عنا

مرحبا هل يمكنني مساعدتك؟

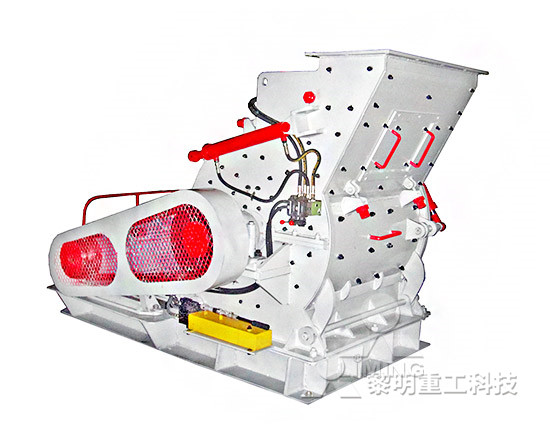

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

block diagram of stages in al handling plant

2022-03-10T04:03:47+00:00

Coal handling plant in a thermal power generating station

Mar 04, 2012 Stages in coal handeling power plant Equipment used in a coal handling plant 1 Pull chord switch A series of such switches are arranged in series at a 1m distance on the side of conveyor belt The power supply to rotor of the conveyor belt is established only if all switches in series are connected 2 Vibrating feederNov 13, 2016 The initial process in coal based thermal power plant is coal handlingThe Function of coal Handling Plant in thermal power plant is to receive , process, store, feed the coal bunkers consistently over entire life of the power plant Coal is transported in thermal power station either by railways,roadways or rope waysCoal Handling System Coal Handling Plant In Thermal Fig 2 PLC and Sensors block diagram At this stage the coal is Mined coal transportation and coal handling plant are the two major energy intensive areas of opencast coal mining which (PDF) Automation of Coal Handling Plant

Diagrams for Understanding Chemical Processes 11 Block

Nov 17, 2020 112 Block Flow Plant Diagram An example of a block flow plant diagram for a complete chemical complex is illustrated in Figure 12 This block flow plant diagram is for a coal to higher alcohol fuels plant Clearly, this is a complicated process in which there are a number of alcohol fuel products produced from a feedstock of coalThe basic layout of Coal Handling Plant is shown by block diagram (See Fig No5) the coal is unloaded at various unloading station and transported by conveyors to crushing and screening plant via transfer house After crushing required quantity of coal is transported to bunker via transfer house and remaining coal is stored in stockyard TheImplementation Of Quality Management System For Coal Mar 30, 2020 Bituminous coal is used as an energy source in many parts of the world The final stage of coal production is the anthracite stage During this stage, soft coal becomes hard coal It takes on a certain luster and is formed due to intense pressure and high temperatures Anthracite produces little smoke and is the coal most people are familiar withWhat Are the Four Stages in Coal Formation?

typical schematic diagram for coal handling plant

InService Inspection For Coal Handling Plant Of Thermal Power In the thermal power plants maximum requirements of fuel is a coal of Critical Equipments for Coal Handling Plants (CHP) of Thermal Power Stations is typical job The basic layout of Coal Handling Plant is shown by block diagram Read moreNov 17, 2020 112 Block Flow Plant Diagram An example of a block flow plant diagram for a complete chemical complex is illustrated in Figure 12 This block flow plant diagram is for a coal to higher alcohol fuels plant Clearly, this is a complicated process in which there are a number of alcohol fuel products produced from a feedstock of coalDiagrams for Understanding Chemical Processes 11 Block Fig 2 PLC and Sensors block diagram At this stage the coal is Mined coal transportation and coal handling plant are the two major energy intensive areas of opencast coal mining which (PDF) Automation of Coal Handling Plant

