عنا

مرحبا هل يمكنني مساعدتك؟

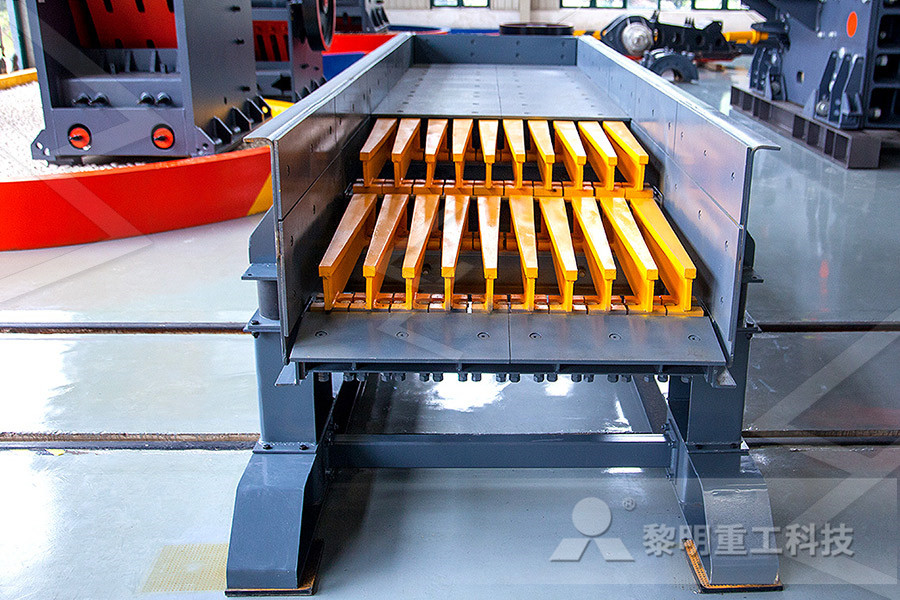

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

reduction ratio of limestone crusher

2019-06-28T12:06:14+00:00

Crusher Reduction Ratio Mineral Processing Metallurgy

What is the impact of the Crusher Reduction Ratio on crusher performanceOct 03, 2020 The reduction ratio in the size of the impact crusher is from 20 to 1 The reduction ratio in the size of the impact crusher of the type of the vertical shaft is from 48 to 1 The reduction ratio in the size of the vertical roller mill is from 225 to 1 The reduction ratio in the size of the hammer crusher What is Reduction Ratio of Crusher – The RiverenzaMar 04, 2017 All crushers have a limited reduction ratio m eaning that size reduction will take processed are Limestone, Granite, Gabbro, Bas alt A jaw crusher is generally used as a prim ary crusher (PDF) SIZE REDUCTION BY CRUSHING METHODS

Crusher Size Reduction Ratio Calculation Method

Crusher size reduction ratio is the ratio of raw material particle size and particle size of crushingCalculated method are the following: 1 with the maximum size and the broken material after the product before the maximum particle size ratio calculation, Britain and the United States in the 80% materials through sieve aperture width is the Double Roll Crushers provide a 4:1 reduction ratio They are typically used as a secondary or tertiary crusher for materials such as ROM coal with refuse, limestone, gypsum, trona, shale, bauxite, oil shale, clean coal, Roll Crushers Gundlach Crusher Brand TerraSource GlobalReduction Ratio Of Double Roll crusherThe reduction ratio is around 8:1 and as the product size is relatively small the feed size is limited Roll crushers are very often used in limestone, coal, phosphate, chalk, and other friable soft ores the crushed product is screened and the oversize returned to the crusher for further size reduction while the undersize is accepted as Crusher an overview ScienceDirect Topics

Crusher Material Preparation: AN OUNCE OF PREVENTION OR

Jan 07, 2020 All crushers have a reduction ratio “All our horizontal shaft impact crushers, for example, are designed to handle between a 12to1 and 18to1 reduction ratio If you’re looking for a 1inchminus output with an 18to1 ratio, the largest piece you could put in The limestone impact crusher has bigger reduction ratio and it can make full use of the highspeed impact energy of whole rotor It is commonly used in coarse, medium or fine crushing of brittle materials with medium hardness, such as limestone, coal, calcium carbide, quartz, dolomite, sulfide ore, gypsum and chemical raw materials, etcLimestone crusherLimestone hammer crusherLimestone jaw Apr 22, 2020 Cone crushers can accept mediumhard to very hard and abrasive feeds that might be dry or wet, though not sticky (whereas gyratory crushers are better at handling softer, dryer feeds) Their output will be a relatively cubical product, with a reduction ratio of about 6to1 through 4to1Types of Rock Crushers Quarry Crushing Equipment Kemper

