عنا

مرحبا هل يمكنني مساعدتك؟

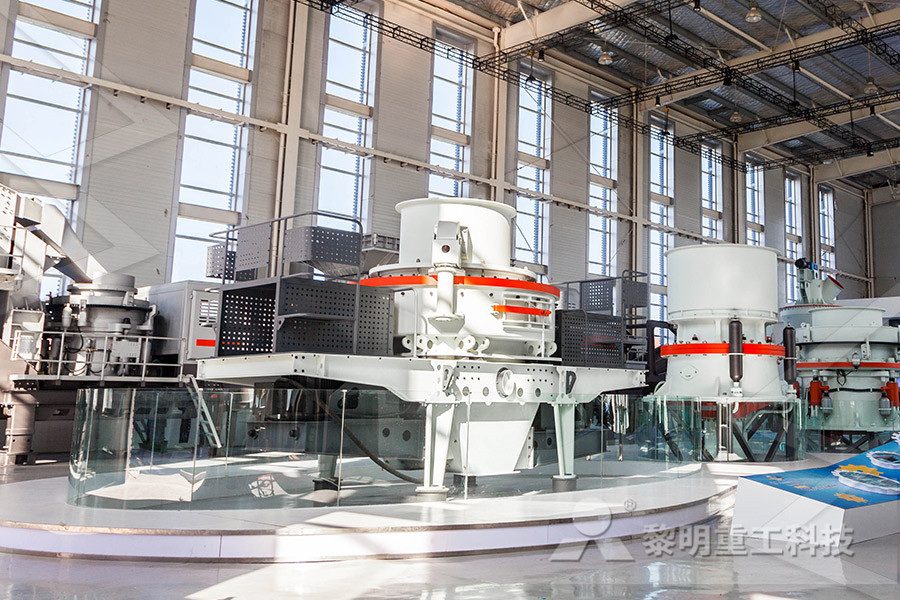

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

gravity separation ceruzit ore

2019-02-03T02:02:39+00:00

Gravity separation and Ore Beneficiation – IspatGuru

Oct 12, 2018 Gravity separation is the oldest known ore beneficiation technique and is practiced extensively in ‘Nature’ Earliest recorded human use of gravity separation was recovery of gold by panning from the Upper Nile by ancient Egyptians, dating back to 1900 BCEThe gravity separation process is used to separate ore minerals It is an old dressing technic for ore concentration The concentration is achieved either by gangue removing or valuable minerals recovering It is mostly applicable for coarse liberated ores, and it Gravity Separation Principle, Uses and Applications Mar 12, 2017 Gravity separation is an industrial method o f separating two components, either in suspension, o r in dry condition, from a granular mixture differen (PDF) GRAVITY SEPARATION IN ORE DRESSING

What is Gravity Separation? (with pictures)

May 15, 2020 Gravity separation is commonly used in medical settings to separate red blood cells from plasma There are a multitude of ways to achieve gravity separation, the most common being static separation, centrifugation, and jiggingGravity separation dates back to at least 3000 BC when Egyptians used the technique for separation of gold It is necessary to determine the suitability of a gravity concentration process before it is employed for concentration of an ore The concentration criterion is commonly used for this purpose, designated in the following equation (whereMineral processing WikipediaGravity separation has been applied to process chrome slag by steel researchers in India Heavy media separation (Choudhury et al, 1996) and crushing and jigging (Khan et al, 2001) are the principal techniques used The slag is subjected to 2stage crushing to reduce the size to −10 mm and then screened into −10 +1 mm and −1 mm fractionsGravity Separation an overview ScienceDirect Topics

