عنا

مرحبا هل يمكنني مساعدتك؟

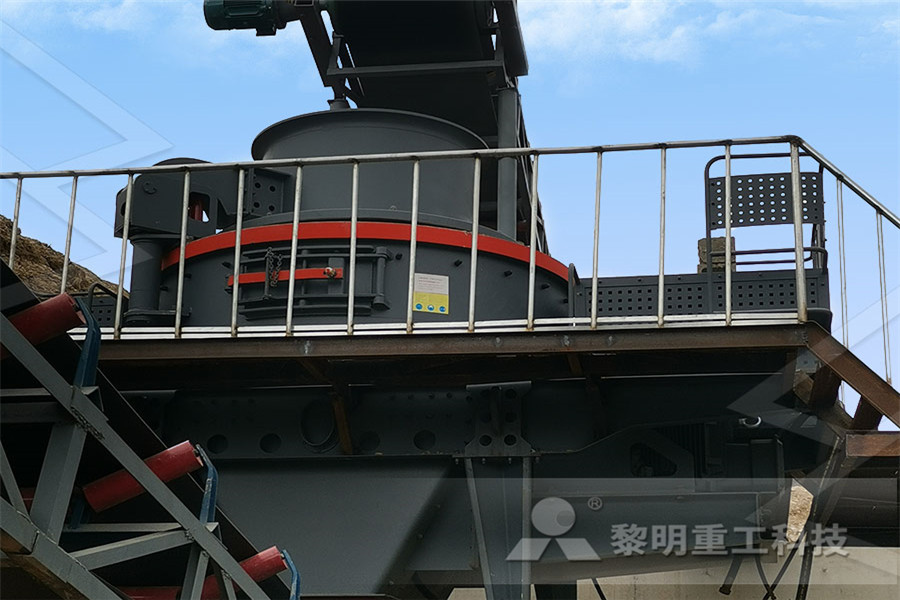

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

Principle Of Belt Conveyors

2022-11-14T09:11:52+00:00

Belt Conveyor working principle/technical parameters

Working Principle Belt Conveyor is a machine taking the friction as the driving force to transport materials in continuous way The equipment consists of frame, conveyor belt, support, roller, tensioning device, driving device etcBelt conveyors are essential systems in today’s industry The proper operation of the conveyor belt can be decisive in the efficiency of the entire production chain and the logistics of a warehouse Although operation principle is the same for all of them, brackets are a very versatile systemThe conveyor belt and its operating principles Belt conveyor and belt conveyor, conveyor belt according to the principle of friction drive and movement, and is suitable for conveying is easy to take out the low grinding powder, granular, small block cut materials, or packaged materials, such as coal, gravel, sand, cement, chemical fertilizer, food, etc Belt conveyor at ambient temperature The working principle of the belt conveyor is introduced

What is a conveyor belt? Principles of operation Calm

Although the operating principle is general for all of them, it is a very versatile system, since there is a great variability of belt conveyors (flat, ascending, inflected, curved, low and high speed spirals) as well as different options of manufacturing , allowing its operation to be adapted to the transport and handling of almost any type of Aug 20, 2019 A conveyor belt works by using two motorized pulleys that loop over a long stretch of thick, durable material When motors in the pulleys operate at the same speed and spin in the same direction, the belt moves between the twoHow Do Conveyor Belts Work? Belt Functions, Uses Mar 03, 2021 A conveyor belt works on friction It consists of a belt fitted over two or more rotating rollers The friction between the belt and rollers causes the belt to move forward or backward This way, rotational motion of the roller is converted to linear motion of the beltHow does a conveyor belt work? Quora

Conveyors and types SlideShare

Sep 11, 2017 Working principle Belt conveyor is composed by two pulleys and a closed conveyor belt The pulley that drives conveyor belt is called drive pulley ; the other one–only used to change conveyor belt movement direction–is called bend pulley Drive pulley is driven by the motor, The drive pulleys are generally installed at the discharge endBelt conveyor and belt conveyor, conveyor belt according to the principle of friction drive and movement, and is suitable for conveying is easy to take out the low grinding powder, granular, small block cut materials, or packaged materials, such as coal, gravel, sand, cement, chemical fertilizer, food, etc Belt conveyor The working principle of the belt conveyor is introducedNOTE: If the belt movement were reversed, the pulley would be pushing the belt When the conveyor was fully loaded or when the belt stretched, the pulley could turn and not move the belt 4 THE SNUB IDLER The Snub Idler is closer to the drive pulley It makes the belt Basic Belt Conveyors FloStor

The Working Principle Of The Conveyor Belt

Principle Of Belt Conveyors Ditaucoza Principle of conveyors a1acoza Belt Conveyor working principletechnical parameters , Working Principle Belt Conveyor is a machine taking the friction as the driving force to transport materials in continuous way The equipment consists of frame, conveyor beltThis element is important because belt slippage occurrence is a usual incident in this type of conveyor system and it can cause friction between drum and belt which can result in wear in belt C Fuzzy Logic to Control Motor SpeedThreephase induction motors used as drives in most belt conveyor (PDF) Belt Conveyor Drives and Control Systems Aini Belt Conveyor System Success is often measured by effi ciency and speed For Robotunits customers this means always keeping one step ahead regarding the time required for delivery, design and assembly An important contributor to this is the fact that the Belt Conveyor System isBelt Conveyor System Izumi International

