عنا

مرحبا هل يمكنني مساعدتك؟

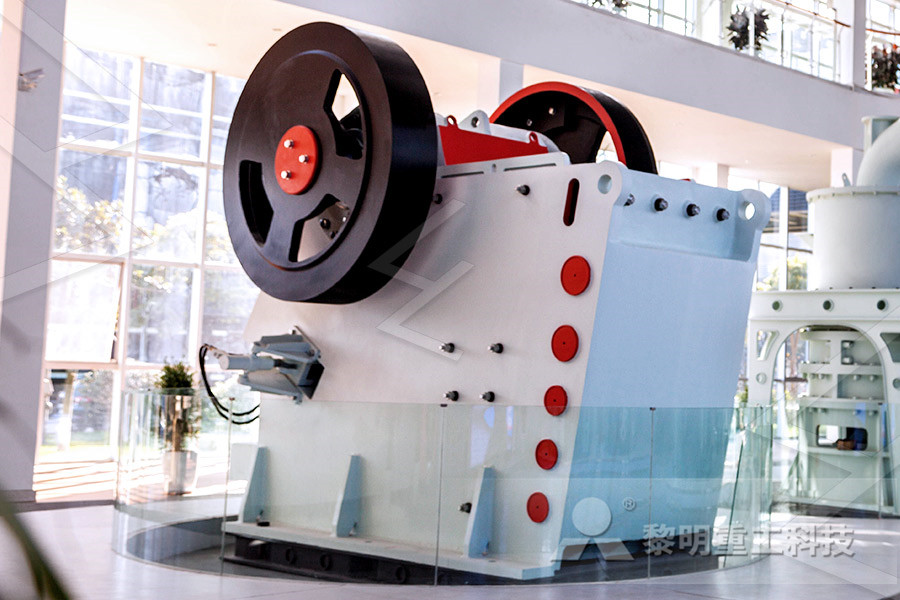

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

use of iron ore waste products

2020-07-29T18:07:24+00:00

Reuse of iron ore mineral wastes in civil engineering

Sep 01, 2008 Copper, lead, zinc and iron ore tailings from various US sources were also used to produce cemented blocks Investigations in USA, Canada and Britain have shown that the tailings and mine waste have potential for use in manufacture of building material, glass, and ceramicsOct 14, 2019 Commissioned in late 2017, the two CDE processing plants wash, separate and gravity beneficiate about 17 Mt of low grade overburden iron ore that was stockpiled in waste dumps into a highgrade saleable product with a 63% iron content – upgraded from an average lowgrade grade of between 45% and 50% iron content in the waste dumps, explains Unlocking maximum value saleable tons from iron ore wasteand greener development The literature shows the potential use of iron ore tailings as a replacement of natural fine aggregates As natural sand reserves are d epleting day by day, there is a need for substitution for sand in concrete A comprehensive overview of the published literature on the use of iron ore waste andSustainable use of mine waste and tailings with suitable

Is a waste product from iron ore? Answers

No, iron ore is a nonrenewable resource, meaning it will not grow back Products made from iron ore can be recycled depending on the productSep 01, 2020 Solid wastes in steel plants are essential byproducts generated during various processing steps involved in the production of iron and steel Solid wastes generated by integrated iron and steel works cause environmental pollution and therefore must be discardedWaste Disposal and Recycling in Steel IndustryFor iron ore mines, the stripping ratio ranges around 22515 This means that for every tonne of iron ore produced, double the quantity of waste is generated In 200304 itself, SAIL generated 476 million tonnes of overburden and rejects from its 12 mines in the country16Mine wastes management Mining and Blasting

Recycling Ways of reducing the use of resources AQA

Aluminium is extracted from its ore using electrolysis but iron is extracted by heating with carbon Electrolysis uses more energy, so more energy is used to extract aluminium in the first placeWhat valuable products can be be derived from iron ore mine waste? The type, amount, and properties of mine waste produced at different mines vary depending on the resource being mined, process What valuable products can be be derived from iron ore Table 5 : A comparative view of iron ore sinter and pellet making processes S N Process Parameters Sinter Making Pellet Making 1 Feed size Coarse ( 10 + 3 mm) Fines (80% below 50 m 2 Fuel Coke breeze (a waste from Oil (high cost) coke oven : low cost) 3 Product size Wide size range (1025 mm) Close size range (1216 mm) 4 Product Shape (PDF) The utilisation of iron ore fines : Technical

