عنا

مرحبا هل يمكنني مساعدتك؟

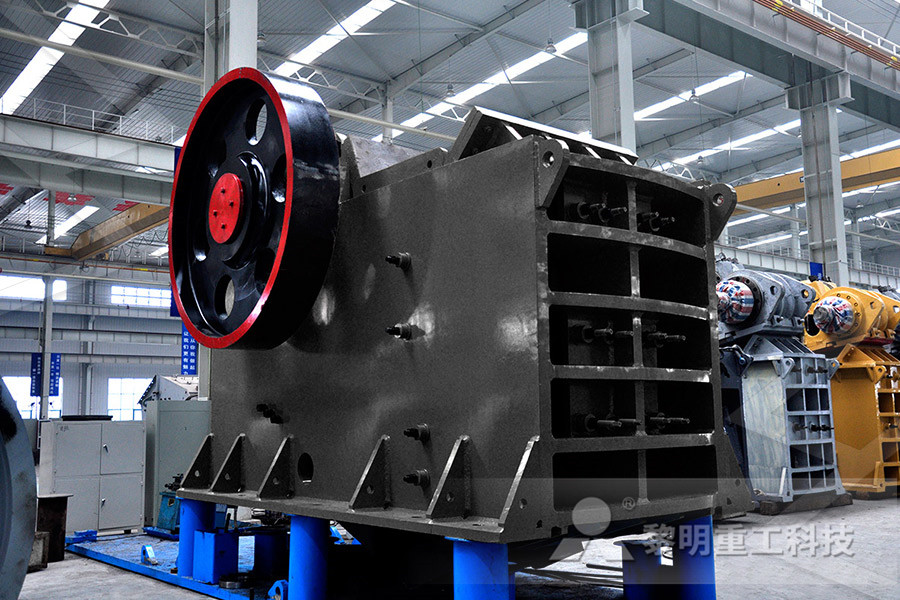

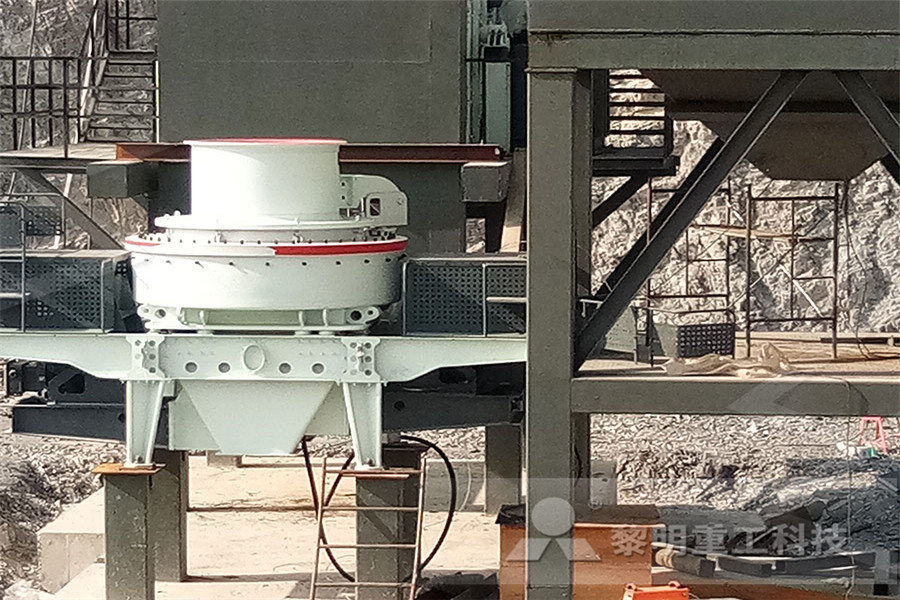

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

disadvantages of makino machine

2022-01-18T14:01:32+00:00

Makino Machine Tool Manufacturer Machining Centers

The Makino commitment starts with global leadership in metalcutting and manufacturing technology, with industryleading horizontal machining centers, vertical machining centers, wire EDM and Ram EDM, and graphite machining centersMakino machines combine grinding and milling to reduce part cycle times by up to 75% Makino Grinding helps you cut costs by minimizing noncut time, setup time and toolchanging time Featured Content MakinoArticle PandemicProof ManufacturingMachines MakinoFor more than 40 years, wire electrical discharge machining (EDM) has been a reliable staple of metal machining, albeit with a few disadvantages Makino, an industry leader in machinery design and digital innovation, hopes to bring EDM to the future and eliminate a few associated issues with its new U6 HEAT ExtremeMakino Changing EDM with New Coated Wire Technology