Implementation Of Quality Management System For Coal

The basic layout of Coal Handling Plant is shown by block diagram (See Fig No5) the coal is unloaded at various unloading station and transported by conveyors to crushing and screening plant via transfer house After crushing required quantity of coal is transported to bunker via transfer house and remaining coal is stored in stockyard TheThe coaltomethanol process used for this project typically incorporates the following process operations, shown in Figure 1 4 Fig 1 Block diagram of coaltomethanol process First, coal is preprocessed by methods such as crushing, sizing and drying to prepare it for the coal gasification process(DOC) Final Design for CoaltoMethanol Process Sheida system should be operating when there is coal flow This is done by sensing via simple mechanical under belt switch The measurement of coal flow is done by using load cell The block diagram of shown in figure no 1 will give idea about control system Figure No 1 Under belt switch Zero speed switch Spray for Con 23 Spray for Con 22 Coal FlowAn Intelligent Conveyor Control System For Coal Handling

Thermal Power Plant Block Diagram Thermal Power

The coal is burnt in the boiler and the ash produced after the complete combustion of coal is removed to the ash handling plant and the delivered to the ash storage plant for disposal Indian coal has ash content of 20% to 40% In thermal power plant bituminous coal is used because, it has low ash contentFigure: Pulverized coal handling plant showing all required equipment for unit and central system The arrangement of different equipment required in both systems is shown in figure With the help of a block diagram The coal received by the plant from the mine may vary widely in sizesPulverized coal storage in Bunker and coal handing system• Availability of Coal: Huge amount of coal is required for raising the steam Since the government policy is to use the only low grade coal with 30 to 40 % ash content for power generation purposes, the steam power plants should be located near the coal mines to avoid the transport of coal ashUNIT1 THERMAL POWER STATIONS Introduction

Coal Handling System SlideShare

Aug 21, 2016 Coal Handling System 1 Shaikh Saif COAL HANDLING SYSTEM By: Shaikh Saif 2 NECESSITY OF COAL HANDLING SYSTEM A 600MW Power Plant handles about 7200 tons of coals per day Coal handlings are to be flexible, reliable capable of handling large quantities in less time than even before Coal plays a vital role in electricity generation worldwide Coalfired power plants cur• A coal handling plant is the area of the thermal power plant where the raw coal is brought from the coal mines and is processed into a form that can fed into the boiler 1 Transportation System 2 Coal Crusher 3 Coal Storage Area 4 Pulverizer 5 Conveyers Coal Handling SystemCoal Handling Coal based power plant Excel Automation SolutionsDiagram Of Steam Power Plant Figure shows a schematic arrangement of equipment of a steam power station Coal received in coal storage yard of power station is transferred in the furnace by coal handling Steam Power Plant Components, Diagram, Working

Diagrams for Understanding Chemical Processes 11 Block

112 Block Flow Plant Diagram An example of a block flow plant diagram for a complete chemical complex is illustrated in Figure 12 This block flow plant diagram is for a coal to higher alcohol fuels plant Clearly, this is a complicated process in which there are a number of alcohol fuel products produced from a feedstock of coalCoal: In a coal based thermal power plant, coal is transported from coal mines to the generating station Generally, bituminous coal or brown coal is used as fuel The coal is stored in either 'dead storage' or in 'live storage' Dead storage is generally 40 days backup coal storage which is used when coal supply is unavailableBasic Layout and Working of a Thermal Power Plant The basic layout of Coal Handling Plant is shown by block diagram (See Fig No5) the coal is unloaded at various unloading station and transported by conveyors to crushing and screening plant via transfer house After crushing required quantity of coal is transported to bunker via transfer house and remaining coal is stored in stockyard TheImplementation Of Quality Management System For Coal

Coal Handling System SlideShare

Aug 21, 2016 Coal Handling System 1 Shaikh Saif COAL HANDLING SYSTEM By: Shaikh Saif 2 NECESSITY OF COAL HANDLING SYSTEM A 600MW Power Plant handles about 7200 tons of coals per day Coal handlings are to be flexible, reliable capable of handling large quantities in less time than even before Coal plays a vital role in electricity generation worldwide Coalfired power plants curThe basic layout of Coal Handling Plant is shown by block diagram (See Fig No 1) the coal is unloaded at various unloading station and transported by conveyors to crushing and screening plant via transfer house After crushing required quantity of coal is transported to bunker via transfer house and remaining coal is stored in stockyardInService Inspection For Coal Handling Plant Of Thermal 112 Block Flow Plant Diagram An example of a block flow plant diagram for a complete chemical complex is illustrated in Figure 12 This block flow plant diagram is for a coal to higher alcohol fuels plant Clearly, this is a complicated process in which there are a number of alcohol fuel products produced from a feedstock of coalDiagrams for Understanding Chemical Processes 11 Block

