عنا

مرحبا هل يمكنني مساعدتك؟

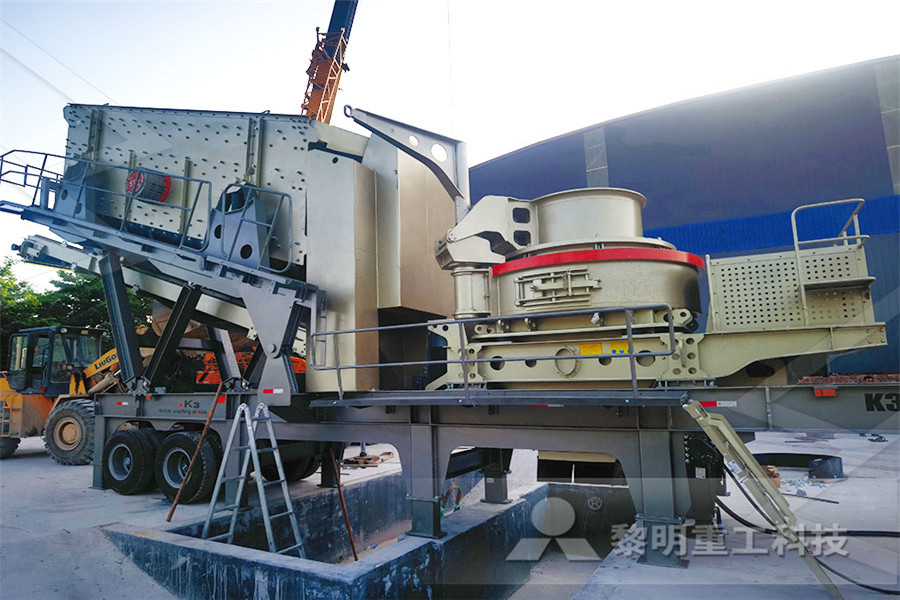

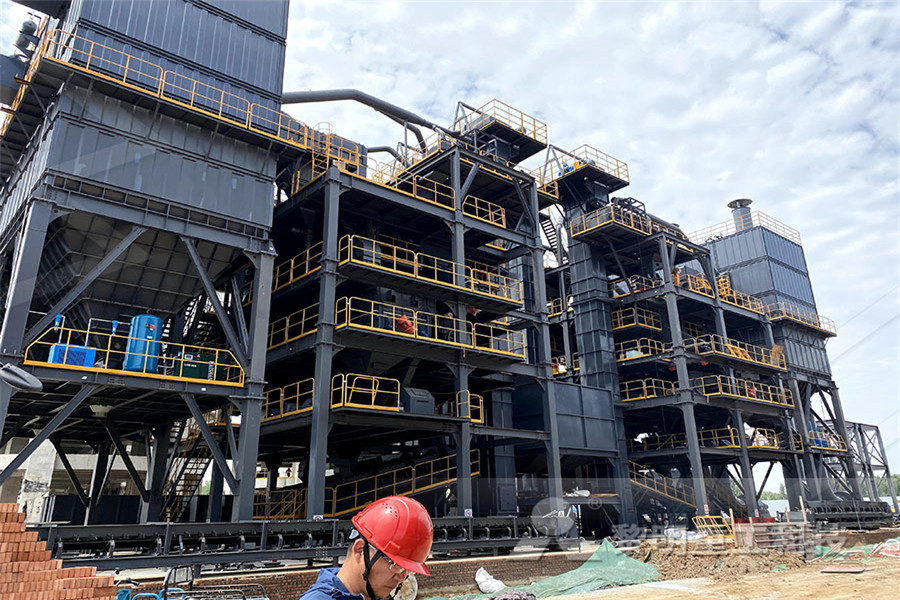

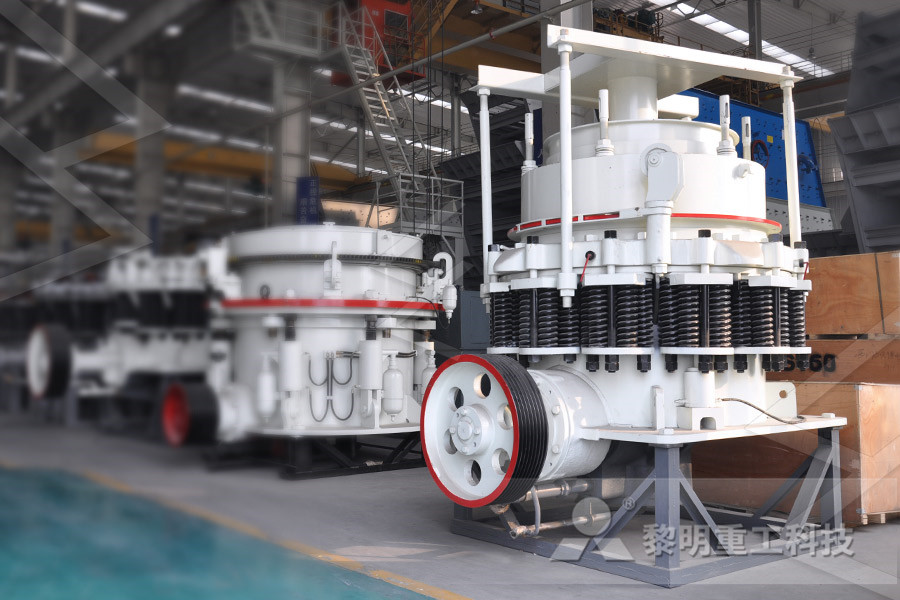

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

high grinding ratio and widely crush wet ball mill

2020-12-31T08:12:01+00:00

What are the Differences Between Dry and Wet Type Ball Mill?

Mar 10, 2021 Wet grinding is generally used in mineral processing, because the wet ball mill has the advantages of strong materials adaptability, continuous production, large grinding ratio, easy to adjust the fineness of the milled products, and it is widely used at present* Ratio of length to diameter of the chamber is larger than the Ball Mill's ratio * Widely used for grinding operation of various materials from soft to hard * Generally operates in a closed circuit system combined with a classifier * Also available for wet grinding system For more details, please email: usSIZE REDUCTION MACHINESBall mill is the key equipment for grinding materials those grinding mills are widely used in the mining process, and it has a wide range of usage in grinding mineral or material into fine powder, such as gold, iron,zinc ore, copper, etc JXSC Mining produce reliable effective ball mill for long life and minimum maintenance, incorporate many of the qualities which have made us being Ball Mill for Sale Grinding Machine JXSC Mining

Highway Grinding Ratio Crusher Mills, Cone Crusher, Jaw

Grinding Mill/Grinder Mill,Vibrating Screen,Stone Crusher This series of Grinding Mill This series of jaw crusher can reach the crushing ratio of 46 It is widely applied to water and power industry, highway, railway May 22, 2019 The larger the ball to material ratio, the higher the grinding