عنا

مرحبا هل يمكنني مساعدتك؟

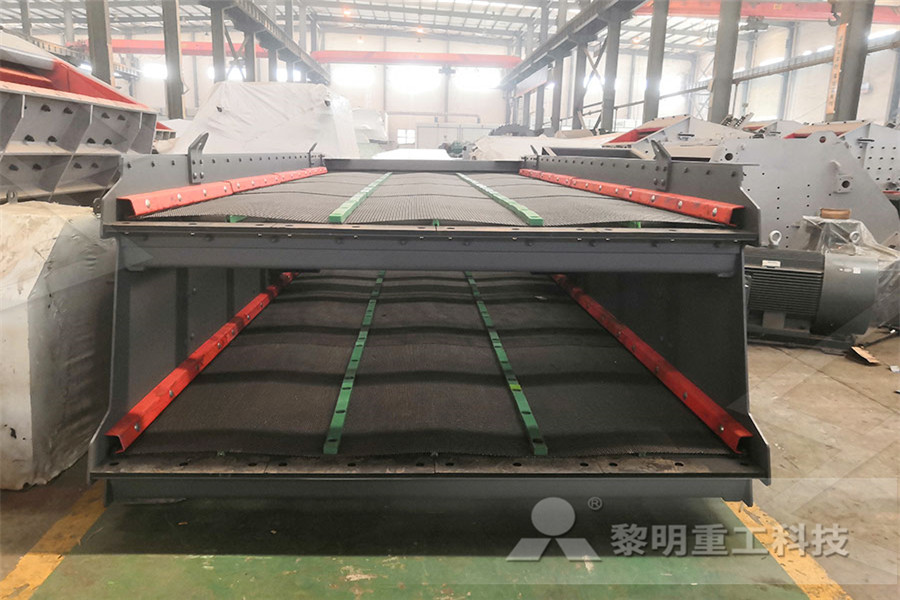

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

ball mill internal design

2019-04-08T15:04:15+00:00

Ball Mill Application and Design Paul O Abbe

Ball mills are simple in design, consisting of horizontal slow rotating vessels half filled with grinding media of ¼” to 15” The particles to be milled are trapped between the grinding media or balls and are reduced in size by the actions of impact and attritionBall Mill Design A survey of Australian processing plants revealed a maximum ball mill diameter of 524 meters and length of 884 meters (Morrell, 1996) Autogenous mills range up to 12 meters in diameter The lengthtodiameter ratios in the previous table are for normal applicationsAMIT 135: Lesson 7 Ball Mills Circuits – Mining Mill A) Total Apparent Volumetric Charge Filling – including balls and excess slurry on top of the ball charge, plus the interstitial voids in between the balls – expressed as a percentage of the net internal mill volume (inside liners) B) Overflow Discharge Mills operating at low ball fillings – slurry may accumulate on top of the ball charge; causing, the Total Charge Filling Level to How to Size a Ball Mill Design Calculator Formula

(PDF) DESIGN AND FABRICATION OF MINI BALL MILL

May 30, 2016 Ball mill is a cylindrical device that used to grind and blend raw materials and it rotates around a horizontal axis, partially filled with the material to be ground plus the grinding mediumTo ensure the stability of the mini ball mill, a ball mill base is design and fabricate to withstand the weight of the rotating jar, motor and gears After a few hours, stop the mini ball mill and(PDF) DESIGN AND FABRICATION OF MINI BALL MILL A ball mill is a type of grinder used to grind and blend bulk material into QDs /nanosize using different sized balls The working principle is simple; impact and attrition size reduction take place as the ball drops from near the top of a rotating hollow cylindrical shellBall Mills an overview ScienceDirect Topics

What's the Difference Between SAG Mill and Ball Mill

Ball mills are fine grinders, have horizontal ball mill and vertical ball mill, their cylinders are partially filled with steel balls, manganese balls, or ceramic balls The material is ground to the required fineness by rotating the cylinder causing friction and impactBall mills are simple in design, consisting of horizontal slow rotating vessels half filled with grinding media of ¼” to 15” The particles to be milled are trapped between the grinding media or balls and are Ball Mill Application and Design Paul O AbbeSince for the ball mill design we are using 80% passing, the required value of C2 for the ball mill will be equal to120 C3 is the correction factor for mill diameter and is given as; 𝐶𝐶3 = 244 𝐷𝐷 02 (3) However, it is important to note that C3 =0914 vessel used in producing the ball mill Design, Construction and Performance Analysis of a 5

Design Method of Ball Mill by Sumitomo Chemical Co, Ltd

Design Method of Ball Mill by Discrete Element Method collected The diameter of the gibbsite powder was measured using a Master Sizer 2000 (Sysmex Corporation) Details of the experimental conditions are given in Table 2 Results and Discussion 1 Effects of Fins on Ball Motion in the Mill To predict ball mill The design of a ball mill can vary significantly depending on the size, the The internal energy potential of techno genic raw materials is determined by its defective structure, which (PDF) Grinding in Ball Mills: Modeling and Process ControlTo participate in the 911Metallurgist Forums, be sure to JOIN LOGIN Use Add New Topic to ask a New Question/Discussion about Grinding OR Select a Topic that Interests you Use Add Reply = to Standards for design and sizing ball mill Grinding