An Intelligent Conveyor Control System For Coal Handling

system should be operating when there is coal flow This is done by sensing via simple mechanical under belt switch The measurement of coal flow is done by using load cell The block diagram of shown in figure no 1 will give idea about control system Figure No 1 Under belt switch Zero speed switch Spray for Con 23 Spray for Con 22 Coal FlowFigure: Pulverized coal handling plant showing all required equipment for unit and central system The arrangement of different equipment required in both systems is shown in figure With the help of a block diagram The coal received by the plant from the mine may vary widely in sizesPulverized coal storage in Bunker and coal handing systemblock diagram of how a coal thermal plant working An Intelligent Conveyor Control System For Coal An Intelligent Conveyor Control System For Coal Handling Plant Of Thermal Power Plant By The block diagram of shown in figure no 1 will give idea about control block diagram of coal cycle in thermal power plant Chat Onlinepower plant coal conveyor coal link plc control system

Coal Handling System In Power Plant Quarry Crusher Machine

Block Diagram Of Coal Crusher And Conveyor Systems ensp0183enspb coal crusher and conveyor system block crusher and conveyor system in power plant coal handling system block crusher hp25d schematic diagram jaw crusher system conveyor block diagram crusher and conveying system diagram jaw crusher system diagram the following is a design drawing showing a brief Coal: In a coal based thermal power plant, coal is transported from coal mines to the generating station Generally, bituminous coal or brown coal is used as fuel The coal is stored in either 'dead storage' or in 'live storage' Dead storage is generally 40 days backup coal storage which is used when coal supply is unavailableBasic Layout and Working of a Thermal Power Plant Mar 07, 2021 The theory of thermal power stations or the working of the thermal power stations is very simple A power generation plant mainly consists of alternator runs with help of a steam turbine The steam is obtained from highpressure boilers Generally in India, bituminous coal, brown coal, and peat are used as fuel for the boilerThe bituminous coal is used as boiler fuel has volatile matter from Thermal Power Generation Plant or Thermal Power Station

Block Flow Diagram processdesign

Mar 01, 2015 Block Flow Plant Diagram This model of flow diagram is used to explain the general material flows throughout an entire plant They will be generalized to certain plant sectors or stages These documents would help orient workers to the products and important operation zones of a chemical facility (Peters and Timmerhaus, 2003)Aggregate Crushing Plant Layout Coal Surface Mining Crusher and 2 conveyor cuircut diagram conveyor belt diagram coal to crusher block diagram of coal crusher and conveyor systems crusher and 2 conveyor cuircut diagram diagram jaw crusher get more info image coal handling plant in a thermal power generating station a railway siding line is taken into the power station and the coalcrushing coal crushing conveyor using block diagramcoal handling unit is used Steps/Activities for coal handling: 1 coal delivery 2 coal unloading 3 coal storage: a) outdoor storage (dead storage) b) Indoor storage (live storage) 4 In the plant coal is crushed into small pieces with the help of crusher and breaker The coal is crushed to 25 cm or less 5Mr Nitin S Patil Electrical Engineering Department

coal handlingplant of 210 mw thermal power plant block diagram

FICCI – HSBC – Federation of Indian Chambers of Commerce and A typical schematic diagram of the thermal power plant is given in Figure 1 660 MW coal based super thermal power plants with ash water recycling Water from treated ash water pond is sent to ash handling plant where it is used for ash capacity of the VSTPS at Stage I is 1260 (6x 210) MW while that of StageII