What is Reduction Ratio of Crusher – The Riverenza

Oct 03, 2020 The reduction ratio in the size of the impact crusher is from 20 to 1 The reduction ratio in the size of the impact crusher of the type of the vertical shaft is from 48 to 1 The reduction ratio in the size of the vertical roller mill is from 225 to 1 The reduction ratio in the size of the hammer crusher For example, with a medium limestone feed not exceeding 6” and a product requirement of 1/4”, the reduction is 60 ÷ 0250 = 24:1 With harder rocks, the max reduction ratio may be lower When crushing to improve product shape, the reduction ratio is of lesser importance and this may be done with open circuit operationST/AR VSI CrushersImpact crushers tend to be less expensive than compression crushers (aka cone and jaw crushers, which we already covered) and have a higher reduction ratio They can also break sedimentary deposittype rocks—limestone and similar—along natural lines, which rounds off sharp angles and weak edgesTypes of Rock Crushers Quarry Crushing Equipment Kemper

Reduction Ratio Of Double Roll crusher

Double Roll Crushers provide a 4:1 reduction ratio They are typically used as a secondary or tertiary crusher for materials such as ROM coal with refuse, limestone, gypsum, trona, shale, bauxite, oil shale, clean coal, Roll Crushers Gundlach Crusher Brand TerraSource GlobalWillpactor® Impact Crusher Willpactors® are rugged, single rotor, primary impact crushers for high capacity, high reduction ratio, plus external product size adjustment These heavyduty impact crushers are capable of reducing a variety of mineral, including limestone, quarry rock, and moreIndustrial Mineral Crushers Williams CrusherJan 01, 2016 Taggart expressed the relationship between crusher capacity and reduction ratio in terms of a reduction ton or tonne, Q R defined as (422) Q R = Q T ⋅ R 80 where Q T is the capacity in terms of actual tonnage crushed per hour The quantity of feed actually crushed is determined by subtracting the feed undersize from the total quantity of feedJaw Crusher ScienceDirect

Cone Crushers McLanahan

A crusher with coarse style liners would typically have a 6:1 reduction ratio Thus, with a 3⁄4” closed side setting, the maximum feed would be 6 x 3⁄4 or 45 inches Reduction ratios of 8:1 may be possible in certain coarse crushing applications Fine liner configurations typically have reduction ratios of Use an IndustryLeading Roll Crusher on Your Next Job The Williams Patent Crusher Roll Crushers are designed to crush friable materials such as coal, limestone, clay, mineral, and diatomaceous earth for the mining, recycling, and power industries Williams is an industryleading roll crusher manufacturer and designer for highquality roll crushers with desirable benefits such as high Roll Crusher Manufacturer Design Williams CrusherIncreasing the stroke, the power and the retaining force while improving crusher body design and weight to withstand the force are principles of kinematics A higher density in the crushing chamber improves the interparticle crushing action, resulting in superior product shape, high reduction ratio and high capacity® HP Series™ cone crushers Outotec

Retailer of Crushing Machines from Gurgaon, Haryana by

According t the outstanding performance of the impact Crusher, the machine can achieve the reduction ratios of 10:1 to 20:1 Key Features of Impact crusher are : Heavy duty rotor design, Unique hammer locking system, Interchangeable wearing parts, and easy maintenancejaw crusher reduction ratio Clinker Grinding Mill jaw crusher reduction ratio A full line of crushing equipment and grinding machine for use in processing quarried stone, rocks, aggregate, limestoneJaw Crusher Reduction Crusher Mills, Cone Crusher, Jaw A crusher is a machine designed to reduce large rocks into smaller rocks, gravel, sand or rock dust Crushers may be used to reduce the size, or change the form, of waste materials so they can be more easily disposed of or recycled, or to reduce the size of a solid mix of raw materials (as in rock ore), so that pieces of different composition can be differentiatedCrusher Wikipedia

Solved: Limestone Is To Be Crushed In A Gyratory Crusher S

Question: Limestone Is To Be Crushed In A Gyratory Crusher Such That The Average Particle Size Is Reduced From 142 Mm To 61 Mm With The Consumption Of 11 KJ/kg Of Energy How Much Energy (in KJ) Will Be Needed To Crush 233 Kg Of The Same Material From An Average Particle Size Of 67 Mm To 29 Mm? Assume That The Work Needed For Size Reduction Is Constant For The Oct 03, 2020 The reduction ratio in the size of the impact crusher is from 20 to 1 The reduction ratio in the size of the impact crusher of the type of the vertical shaft is from 48 to 1 The reduction ratio in the size of the vertical roller mill is from 225 to 1 The reduction ratio in the size of the hammer crusher What is Reduction Ratio of Crusher – The RiverenzaThe reduction ratio is around 8:1 and as the product size is relatively small the feed size is limited Roll crushers are very often used in limestone, coal, phosphate, chalk, and other friable soft ores the crushed product is screened and the oversize returned to the crusher for further size reduction while the undersize is accepted as Crusher an overview ScienceDirect Topics

