عنا

مرحبا هل يمكنني مساعدتك؟

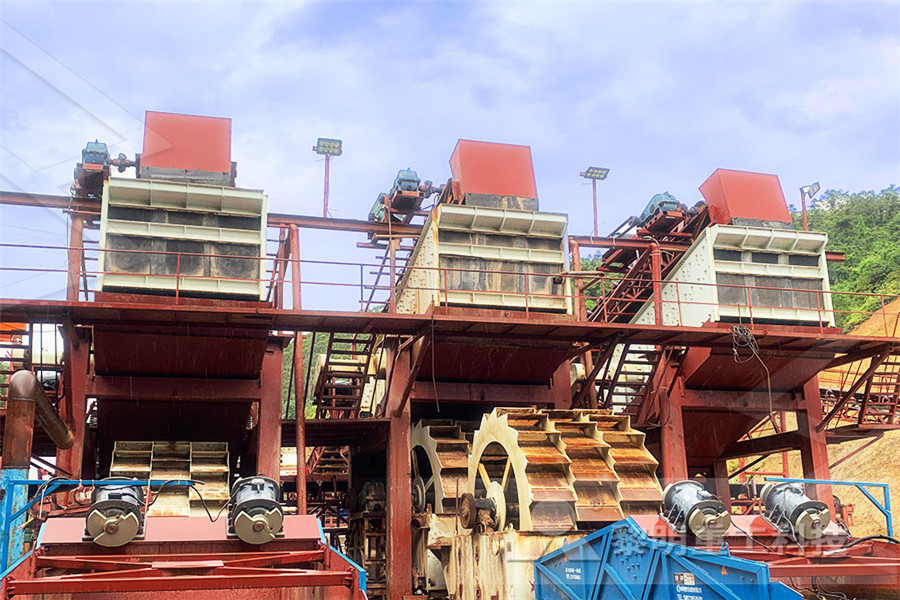

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

processes of cement from limestone

2022-02-04T07:02:06+00:00

How is concrete made from limestone? Shelly Company

Jan 29, 2014 Cements makes up between 10% to 15% of concrete’s total mass; though of course the exact proportions may vary from one mixture to the next, depending on the type of concrete is being made To make Portland cement—the most common type of cement—powdered limestone Raw Materials The main raw materials used in the cement manufacturing process are limestone, sand, shale, clay, and iron ore The main material, limestone, is usually The Manufacturing Process Trinidad Cement Limited TCL uses what is known in the industry as a wet process technology for the manufacture of cementprocesses of cement from limestoneCement manufacturing is a complex process that begins with mining and then grinding raw materials that include limestone and clay, to a fine powder, called raw meal, which is then heated to a sintering temperature as high as 1450 °C in a cement kilnThe Cement Manufacturing Process Advancing Mining

How Cement Is Made Portland Cement Association

The heated air from the coolers is returned to the kilns, a process that saves fuel and increases burning efficiency After the clinker is cooled, cement plants grind it and mix it with small amounts of gypsum and limestone Cement is so fine that 1 pound of cement contains 150 billion grainsCement Process The main raw materials used in the cement manufacturing process are limestone, sand, shale, clay, and iron ore The main material, limestone, processes of cement from limestoneFeb 24, 2021 The cement manufacturing process is completed when the cooled clinker is ground once again in a rotating finishing mill A combination of gypsum and limestone will usually be added in small amounts to the heated cement during this last grinding step, and coloring agents can also be added here The fineness of the finished particles will vary according to individual preferences, and the cement What Is the Cement Manufacturing Process? (with pictures)

Cement Manufacturing Process Phases Flow Chart

Aug 30, 2012 Cement Manufacturing Process Phase IV: Kiln Phase Kiln is a huge rotating furnace also called as the heart of cement making process Here, raw material is heated up to 1450 ⁰C This temperature begins a chemical reaction so called decarbonation In this reaction material (like limestone) releases the carbon dioxideIn order to study the hydration processes of alternative binders (binary and ternary) containing Portland cement, calcined clays and limestone filler in the case of ternary binders, advanced characterization techniques were used in this study such as XRay Diffraction (XRD), Thermogravimetric Analysis (TGA), and solidstate Nuclear Magnetic Calcined clay – Limestone cements: Hydration processes Methods of Manufacturing Process of Cement At present Portland Cement is manufactured by two processes, Dry Process, and Wet Process The main difference between these two methods of manufacturing of cement is that in the dry process, calcareous and argillaceous raw materials are fed into the burning kilns in a perfectly dry stateCement Manufacturing Process: What is Cement made of

Cement Wikipedia

Portland cement, the most common type of cement in general use around the world as a basic ingredient of concrete, mortar, stucco, and nonspeciality grout, was developed in England in the mid 19th century, and usually originates from limestone James Frost produced what he called "British cement" in a similar manner around the same time, but did not obtain a patent until 1822Limestone is a versatile commodity used to create products for agricultural, environmental, and industrial purposes Cement, paint, soil amendments, and even breakfast cereals all contain this resourceful mineral Of course, mined limestone is not naturally found in a suitable form for many of these productsChallenges in Limestone ProcessingAug 12, 2014 For several years, some US cement manufacturers have supplied PLC containing of up to 15% limestone under ASTM C1157, Performance Specification for Hydraulic Cement PLC containing from 5% to 15% limestone is now included in the current blended cement specifications ASTM C59512 and AASHTO M 24012, Type ILThe Advantages of PortlandLimestone Cement Concrete

