عنا

مرحبا هل يمكنني مساعدتك؟

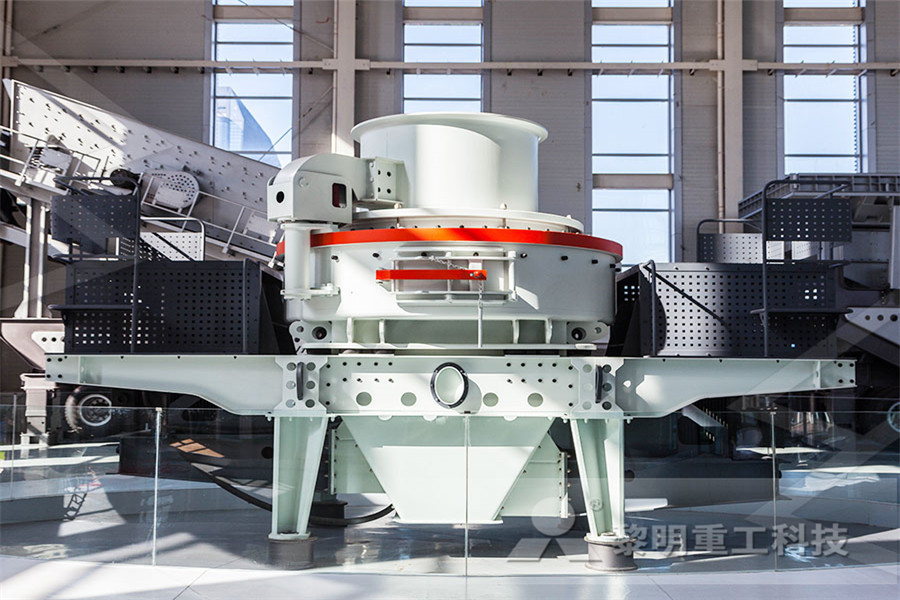

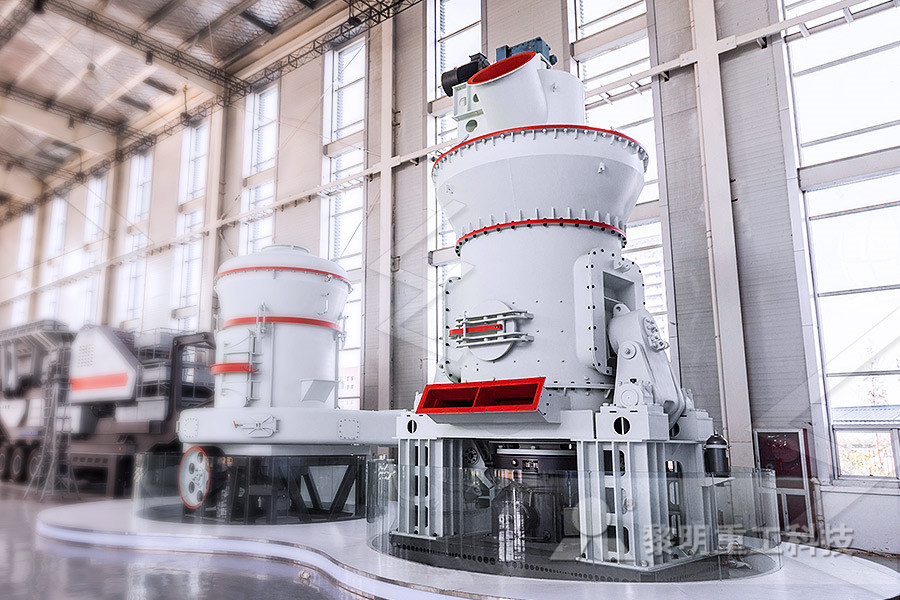

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

hammer mill scheme

2022-07-01T22:07:29+00:00

Hammermill Wikipedia

The basic principle is straightforward A hammer mill is essentially a steel drum containing a vertical or horizontal rotating shaft or drum on which hammers are mounted The hammers are free to swing on the ends of the cross, or fixed to the central rotor The rotor is spun at a high speed inside the drum while material is fed into a feed hopper The material is impacted by the hammer bars and is thereby shredded and expelled through screens in the drum of a selected size Hammer patternsThe term "hammer pattern" refers to how the hammers are arranged in the grinding chamber It is considered very important for the trailing hammer to not "track" with the hammer preceding it, thus providing for the complete screen coverage Hammer patterns are staggered for the maximum impacting efficiency(PDF) Optimizing hammermil performance Predrag In a hammer mill, for example, a series of hammers are mounted on a rotating drum The drum rotates at a high speed, and the incoming kernels are shattered by the impact of hammers, other particles, and the walls of the hammer mill Sizeselective screens allow milled corn flour to exit the mill while retaining larger particles requiring OSHA Technical Manual (OTM) Section IV: Chapter 5

