عنا

مرحبا هل يمكنني مساعدتك؟

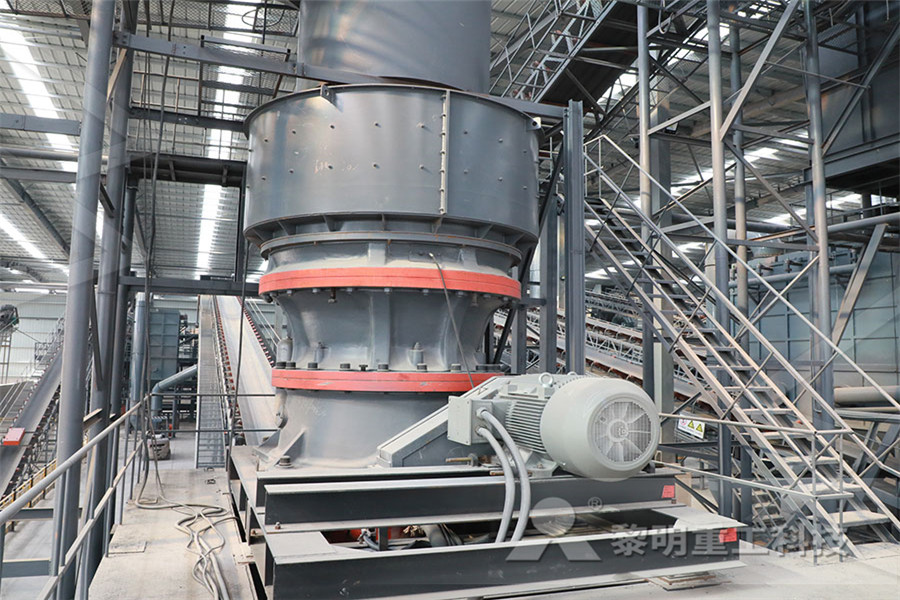

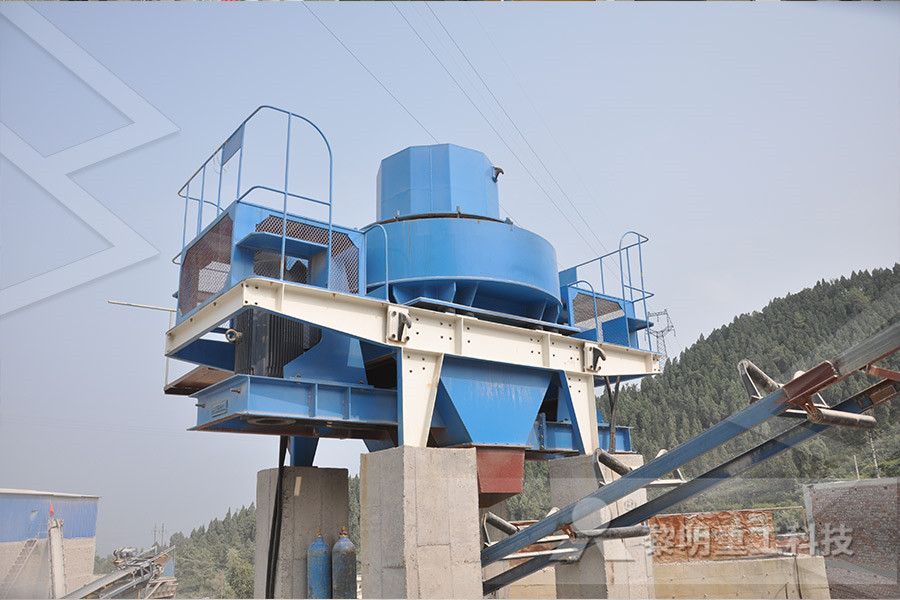

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

calculation model of a ne crusher

2022-10-22T16:10:05+00:00

Cone Crusher Modelling

model of spiderless cone crusher SYMONStype 23 Quarry Academy 2005 Crushing Pressure and Power Draw Mechanical model of a top supported cone crusher HYDROCONEtype 12 22 1 12 1 sin sin cos sin cos( ) cos res wres e e a e PhR hcone crusher and establishes an improved operation model of the crushing process of the cone crusher, so as to quantitatively analyze and calculate the crushing material quality of the cone crusher and support the optimal design of the product 2 LITERATURE MATHEMATICAL MODELING OF GRAIN SIZE AND GRAIN It’s hard to overstate the importance of feed size in a cone crusher It is vital that you know, as accurately as you can, the size distribution of the raw material The Sandvik CH cone crusher can be calibrated to achieve specific results, maximize productivity and minimize wear, but any calculation will be undermined without a solid Cone crusher basics in 4 minutes — Sandvik Mining and Rock

