عنا

مرحبا هل يمكنني مساعدتك؟

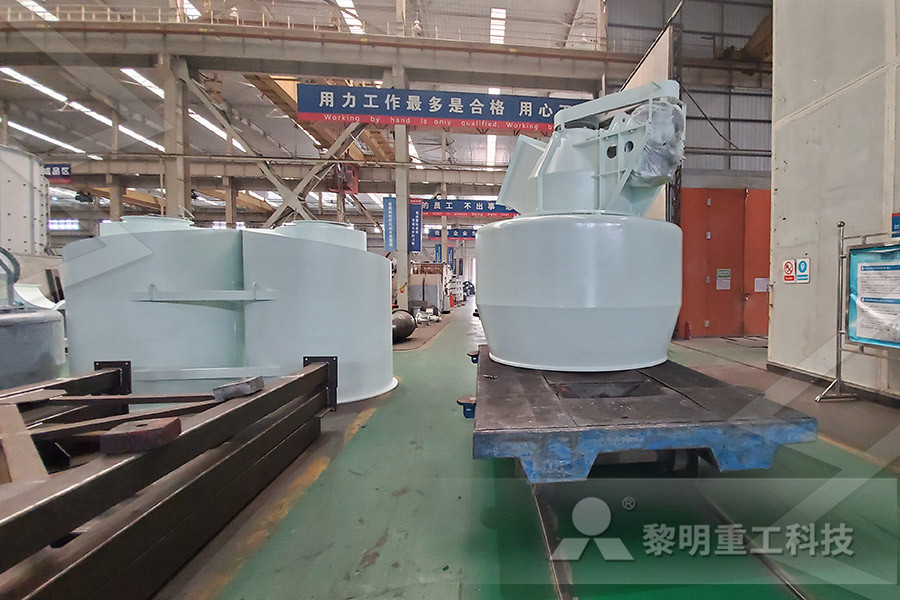

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

milling cutters and cutting fluids

2020-02-24T07:02:47+00:00

Milling Cutters and Cutting Fluids ~ Machined Parts Services

Mar 28, 2013 Milling Cutters and Cutting Fluids Milling cutters are used on the milling machine to remove material from the work piece Typically the milling cutter is revolving at a calculated speed (RPM) and work is fed to the revolving cutter at a calculated feed rateMilling with cutting fluid There are some exceptions to when cutting fluid should be used: Finishing of stainless steel and aluminum – to prevent smearing metal particles into the surface texture Milling of heat resistant alloys at low cutting speeds – to lubricate and to cool down the componentDry milling or with cutting fluid Sandvik CoromantJun 06, 2020 The cutting speed, feed, and cutting fluid should be most appropriate for the material, cutter, and milling process The cutter when should be stored properly in the racks It should be ensured that the teeth do not hit other cutters or metal partsMilling Cutter: Definition, Types in detail, Geometry

Metalworking Fluids Coolants MSC Industrial Supply

Spray foams are highperformance cutting fluids used on several types of materials It offers an adhesive property that makes the foam stick to the material for long periods of time during an application It is ideal for use with cuttersCutting Scenarios So, lets combine all these factors Let’s say I’m machining an aluminum part with a HSS cutting tool I should choose a synthetic flood coolant, since the fluid will keep the heatsensitive cutting tool cool, blast away chips with the fluidCoolant and Cutting Tools: How to Choose the Right System Mar 24, 2019 Cutting fluids are the fluids which are generally applied while the machining (or cutting) operation is taking place The machining operation can be any ie milling, turning, drilling etc Sometimes a cutting fluid is also referred as coolant but it is wrong A cutting fluid Cutting Fluids Functions, Types, Properties, Methods of

Cutting Fluid: Purposes, Properties, Types, Applications

Cutting fluid can be also used for coolant and lubrication purposes like Fatty Oil As a Flashing Action To wash off chips, to get a better surface finish; Selection of Cutting Fluid: So now let see how to select a cutting fluid for some particular operation: The selection of Cutting fluid Designed to hold your part on 4 and 5axis milling machines, these vises provide rigid clamping while exposing five full sides of the workpiece This allows even complex parts to be completed in a single operation You must cut Milling Cutters McMasterCarr40Pcs End Mill Bits Set 1/8" Shank, mcwdoit Router Bits Cutter Cutting Milling Tool (4 Type, Each 10Pcs) Including Flat Nose/Ball Nose End Mill, 20° VShape Engraving Bits and 4 Flutes End Mill 44 Milling Bits, Cutters Tools: Amazon