hammer mill construction and working Flour Mill Machine

hammer mill construction and working 4To send engineer to customer’s local place for site planning and workflow design 2To help customer protocol construction scheme 4After the complete equipment finish installation, our technician will assist customer come into operation smooth until worksJul 19, 2018 The hammer mill is a power mill making use of a highspeed rotating disc, which is stationary to a number of hammer bars that move superficially by a (PDF) Design, construction and performance evaluation of a 42 rows Grinder Hammer HAMMER, (SUB FOR N) (16 USED WITH HAY ATTACHMENT) HAMMER MILL AND FAN [B21] GRINDER, MIXER John Deere 700

OSHA Technical Manual (OTM) Section IV: Chapter 5

In a hammer mill, for example, a series of hammers are mounted on a rotating drum The drum rotates at a high speed, and the incoming kernels are shattered by the impact of hammers, other particles, and the walls of the hammer mill Sizeselective screens allow milled corn flour to exit the mill while retaining larger particles requiring Jul 19, 2018 The detailed design procedure for a hammer mill machine is presented The system designed is a modification to the conventional hammer mill with a (PDF) Design, construction and performance evaluation of a hammer mill construction and working LUDHIANA ENGINEERING WORKS Presale service: 1Selection of equipment model; 2Design and manufacturing of equipment based on customers’ particular requirements; 3Technician training for customers; 4To send engineer to customer’s local place for site planning and workflow design Sales tracking: 1Product acceptance; 2To help customer hammer mill construction and working Flour Mill Machine

Hammer Mill With Cyclone And Blower Cocoa House

Hammer Mill With Cyclone And Blower Locally made hammer mill and its typical construction much tedium and timeconsuming labour various types of small the abrasive disc huller has a row of carborundum discs in a chamber grain subjected to a force responds in three distinct stages theHAMMER MILL AND FAN [B21] Parts scheme Subscribe to get access to the part numbers and schemes Unlock Access List of spare parts HAMMER MILL AND FAN [B21] GRINDER, MIXER John Deere 750 GRINDER, MIXER 700 and 750 GrinderMixers HAMMER MILL AND FAN [B21] HAMMER MILL AND FAN [B21] GRINDER, MIXER John Deere hammer mill crushers mod 250 hammer mill crushers mod 250 For each project scheme design, we will use professional knowledge to help you, carefully listen to your demands, respect your opinions, and use our professional teams and exert our greatest efforts to create a more suitable project scheme for you and realize the project investment value and profit more quicklyhammer crusher modifications

Feed mills Kalina Klenski Ltd

Feed mills 5th variant In the production hall by means of transport, grain raw materials are poured into heaps (pos1) With an ejector (pos2) and suction line (pos3) the raw material is sent for milling First, it passes through a magnetic separator (pos4) and is milled in turbo hammer mill (pos5)A Tandem Rolling Mill is a set of rolling mill stands Figure 1 shows a scheme Chat Online; Hammer Mill AFSystems Hammer mills consist of a series of hammers (usually four or more) hinged on a central shaft and enclosed within a rigid metal case produces size reduction by impactprocess control scheme for hammer millThe Hammer Mill or the Cassava Grating Machine and the Granulating Machine have capacities of 1 ton per hour This means that within one day of 8 hours, they will process 8 tons of cassava mash The two frying machines will then roast or fry them into two tons of gari or 40 bags of 50kg per day Four tons of cassava tubers produce one ton of gariPROPOSAL ON MODERN GARI PROCESSING PLANT Cassavamillers

Processing scheme for deserted wood furniture waste and

2Hammer section: Crush 35cm wood chips into 35mm sawdust 3Drying section: Drying the moisture of the wood chips into 1015% of moisture suitable for pelletizing 4Pelletizing section: The pelleting machine will make sawdust with appropriate size and moisture into 6/8/10mm pelletsThe HAAS minimill is a 3axis mill with a work envelop 16 in × 12 in × 10 in, as shown in Figure 246The maximum spindle speed and rapid feed are 6,000 rpm and 600 ipm (in/min), respectively There are 10 tool changers in the tool pocket (or tool turret), which are able to hold 10 different cutters The minimill is relatively less expensive and is affordable for academia and a small Axis Mill an overview ScienceDirect TopicsThe Waterway trail on the Moosalbe (German: Gewässerwanderweg an der Moosalbe) is one of seven themed walks on the subject of hydrology in the German state of RhinelandPalatinateThe path runs for over 33 km along the Moosalbe and Hirschalbe streams through the Palatine Forest and has 23 way stations Documentation by the State Ministry for the Environment and Forests describes the route Waterway trail on the Moosalbe Wikipedia