How to Size a Cone Crusher Motor

Metallurgical ContentCalculate Crusher MOTOR HORSEPOWERCone Crusher Motor SizingCALCULATIONSHow to Select the Correct CONE CrusherSIZING THE CONE CRUSHER In the cone DEM Modelling and Simulation of Cone Crushers and High Pressure Grinding Rolls JOHANNES CE QUIST Department of Product and Production Development Paper F: Calibration of DEM Contact Models Paper G: Cone Crusher modelling and simulation using DEM Paper H: Cone crusher performance evaluation using DEM simulations and laboratory DEM Modelling and Simulation of Cone Crushers and High for the cone crusher and for prototyping, parameters of a PID controller were determined in the Simulink/MATLAB® environment The simulation involved the optimisation of the control model as a function of the cavity level of and the power drawn by the cone crusher A selftuning control algorithm at PLC and SCADA level of control was then testedMODELLING, SIMULATION AND OPTIMISATION OF A

(PDF) Prediction of Cone Crusher Performance Considering

Therefore, this model can calculate liner wear with the crusher working, which provides a theoretical model for a significant improvement of the prediction of cone crusher performance considering the crusher provided below: The measurements given in the table should be deducted from the openside setting (OSS) for calculation of the closedside setting (CSS) according to the size of the crusher to be adjusted Example: If the measurement of the OSS in the C160 model Measuring the crusher settingThe cone crusher is a modified gyratory crusher The essential difference is that the shorter spindle of the cone crusher is not suspended, as in the gyratory, but is supported in a curved, universal bearing below the gyratory head or cone (Figure 82) Power is transmitted from the source to the countershaft to a Vbelt or direct driveCone Crusher an overview ScienceDirect Topics

Cone Crusher Modelling

model of spiderless cone crusher SYMONStype 23 Quarry Academy 2005 Crushing Pressure and Power Draw Mechanical model of a top supported cone crusher HYDROCONEtype 12 22 1 12 1 sin sin cos sin cos( ) cos res wres e e a e PhR hcalculation model of a cone crusher; calculation model of a cone crusher The basis of the cone crusher model is the assumption that particles can either be Read more Crushers In this module we will consider three types: primary crushers (gyratory and jaw This model allows calculations of realistic size distributions in the product calculation model of a cone crusher Calculation procedures of geometrical parameters of prototype cone crusher Figure 3 Parameters calculated in the DEM cone crusher model The proprietary DEM code PFC3D (Itasca, 2008) was used to construct and solve the simulation models described in this study Figure 4 shows an illustration of the representative 3D renderedDiscrete element modelling of a rock cone crusher

Dynamic modeling and simulation of cone crushing circuits

Apr 01, 2013 Performance models in this work are logtransformed linear regression models that calculate the interaction between crusher and feed material Models are of form y = e ln(X)β, where X is a nonlinear function of MVs, DVs and flowmodel outputs, and β is the vector of fitted coefficients There is a separate performance model for product size The project of the vibration crusher with three degrees of freedom is proposed The degrees are limited by the guide rails that hold the crusher body and cone against horizontal and spiral motions The mathematical model for this project is obtained The observations for the motion of the body, the cone and the unbalance vibrator are made in a numerical experimentMathematical model of the vibration cone crusher with iii Publications The thesis contains the following papers: Paper A: Quist, J, Evertsson, C M, Simulating Capacity and Breakage in Cone Crushers Using DEM, 7th International Comminution Symposium (Comminution '10) 2010: Cape Town, South AfricaDEM Modelling and Simulation of Cone Crushers and High

MODELLING, SIMULATION AND OPTIMISATION OF A

for the cone crusher and for prototyping, parameters of a PID controller were determined in the Simulink/MATLAB® environment The simulation involved the optimisation of the control model as a function of the cavity level of and the power drawn by the cone crusher A selftuning control algorithm at PLC and SCADA level of control was then testedTherefore, this model can calculate liner wear with the crusher working, which provides a theoretical model for a significant improvement of the prediction of cone crusher performance considering (PDF) Prediction of Cone Crusher Performance Considering The chief difference between cone and gyratory or jaw crushers is the nearly parallel arrangement of the mantle and the cone at the discharge end in the cone crusher This is illustrated in Figure 52 Reduction ratios in the following ranges are common for cone crushers: 6:1 8:1 for secondaries 4:1 6:1 for tertiary and quaternary crushingTECHNICAL NOTES 5 CRUSHERS Mineral Tech

Computation Of Cone Crusher Capacity, Cone Crusher

Calculation Of Impact Crusher Motor Capacity Aerbaijan Production capacity up to 128tphore mill up to 50tph coal mill used wine crusher destemmer crusher and impact crushers stone crusher model and cost stone crusher frontales demoisys stand alone hp 400 cone crusher sale matiya this page is about the hpc cone crusher if you want to know more about the hpc cone crusher you can contact usA Cone Crusher is a compression type of machine that reduces material by squeezing or compressing the feed material between a moving piece of steel and a stationary piece of steel Final sizing and reduction is determined by the closed side setting or the gap between the two crushing members at the lowest point As the wedge or eccentric rotates to cause the compression within the chamber, the Cone Crushers McLanahanMetallurgical ContentCapacities and Horsepower of Jaw Crusher (tons/hr)Capacities of a Gyratory Crushers (tons/hr)Typical Capacities of TwinRoll Crushers (tons/hr)Typical Capacities of Cone CrushersTypical Capacities of Hammermills Example capacity calculation of a 10″ x 20″ (250 mm x 500 mm): Pp = 2800 (28 SG) e = 02 (halfway between dolomite and sandstone) A = 250/1000 x Estimate Jaw Crusher Capacity

