عنا

مرحبا هل يمكنني مساعدتك؟

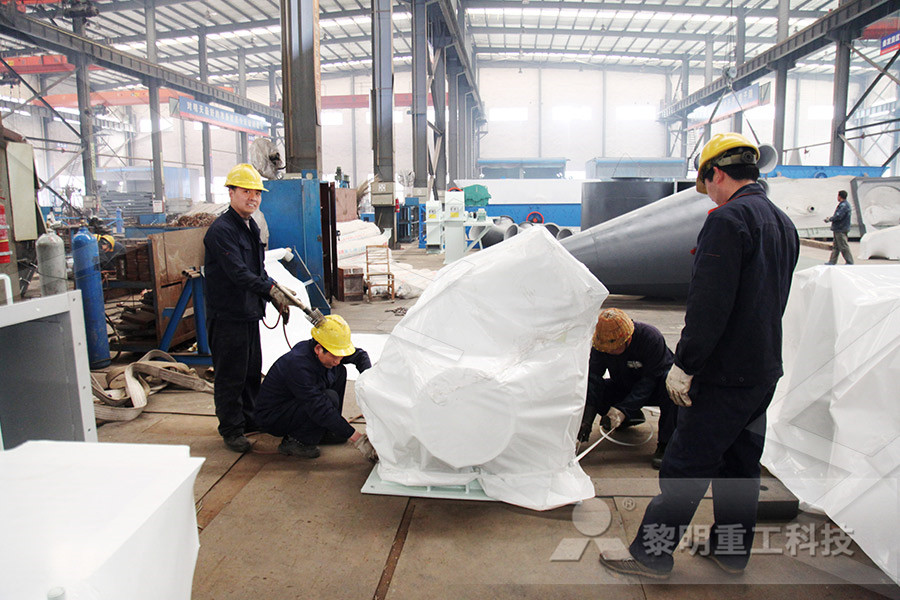

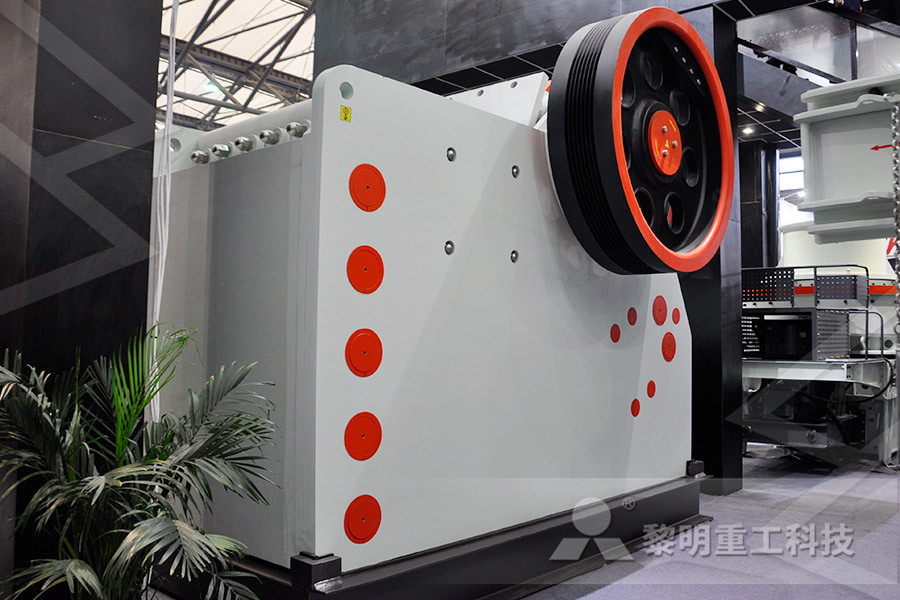

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

pper and nickel flotation equipment

2019-10-04T02:10:35+00:00

Copper Nickel Flotation

Table of ContentsRaw OrePit Ore SampleShaft Ore SampleLaboratory Copper Nickel Ore Flotation Pit Sample ProcedureResultsShaft SampleBatch Copper Nickel Flotation All the flotation testwork was done using the Denver laboratory machine with a 15l stainless steel flotation cell The required mass of nickelcopper sulphide ore material ground to 70% passing 75 µm was weighed and placed in the flotation cell This was followed by the addition of distilled water to aboutFlotation of NickelCopper Sulphide Ore: Optimisation of Separation of the bulk concentrate copper and nickel minerals is generally accomplished by flotation of the copper from pentlandite and nickelbearing iron sulphides which report to the flotation tails Pentlandite and iron sulphides are depressed by raising the pH CopperNickel ores Danafloat

