عنا

مرحبا هل يمكنني مساعدتك؟

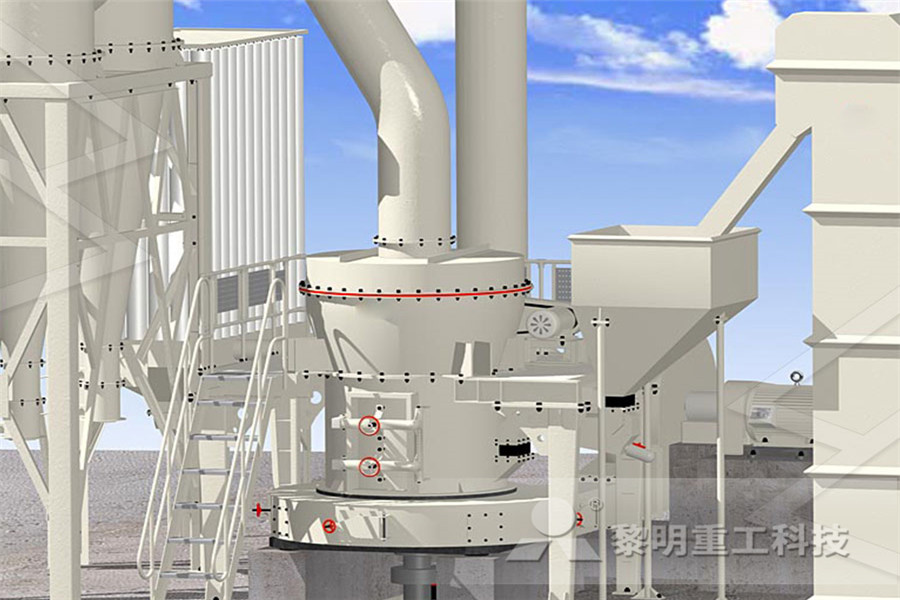

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

energy saving ball mill for flotation cell material

2020-08-13T05:08:54+00:00

Ball Mills Crushers, Ball Mills and Flotation Cells for

Energy Saving Mining Ball Mill The Energy Saving Mining Ball Mill is a new developed mill by our factory It adopts the center transmission, the rolling bearing support, side discharging, overflow discharging and grate discharging It is suitable for the grinding of the metal mines of less than 25mm feeding and 200mesh dischargingA high efficiency and energy saving ball mill with rolling bearing Capacity Up to 160t/h The features of structure and performance of the cell is similar to KYF flotation cell The difference is that there is a stator specially set above the impeller to form a special negative pressure area Magnetic system materials adopt ferrite and Xinhai Products Center XinhaiFlotation Machine, Copper Flotation Machine, Flotation Cell manufacturer / supplier in China, offering Ore Flotation Machine Price for Gold Copper Graphite Sf Kyf Xcf Bf Lab Flotation Cell Machine, Mqg600 *1800 EnergySaving Ball Mill for Gold, Copper Grinding, EnergySaving Rod Mill Power 22kw for Dry and Wet Gold Mining and so onChina Ore Flotation Machine Price for Gold Copper Graphite

(PDF) Energy Efficient Ball Mill Circuit – Equipment

The energy saving resulting from the replacement of cyclones with screens in a closed ball mill circuit was estimated to be in the range of 10 to 25% (Jankovic and Valery, 2012a) An analysis of theEnergy saving ball millcone ball milltube ball mill inguang mining machinery is a professional mining solutions and equipment manufacturere provide mining equipments such as cone ball mill, tube ball mill, dry magnetic separators, wet magnetic separators, goldcopperhematite separation machine, etc Mining Buy Electric Saving Flotation Cell PlantEnergy Saving Equipment Iron Ore Ball Mill Mining A flotation cell used for coarse and heavy particles Agitation Tank Energy Saving Ball Mill Energysaving ball mill is a high efficient and energysaving ball mill with rolling bearing Related CASES Vietnam 800t/d Graphite Mineral Processing Plant Material: * Capacity(t/d): * Graphite Processing Test Project in Tanzania xinhai

Energy efficiency • Energy intensity in copper and gold

Oct 01, 2017 Due to their relatively low energy requirements, both these mill types are also being increasingly used for secondary and tertiary grinding as replacements for ball mills [8, 9, 10] The decreasing mineral grades in the ores have also led to increased throughput rates in the flotation Cylinder EnergySaving Overflow Ball Mill An overflow ball mill with rolling bearings, high efficiency and energy saving KYF Air Inflation Flotation Cell An airinflation mechanical agitation flotation cell without slurry suction (This type of cell is designed referring to Finland Autoquenpu OK flotation cell)China Hebei 400t/d Feldspar Mineral Processing Plant xinhai[Introduction]: Energysaving ball mill is a high efficient and energysaving ball mill with rolling bearing [Capacity]: Up to 160t/h [Improvement]: Cylindrical energysaving grid ball mill is lined with the grooved ring plate which increases the contact surface of ball and ore, strengthens the grinding effect, and has the ability to improve the ore with lower energy consumptionEnergy Saving Ball Mill, Ball Mill Design, Ball Milling