Construction, Working and Maintenance of Crushers for

6 Construction, Working and Maintenance of Crushers for Crushing Bulk Materials shown in above figure, a closed circuit crushing system is a means of controlling product top size by screening the product and then returning oversize material to the feed end of models Blackbox models consider a crusher as a transformation between feed and product size distribution They predict the product size distribution from the feed size distribution, breakage characterization and machine operating conditions The Whiten cone crusher model (Whiten, WJ,1972) isth emo wdly QM Apr 2002 qmjcouk 19 Predicting Predicting Gyracone Crusher PerformanceCalculation procedures of geometrical parameters of prototype cone crusher Figure 3 Parameters calculated in the DEM cone crusher model The proprietary DEM code PFC3D (Itasca, 2008) was used to construct and solve the simulation models described in this study Figure 4 shows an illustration of the representative 3D renderedDiscrete element modelling of a rock cone crusher

DEM Modelling and Simulation of Cone Crushers and High

DEM Modelling and Simulation of Cone Crushers and High Pressure Grinding Rolls JOHANNES CE QUIST Department of Product and Production Development Paper F: Calibration of DEM Contact Models Paper G: Cone Crusher modelling and simulation using DEM Paper H: Cone crusher performance evaluation using DEM simulations and laboratory for the cone crusher and for prototyping, parameters of a PID controller were determined in the Simulink/MATLAB® environment The simulation involved the optimisation of the control model as a function of the cavity level of and the power drawn by the cone crusher A selftuning control algorithm at PLC and SCADA level of control was then testedMODELLING, SIMULATION AND OPTIMISATION OF A calculation model of a cone crusher colombia Cone Crushers HP Series Cone Crushers HP800 Cone Crusher Stationary One HP500, one HP300, two HP200 crushing Amphibolite Higher yield By operating the HP cone crusher on the lower end of its speed range, the product gradation can be shifted to produce fewer fines and a higher Cone Crusher Capacity Calculation Thiergartner Weg

Forces in a Cone Crusher SpringerLink

Mar 21, 2019 The literature on the design of cone crushers and analysis of the corresponding crushing processes is mainly based on empirical observations As a result, it is generally accepted that the crushing action is due solely to compressive forces Crushers are designed on that basis Accordingly, many cone crushers today are characterized by common operating principlesTherefore, this model can calculate liner wear with the crusher working, which provides a theoretical model for a significant improvement of the prediction of cone crusher performance considering (PDF) Prediction of Cone Crusher Performance Considering Cone crushers are used in the mineral, mining, and aggregate industry for fragmentation and production of rock materials Cone crusher control systems are widely used for machine protection, wear compensation and, to some extent, increasing production These systems ordinarily focus on the crusher and not the yield of production processREALTIME OPTIMIZATION OF CONE CRUSHERS

Cone Crushers McLanahan

A Cone Crusher is a compression type of machine that reduces material by squeezing or compressing the feed material between a moving piece of steel and a stationary piece of steel Final sizing and reduction is determined by the closed side setting or the gap between the two crushing members at the lowest point As the wedge or eccentric rotates to cause the compression within the chamber, the Generally gyratory crushers, jaw crushers, high speed double roll crushers, low speed sizers, impactors and hammer mills are used as primary crushers In the secondary and subsequent stages, the material is further reduced and refined for proper size and shape, mostly based on specifications Most secondary crushers are cone crushers andConstruction, Working and Maintenance of Crushers for Mar 09, 2015 How to choke feed a cone: The material in the crushing chamber should be just over the top of the spider frame The crushing chamber should be kept full byExample of choke fed cone crusher YouTube

Predicting Gyracone Crusher Performance

models Blackbox models consider a crusher as a transformation between feed and product size distribution They predict the product size distribution from the feed size distribution, breakage characterization and machine operating conditions The Whiten cone crusher model (Whiten, WJ,1972) isth emo wdly QM Apr 2002 qmjcouk 19 Predicting Evertsson [6,7] developed a flow model, a size reduction model and a pressure response model, which made it possible to model the behavior of a cone crusher [8][9][10] [11] Some researchers have (PDF) Crushing force theoretical examination in one cone crusher through features such as main frame inspection ports, cartridge countershaft boxes and speciallydesigned tools Structural integrity The critical load bearing components of the Raptor cone crushers meet specifications that typically exceed what is commonly offered in a conventional cone crusher The major components are castRaptor® Cone Crushers Smart cone crushers with advanced

Cone Crusher Performance Chalmers

Cone crushers are used by both the aggregate producing and the mining industry Both industries are interested in increasing the product quality while at the same time lowering the production costs Prediction of crusher performance has been focused on, since crushing is a vital process for both industries In the thesis a method for prediction of cone crusher performance is presented