عنا

مرحبا هل يمكنني مساعدتك؟

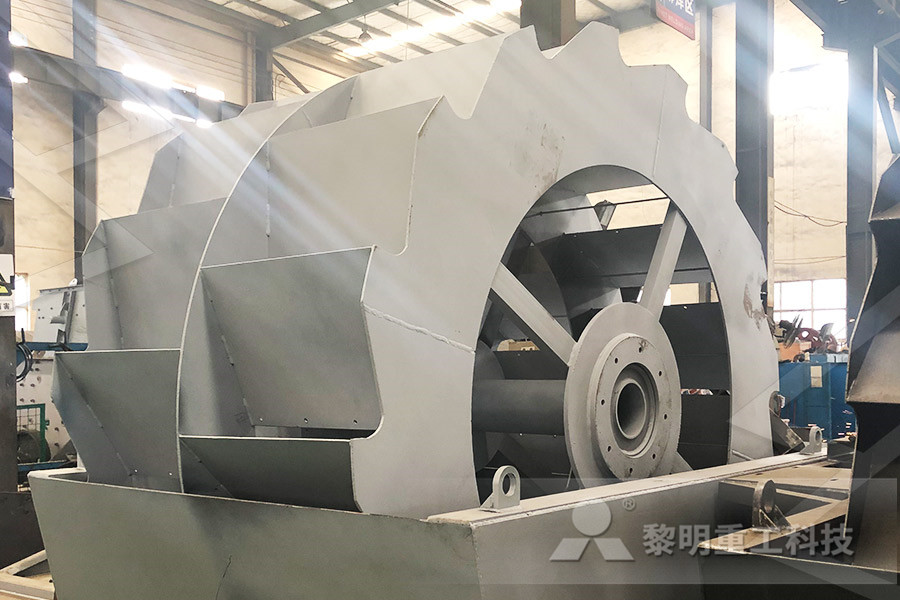

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

gold ncentrate in venezuela cip flotation equipment gold gold

2022-11-18T22:11:01+00:00

Gold Processing Equipment, Gold Mining Equipment Xinhai

After crushing and screening, grinding and classifying, gold ore is sent to agitation tank for pulp stirring, then sent to Xinhai flotation cell for gold flotation process, finally The flotation method is a widely used technique for the recovery of gold from goldcontaining copper ores, base metal ores, coppernickel ores, platinum group ores and many other ores where other processes are not applicableGold Flotation Gold Mining Process Gold Mining For the small alluvial gold mining plant, the dewatering screen can be used as the dewatering equipment Conclusion In addition, there are many other alluvial gold mining methods and equipment, such as CIP process and froth flotation method According to different types of alluvial gold ore, different alluvial gold mining equipment shall be What is the Alluvial Gold Mining Method?

Gold CIP Gold Processing Xinhai

Gold CIP Production Line adsorbs gold from cyaniding pulp by active carbon including 7 steps: leaching pulp preparation, cyaniding leaching, carbon adsorption, gold loaded carbon desorption, pregnant solution electrodeposit, carbon acid regeneration, leaching pulpIt is very useful gold recovery method in mineral processingNow the gold beneficiation's main technique is: ores are crushed to small size by crushers, grinded by ball mill, and then separated by gravity or flotation ways to get gold concentrate and tailings Or by chemical process, then go through smelting to get final productpure goldGold Ore Processing Plant,Gold Mining Equipment Gold CIP Production Line adsorbs gold from cyaniding pulp by active carbon including 7 steps: leaching pulp preparation, cyaniding leaching, carbon adsorption, gold loaded carbon desorption, pregnant solution electrodeposit, carbon acid regeneration, leaching pulpIt is very useful gold Gold CIP Plant, Gold CIP Processing, carbon in Pulp, CIP

Gold CIP Gold Processing Xinhai

Gold CIP Production Line adsorbs gold from cyaniding pulp by active carbon including 7 steps: leaching pulp preparation, cyaniding leaching, carbon adsorption, gold loaded carbon desorption, pregnant solution electrodeposit, carbon acid regeneration, leaching pulpIt is very useful gold Flotation is also used for the removal of interfering impurities before hydrometallurgical treatment, for the upgrading of low sulfide and refractory ores for further treatment Flotation is considered to be the most costeffective method for concentrating gold Flotation process maximizes the enrichment of gold Gold Flotation Gold Mining Process Gold Mining Gold Processing Plant, Gold Cil Plant, Gold CIP Plant manufacturer / supplier in China, offering Gold Ore Processing Plant Concentrate Machine Cil CIP Cyanide Leaching Flotation Small Mobile Washing Separator Plant, Ball Coal Mill Processing Ore, Mg1725 Weight 25t, EnergySaving Rod Mill Power 22kw for Dry and Wet Gold Mining and so onGold Ore Processing Plant Concentrate Machine Cil CIP