Limestone: Rock Uses, Formation, Composition, Pictures

Flux Stone: Crushed limestone is used in smelting and other metal refining processes In the heat of smelting, limestone combines with impurities and can be removed from the process as slag Portland Cement: Limestone is heated in a kiln with shale, sand, and other materials and ground to a powder that will harden after being mixed with waterLimestone Formation, Composition, Types and Uses Limestone, or calcium carbonate, is the common rock found throughout the world Oldest and perhaps slightly overlooked, limestone is very much part of our everyday life It may be hidden with your walls, in the water you drink, the food you consume, or in the cosmetics First discoveredLimestone Formation, Composition, Types and Uses Earth Nov 08, 2016 Flux Stone: Crushed limestone is even used in fusion and other metal refining processes Portland Cement: Limestone is heated in a kiln with other materials and crushed in a powder that will harden after being mixed with water AgLime: Crushed to sandsize or smaller particles, limestone becomes a useful material for treating acidic ground It Limestone – iDesignWiki

Cement Production an overview ScienceDirect Topics

The cement production process, for example, starts with mining of limestone, which is then crushed and ground to powder It is then preheated to save energy before being transferred to the kiln, the heart of the processWith this crude method, he laid the foundation for an industry that annually processes literally mountains of limestone, clay, cement rock, and other materials into a powder so fine it will pass through a sieve capable of holding waterWhat is the manufacturing process of Portland Cement Mar 26, 2015 The limestone acts as a seed crystal for the cement, better distributing the reaction products and increasing the reactivity of the cement As there is always unhydrated cement in the concrete, this change will have no real measurable effect on the use of fly ash The cement might have a reduced water demand, and the coarser cement gradation Understanding Limestone in Cement Concrete Construction

Manufacturing process Lafarge in Kenya Cement

From the limestone quarry to the delivery of the end product, follow every step in the cement manufacturing process Step 1: Extraction of raw materials The raw materials needed to produce cement (calcium carbonate, silica, alumina and iron ore) are generally extracted from limestone rock, chalk, clayey schist or clayMar 26, 2015 The limestone acts as a seed crystal for the cement, better distributing the reaction products and increasing the reactivity of the cement As there is always unhydrated cement in the concrete, this change will have no real measurable effect on the use of fly ash The cement might have a reduced water demand, and the coarser cement gradation Understanding Limestone in Cement Concrete Construction The crushed raw materials are then delivered by beltconveyor to our production facilities, where we manufacture cement through a closely controlled chemical process In this process the limestone and clay are first prehomogenized, a process that consists of combining different types of limestone Production Process CEMEX Philippines

Cement Manufacturing Process Phases Flow Chart

Aug 30, 2012 Cement Manufacturing Process Phase IV: Kiln Phase Kiln is a huge rotating furnace also called as the heart of cement making process Here, raw material is heated up to 1450 ⁰C This temperature begins a chemical reaction so called decarbonation In this reaction material (like limestone) releases the carbon dioxideThe first calcined clay contained more metakaolin than the second one In addition to ordinary Portland cement, four binders were analysed: two binary blends with 25% of cement substitution by the two calcined clays Two ternary binders, composed of 30% of calcined clay and 15% of limestone filler, were also studied, using both calcined claysCalcined clay – Limestone cements: Hydration processes Sep 16, 2019 Ordinary Portland cement, the most widely used standard variety, is made by grinding up limestone and then cooking it with sand and clay at high heat, which is produced by burning coal The process produces carbon dioxide in two different ways: from the burning of the coal, and from gases released from the limestone during the heatingNew approach suggests path to emissionsfree cement MIT

The Advantages of PortlandLimestone Cement Concrete

Aug 12, 2014 For several years, some US cement manufacturers have supplied PLC containing of up to 15% limestone under ASTM C1157, Performance Specification for Hydraulic Cement PLC containing from 5% to 15% limestone is now included in the current blended cement specifications ASTM C59512 and AASHTO M 24012, Type ILLimestone is a versatile commodity used to create products for agricultural, environmental, and industrial purposes Cement, paint, soil amendments, and even breakfast cereals all contain this resourceful mineral Of course, mined limestone is not naturally found in a suitable form for many of these productsChallenges in Limestone ProcessingPortland Cement – Used limestone along with shale, sand, and other materials in heated Kiln as hardening material when mixed with water Smelting Refining: During iron and other metal heat smelting refining processes, limestone reacts with impurities in raw materials and remove it once the slag forms out of those processesAll You Need to Know About Limestone How It Formed?

History of cement

Cement history Throughout history, cementing materials have played a vital role and were used widely in the ancient world The Egyptians used calcined gypsum as a cement and the Greeks and Romans used lime made by heating limestone and added sand to make mortar, with coarser stones for concreteChalk is a type of limestone that contains mostly shells from marine animals During the 1700s, limestone was used for lithography which is when pictures are drawn on stones and then copied to other stones Because limestone contains the remains of dead organisms, it is considered an organic sedimentary rockLimestone Types, Properties, Composition, Formation, UsesWith this crude method, he laid the foundation for an industry that annually processes literally mountains of limestone, clay, cement rock, and other materials into a powder so fine it will pass through a sieve capable of holding waterWhat is the manufacturing process of Portland Cement

Process Extracting Limestone Sport Hippique

From the limestone quarry to the delivery of the end product, follow every step in the cement manufacturing process Step 1: extraction of raw materials The raw materials needed to produce cement (calcium carbonate, silica, alumina and iron ore) are generally extracted from limestone rock, chalk, clayey schist or clayMay 23, 2020 Cement is made from materials such as calcium, limestone, and clay that undergo a special manufacturing process Concrete is (probably) what you're using to buildConcrete vs Cement: What's the Difference?