Nickel Ore Mining Process

【Process Description】 Crushing equipment and Screening Equipment in Mining Process Mixing Flotation Process The mixing flotation process is to separate nickel ore in which copper has lower content than Nickel, the mixed concentrate of copper and nickel will smelt into high grade nickel Copper nickel ore flotation process: Use collector and foaming agent in the flotation of nickel ore with copper sulfide The principle for determine the flotation process is avoid the nickel goes into the copper concentrate as possible When copper grade is higher than nickel, we could separate copper as copper Nickel Ore processing Yantai Jinpeng Mining equipment A typical example of a nickel sulRde plant operating with highly Soatable talcose gangue is at Trojan mineinZimbabweTheZimbabweansulRdedeposits contain very low grades of nickel (06%) and copper (004}04%) The easily Soatable nonsulRde minerals dilute the grade of the concentrate and also result in nickel losses into the tailings This NICKEL AND COBALT ORES: FLOTATION

nickel and copper flotation Hotel Kottaram

copper and nickel flotation equipment Copper Ore Processing Equipment Capacity: 0187 (m ³/min) Suitable Materials: Copper, zinc, lead, nickel, gold and other nonferrous metals, ferrous and nonmetal Major Equipment: Jaw crusher, ball mill, sprial classifier, flotation machine, concentrator Get PriceAlibaba features a broad selection of optimal quality copper flotation equipment that work with high precision and make your work easier Grab these copper flotation equipment at low prices flotation machine for Ores concentrate separation plant Mining copper lead zinc nickel molybdenum Up to 5 years warranty US $5000$8000 / Set 1 High Precision, Advanced copper flotation equipment A Comparative Study of Kinetics of Flotation of a CopperNickel Ore by time t It is generally accepted that froth flotation follows first order kinetics, and n is equal to 1 The rate expression therefore becomes dC = kC (2) dt This may be integrated over the limits c, A Comparative Study of Kinetics of Flotation of a Copper

Nickel Ore Mining Process

【Process Description】 Crushing equipment and Screening Equipment in Mining Process Mixing Flotation Process The mixing flotation process is to separate nickel ore in which copper has lower content than Nickel, the mixed concentrate of copper and nickel will smelt into high grade nickel A typical example of a nickel sulRde plant operating with highly Soatable talcose gangue is at Trojan mineinZimbabweTheZimbabweansulRdedeposits contain very low grades of nickel (06%) and copper (004}04%) The easily Soatable nonsulRde minerals dilute the grade of the concentrate and also result in nickel losses into the tailings This NICKEL AND COBALT ORES: FLOTATIONShandong 500t/d Copper Lead and Zinc Ore Bulk Flotation Project Ore Property: Shandong client commissioned Xinhai Mine Research Institute to conduct ore dressing experiment after collected 50kg samples on the scene After tested the ore properties of sample ore, Xinhai lab concluded that the main metal minerals of the project were copper, lead, zinc, and a certain amount of magnetiteCopper Flotation, Extraction of Copper, Copper Processing

Smelting of NickelCopper and Nickel Sulfide

Collectors and foamers are often used for flotation of copper sulfide ores A basic principle for determining flotation process is that copper can enter nickel concentrate rather than nickel Because the nickel in the copper concentrate is lost greatly in the smelting process, and the copper in the nickel concentrate can be recovered completelyMixingpreferably Flotation then Nickel Recovery: When floatability difference happens to the various nickel elements in the raw ore, the nickel ore can be recycled from tailings after the copper and nickel did the mixing flotation Copper Nickel Ore Flotation Process: A basic principle of coppersulfide nickel ore process is that it is better Nickel Ore Mineral ProcessingFroth flotation is a process for selectively separating hydrophobic materials from hydrophilicThis is used in mineral processing, paper recycling and wastewater treatment industries Historically this was first used in the mining industry, where it was one of the great enabling technologies of the 20th centuryFroth flotation Wikipedia

Mineral processing Wikipedia

Other equipment used historically includes the hutch, a trough used with some oredressing machines and the keeve or kiekkkve, a large tub used for differential settlement Froth flotation cells used to concentrate copper and nickel sulfide minerals, Falconbridge, Ontario The flotation columns are used for finer minerals and they Nickel Mineral Ore Dressing Line, Jaw Crusher, Cone Crusher manufacturer / supplier in China, offering Nickel Mineral Ore Dressing Line for Processing Copper Nickel Ore, 2021 Cheap Price Africa Diamond Gold Washing Plant Machine for Sale, High Recovery Rate Gold Mining Equipment 510 Tph Rock Gold Wash Plant Small Scale Gold Processing Plant and so onNickel Mineral Ore Dressing Line for Processing Copper Nickel processing Nickel processing Extraction and refining: The extraction of nickel from ore follows much the same route as copper, and indeed, in a number of cases, similar processes and equipment are used The major differences in equipment are the use of highertemperature refractories and the increased cooling required to accommodate the higher operating temperatures in nickel Nickel processing Extraction and refining Britannica