Comparing ball and vertical mills performance: An

the ball mills It was expected a loss on mills performance as predicted by grinding tests, showed on Figure 8 Figure 8 Comparison to standard charge and balls scraps Thankfully, the performance of the vertical mill was still better than the ball millsThe ball mill adopts a discharge screen similar to the ball mill, and the function of blocking the internal medium of the overflow ball mill is accomplished inside the rotary part of the ball mill The discharge screen is only responsible for forcing out a small amount of the medium that overflows into the discharge screen through the internal What's the Difference Between SAG Mill and Ball Mill The geometry of a mill with conical ends is shown in Figure 86 The total volume inside the mill is given by Vm 4 D2 mL 1 2(Lc L) L 1 (Dt/Dm) 3 1 Dt/Dm (816) The density of the charge must account for all of the material in the mill including the media which may be steel balls in a ball millTECHNICAL NOTES 8 GRINDING R P King

Difference Between Sag Mill vs Ball Mill mech4study

Oct 12, 2017 The ball charge of a SAG mill is about 29% to 30% By friction and influence of tumbling balls inside rotating cylinder grinds the raw material to the required fineness The internal machinery of ball mill Beaver Mills Design Inc is a family owned and operated business We offer a curated collection of quality antiques, custom home design services, and are a Farrow Ball paint and wallpaper stockist Our Beaver Mills Design Interior Design Ontariointernal mill diameter Ball mills are usually the largest consumers of energy within a mineral concentrator Comminution is responsible for 50% of the total mineral processing cost In today’s global markets, expanding mining groups are trying Mill speed Soft design Aggressive designOptimization of mill performance by using

Ball Mill Court Project • Before and After — Morse Design

May 04, 2019 Atlanta Interior Design Ball Mill Court Project • Before and After One of my most favorite projects to date was renovating a powder bath We took a bathroom that was traditional and Ball mills are simple in design, consisting of horizontal slow rotating vessels half filled with grinding media of ¼” to 15” The particles to be milled are trapped between the grinding media or balls and are Ball Mill Application and Design Paul O AbbeJun 20, 2019 Learn how a ball mill works, all of its main parts and some of its design features! This 3D animated video allows you to see all the internal parts of a ballHow Ball Mills Work (Engineering and Mining) YouTube

Design, Construction and Performance Analysis of a 5

Since for the ball mill design we are using 80% passing, the required value of C2 for the ball mill will be equal to120 C3 is the correction factor for mill diameter and is given as; 𝐶𝐶3 = 244 𝐷𝐷 02 (3) However, it is important to note that C3 =0914 vessel used in producing the ball mill Design Method of Ball Mill by Discrete Element Method collected The diameter of the gibbsite powder was measured using a Master Sizer 2000 (Sysmex Corporation) Details of the experimental conditions are given in Table 2 Results and Discussion 1 Effects of Fins on Ball Motion in the Mill To predict ball mill Design Method of Ball Mill by Sumitomo Chemical Co, Ltd May 04, 2019 Atlanta Interior Design Ball Mill Court Project • Before and After One of my most favorite projects to date was renovating a powder bath We took a bathroom that was traditional and Ball Mill Court Project • Before and After — Morse Design

Ball Milling University of Massachusetts Boston

Design Safer Chemicals Planetary ball mills 9 Vibration Mills 10 Mixer Mill MM 400 11 Feed material: hard, mediumhard, soft, brittle, elastic, fibrous Material feed size: ≤ 8 mm Final fineness: ~ 5 Aug 10, 2020 Ball mills are a special instrument used to break up hard solids into a fine powder They are similar to rock tumblers in that the instrument is a rotating container filled with heavy balls to grind the substance into powder Ceramic material, crystalline compounds, and even some metals can be ground up using a ball millHow to Make a Ball Mill: 12 Steps (with Pictures) wikiHowThe ball mill adopts a discharge screen similar to the ball mill, and the function of blocking the internal medium of the overflow ball mill is accomplished inside the rotary part of the ball mill The discharge screen is only responsible for forcing out a small amount of the medium that overflows into the discharge screen through the internal What's the Difference Between SAG Mill and Ball Mill

Beaver Mills Design Interior Design Ontario

Beaver Mills Design Inc is a family owned and operated business We offer a curated collection of quality antiques, custom home design services, and are a Farrow Ball paint and wallpaper stockist Our MILL CASA Interior Design 153 likes Big city style with small town vibes in Lake Mills, WI (travel clients encouraged) Express rather than impress with me and I can guarantee you'll want to showMILL CASA Interior Design Home Facebookhttps://911metallurgist/blog/ballmill Learn about Ball Mill Critical Speed and its effect on inner charge movements The effect of Ball Mill RPM sBall Mill Critical Speed Working Principle YouTube

Quick and Easy Black Powder Ball Mill — Skylighter, Inc

BallMill Base with Ventilated MotorCover Installed BallMill Base with Ventilated MotorCover Removed The BallMill Drive System Looking inside the mill's motor compartment, you can now see The design of a ball mill can vary significantly depending on the size, the equipment used to load the starting material (feeders), and the system for discharging the output product The size of a mill is Grinding in Ball Mills: Modeling and Process Control