Machines Makino

Makino Brings IIoT Connectivity and Efficiency to EDM Processing with HyperConnect Machine networking application facilitates machinetomachine and machinetoPC virtual connectivity for improved efficiencies AUBURN HILLS, Mich – December 12, 2017 – With the release of HyperConnect, Makino offers a suite of Industrial Internet of Things Makino Introduces U6 HEAT Extreme Wire EDM Utilizing FirstofitsKind 0016” Coated Wire Technology New machine doubles rough machining rates without increasing manufacturing costs To be competitive in the marketplace manufacturers must continuously identify opportunities to improve efficiency and increase capacity while maintaining the Machining Processes MakinoMakino is committed to providing highperformance, leadingedge machining technologies and innovative engineered process solutions that enable machine shop manufacturers to focus on improving their product quality, eliminating waste, improving cycle times, reducing production times and costs, and increasing profitabilityMakino Machine Tools Horizontal + Vertical Machining Centers

Machine Technology Makino

Machine networking application facilitates machinetomachine and machinetoPC virtual connectivity for improved efficiencies AUBURN HILLS, Mich – December 12, 2017 – With the release of HyperConnect, Makino offers a suite of Industrial Internet of Things (IIoT) applications for electricalMachine networking application facilitates machinetomachine and machinetoPC virtual connectivity for improved efficiencies Asia – January, 2019 – With the release of HyperConnect, Makino offers a suite of Industrial Internet of Things (IIoT) applications for electrical discharge machinesMachines MakinoJul 26, 2013 Pictured is my 2011 VF3, 2008 Mori Dura Vertical, and 2007 Mazak 510 Each of these is a 40 x 20 CT40 Each machine has distinct advantages and disadvantages We have run the same part number using the same tooling on each of these machinesHaas vs Makino Practical Machinist

Machine Tool Spindle Bearing Lubrication: What to Know

Under Raceway Lubrication (Makino): This method lubricates the bearings through holes in the inner races of the bearing Oil is pumped through the shaft, through the bearing, and then recovered by a vacuum system Advantages: Helps to keep a constant shaft temperature Disadvantages: The spindle bearings become proprietary to the OEM, leaving veryOct 01, 2012 Courtesy of Makino This Ti6Al4V medical part was machined on Makino’s DUO43 wire EDM in 5 minutes, 30 seconds (3 hours, 40 minutes for 40 parts) It took four passes to produce a 30 µin Ra surface finish with 0004 "dia brass wireTips for getting the most out of a wire EDM Cutting Tool Makino’s HQSF, for example, requires specialized orbiting software, machine construction and fluid management systems in order to provide ultra fine finishes on EDMed parts (Figure 2, at left) For example, the dielectric management system must be structured very differently from a conventional dielectric systemThe Case For Additive Technology In EDM Makino

Ramping Up To High Speed Machining Makino

The idea here is to keep the original machine tool spindle and simply bolton high rpm capacity One secondary spindle option is a fixed center line spindle Speeds for these units go up to 50,000 rpm, and up to 17 hp is available on some models The unit mounts in the machine tool spindle but has its own power source and controlPRODUCT MANAGER, MAKINO INC Brian Pfluger is EDM product manager at Makino/SST (Auburn Hills, Mich) He has 11 years of EDM experience at Makino and supports the company’s EDMmatters blog (EDMmatters) He has worked in the manufacturing industry for 10 years prior to joining Makino, and has been heavily involved in the machine tradesSELECTING THE APPROPRIATE EDM TECHNOLOGY FOR HOLE May 20, 2019 Makino (Makino Milling Machine Company) developed Japan’s first numerically controlled (NC) milling machine in 1958 By Tsunezo Makino It was established on May 1, 1937, and by 1966 it established Japan’s first machining center 1966 It was headquartered in Tokyo, Japan Makino introduced gamechanging solutions for performance5 Common Types of Machines Tramar Industries

Pros and Cons of Computer Technology in the Classroom

approximately one machine for every nine students (Provenzo, Brett, McCloskey, 1999) An advantage of having computerassisted instruction in the classroom is that the computer can serve as a tutor Teachers can only aid students in the learning process so far Computers can assist teachers and act as a tutor for the students who are falling The Machine has Higher Production and capability It can run for 24 hours a day Reliable Disadvantages of Machine: Here are some disadvantages of machine: The installation cost is high Even do the parts of the machine are high When any failure occurs in the machine the high skilled profession requires to solve the C Machine: Types, Parts, Advantages, Disadvantages Now the machine’s Z readout is the same as a height gage readout relative to that probe tip! Since you can now use your machine as a height gage, you can use it to measure the height of some feature, like a fixed vise jaw, that you want to use for tool length offset touchoffs because it is inconvenient o reach the table Given the height of Touch Off Tool Setter: Measuring Tools for Length