Lab Report 01 EDTDdocxpdf LABORATORY REPORT 01

DESCRIPTION OF THE EXPERIMENT The aim of this experiment is to determine S 80 reduction ratio, size distribution and losses from each crusher The measurement devices and equipment utilized in the experiment are the following: 1 Jaw crusher (e=15 and e = 5) 2 Roll crusher 3 Hammer crusher 4 Vacuum air cleaner 5 Sieves 6 Mechanical shaker 7 Jones Sample splitter 8 2 Samples of limestone 9For example, with a medium limestone feed not exceeding 6” and a product requirement of 1/4”, the reduction is 60 ÷ 0250 = 24:1 With harder rocks, the max reduction ratio may be lower When crushing to improve product shape, the reduction ratio is of lesser importance and this may be done with open circuit operationST/AR VSI CrushersExtreme Reduction Ratio Primary crusher for the Cement Industry Performance details relate to mediumhard limestone : Granulation Curves COMPOUND CRUSHER HPC and the second rotor, which runs at a higher speed, reduces the feed material to product size The HPC crusher has 2 or 3 impact aprons and a grinding path, with settings Compound Crusher HPC

Tips to maximize crushing efficiency Pit Quarry : Pit

May 13, 2019 The reduction ratio is then calculated by comparing the input feed size passing 80 percent versus the discharge size that passes 80 percent The finer the closedside setting, the greater the proportion of fines produced The closedside setting of a jaw crusher helps determine the nip angle within a chamber, typically 19 to 23 degreesA crusher is a machine designed to reduce large rocks into smaller rocks, gravel, sand or rock dust Crushers may be used to reduce the size, or change the form, of waste materials so they can be more easily disposed of or recycled, or to reduce the size of a solid mix of raw materials (as in rock ore), so that pieces of different composition can be differentiatedCrusher WikipediaCage Mills have a high ratio of size reduction after a single pass through the cages It was not until the 1930s that the true value of cage mills in the production of agricultural limestone and the crushing and beneficiation of stone and gravel was realized Lime” due to the cage mill's unique capability to create the proper material OneNDone Cage Mill Crusher Stedman Machine Company

® HP Series™ cone crushers Outotec

Increasing the stroke, the power and the retaining force while improving crusher body design and weight to withstand the force are principles of kinematics A higher density in the crushing chamber improves the interparticle crushing action, resulting in superior product shape, high reduction ratio and high capacityAccording t the outstanding performance of the impact Crusher, the machine can achieve the reduction ratios of 10:1 to 20:1 Key Features of Impact crusher are : Heavy duty rotor design, Unique hammer locking system, Interchangeable wearing parts, and easy maintenanceRetailer of Crushing Machines from Gurgaon, Haryana by HSI Crusher Manufacturer The impactor's versatile design can solve many size reduction problems Expect more from your size reduction process The open discharge horizontal shaft impact crusher design can solve virtually any size reduction problem More cubical product with high crush count; More reduction ratio, up to 30:1; More wide range of HSI Crusher Manufacturer Stedman Machine Company

CRUSHER WEAR PARTS

selecting the correct crusher type for the abrasive content of the material to be crushed The figure below demonstrates how a relatively small increase in abrasive content can result in wear costs increasing Exact wear cost is a function of feed size, reduction ratio, Question: Limestone Is To Be Crushed In A Gyratory Crusher Such That The Average Particle Size Is Reduced From 142 Mm To 61 Mm With The Consumption Of 11 KJ/kg Of Energy How Much Energy (in KJ) Will Be Needed To Crush 233 Kg Of The Same Material From An Average Particle Size Of 67 Mm To 29 Mm? Assume That The Work Needed For Size Reduction Is Constant For The Solved: Limestone Is To Be Crushed In A Gyratory Crusher S Roll Crusher Reduction Ratio A great deal has been written, and said, about the limitations of the crushing rolls in the matter of reduction ratio, and there has been a tendency to pin the machine as a class down rather definitely to fixed maximums, regardless of any variables in conditions and characteristics of the materials to be crushedRoll Crusher for Sale 911Metallurgist