Ball Mills Crushers, Ball Mills and Flotation Cells for

Energy Saving Mining Ball Mill The Energy Saving Mining Ball Mill is a new developed mill by our factory It adopts the center transmission, the rolling bearing support, side discharging, overflow discharging and grate discharging It is suitable for the grinding of the metal mines of less than 25mm feeding and 200mesh dischargingA high efficiency and energy saving ball mill with rolling bearing Capacity Up to 160t/h The features of structure and performance of the cell is similar to KYF flotation cell The difference is that there is a stator specially set above the impeller to form a special negative pressure area Magnetic system materials adopt ferrite and Xinhai Products Center XinhaiEnergy Saving Equipment Iron Ore Ball Mill Mining Flotation Cell In the future, xinhai will continue to rely on three big supporting technology, talents, management, adhere to the international development strategy, and concentrate on providing customers with modern, efficient, energysaving mine overall construction and operational solution, to create international leading enterprises in Energy Saving Equipment Iron Ore Ball Mill Mining

China Ore Flotation Machine Price for Gold Copper Graphite

Flotation Machine, Copper Flotation Machine, Flotation Cell manufacturer / supplier in China, offering Ore Flotation Machine Price for Gold Copper Graphite Sf Kyf Xcf Bf Lab Flotation Cell Machine, Mqg600 *1800 EnergySaving Ball Mill for Gold, Copper Grinding, EnergySaving Rod Mill Power 22kw for Dry and Wet Gold Mining and so onA flotation cell used for coarse and heavy particles Agitation Tank Energy Saving Ball Mill Energysaving ball mill is a high efficient and energysaving ball mill with rolling bearing Related CASES Vietnam 800t/d Graphite Mineral Processing Plant Material: * Capacity(t/d): * Graphite Processing Test Project in Tanzania xinhaiEnergy Saving Ball Mill Ball mill, an energysaving grinding device, is widely used in mineral processing, building materials and chemical industriesBall Mill machine grinds material by rotating a cylinder with steel grinding balls, causing the balls to fall back into the cylinder and onto the material Ball Mill,Ball Mills,Ball Mill Machine,Ball Grinding Mill

How is the ball mill applied to mineral grinding composed

Ball mill is widely used in the mining industry and other manufacture industries, such as cement, silicate, new building material, refractory material, fertilizer, ferrous metal, nonferrous metal and glass ceramics, it also can be used for the dry and wet grinding for all kinds of ores and other grindable materials Xinhai Energy Saving Ball Energy Saving Ball Mill Rod Mill Grid Type Ball Mill Overflow Type Ball Mill More Details where settled materials returned to the ball mill and overflow flowedby gravity to the separation process 03 the mixture flowedby gravity to the indirect flotation process comprising XCF and KYF flotation cells to remove ferric oxide and micaChina Hebei 400t/d Feldspar Mineral Processing Plant xinhaiDue to their relatively low energy requirements, both these mill types are also being increasingly used for secondary and tertiary grinding as replacements for ball mills [8, 9, 10] The decreasing mineral grades in the ores have also led to increased throughput rates in the flotation stage (Fig 15)Energy efficiency • Energy intensity in copper and gold

Mining Processing Equipment, Mining Equipment, Gold mining

The new grooved annular liner increases the ball ore contact surface, strengthens the grinding effect, and has the ability to lift the ore, reducing energy consumption; the large doublerow spherical roller bearing design can greatly reduce the friction and effectively Energy saving 2030%, and easy to start; the small ball mill with a diameter of 21 Rod Mill Flotation cell Gold Cyanide Process Gold Cyanide Process is an efficient design of extracting and recovering gold from its ore By cyaniding and carbon leaching crushed gold ore slurry simultaneously, CIL process lower the gold mining operation cost and increase gold recovery rate to a degree of 99% small gold ball mill Energy Saving Ball Mill,Small Scale Mining Ball Mill energy saving widely used metal flotation machine Energy Saving Iron Ore Coarse Grinding Ball Mill,China Gold Ore Crusher Milling 2 Ball mill is widely used in building material, and chemical industry on the original mineral processing equipment crusher, ball mill,flotation machine, cooler, coal energy saving flotation cell machine for mining magnetic

