عنا

مرحبا هل يمكنني مساعدتك؟

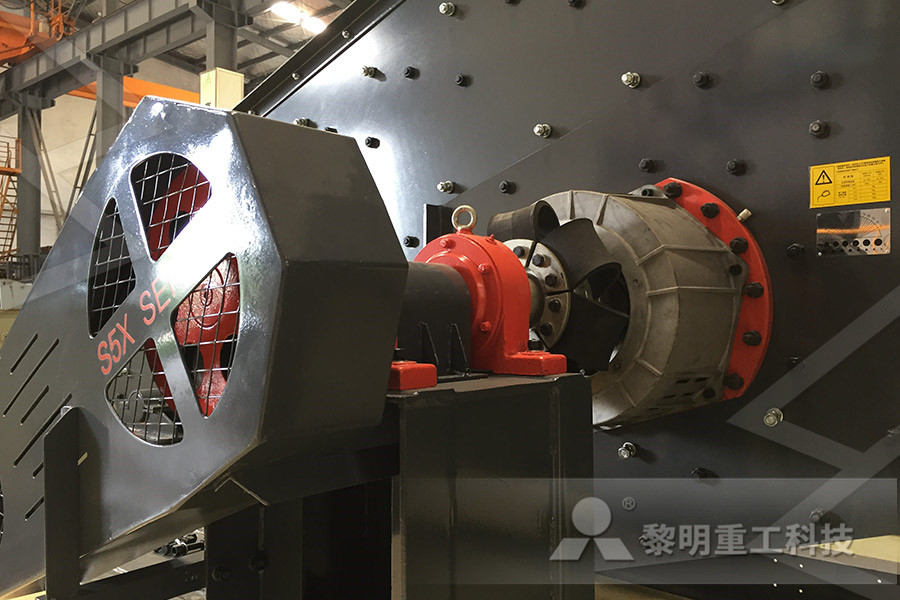

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

process of making gypsum ncentrate

2019-10-31T03:10:38+00:00

1116 Gypsum Manufacturing

A flow diagram for a typical gypsum process producing both crude and finished gypsum products is shown in Figure 11161 In this process gypsum is crushed, dried, ground, and calcined Not all of the operations shown in Figure 11161 are performed at all gypsum plants Some plants produce only wallboard, and many plants do not produce soil Sep 26, 2017 Gypsum is a common mineral found in many places around the world The scientific name for raw gypsum is anhydrous calcium sulphate Gypsum contains a large amount of water in crystalline form The process of making gypsum products involves removal of the moisture content from the raw ore and reintroducing the How to Make Gypsum Products BizfluentGypsum is a particularly useful processed material Its main application is as a building material, mostly produced as socalled plaster of Paris for plastering walls and making decorative features in buildings However gypsum also has a diversity of other uses including making writing chalk, soil conditioning for agriculture, makingGypsum processing and use Humanitarian Library

Separation of Gypsum by the Flotation Process

In the latter, moreover, it was acertained that the rate of flotation was up to arround 86%, with the results that the concentrate contained about 4048% gypsum, in which dihydrate was 883%, and The main purpose of adding gypsum in the cement is to slow down the hydration process of cement once it is mixed with water The process involved in hydration of cement is that, when the water is added into cement, it starts reacting with the C3A and hardensRole of Gypsum in Cement and its Effects The ConstructorFruit Juice Concentrate is the concentrated form of a freshly squeezed Fruit Juice which is produced by concentrating the fruit juice by evaporating (removing) some part of the water inside Fruit Juice Concentrate production on industrial scale starts with the transportation of harvested fresh fruits to the fruit juice concentrate production facilityProduction Process of Fruit Juice Concentrates

How It Made: Step By Step Gypsum Board False Ceiling Tips

Jun 26, 2018 Gypsum board is factorymanufactured from gypsum with water and a few additives, sandwiched between paper When gypsum is semidehydrated by heating, it forms plaster of paris or POP, a quicksetting fine white powder, which has many uses, including making false ceilings on siteThere are two ways to make juice concentrate from fruit They depend on the type of fruit you are using For wetter, easily juiceable fruits, go to Step 1: Frozen Concentrate Good for oranges, lemons, many other fruits if you have a juicer For fruits that will be a pain to juice, go to Step 2: Boiled ConcentrateJuice Concentrate From Fruit : 3 Steps (with Pictures Dec 18, 2019 Easy DIY Steps for Making Cannabis Concentrate with Everclear (HighProof Alcohol) For this first method on how to make weed concentrate using alcohol, we’ll discuss the process when using 95% (190proof) Everclear alcohol, as this is probably the most common technique (Everclear is fairly easily available in most US states)Make Your Own Cannabis Concentrates Using Alcohol Extraction