Is a waste product from iron ore? Answers

No, iron ore is a nonrenewable resource, meaning it will not grow back Products made from iron ore can be recycled depending on the productNov 19, 2018 The making of iron and steel generates residual products, namely byproducts and waste In Sweden, no less than 80 per cent of the residual products are either reused as raw materials for new steel production or sold on for other areas of application The Swedish steel industry’s vision is for none other than socially useful products to leave the company premisesSteel production residues JernkontoretThe recovery and use of steel industry coproducts has contributed to a material efficiency rate of 976% worldwide1 Our goal is 100% efficient use of raw materials and zerowaste Recovered coproducts can be reused during the steelmaking process or sold for use by other industries This prevents landfill waste, reduces CO 2FACT SHEET Steel industry coproducts

Metal Types and Recycling Process

Mar 05, 2021 Steel and iron are the most recycled materials in the world due in part to the opportunity to recover large structures as well as the ease of reprocessing The use of magnets in the sorting process enables recyclers to easily separate them from the mixed waste stream Currently, the single most recycled container in the world is the aluminum canWrought iron contains less than 015% carbon and was made by reducing iron ore in the solid state, and then hammering to remove the slag Because it could be bent and hammered into shape, it was used for 'traditional' gates, garden furniture and other decorative productsIron Essential Chemical IndustryApr 16, 2015 A mixture of used car parts, construction waste and foundry returns We don’t use any ‘pig’iron at all Foundries have always recycled scrap iron whenever possible, it is after all cheaper The Sustainability of Cast Iron and its use as a modern

What Are the Different Uses of Iron Ore? (with pictures)

Feb 21, 2021 Mary McMahon Date: February 21, 2021 Iron is often used to make permanent magnets One of the most important uses of iron ore is steel production, accounting for the bulk of iron ore processed annually Ironrich ores have a number of other uses, some of which are literally quite colorful; they are used in cosmetics, for example, and in the production of some paints, inks, and dyesThe ore is loaded into a blast furnace along with measured quantities of coke and limestone Hot combustion air is supplied to the furnace and some form of fuel used to raise the temperature The iron is reduced from the ore by carbon in the coke, the limestone aiding slag separation from the molten iron The slag and molten iron are tapped off from the bottom of the furnace, the slag being Iron Ore Smelting Process Bright Hub EngineeringAnnual generation of hard coal mining waste in 2001 accounted for 384 Mt and waste from ore mining, almost entirely tailings, accounted for 299 Mt Current percentage of mining waste use was relatively high and accounted for 910% of generated coal mining waste and 751% of ore mining and processingMining Waste an overview ScienceDirect Topics

Coking Coal for steel production and alternatives Front

1 Coal is needed as a reducing agent “Reduction” is a chemical reaction that turns iron ore (Fe2O3) into pig iron (2Fe) Carbon monoxide (CO) is the crucial ingredient (Fe2O3 + 3CO → 2Fe + 3CO2) and is produced in blast furnaces by burning coal This also produces carbon dioxide as a waste productIron ore is found in nature in the form of rocks, mixed with other elements By means of various industrial processes incorporating cuttingedge technology, iron ore is processed and then sold to steel companies The iron ore produced by Vale can be found in houses, cars and household appliancesIron Ore and Pellets ValeMill scale is one of waste materials which is produced as a result of hot rolling of steel in all steel companies On the other hand, mill scale is considered a rich iron source with minimum impurities This work aims at conversion of mill scale by adjusting smelting processes to produce different valuable products The smelting processes were carried out using carbothermic reduction in a Conversion of Mill Scale Waste into Valuable Products via