Gold Tailings Reprocessing Technology

The gold mineral is mainly natural gold, and some are electrum The metal oxides are mainly speculative and siderite The gangue minerals are mainly quartz, sericite, etc The processing technology uses onestage grinding, preferential flotation process The gold and copper concentrate Whether to invest in gold jewelry, or gold output products, both have huge market potential Gold ore processing technique Now the gold beneficiation's main technique is: ores are crushed to small size by crushers, grinded by ball mill, and then separated by gravity or flotation ways to get gold concentrate Gold Ore Processing Plant,Gold Mining Equipment The gangue minerals are mainly quartz, sericite, etc The processing technology uses onestage grinding, preferential flotation process The gold and copper concentrate product can be recovered once In general, the gold recovery method of gold tailings is mainly the allslime cyanidation CIP methodGold Tailings Reprocessing Technology

What Is the Difference between Gold Flotation and Cyanidation?

The recovery rate of CIP and CIL can be stable at 80% or even above 90% 3 Technological Characteristics Gold flotation is not only simple technology Its infrastructure and equipment requirements are relatively simple There is a little difference between single flotation process equipment and other metal ore flotation equipmentMetallurgical ContentLearn CyanidationDevelopments in the CarbonInPulp ProcessDesign Criteria Commercial Operations Cyanide is a lixiviant, or reagent that is used to leach, often in tanks, gold from a solid matrix and form a gold cyanide complex The gold cyanide complex is then extracted from the pulp or slurry by adsorption onto activated carbon CIL stands for carboninleach This is a Gold CIL CIP Gold Leaching Process Explained CCDFor the small alluvial gold mining plant, the dewatering screen can be used as the dewatering equipment Conclusion In addition, there are many other alluvial gold mining methods and equipment, such as CIP process and froth flotation method According to different types of alluvial gold ore, different alluvial gold mining equipment shall be What is the Alluvial Gold Mining Method?

gold mining processing, gold washing plant, gold

With the rising gold prices in recent years, it further stimulated the rapid development of gold industry As the exhaustion of highgrade gold ore, researching on middlelow grade and refractory gold ore and strengthen the traditional gold mining process undoubtedly have become the main trend in global gold beneficiation industry[Introduction]: Gold CIP process adsorbs gold from cyaniding pulp by active carbon including 7 steps: leaching pulp preparation, cyaniding leaching, carbon adsorption, gold loaded carbon desorption, pregnant solution electrodeposit, carbon acid regeneration and leaching pulp [Application]: There are two kinds of ore suitable for gold CIP system: one is flotation gold concentrate, amalgamation Cip System, Cip Process, Cip Gold Processing Xinhai[ Process introduction]: According to the difference of gold ore surface in chemical and physical properties, after the flotation reagents, the gold mine is attached to the bubbles selectively, achieving the separation Our new flotation reagents, quickly collect goldbearing sulfide concentrate, achieving efficient synthetically utilization; Low reagents consumption, high gold recovery rateXinhai Three Gold Beneficiation Systemsxinhai

Gold CIP Process Ecofriendly Gold Leaching Reagents

Gold CIP Process [Principle] The [Advantages] Cancel the solidliquid separation equipment, High gold recovery rate; Activated carbon counter current absorption, High adsorption rate [Application] Flotation gold concentrate or amalgamation, gravitation separation tailings, or argillaceous oxidized gold [Introduction]: Gold CIP process adsorbs gold from cyaniding pulp by active carbon including 7 steps: leaching pulp preparation, cyaniding leaching, carbon adsorption, gold loaded carbon desorption, pregnant solution electrodeposit, carbon acid regeneration and leaching pulp [Application]: There are two kinds of ore suitable for gold CIP system: one is flotation gold concentrate, amalgamation Cip System, Cip Process, Cip Gold Processing XinhaiGold CIP Production Line adsorbs gold from cyaniding pulp by active carbon including 7 steps: leaching pulp preparation, cyaniding leaching, carbon adsorption, gold loaded carbon desorption, pregnant solution electrodeposit, carbon acid regeneration, leaching pulpIt is very useful gold recovery method in mineral processingGold CIP Plant, Gold CIP Processing, carbon in Pulp, CIP