Grinder, Ball Mill, Ball Mill Machine, Grinding Mill Xinhai

Includes overflow energysaving rod mill and grid type energysaving rod mill The medium of rod mill is steel rod with selective grinding effect,even particle size of product, little over grinding; Compared with ball mill machine,rod mill can accept larger feed particle size (upper limit is 15 to 25 mm);A high efficiency and energy saving ball mill with rolling bearing Capacity Up to 160t/h The features of structure and performance of the cell is similar to KYF flotation cell The difference is that there is a stator specially set above the impeller to form a special negative pressure area Magnetic system materials adopt ferrite and Xinhai Products Center XinhaiEnergy Saving Ball Mill Ball mill, an energysaving grinding device, is widely used in mineral processing, building materials and chemical industriesBall Mill machine grinds material by rotating a cylinder with steel grinding balls, causing the balls to fall back into the cylinder and onto the material Ball Mill,Ball Mills,Ball Mill Machine,Ball Grinding Mill

Graphite Processing Test Project in Tanzania xinhai

A flotation cell used for coarse and heavy particles Agitation Tank Energy Saving Ball Mill Energysaving ball mill is a high efficient and energysaving ball mill with rolling bearing Related CASES Vietnam 800t/d Graphite Mineral Processing Plant Material: * Capacity(t/d): * 2 Working principle of energysaving ball mill: After the crushing process by the jaw crusher or the twostage closed circuit crushing system composed of jaw crushers, the materials are uniformly fed into the energysaving ball mill by the ore feeder, and then sent to classifying equipment for classifying treatment That unqualified ore that Introduction of Four Kinds of Grinding EquipmentxinhaiIncludes overflow energysaving rod mill and grid type energysaving rod mill The medium of rod mill is steel rod with selective grinding effect,even particle size of product, little over grinding; Compared with ball mill machine,rod mill can accept larger feed particle size (upper limit is 15 to 25 mm);Grinder, Ball Mill, Ball Mill Machine, Grinding Mill Xinhai

ore flotation cells machine

ore flotation cells machine Mon Sat 800 2000 Sunday CLOSED Energy Saving Ball Mill Category Belt Conveyor With High Inclination Angle And Waved Guard Side mine operation, mine materials procurement management as well as industry resources integration The new grooved annular liner increases the ball ore contact surface, strengthens the grinding effect, and has the ability to lift the ore, reducing energy consumption; the large doublerow spherical roller bearing design can greatly reduce the friction and effectively Energy saving 2030%, and easy to start; the small ball mill with a diameter of 21 Mining Processing Equipment, Mining Equipment, Gold mining ball mill operation cost Ball mills account for the majority of all mills in cement plants and therefore savings in electrical energy this measure can reduce the cost induced by wearprofessional ball mill for gold ore flotation cell

magnetite iron ore grinding ball mill machine

ball mill operation cost Ball mills account for the majority of all mills in cement plants and therefore savings in electrical energy this measure can reduce the cost induced by wearWhat you need is we can do! Xinhai Mining Technology Equipment Inc, is a stockholding high and new technology enterprise to provide the Turnkey Solution for Mineral Processing Plant; including design and research, machine manufacturing, equipment procurement, management service, mine operation, mine materials procurement management as well as industry resources integrationenergy saving grid ball mill for kaolin mobileball mill operation cost Ball mills account for the majority of all mills in cement plants and therefore savings in electrical energy this measure can reduce the cost induced by wearore dressing machine flotation cell for granulated sla

Energy Saving Equipment Iron Ore Ball Mill Mining

Energy Saving Equipment Iron Ore Ball Mill Mining Flotation Cell In the future, xinhai will continue to rely on three big supporting technology, talents, management, adhere to the international development strategy, and concentrate on providing customers with modern, efficient, energysaving mine overall construction and operational solution, to create international leading enterprises in Shandong Xinhai Mining Technology Equipment Inc was founded in 1997 Now it is a stockholding high and new technology enterprise to provide “Turnkey Solution for Mineral Processing Plant” including design and research, machine manufacturing, equipment procurement, management service, mine operation, mine materials procurement management as well as industry resources integrationmineral processing gold flotation cells,grinding ball mill copper ball mill for ore grind mozartlogeklde 2018 Hot Sale Grinding Ores Wet Ball Mill For Copper Buy The ball mill is a key equipment to grind the crushed materials, and the ball mill is widely used in powdermaking production line including cement, silicate, newtype building material, refractory material, fertilizer, ore dressing of ferrous metal and nonferrous metal, glass ceramics, etcOre Dressing Ore Gold Flotation Cell Ball Mill In