1116 Gypsum Manufacturing

A flow diagram for a typical gypsum process producing both crude and finished gypsum products is shown in Figure 11161 In this process gypsum is crushed, dried, ground, and calcined Not all of the operations shown in Figure 11161 are performed at all gypsum plants Some plants produce only wallboard, and many plants do not produce soil Sep 26, 2017 Gypsum is a common mineral found in many places around the world The scientific name for raw gypsum is anhydrous calcium sulphate Gypsum contains a large amount of water in crystalline form The process of making gypsum products involves removal of the moisture content from the raw ore and reintroducing the How to Make Gypsum Products BizfluentApr 22, 2020 in this video we visit in the gypsum factory and showing process of gypsum powder in this video we visit in the gypsum factory and showing process of gypsum powderHow to make Gypsum powder YouTube

Making Gypsum Board – Gypsum Association

A notforprofit trade association founded in 1930, promoting the use of gypsum while advancing the development, growth, and general welfare of the gypsum industry in the United States and Canada on behalf of its member companiesMay 12, 2015 scalability still make the dihydrate process the most widely used technique1 Immediately after the reactive crystallization step, filtration is carried out to separate acid from gypsum crystals The overall productivity is closely correlated to the efficiency of the filtration step, which highly depends on the crystal shape and size Gypsum Crystallization during Phosphoric Acid Production 1 tsp Calcium Sulfate (gypsum) 230 ml warm tap water Use cotton plugs and paper bags over plugs and autoclave for 45 minutes at 121°C Fast Exhaust PLEUROTUS RYE SPAWN In making spawn for Pleurotus, substitute same amount of Calcium Carbonate (lime) INSTEAD of Calcium Sulfate (gypsum)Spawn Preparation — Department of Plant Pathology and

Gypsum Wallboard Chemical Additives

Gypsum wallboard consists of a hardened gypsum containing core surfaced with paper or other fibrous material suitable to receive a coating such as paint It is common to manufacture gypsum wallboard by placing an aqueous core slurry comprised predominantly of calcined gypsum between two sheets of paper thereby forming a sandwich structurebuilding gypsum materials,16,17) fireproof panels,18,19) and slagmaking material,20) etc However, the utilization rate of gypsum waste through these methods is low, typically less than 50%20) The decomposition of CaSO 4 is a function of temperature, O 2 and SO 2 partial pressures 21) The thermal degradation of CaSO 4 (Eqs (1) and (2)) in Transformation Behaviour of Sulfur from Gypsum Waste 4 Jan 15, 2021 A brackish water reverse osmosis concentrate consisting of 4170 mg/L total dissolved solids (TDS) and a gypsum saturation ratio (SR) of 152, was treated to a volumetric recovery of 965% in a total recycle process utilising hydrated lime and CO 2 induced precipitation reactors and nanofiltration (NF) separation units A chemical model that incorporates PHREEQC COM v3 and the Process for high recovery treatment of brackish water

(PDF) Nonthermal Process for Recovering Reverse Osmosis

The PRO concentrate was obtained from the RO process of the direct drinking water preparation system designed for the 29th Olympic Games with 50% recovery pH adjustment to 1010, 5 g/L calcite The mixture then sent to final grinding process For ordinary Portland cement it remains between 3 to 4% and in case of Quick setting cement it can be reduced up to 25% Role of Gypsum in Cement The main purpose of adding gypsum in the cement is to slow down the hydration process of cement once it is mixed with waterRole of Gypsum in Cement and its Effects The ConstructorFruit Juice Concentrate is the concentrated form of a freshly squeezed Fruit Juice which is produced by concentrating the fruit juice by evaporating (removing) some part of the water inside Fruit Juice Concentrate production on industrial scale starts with the transportation of harvested fresh fruits to the fruit juice concentrate production facilityProduction Process of Fruit Juice Concentrates

USA Copper smelting process Google Patents

A copper smelting process is disclosed in which copper concentrate is smelted in a furnace to produce purified copper Flue gas discharged from the furnace is treated to produce sulfuric acid Furthermore, waste liquid discharged during the production of sulfuric acid is treated to produce gypsum, and the gypsum thus produced is recycled to the furnace as a fluxGypsum plaster, white cementing material made by partial or complete dehydration of the mineral gypsum, commonly with special retarders or hardeners added Applied in a plastic state (with water), it sets and hardens by chemical recombination of the gypsum with water For especially hard finishGypsum plaster building material BritannicaA flow diagram for a typical gypsum process producing both crude and finished gypsum products is shown in Figure 11161 In this process gypsum is crushed, dried, ground, and calcined Not all of the operations shown in Figure 11161 are performed at all gypsum plants Some plants produce only wallboard, and many plants do not produce soil 1116 Gypsum Manufacturing

