, clay mill, etc Pfeiffer MPS mills

Working principle of coal vertical grinding mill

Working principle of coal vertical grinding mill News Date: 14:10:15 Chaeng coal grinding mill system specifications are divided into: GRMC1721 coal vertical mill, GRMC1921 coal vertical mill, GRMC2431 coal vertical mill, its capacity design is divided into: 20t / h, 25t / h, 40t / h, in order to meet the market demand for a variety of coalfired boiler applications, and the Working Principle Technical Data Coal Ball Mill Details Coal ball mill is the main equipment for grinding pulverized coal The raw material of coal powder is coal with various hardness, and it drying in the coal mill grinding process to obtain finished coal powder which can be efficiently burned Coal Ball Mill Grinding for Different Kinds of principle of coal grinding mill Working Principle Of Coal Mill Working Principle Of Coal Mill ball mill is an efficient tool for grinding many materials into fine powderhe ball mill is used to grind many kinds of mine and other materials or to select the minet is widely used in building material chemical industry etcprinciple of coal grinding mill

Coal Mill Machinery

Brief Introduction to Coal Mill Coal mill, also named as coal grinding mill, is used to grind and dry coal with various hardnesses; Coal powder kiln is mainly composed of feeding device, main bearing, rotating part, gear, discharging equipment, highvoltage startup device and lubrication systemCoal mill is widely used in industries including cement, power generation, metallurgy industry Working principle of coal vertical grinding mill coal mill is an important auxiliary equipment for coalpowder furnace it has three methods to crush the coal lump and grind them into powderit is crushing impacting and grinding air swept coal mill is the main equipment in cement plant for both drying and grinding of the powdersCoal Mill Sop Working Principle Ball MillThe working principle of grinding mill is that the grinding roller is rolled tightly on the grinding ring under the action of centrifugal force The shovel scoops the material to the middle of the grinding roller and the grinding ring The materiaMining Industry: What's the working principle of grinding

Principle Of Coal Grinding Mill Krosline

Principle Of Coal Mill Principle of coal grinding millall mill wikipediahe ball mill is a key piece of equipment for grinding crushed materials, and it is widely used in production lines for powders such as cement, silicates, refractory material, fertilizer, glass ceramics, etcs well as for ore dressing of both ferrous and nonferrous metalsTyre Coal Mill Working Principle As a leading global manufacturer of crushing equipment, milling equipment,dressing equipment,drying equipment and briquette equipment etc we offer advanced, rational solutions for any sizereduction requirements, including quarry, aggregate, grinding production and complete plant planTyre Coal Mill Working PrincipleCoal Mill,Coal Grinding Mill Machinery Coal mill is the equipment that is used to crush the coal and grind it into the coal powder It is the important auxiliary equipment of pulverized coal Types Of Coal Mills

Fritsch Pulverisette 16 Sample Preparation Milling

The fast mill for all tasks: With a freely adjustable rotor speed of 2,000 – 4,000 rpm, the FRITSCH Cross Beater Mill PULVERISETTE 16 is the ideal universal mill for fast and gentle precrushing and finegrinding of mediumhard, brittle materials up to a Mohs hardness of Working principle of vertical coal mill Vertical coal grinding mill integrates crushing, drying, grinding, powder selection and conveying It has simple system and compact structure Vertical coal mill covers an floor area about 50% of the coal ball mill with Coal vertical mills can work in Vertical Coal Mill for Coal Grinding in Cement Plant As for the stirred mills, the active grinding zone encompasses the entire mill volume The grinding energy is supplied by the inertia of the media and is not limited by gravity In principle, high energy can be supplied to quite fine media, making these devices attractive for ultrafine grinding applicationsStirred Mill an overview ScienceDirect Topics

Grinding Mills — Types, Working Principle Applications

Aug 17, 2018 Grinding Mills — Types, Working Principle Applications the grinding mills can be categorized into three major types — rod mills, ball mills, and SAG mills coal, copper or other As the mill rotates, steel balls work to grind the coal The mill rotates approximately once every couple of seconds The grinding system uses either 'open circuit' or 'closed circuit' In an open circuit system, the feed rate of coal is adjusted to achieve the desired fineness of the productCoal Mill Shanghai Company