DESIGN OF MATERIAL HANDLING EQUIPMENT: BELT

safely The design of belt conveyor system involves determination of the correct dimension of the belt conveyor components and other critical parameter values so as to ensure optimum efficiency during loading and unloading conditions Some of the components are: Conveyor beltBelt conveyors working principle processing line working principle and feature of belt conveyor animalspetsorking principle belt conveyor is composed by two endpoint pulleys and a closed conveyor belthe pulley that drives conveyor belt rotating is called drive pulley or transmission drum the other onenly used to change conveyor belt Working Principle Of Belt Conveyors SPECIAL Mining machineMar 21, 2014 1 CARCASS The reinforcement usually found on the inside of a conveyor belt is normally referred to as the “carcass” In a sense, the carcass is in the conveyor belt since it must: 1 Provide the tensile strength necessary to move the loaded belt 2 Absorb the impact of the impinging material being loaded onto the conveyor beltBelt conveyor SlideShare

Basic Belt Conveyors FloStor

NOTE: If the belt movement were reversed, the pulley would be pushing the belt When the conveyor was fully loaded or when the belt stretched, the pulley could turn and not move the belt 4 THE SNUB IDLER The Snub Idler is closer to the drive pulley It makes the belt hug more of the drive pulley surfacePrinciple Of Belt Conveyors Ditaucoza Principle of conveyors a1acoza Belt Conveyor working principletechnical parameters , Working Principle Belt Conveyor is a machine taking the friction as the driving force to transport materials in continuous way The equipment consists of frame, conveyor beltThe Working Principle Of The Conveyor BeltWorking Principle of Belt Conveyor: The belt conveyor is mainly composed of frame, conveyor belt, belt roller, tensioning device, transmission device The fuselage is made of highquality steel plates, and frame is formed by the height difference of the front and rear legs, and the plane is inclined at a Belt Conveyor Types for Cement Production Line

DESIGN OF MATERIAL HANDLING EQUIPMENT: BELT

safely The design of belt conveyor system involves determination of the correct dimension of the belt conveyor components and other critical parameter values so as to ensure optimum efficiency during loading and unloading conditions Some of the components are: Conveyor belt, motor, pulley and idlers, rollers, pneumatic cylinder, etcBelt conveyor systems consist of two or more pulleys (aka drums) An endless loop of carrying medium—the conveyor belt— rotates about them To move the belt and the material it carries forward, one or both pulleys are powered The powered pulley is What is a Belt Conveyor? materials handling definitionMar 21, 2014 1 CARCASS The reinforcement usually found on the inside of a conveyor belt is normally referred to as the “carcass” In a sense, the carcass is in the conveyor belt since it must: 1 Provide the tensile strength necessary to move the loaded belt 2 Absorb the impact of the impinging material being loaded onto the conveyor belt 3Belt conveyor SlideShare

How does a conveyor belt work? Quora

Mar 03, 2021 The Basics of a Conveyor Belt: A conveyor belt is basically a huge wide belt that is fixed onto the conveyor rollers in a circle shape This circle is associated with a few rotors which are controlled by engines The circled piece of the machine iconveyor belt and inrunning nips when in contact with rollers and drums, and to falling return In conveyor belts, fixed guards that only partially surround the danger zone take on two principle(PDF) Best Practices on Conveyor SafetyPrinciple of Belt Conveyor Belt conveyor is composed by frame, belt, roller, tensioning device, transmission device, etc The frame adopts high quality steel for connection, a certain angle inclined plane is formed because of the different heights of front and rear legsmobile belt conveyor

Measuring Bulk Solids on a Conveyor powderbulksolids

Belt Conveyor Load Cells, Principle of Operation A belt conveyor load cell system replaces a short section of the support mechanism of the belt, often one or more sets of idler rollers This support roller is mounted on load cells, so the weight of the dry bulk material on the belt is measured (Figure 3)Mar 15 2018 belt conveyor systems comprise of two or more pulleys the conveyor belt rotate around them to move the belt forward one or two pulleys are powered the powered pulley is called drive pulley the unpowered one is known as idler pulley the mechani,Working Principle Of Belt ConveyorsWorking Principle Of Belt Conveyors EXODUS Mining machineThe flat belt conveyor belt is one of the most prevalent conveyor systems in use today Flat belts are useful for internal conveyance, ie transporting items within a facility This type of conveyor belt uses a series of powered pulleys to move a continuous flat belt, which can consist either of natural material or synthetic fabric (ex 8 Basic Types of Conveyor Belts and Their Applications

Roller / Industrial Conveyor Belt System Belt Conveyor

Nov 30, 2016 Operating Principle Of Industrial Conveyor Belt System Before starting conveyor belt system it is necessary to start first receiving conveyor and then start feeding conveyor ie operating logic is from down stream to upstream For stopping of conveyor system the operation will be opposite ie from upstream to down streamPrinciple of the brake system of the belt conveyor With the wide application of longdistance, largecapacity, highpowered lower belt conveyors, the perfect function and performance of the brake device directly affect the safe and reliable operation of the lower belt conveyorWhat is the principle of the brake Sungda conveyor belt