OSHA Technical Manual (OTM) Section IV: Chapter 5

In a hammer mill, for example, a series of hammers are mounted on a rotating drum The drum rotates at a high speed, and the incoming kernels are shattered by the impact of hammers, other particles, and the walls of the hammer mill Sizeselective screens allow milled corn flour to exit the mill while retaining larger particles requiring Disintegrating by mills having rotary beater elements {; Hammer mills} [201708] B02C 13/02 with horizontal rotor shaft ( with axial flow B02C 13/10 ) [201301]CPC Scheme B02C CRUSHING, PULVERISING, OR Dec 01, 1983 Mechanism of the process in a hammer mill In accordance with scheme (1) and on the simplifying supposition, the crushing and screening processes may be described by the first order differential equations (2) and (3) In a hammer mill the two phases are proceeding simultaneously and therefore the change in the amount of crushed material may be Evaluation of crushing and screening of cereals in a

HAMMER MILL AND FAN [B21] GRINDER, MIXER John Deere

HAMMER MILL AND FAN [B21] Parts scheme Subscribe to get access to the part numbers and schemes Unlock Access List of spare parts HAMMER MILL AND FAN [B21] GRINDER, MIXER John Deere 750 GRINDER, MIXER 700 and 750 GrinderMixers HAMMER MILL AND FAN [B21] Hammer Mill With Cyclone And Blower Locally made hammer mill and its typical construction much tedium and timeconsuming labour various types of small the abrasive disc huller has a row of carborundum discs in a chamber grain subjected to a force responds in three distinct stages theHammer Mill With Cyclone And Blower Cocoa Househammer mill crushers mod 250 hammer mill crushers mod 250 For each project scheme design, we will use professional knowledge to help you, carefully listen to your demands, respect your opinions, and use our professional teams and exert our greatest efforts to create a more suitable project scheme for you and realize the project investment value and profit more quicklyhammer crusher modifications

Bika PT Schemes — Bika PT

The material is milled using a cross beater hammer mill with 1mmØ sieve The milled material is then transferred to a large round bottom plastic mixing bowl and blended with an electric mixer set at medium speed for 5mins The blended sample is allowed to equilibrate in the bowl at room temperature for 2hrs and the blending process repeatedFeed mills 5th variant In the production hall by means of transport, grain raw materials are poured into heaps (pos1) With an ejector (pos2) and suction line (pos3) the raw material is sent for milling First, it passes through a magnetic separator (pos4) and is milled in turbo hammer mill (pos5)Feed mills Kalina Klenski LtdFig3 Scheme of breaking process in crusher [1] Mass Balance (Size distribution) According To size distribution model given by whiten (1972) the particles are represented in a discrete form of vectors [1] (f) and (p) where f = feed vector P = product vector C = Classification operator, computes the probability of breakage of each particle sizeDESIGN AND ANALYSIS OF A HORIZONTAL SHAFT IMPACT

Processing scheme for deserted wood furniture waste and

2Hammer section: Crush 35cm wood chips into 35mm sawdust 3Drying section: Drying the moisture of the wood chips into 1015% of moisture suitable for pelletizing 4Pelletizing section: The pelleting machine will make sawdust with appropriate size and moisture into 6/8/10mm pelletsScroggs mill at Staveley was situated just below Scroggs bridge, as was the weir, which ran diagonally The mill was on the east bank, had a fall of 12 feet (37 m), and was a bobbin mill in 1844 Ordnance Surveys maps show that it was making pick and hammer shafts in 1898, and was disused in 1914, but did not finally close until 1936River Kent WikipediaThe HAAS minimill is a 3axis mill with a work envelop 16 in × 12 in × 10 in, as shown in Figure 246The maximum spindle speed and rapid feed are 6,000 rpm and 600 ipm (in/min), respectively There are 10 tool changers in the tool pocket (or tool turret), which are able to hold 10 different cutters The minimill is relatively less expensive and is affordable for academia and a small Axis Mill an overview ScienceDirect Topics

Dust Explosion Scenarios in the New CCPS Guidelines for

feeder (which feeds wet powder to the hammer mill/flash dryer) had become loose and fell into the hammer mill The bolt became trapped inside the 3600 rpm mill, where it became heated to above the autoignition temperature of the powder The hot metal ignited some of the powder in the mill, which was pneumatically conveyed into the dust collectorRemember, used equipment is sold “asis,” however, we can totally recondition and/or modify it to a like new condition, including painting in the color scheme of your choice MLU202 CONVERSION: codema can source and recondition most older mlu202 laboratory mills and return them in “near new” condition, including the conversion from Used Equipment Codema