Development of value added product using iron ore waste

India is one of the major iron ore producer and exporter in the world It was estimated that about 10–15 % of the iron ore mined in India is unutilized, even now, and is discarded as waste Waste products from iron ore separation usage of waste product of iron ore magnetic separation machine magnetic separation is generally a low cost method of recovery use of iron ore mining amp ore processing while copper is used for electronics and construction and iron is used as a base for waste products are the main source of pollutionIron Ore Mining Waste ProductsThis rocklike or earthy substance is called iron ore • Iron Ore represents – according to the mining sector – an iron content of between 30 to 70 percent of total weight It exists in various combinations, eg in the relationship of 2 atoms iron (2 x Fe[1]) and 3 atoms of oxygen (3 x O2[2]), Fe2O3 = iron oxide • Hot metal is the Plastics convert iron ore to steel Feedstock recycling in

FACT SHEET Steel industry coproducts

The recovery and use of steel industry coproducts has contributed to a material efficiency rate of 976% worldwide1 Our goal is 100% efficient use of raw materials and zerowaste Recovered coproducts can be reused during the steelmaking process or sold for use by other industries This prevents landfill waste, reduces CO 2Mar 05, 2021 Steel and iron are the most recycled materials in the world due in part to the opportunity to recover large structures as well as the ease of reprocessing The use of magnets in the sorting process enables recyclers to easily separate them from the mixed waste stream Currently, the single most recycled container in the world is the aluminum canMetal Types and Recycling ProcessApr 16, 2015 A mixture of used car parts, construction waste and foundry returns We don’t use any ‘pig’iron at all Foundries have always recycled scrap iron whenever possible, it is after all cheaper The Sustainability of Cast Iron and its use as a modern

Lecture 4: Mining waste SGU

Waste rock is the rock that is excavated to reach the ore The amount of waste rock that needs to be removed depends on the geometry and location of the ore body, along with the mining method used and the composition and stability of the rocks The ratio between waste rock and ore Feb 21, 2021 Mary McMahon Date: February 21, 2021 Iron is often used to make permanent magnets One of the most important uses of iron ore is steel production, accounting for the bulk of iron ore processed annually Ironrich ores have a number of other uses, some of which are literally quite colorful; they are used in cosmetics, for example, and in the production of some paints, inks, and dyesWhat Are the Different Uses of Iron Ore? (with pictures)Wrought iron contains less than 015% carbon and was made by reducing iron ore in the solid state, and then hammering to remove the slag Because it could be bent and hammered into shape, it was used for 'traditional' gates, garden furniture and other decorative productsIron Essential Chemical Industry

Iron Ore Smelting Process Bright Hub Engineering

The ore is loaded into a blast furnace along with measured quantities of coke and limestone Hot combustion air is supplied to the furnace and some form of fuel used to raise the temperature The iron is reduced from the ore by carbon in the coke, the limestone aiding slag separation from the molten iron The slag and molten iron are tapped off from the bottom of the furnace, the slag being Mar 05, 2019 PRODUCT SPOTLIGHT: Arctic iron ore mine; PRODUCT SPOTLIGHT: Arctic iron ore mine March 5, 2019; Tested under arctic operating conditions of 40°C Waste Challenge: The construction of a mining operation on an island in the high arctic during the winter season is extremely challenging The construction workforce of over 1000 people spread PRODUCT SPOTLIGHT: Arctic iron ore mine Eco WasteSLAG is an industrial waste product – there is no standards about the quality of it What is in it depends on what was the raw material used for the production of iron – eg scrape metal, iron ore, Orcem claims that absolutely none of the Orcem’s material or products are toxicThe Health Risk of SLAG – an Industrial Waste Product

Iron Ore and Pellets Vale

Iron ore is found in nature in the form of rocks, mixed with other elements By means of various industrial processes incorporating cuttingedge technology, iron ore is processed and then sold to steel companies The iron ore produced by Vale can be found in houses, cars and household appliancesZero waste strategies and optimal use of resources, combined with steel’s exceptional strength, offer an array of Most steel products remain in use for decades before they can be recycled Therefore, there is not enough recycled steel 14 tonnes of iron ore, 740 kg of coal, and 120 kgsteel FACTS