Ore Processing Equipment Of Nickel Flotation Machine Price

Ore Processing Equipment Of Nickel Flotation Machine Price beneficiation methods the most important is the flotation magnetic and reelection is usually secondary dressing method Flotation copper sulfide nickel ore often used in the flotation of copper sulphide minerals collector and frother A basic principle for determining the flotation At the beginning, you need to prepare an ore composed of copper and nickel Then, find some equipment to crush and grind the ore, and separate out the worthless material by the method of flotation, which will leave you a concentrate that typically composed by 2%10% nickel and 5%20% copper The Best Way to Separate Copper and NickelNov 01, 2009 Process mineralogy of coppernickel sulphide flotation by a cyclonicstatic microbubble flotation column Raw ore grade Concentrate grade Tailings grade Recovery Test equipment Ni Cu Ni Cu MgO Ni Cu Ni Cu Flotation column 044 034 821 364 747 020 024 5524 3132 Flotation machine 044 034 502 222 800 025 027 4471 2526 3 Process mineralogy of coppernickel sulphide flotation by

Nickel Ore Mining Process

【Process Description】 Crushing equipment and Screening Equipment in Mining Process Mixing Flotation Process The mixing flotation process is to separate nickel ore in which copper has lower content than Nickel, the mixed concentrate of copper and nickel will smelt into high grade nickel A typical example of a nickel sulRde plant operating with highly Soatable talcose gangue is at Trojan mineinZimbabweTheZimbabweansulRdedeposits contain very low grades of nickel (06%) and copper (004}04%) The easily Soatable nonsulRde minerals dilute the grade of the concentrate and also result in nickel losses into the tailings This NICKEL AND COBALT ORES: FLOTATIONMixingpreferably Flotation then Nickel Recovery: When floatability difference happens to the various nickel elements in the raw ore, the nickel ore can be recycled from tailings after the copper and nickel did the mixing flotation Copper Nickel Ore Flotation Process: A basic principle of coppersulfide nickel ore process is that it is better Nickel Ore Mineral Processing

Nickel processing Extraction and refining Britannica

Nickel processing Nickel processing Extraction and refining: The extraction of nickel from ore follows much the same route as copper, and indeed, in a number of cases, similar processes and equipment are used The major differences in equipment are the use of highertemperature refractories and the increased cooling required to accommodate the higher operating temperatures in nickel At the beginning, you need to prepare an ore composed of copper and nickel Then, find some equipment to crush and grind the ore, and separate out the worthless material by the method of flotation How can I seperate copper from nickel? ResearchGateOther equipment used historically includes the hutch, a trough used with some oredressing machines and the keeve or kiekkkve, a large tub used for differential settlement Froth flotation cells used to concentrate copper and nickel sulfide minerals, Falconbridge, Ontario The flotation columns are used for finer minerals and they Mineral processing Wikipedia

Nickel Mineral Ore Dressing Line for Processing Copper

Nickel Mineral Ore Dressing Line, Jaw Crusher, Cone Crusher manufacturer / supplier in China, offering Nickel Mineral Ore Dressing Line for Processing Copper Nickel Ore, 2021 Cheap Price Africa Diamond Gold Washing Plant Machine for Sale, High Recovery Rate Gold Mining Equipment 510 Tph Rock Gold Wash Plant Small Scale Gold Processing Plant and so onNorilsk Nickel’s Siberian operations include two ore concentrators, capable of treating 11Mt/y of ore, and three smelters with a combined capacity of 350,000t of copper and 160,000t of nickel Sulphide ores are first preconcentrated using heavymedium separation, then treated by flotation to recover copper and nickel concentrates for smelter Norilsk Mining Centre Mining Technology Mining News cone crusher is widely used in the nickel ore crushing It has standard cone crusher and short head cone crusher They have been used as a nickel ore crushercoppernickel sulfide ore beneficiation

Flotation Developments Best Practice International Mining

Huntsman Performance Products has developed The POLYMAX®T10 and POLYMAX T12 low molecular weight liquid dispersants that have been shown to improve mineral recoveries and concentrate grades in the flotation of copper, copper gold, gold, carbonaceous gold, nickel, phosphate ores and coalFlotation of nickelcopper sulphide ore optimisation of the flotation recovery of ni cu and co from a nickelcopper sulphide orethe effect on flotation performance of various parameters such as ph collector dosage solids and depressant dosage at different levels was investigatedCopper Sulphide Ore Reagents For Copper FlotationRio Tinto discovered the Eagle nickelcopper mine in 2002 and conducted the feasibility study in 2007 Lundin Mining acquired the mine from Rio Tinto in 2013 for a cash consideration of approximately $315m In addition to the underground mine, Lundin also gained control of the historic Humboldt mill site and the mineral, water, access and surface rights around the mineEagle NickelCopper Mine, Michigan Mining Technology

Ore Processing Equipment Of Nickel Flotation Machine Price

Ore Processing Equipment Of Nickel Flotation Machine Price beneficiation methods the most important is the flotation magnetic and reelection is usually secondary dressing method Flotation copper sulfide nickel ore often used in the flotation of copper sulphide minerals collector and frother A basic principle for determining the flotation