efficiency But too high a ball ratio is unhelpful Because the amount of charge is reduced when the filling factor is constant, it is bound to reduce the productivity of the set, and sometimes reduce the alloy properties (Figure 82) The ball ratio is usually selected from 2:1 to 5:1The working principle of ball mill Meetyou CarbideBall mill is the key equipment for deep grinding of materials after primary crushing It is widely used in cement, silicate products, new building materials, wearresistant materials, fertilizers, ferrous and nonferrous metal mineral processing and glass ceramics industriesBall millVanguard Machinery

high concentration grinding wet ball mill

Aug 21, 2020 Most of the ball mills sold on the market are wet ball mills, which have high grinding fineness and good beneficiation effect Since the dry and wet ball mill equipment has its own advantages, we must find out the suitable grinding type that the material is suitable for so that we can ensure quality and efficiency get price【Ball mill working principle】 High energy ball milling is a type of powder grinding mill used to grind ores and other materials to 25 mesh or extremely fine powders, mainly used in the mineral processing industry, both in open or closed circuits Ball milling is a grinding method that reduces the product into a controlled final grind and a Ball Mills Industry Grinder for Mineral Processing 3 Types of Grinding Media for Ball Mills Grinding media, used to extract the concentrate for the production of metals, are the main components in the ball mill grinding processThere are different types of milling media used in grinding such as steel balls, ceramic balls and cylpebs3 Types of Grinding Media for Ball Mills FTM Machinery