Gravity Separation SGS

gravity separation techniques in a tin recovery plant as a replacement for the last flotation cleaner increased recoveries 10% and, in another instance, use of specialist techniques and procedures increased tin recoveries by 8% Release analysis is used as the preferred1) [8] And if CC is greater than 25, then the separator is suitable for working with particle size above 74 µm, for CC in the range 175 25 the separator can work with particle size above 150 (PDF) GRAVITY SEPARATION IN ORE DRESSINGFeb 26, 2021 Angela Brady Date: February 26, 2021 Centrifuges are typically used during gravity separation Gravity separation is a method of separating a suspension into its individual components It is commonly used in medical settings to separate red blood cells from plasma, and in metallurgical industries to separate particles of different metalsWhat is Gravity Separation? (with pictures)

Gravity Separation SGS

gravity separation techniques in a tin recovery plant as a replacement for the last flotation cleaner increased recoveries 10% and, in another instance, use of specialist techniques and procedures increased tin recoveries by 8% Release analysis is used as the preferredUSA USA USA USA US A US A US A US A US A US A US A US A US A US A US A US A Authority US United States Prior art keywords particles coal vessel pyrites stream Prior art date Legal status (The legal status is an assumption and is not a legal USA Gravity separation of coal ore Google PatentsMar 07, 2021 Gravity separation of minerals is based upon the difference in specific gravity between the target mineral and gangue minerals (Wills and Finch, 2015) was obtained from the tetrahedrite ore (PDF) Gravity Separation: Old Technique/New Methods

Mineral Jig Concentrators for Ore Processing Separation

Aug 14, 2018 The process combines conventional gravity separation and centrifugal force allowing for size recovery down to 10 microns Sepro builds selective mineral jigs ranging in capacity from 5–400 tons Jan 25, 2012 Gold concentration usually consists of gravity separation, flotation, cyanidation, or the combination of these processes The choice among these processes depends on the mineralogical characterization and gold content of the ore Recently, the recovery of gold using gravity methods has gained attention because of low cost and environmentally friendly operationsBeneficiation of the gold bearing ore by gravity and 6 Separation and concentration Following milling, the ore is subjected to different processes according to its nature Pulp may require to be thickened ahead of these processes in large tanks called Thickeners, in which the solid component is allowed to settle and is raked towards the centre by large, rotating rakes while relatively clear water overflows into a peripheral drain or LaunderSeparation and Concentration Mineral Processing

Manganese ore Gravity Separation YouTube

Jan 24, 2018 more about manganese ore gravity separation process, please check our websitefrjig/news/ManganeseBeneficiationFlowCharthtmlIf To participate in the 911Metallurgist Forums, be sure to JOIN LOGIN Use Add New Topic to ask a New Question/Discussion about Gravity Separation/Concentration OR Select a Topic that Interests you Use Add Reply = to Reply/Participate in a Topic/Discussion (most frequent) Using Add Reply allows you to Attach Images or PDF files and provide a more complete input Use Add Comment = to comment CHROMITE ORE CONCENTRATION Gravity Separation Gravity Separators, also known as gravity air tables or density separators, use a combination of air for weighing, vibration for fluidization and conveying and tilt (or slope) for separation Made for ease of use, longevity and above all, accuracy, Oliver Gravity Separators sort dry, granular, freeflowing material into streams according to Gravity Separator Oliver Manufacturing

Philippines Chromite Ore Mining Processing Approach With

This video was taken in Philippines for chromite ore This is the thirteen's chromite plant in Philippines we made The flow sheet and machines are quite simFeb 26, 2021 Gravity separation is a method of separating a suspension into its individual components It is commonly used in medical settings to separate red blood cells from plasma, and in metallurgical industries to separate particles of different metalsEffective separation relies upon the different densities and sizes of the particulate matter, and works by combining forces of gravity with What is Gravity Separation? (with pictures)Gravity separation and ore beneficiation ispatguruct 12, 2018gravity separation is a physical process which consists of the separation of different mineral types in the ore from one another based on differences in their specific gravities using the force of gravity, which can be influenced by one or more of other forces such as centrifugal Gravity Separation Of Iron Ores