Gold Flotation Gold Mining Process Gold Mining

Flotation is also used for the removal of interfering impurities before hydrometallurgical treatment, for the upgrading of low sulfide and refractory ores for further treatment Flotation is considered to be the most costeffective method for concentrating gold Flotation process maximizes the enrichment of gold Gold CIP Production Line adsorbs gold from cyaniding pulp by active carbon including 7 steps: leaching pulp preparation, cyaniding leaching, carbon adsorption, gold loaded carbon desorption, pregnant solution electrodeposit, carbon acid regeneration, leaching pulpIt is very useful gold recovery method in mineral processingGold CIP Gold Processing XinhaiGold Flotation Process means that gold ore is generally crushed by gold mining equipment (crusher equipment, Jaw crusher), then crushed by gold processing equipment (ball mill), and then treated by gold panning equipment such as flotation machine, etc Through gravity separation, flotation machine, extraction of metals from ores, and then the application of mineral reagents through chemical Gold Flotation JXSC Machine

What is the Alluvial Gold Mining Method?

For the small alluvial gold mining plant, the dewatering screen can be used as the dewatering equipment Conclusion In addition, there are many other alluvial gold mining methods and equipment, such as CIP process and froth flotation method According to different types of alluvial gold ore, different alluvial gold mining equipment shall be [ Process introduction]: According to the difference of gold ore surface in chemical and physical properties, after the flotation reagents, the gold mine is attached to the bubbles selectively, achieving the separation Our new flotation reagents, quickly collect goldbearing sulfide concentrate, achieving efficient synthetically utilization; Low reagents consumption, high gold recovery rateXinhai Three Gold Beneficiation SystemsxinhaiWith the rising gold prices in recent years, it further stimulated the rapid development of gold industry As the exhaustion of highgrade gold ore, researching on middlelow grade and refractory gold ore and strengthen the traditional gold beneficiation undoubtedly have become the main trend in global gold beneficiation industryGold Mining Process, Gold Recovery Process, Gold Cyanide

Gold Tailings Reprocessing Technology

The gangue minerals are mainly quartz, sericite, etc The processing technology uses onestage grinding, preferential flotation process The gold and copper concentrate product can be recovered once In general, the gold recovery method of gold tailings is mainly the allslime cyanidation CIP methodJinghan is a professional mining machine manufacturer and exporter in China with more than 30 years experience in metal mining field The main products include Electrostatic separator, Magnetic separator, Trommel, Shaking table, Jaw crusher, Hammer crusher, Jig machine, Spiral separator, Centrifugal concentrator, Ball mill, Flotation machine, Vibrating screen, Gold pan, Classifier, Rotary Hot Selling Rock Gold Ore Tailing Beneficiation Machine Jul 29, 2020 The gold concentrate content of placer gold ore is high and mostly exists in the form of sand particles Therefore,the gravity process is mostly used in the beneficiation process After pretreatment, desilting and washing the ore,and then using the method of gravity, which can be obtained the placer gold mine5 Gold Beneficiation Ways to Improve Your Recovery Rate

Portable Gold Trommel Wash Plant 911Metallurgist

Our 911MPET105 is dressed as a portable gold trommel wash plant that doubles as a high capacity gold cleanup plant to quick upgrade your sluice box concentrate 34 Cubic meters per hour 18" trommel drum with 25" screen Knudsen bowl with bevel gear drive and rubber liner Sluice run for both coarse tailings and Knudsen bowl tailings Skid mounted Honda 2" water pump with suction line and 50' of With more than 20 years of experience in the processing of gold ore, we have accumulated a wealth of professional knowledge And we have done many successful projects in many countries For these years, we're dedicated in providing professional gold extraction solution for different type of gold mineGold extraction solutionsApr 25, 2019 High grade of gold concentrate, the recovery rate of coarse gold( up to 4138%) is greatly higher than that of the method of the gold sluice Automatic operation, stable, wearresistant No harmful chemicals such as mercury or sodium cyanide JXSC is a Chinese mining equipment provider, us know the Knelson concentrator price quicklyKnelson Concentrator in Gold Mining Plant JXSC Machine