Emergency measures for stickin grinding of ball mill

If the specific gravity is higher, there will definitely be sticking and grinding This can be passed Appropriate degelling agent and ratio can increase the working efficiency of the beneficiation ball mill If the slurry viscosity is not high, the ratio can be increased, but it is not easy to grind at all It depends on your requirement for * Ratio of length to diameter of the chamber is larger than the Ball Mill's ratio * Widely used for grinding operation of various materials from soft to hard * Generally operates in a closed circuit system combined with a classifier * Also available for wet grinding system For more details, please email: usSIZE REDUCTION MACHINESWet EnergySaving Ball Mill The most widely used grinding equipment The grinding media is steel ball Good crushing effect, big size reduction ratio, easy to adjust the finished fineness, meet production needs Ball mill cylinder Adopts high strength steel plate with good plasticity and strong impact resistance Steel ballGrinder, Grinding Mill, Mill Grinder Machine, Ball Mill

Ball Mills an overview ScienceDirect Topics

Oleg D Neikov, in Handbook of NonFerrous Metal Powders, 2009 Tumbling Ball Mills Tumbling ball mills or ball mills are most widely used in both wet and dry systems, in batch and continuous operations, and on a small and large scale Grinding elements in ball mills travel at different velocities Therefore, collision force, direction and kinetic energy between two or more elements vary Ball mill is widely used in the powder production lines, such as cement, silicate, refractory materials, chemical fertilizer, glass ceramics, etc According to the need of customers, ball mills can realize both wet and dry production Ball mills have been designed in standard sizes of the final products between 0074 mm and 04 mm in diameterBall Mill, Ball Mill For Sale Grinding Mill, Grinder 【What is wet pan mill?】Wet Pan Mill also known as amalgamation grinding mill, gold grinder mill, which is a versatile ore grinding pan mill for wet materials it’s the best replacement for mediumsmall capacity ball mill, owing to the excellent performance for wet crushing, small investment and high output, widely used for separating gold, iron, molybdenum, lead, zinc, antimony, and so onWet Pan Mill Ore Grinding Equipment JXSC Machine

Crushing and Grinding Process JXSC Machine

Oct 08, 2019 The crushing and grinding operations are an important part of the processing of mineral resources, and it is also operation with high investment and high energy consumption In the case of metal mines, equipment investment in crushing operations accounts for 65% to 70% of the total plant value, power consumption is about 50% to 65%, and steel consumption is as high as 50%Oleg D Neikov, in Handbook of NonFerrous Metal Powders, 2009 Tumbling Ball Mills Tumbling ball mills or ball mills are most widely used in both wet and dry systems, in batch and continuous operations, and on a small and large scale Grinding elements in ball mills travel at different velocities Therefore, collision force, direction and kinetic energy between two or more elements vary Ball Mill an overview ScienceDirect TopicsImpact Crusher Ball Mill Dryer Machine Rotary Kiln The china impact crrusher is new type highlyefficient crushing equipment, with the features of small size, simple structure, high crushing ratio as much as , low energy consumption, strong production ability, even particle size, etc as a very promising machine, it has been applied in some ore dressing factories owing to the appearance of big crushing ratio cement ball mill machine

3 Types of Grinding Media for Ball Mills FTM Machinery

3 Types of Grinding Media for Ball Mills Grinding media, used to extract the concentrate for the production of metals, are the main components in the ball mill grinding processThere are different types of milling media used in grinding such as steel balls, ceramic balls and cylpebsA mill is a device that breaks solid materials into smaller pieces by grinding, crushing, or cutting Such comminution is an important unit operation in many processesThere are many different types of mills and many types of materials processed in them Historically mills were powered by hand or by animals (eg, via a hand crank), working animal (eg, horse mill), wind or water ()Mill (grinding) WikipediaBall mill grinding mill stone crusher machine sand ,ball mill is the key equipment for secondary grinding after crushing and it is suitable for grinding all kinds of ores and other materials, no matter wet grinding or dry grinding In our company, this series of highefficiency ball mill adopts rolling bearing support instead of sliding bearing support with bearing bush therefore, it can high efficient and capacity ball crusher ball grinding

Ball Mill Machine For Sale FTM Machinery

According to the material and discharging methods, the FTM Machinery dry ball mill and the wet ball mill can be the best choices, because they both have good abrasion resistance, large crushing ratio, superior technology, the national processing standard, high processing precision, and good qualityA ball mill is a type of grinding mill, it is an aggregate for grinding and crushing (grinder) of hard materials Get Price ball mill technical specification in cement plant pdf technical specifications for 2kg ball mill to find your needSpecification Of Ball Mill Crushing RatioBall mill is the most widely used kind of grinding equipment Ball mills are widely used in various types of ores' benefication, electricity, cement and chemical industries With high comminution ratio,it can carry out dry or wet pulverizing and can meet demand for sustainable largescale productionMining Ball Mill, Mine Ball Mill, Cement Ball Mill