How Gypsum is Made AWCI

How Gypsum is Made Editor’s Note: The following article is based on information supplied by Gold Bond It describes Gold Bond’s manufacturing process Other gypsum manufacturers may differ in certain characteristics from the process described below Chemists call it CaSO 42H 2O It’s found in the pyramids of Egypt as wellSep 26, 2017 Gypsum is a common mineral found in many places around the world The scientific name for raw gypsum is anhydrous calcium sulphate Gypsum contains a large amount of water in crystalline form The process of making gypsum products involves removal of the moisture content from the raw ore and reintroducing the How to Make Gypsum Products BizfluentThe group reported that gypsum actually forms in a threestep process: precipitation of nanocrystals of bassanite — or calcium sulfate hemihydrate, with one water molecule for every two calcium sulfate units — followed by the assembly of those crystals into larger aggregates, and finally transformation of the aggregates into gypsumThe path to gypsum is four steps long EARTH Magazine

Making Gypsum Board – Gypsum Association

A notforprofit trade association founded in 1930, promoting the use of gypsum while advancing the development, growth, and general welfare of the gypsum industry in the United States and Canada on behalf of its member companies1 tsp Calcium Sulfate (gypsum) 230 ml warm tap water Use cotton plugs and paper bags over plugs and autoclave for 45 minutes at 121°C Fast Exhaust PLEUROTUS RYE SPAWN In making spawn for Pleurotus, substitute same amount of Calcium Carbonate (lime) INSTEAD of Calcium Sulfate (gypsum)Spawn Preparation — Department of Plant Pathology and 1 A method of making a moldresistant gypsum product comprising: forming a slurry of calcined gypsum, water in excess of the amount needed to hydrate all of the calcined gypsum to form calcium sulfate dihydrate, and at least 100 ppm of a water soluble pyrithione salt calculated as the equivalent sodium salt and based on the weight of the calcined gypsum; depositing the slurry on a sheet of Moldresistant gypsum panel and method of making same

Transformation Behaviour of Sulfur from Gypsum Waste 4

building gypsum materials,16,17) fireproof panels,18,19) and slagmaking material,20) etc However, the utilization rate of gypsum waste through these methods is low, typically less than 50%20) The decomposition of CaSO 4 is a function of temperature, O 2 and SO 2 partial pressures 21) The thermal degradation of CaSO 4 (Eqs (1) and (2)) in Mix the fruit juice and concentrate with half the sugar and enough water to produce a total volume of 65 pints (37 litres) Add the gypsum, acid, tannin and a vigorous sherry flor yeast Gypsum (calcium sulphate) starter of not more than 075 pint (425 ml) volume Transfer to a demijohn and fit an airlockMaking sherry at home Home Winemaking making wine at Gypsum is an evaporite mineral most commonly found in layered sedimentary deposits in association with halite, anhydrite, sulfur, calcite, and dolomite Gypsum (CaSO 4 2H 2 O) is very similar to Anhydrite (CaSO 4) The chemical difference is that gypsum contains two waters and anhydrite is without water Gypsum is the most common sulfate mineralGypsum Mineral Uses and Properties

what is the process of making gypsum ceiling

How to Make Gypsum Products The process of making gypsum products involves removal of the moisture content from the raw ore and reintroducing the moisture in Patent US Gypsum plaster and process Gypsum plaster and process of making the same US A Abstract available in Images (4) Making Gypsum Ceiling Board Equipment,The PRO concentrate was obtained from the RO process of the direct drinking water preparation system designed for the 29th Olympic Games with 50% recovery pH adjustment to 1010, 5 g/L calcite (PDF) Nonthermal Process for Recovering Reverse Osmosis Gypsum is a slowrelease source of sulphur and calcium which play a key role in improving soil structure, aeration and water retention So you can grow better, healthier cropsWhen Gypsum dissolves, it releases equal proportions of calcium and sulphate Calcium sulphate improves the structure and consistency in soil and most other growing media allowing better water penetration and retention Gypsum Tui Garden

Role of Gypsum in Cement and its Effects The Constructor

The mixture then sent to final grinding process For ordinary Portland cement it remains between 3 to 4% and in case of Quick setting cement it can be reduced up to 25% Role of Gypsum in Cement The main purpose of adding gypsum in the cement is to slow down the hydration process of cement once it is mixed with water