AMIT 145: Lesson 4 Gravity Separation – Mining Mill

Iron Ore Gravity Circuit Iron Ore Gravity Circuit [image 145415] Chromite Processing Chromite Processing [image 145416] Centrifugal Force, F c When the particle size falls below 1 mm, the rate of separation significantly impacts efficiency AMIT 145: Lesson 4 Gravity Separation; AMIT 145: Lesson 5 Froth Flotation;Gravity Concentration GekkoThe gravity concentration separation process gets more complex as the specific gravities between the valuable mineral and the gangue get closer For example, complex gravity separation for ore concentrationgravity separation for ore concentrationGravity separation is an industrial method of separating two components, either a suspension, or dry granular mixture where separating the components with gravity is sufficiently practical: ie the components of the mixture have different specific weight All of the gravitational methods are common in the sense that they all use gravity as the dominant forceGravity separation Wikipedia

Gravity Separation SGS

gravity separation techniques in a tin recovery plant as a replacement for the last flotation cleaner increased recoveries 10% and, in another instance, use of specialist techniques and procedures increased tin recoveries by 8% Release analysis is used as the preferredGravity separation is one of the oldest technique in mineral processing but has seen a decline in its use since the introduction of methods like flotation, classification, magnetic separation and leaching Gravity separation dates back to at least 3000 BC when Egyptians used the technique for separation Mineral processing WikipediaMar 07, 2021 Gravity separation of minerals is based upon the difference in specific gravity between the target mineral and gangue minerals (Wills and Finch, 2015) was obtained from the tetrahedrite ore (PDF) Gravity Separation: Old Technique/New Methods

Separation and Concentration Mineral Processing

6 Separation and concentration Following milling, the ore is subjected to different processes according to its nature Pulp may require to be thickened ahead of these processes in large tanks called Thickeners, in which the solid component is allowed to settle and is raked towards the centre by large, rotating rakes while relatively clear water overflows into a peripheral drain or LaunderSilvia Serranti, Giuseppe Bonifazi, in Use of Recycled Plastics in Ecoefficient Concrete, 2019 Jigging Jigging is one of the oldest methods of gravity concentration (Hori et al, 2009)Jigging can be defined as an “enhanced gravity based separation” method: a water stream is pulsed, or moved by pistons upward and downward, through the material bedGravity Concentration an overview ScienceDirect TopicsAug 25, 2018 In this paper, a sample from Tangezagh iron mine was characterized by gravity and magnetic separation methods The mineralogical studies showed that hematite and goethite are the main ironbearing minerals with insignificant amounts of FeO The results indicated that spiral separation yields higher separation efficiency than others The combination of spiral and multi gravity methods A Beneficiation Study on a Low Grade Iron Ore by Gravity

Mineral processing Concentration Britannica

Mineral processing Mineral processing Concentration: Concentration involves the separation of valuable minerals from the other raw materials received from the grinding mill In largescale operations this is accomplished by taking advantage of the different properties of the minerals to be separated These properties can be colour (optical sorting), density (gravity separation), magnetic Aug 14, 2018 The process combines conventional gravity separation and centrifugal force allowing for size recovery down to 10 microns Sepro builds selective mineral jigs ranging in capacity from 5–400 tons Mineral Jig Concentrators for Ore Processing Separation I'm working on beneficiation of barium sulfate from low grade barite ore (642% BaSO4) in presence of 2801 SiO2 and 48 PbO 48% PbO with 28% SiO2 We want to achieve min 42 SG with less than 250 ppm Lead (OCMA Standard) Does anyone have any experiences on such ore What is the common baritMethod of processing barite Beneficiation process

Philippines Chromite Ore Mining Processing Approach With

This video was taken in Philippines for chromite ore This is the thirteen's chromite plant in Philippines we made The flow sheet and machines are quite simMar 03, 2021 Oil sands slurry produced in the Slurry Preparation Plant (SPP) contains about 5055% sand and less than 10% bitumen The purpose of Extraction is to recover the bitumen portion, while rejecting the heavy solids This is achieved through a simple waterbased gravity separation Bitumen Extraction Explained Oil Sands Magazine