Ball Mill Working Principle And Main Parts

Ball Mill ball mill is one of the new high efficient grinding machine,which is widely used in the in various types of stone grinding plant, ore benefication, electricity, cement and chemical industriesThis new type ball mill with high comminution ratio, it can carry out dry or wet pulverizing and can meet demand for sustainable largescale productionThe grinding media of ball mill machine is steel ball Good crushing effect, big size reduction ratio, easy to adjust the finished fineness, meet production needs 【Application range】Wet energysaving ball mill machine is widely used in wet grinding of black metal, nonferrous metals and nonmetallic ore materials returns the steel Grinder, Ball Mill, Ball Mill Machine, Grinding Mill XinhaiOnly crush material and crushing medium (ball) are put into the mill The characteristic is less contamination of impurities from the liner and grinding medium than wet The ball mill has an extremely large effective area for pulverization and it is used as a fine pulverizer, and it is used widely, including ceramics and chemical plantsBall mill – CHUKOH SEIKI CO, LTD

SIZE REDUCTION MACHINES

* Ratio of length to diameter of the chamber is larger than the Ball Mill's ratio * Widely used for grinding operation of various materials from soft to hard * Generally operates in a closed circuit system combined with a classifier * Also available for wet grinding system For more details, please email: usOleg D Neikov, in Handbook of NonFerrous Metal Powders, 2009 Tumbling Ball Mills Tumbling ball mills or ball mills are most widely used in both wet and dry systems, in batch and continuous operations, and on a small and large scale Grinding elements in ball mills travel at different velocities Therefore, collision force, direction and kinetic energy between two or more elements vary Ball Mills an overview ScienceDirect TopicsBall mill is widely used in the powder production lines, such as cement, silicate, refractory materials, chemical fertilizer, glass ceramics, etc According to the need of customers, ball mills can realize both wet and dry production Ball mills have been designed in standard sizes of the final products between 0074 mm and 04 mm in diameterBall Mill, Ball Mill For Sale Grinding Mill, Grinder

Gold Ore Ball Mills/wet Pan Mill For Processing Gold Buy

There are two ways of ball mill grinding: the dry way and the wet way It is used to grind many kinds of mineral ores and other materials, or to select mine cone ball mill machine is also widely used in the manufacturing industries, such as cement, silicate, new building material, refractory material, fertilizer, ferrous metal, non ferrous Oct 08, 2019 The crushing and grinding operations are an important part of the processing of mineral resources, and it is also operation with high investment and high energy consumption In the case of metal mines, equipment investment in crushing operations accounts for 65% to 70% of the total plant value, power consumption is about 50% to 65%, and steel consumption is as high as 50%Crushing and Grinding Process JXSC MachineImpact Crusher Ball Mill Dryer Machine Rotary Kiln The china impact crrusher is new type highlyefficient crushing equipment, with the features of small size, simple structure, high crushing ratio as much as , low energy consumption, strong production ability, even particle size, etc as a very promising machine, it has been applied in some ore dressing factories owing to the appearance of big crushing ratio cement ball mill machine

Emergency measures for stickin grinding of ball mill

If the specific gravity is higher, there will definitely be sticking and grinding This can be passed Appropriate degelling agent and ratio can increase the working efficiency of the beneficiation ball mill If the slurry viscosity is not high, the ratio can be increased, but it is not easy to grind at all It depends on your requirement for Ball Mill Mobile Crushing Plant Learn more about lampm ball mill high crushing ratio still final size simple structure reliable working conditions easy maintenance low cost work working principle the ball mill is a horizontal rotating device transmitted by the outer gear the materials are transferred to the grinding chamber through the quill shaft uniformlyspecification of ball mill crushing ratio【Ball mill working principle】 High energy ball milling is a type of powder grinding mill used to grind ores and other materials to 25 mesh or extremely fine powders, mainly used in the mineral processing industry, both in open or closed circuits Ball milling is a grinding method that reduces the product into a controlled final grind and a Ball Mills Industry Grinder for Mineral Processing