Acceptable cutting fluid substitutions BladeForums

Jan 06, 2009 If all you're doing is drilling a hole, you don't really have to have a cutting fluidThe only time you absolutely need it is for high pressure stuff like tapping, forming, broaching etcIn general machining it serves three functions, to keep the cutter cool (through heat transfer, not lubrication), to lubricate chips coming out of the cutMilling is a cutting process where we use a cutter to remove the material from the surface of a metal or work piece This cutter which we use has multiple rotating cutting surfaces Milling cutters play an important role in the milling process and they are used in several milling machines Milling cutters Types of Milling Cutters Used in Machining ProcessThe cutting fluid recommended for machining steel with high speed cutting tools depends largely on the severity of the operation For ordinary turning, boring, drilling, and milling on medium and low Cutting Fluids for Machining Thomasnet

Cutting Oil McMasterCarr

Apply just a few drops of these coolants to your cutting tools before and during milling and machining to reduce heat with very little cleanup Coolants for Drill Presses Use these lubricants with magnetic Mar 24, 2019 Cutting fluids are the fluids which are generally applied while the machining (or cutting) operation is taking place The machining operation can be any ie milling, turning, drilling etc Sometimes a cutting fluid is also referred as coolant but it is wrong A cutting fluid Cutting Fluids Functions, Types, Properties, Methods of Spray foams are highperformance cutting fluids used on several types of materials It offers an adhesive property that makes the foam stick to the material for long periods of time during an application It is ideal for use with cuttersMetalworking Fluids Coolants MSC Industrial Supply

Milling Bits, Cutters Tools: Amazon

40Pcs End Mill Bits Set 1/8" Shank, mcwdoit Router Bits Cutter Cutting Milling Tool (4 Type, Each 10Pcs) Including Flat Nose/Ball Nose End Mill, 20° VShape Engraving Bits and 4 Flutes End Mill 44 Aug 30, 2017 Cutting oil is oil used in machining and manufacture of metal products, which generates a great deal of heat Cutting oil is applied to the work area, to carry away some of the heat and lubricate the cutting tool, enabling a better cutting How to Make Cutting Oil eHowJan 06, 2009 If all you're doing is drilling a hole, you don't really have to have a cutting fluidThe only time you absolutely need it is for high pressure stuff like tapping, forming, broaching etcIn general machining it serves three functions, to keep the cutter cool (through heat transfer, not lubrication), to lubricate chips coming out of the cutAcceptable cutting fluid substitutions BladeForums

Geometry of Milling cutter's and Twist drills

Mar 03, 2016 Gang Milling • In gang milling a number of milling cutters are fastened to the arbor to suit the profile of the workpiece to be machined • For example, two side and face milling cutter with a slab milling cutter at the centre to mill an inverted Ushape • The advantage of gang milling Milling is a cutting process where we use a cutter to remove the material from the surface of a metal or work piece This cutter which we use has multiple rotating cutting surfaces Milling cutters play an important role in the milling process and they are used in several milling machines Milling cutters Types of Milling Cutters Used in Machining ProcessThe best cutting fluid for tapping aluminum is Heavy duty soluble oil The best cutting fluid for tapping gray cast iron is No cutting fluid at all Name the three types of taps found in a tap set The milling cutter NIMS Machining Level I Preparation Guide Milling

8 Ways You're Killing Your End Mill In The Loupe

Feb 07, 2018 7 Using a Long Length of Cut While a long length of cut (LOC) is absolutely necessary for some jobs, especially in finishing operations, it reduces the rigidity and strength of the cutting tool Aug 05, 2016 Without cutting fluid, there is no need for a coolant pump, a coolant recycling system and other expensive machine tool accessories, further reducing total costs When neardry milling with MQL, the tool’s cutting edge works inside a mist formed from oil and compressed air, which is sprayed directly into the cutting Which is better: dry or wet machining? Cutting Tool The tools required for completing an 80% lower include: Tabletop vise Router or drill press Handheld drill (if no press) Aluminum cutting fluid Canned air and a brush Gloves, ear and eye protection The optional but recommended tools include: Spare end mill Tools for Completing an 80 Percent Lower (Required

Milling machine risk assessment Dyson

Sharp edges on cutters, work pieces and swarf can cause cuts Contact with cutting fluids, oil and grease can irritate skin Swarf can jam the machine or be ejected if allowed to build up Accidental