Machinery Additions Accelerate Shop’s Growth MoldMaking

Mar 01, 2017 The dependability and predictability of the Makino machines are what Innovation Mold’s production managers and operators say is most important to them By producing feature tolerance repeatability as fine as 00001 inch, these machines have enabled the shop to Dec 10, 2008 3 Advantages and Disadvantages of EDMWire Cut EDMWire Cut also has its own particular advantages The machine capability is cutting materials regardless of its hardness EDMWire Cut is much faster than EDM It can cuts intricate shapes, narrow slots, etc Furthermore no burrs generated during the processPerigiilmu: ELECTRICALDISCHARGE MACHINING (EDM) WIREJul 26, 2013 Pictured is my 2011 VF3, 2008 Mori Dura Vertical, and 2007 Mazak 510 Each of these is a 40 x 20 CT40 Each machine has distinct advantages and disadvantages We have run the same part number using the same tooling on each of these machinesHaas vs Makino Practical Machinist

Makino Changing EDM with New Coated Wire Technology

For more than 40 years, wire electrical discharge machining (EDM) has been a reliable staple of metal machining, albeit with a few disadvantages Makino, an industry leader in machinery design and digital innovation, hopes to bring EDM to the future and eliminate a few associated issues with its new U6 HEAT ExtremeMay 20, 2019 Makino (Makino Milling Machine Company) developed Japan’s first numerically controlled (NC) milling machine in 1958 By Tsunezo Makino It was established on May 1, 1937, and by 1966 it established Japan’s first machining center 1966 It was headquartered in Tokyo, Japan Makino introduced gamechanging solutions for performance5 Common Types of Machines Tramar IndustriesThe idea here is to keep the original machine tool spindle and simply bolton high rpm capacity One secondary spindle option is a fixed center line spindle Speeds for these units go up to 50,000 rpm, and up to 17 hp is available on some models The unit mounts in the machine tool spindle but has its own power source and controlRamping Up To High Speed Machining Makino

The Case For Additive Technology In EDM Makino

Makino’s HQSF, for example, requires specialized orbiting software, machine construction and fluid management systems in order to provide ultra fine finishes on EDMed parts (Figure 2, at left) For example, the dielectric management system must be structured very differently from a conventional dielectric systemDisadvantages (Many): • The tapping unit consumes a considerable amount of Z height, limiting workpiece thickness • The machine must allow the Zaxis to be locked • A separate lead nut is required for each thread size • The necessary clearance between the electrode and the lead nut often results in a sloppy thread • Human beings EDM Tapping MethodsPRODUCT MANAGER, MAKINO INC Brian Pfluger is EDM product manager at Makino/SST (Auburn Hills, Mich) He has 11 years of EDM experience at Makino and supports the company’s EDMmatters blog (EDMmatters) He has worked in the manufacturing industry for 10 years prior to joining Makino, and has been heavily involved in the machine tradesSELECTING THE APPROPRIATE EDM TECHNOLOGY FOR HOLE

5axis and TCP Industrial Forum eMastercam

Dec 15, 2012 I just had a Koma rotary table installed on my Makino A51nx and I am being told by Makino that getting the TCP options is not the way to go as it is more difficult to program and it has been problematic with the horizontal machines with rotary tables I plan to do extensive full 5axis surface machining with this and I want the very best A ball screw is a mechanical linear actuator that translates rotational motion to linear motion with little frictionA threaded shaft provides a helical raceway for ball bearings which act as a precision screw As well as being able to apply or withstand high thrust loads, they can do so with minimum internal frictionBall screw WikipediaDec 10, 2008 3 Advantages and Disadvantages of EDMWire Cut EDMWire Cut also has its own particular advantages The machine capability is cutting materials regardless of its hardness EDMWire Cut is much faster than EDM It can cuts intricate shapes, narrow slots, etc Furthermore no burrs generated during the processPerigiilmu: ELECTRICALDISCHARGE MACHINING (EDM) WIRE

Die Sinking EDM Supply , EDM, WireCut Machines

Electrical Discharge Machine(EDM), Diesinking EDM, also called cavity type EDM or volume EDM, consists of an electrode and workpiece submerged in an insulating liquid such as, more typically, oil or, less frequently, other dielectric fluids The electrode and workpiece are connected to a suitable power supply The power supply generates an electrical potential between the two partsMakino, Mazak (mazak) and other machine tool builders servicing the aerospace industry are all seeing strong sales to that sector, and almost all of it is going to smaller companies "We're seeing an increase in sales for capacity reasons," Alan Hollatz, of Makino's aerospace proposal group, saidAerospace Outsourcing Can Turn Shops Into High Flyers Makino's Cloneswere mental projections from the dome created by Makinowhom were part of the competition to test the power of the competitor They debuted in The Wrath of Makino, and were voiced by Michael Dobson 1 History 11 Animated Films 111 The Wrath of Makino 2 Appearance 3 Abilities 31 Disadvantages 4 Trivia During the competition to decide who was going to be the new Makino's Clones Max Steel Reboot Wiki Fandom

Top 8 Milling Tools for Cutting Fusion 360 Blog

Jun 07, 2018 machines, which have higher rigidity and are significantly less prone to the backlash, will use a Climb Milling process where the tool advances through material from maximum to minimum thickness This cutting process allows the heat to leave the cut with the chip, reducing heat generation and tool wear while producing a better surface