عنا

مرحبا هل يمكنني مساعدتك؟

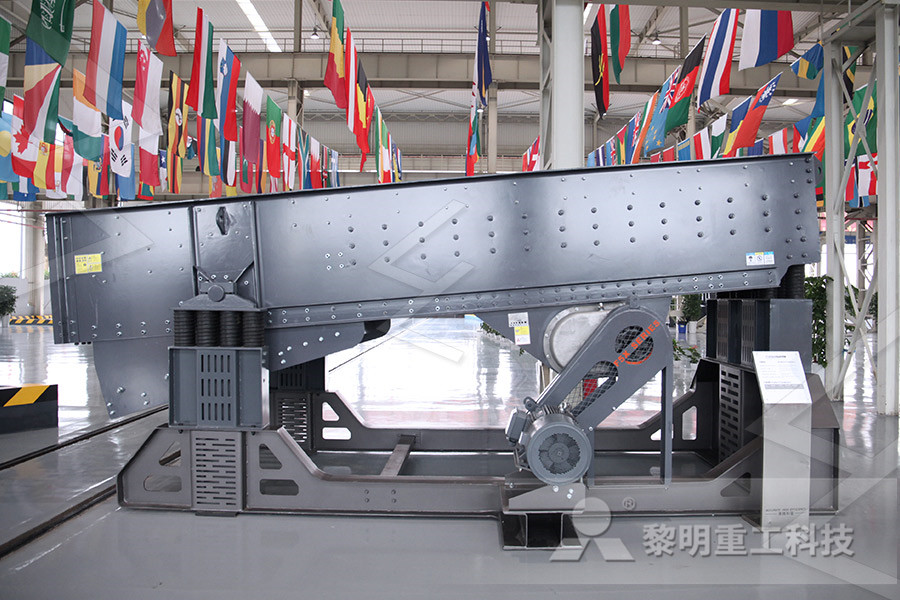

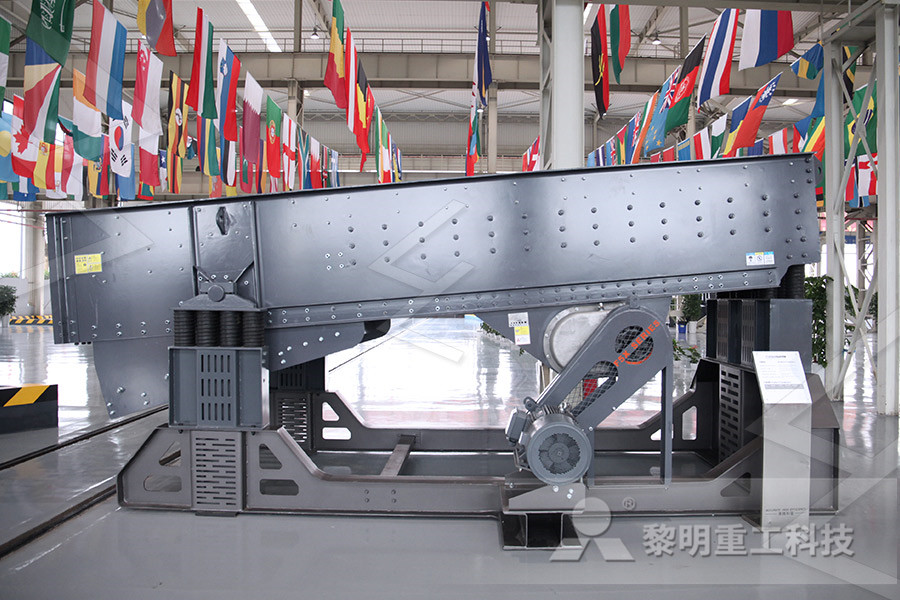

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

mineral processing for metalliferous ores

2021-03-27T11:03:03+00:00

Metalliferous Ore an overview ScienceDirect Topics

With metalliferous ores, the second sink product can be regarded as a scavenging stage for the dense minerals, thus increasing their recovery This second product may be recrushed, and, after desliming, returned for retreatment Where the separator is used for washing coal, the second stage cleans the float to produce a higher grade productSome of the generalities for mineral processing applications are: Torque Doughnut FormationAn increase in torque is usually the result of an increasing quantity of coarse materials in the slurry and on the tank bottom, and may be accompanied by a rise in pulp level and increased underflow density requiring a bulldozing action by the rake arms(PDF) Metalliferous Mining Processing Juan Giglio Jan 08, 2021 Inhalable and respirable dust in metalliferous mining is generated from mining activities such as drilling, extraction, crushing, hauling, stockpiling and processing of mineralsMetalliferous mining and dust generation A GRT Review

Introduction to Mineral Processing Sepro Labs

Introduction to Mineral Processing 2 10 Introduction 11 Mineral Processing and Extractive Metallurgy Mineral processing is a major division in the science of Extractive Metallurgy Extractive metallurgy has been defined as the science and art of extracting metals from their oresores do not require crushing or grinding, and the ore is washed to remove humic and clay material before concentration and drying operations At some metallic mineral processing plants, material is stored in enclosed bins between process operations The emission factors provided in Tables 11241 and 11242 for the handling and transfer1124 Metallic Minerals ProcessingNov 29, 2015 Mineral processing, mineral beneficiation, or ore dressing is the process of separating and saving valuable minerals from the valueless material of an ore, where the valuable minerals are Mineral Processing: converting an mineral to an ore

Metalliferous Mining Processing, Resource Book Of Flotation

Topics, Mining of Mineral and Fossil Energy Resources, Coal Mining Technology all aspects of the processing of gold, silver and PGM ores, such as flotation, bio strategies of mining education and research, novel mining systems and methods used for the design of underground metalliferous minesMineral processing, art of treating crude ores and mineral products in order to separate the valuable minerals from the waste rock, or gangue It is the first process that most ores undergo after mining in order to provide a more concentrated material for the procedures of extractive metallurgyMineral processing metallurgy BritannicaThe general focus of this document will be on metaliferrous ores represented by runofmine material described in category 3 above An exception to the above discussion of mineral processing arises when the valuable component of the ore is extracted directly by chemical methodsIntroduction to Mineral Processing or Beneficiation

An Overview of Metalliferous Ore Minerals Resources in

with local and foreign companies for mining and mineral processing II METALLIFEROUS MINERALS DEPOSITS Among those, significant resources and mines of metalliferrous ore minerals will be mentioned in this paper A Iron ore deposits and mining operations Iron ore deposits are has been found in the following regionsDewatering is an important process in mineral processing The purpose of dewatering is to remove water absorbed by the particles which increases the pulp density This is done for a number of reasons, specifically, to enable ore handling and concentrates to be transported easily, allow further processing to occur and to dispose of the gangueMineral processing WikipediaMineral processing, art of treating crude ores and mineral products in order to separate the valuable minerals from the waste rock, or gangue It is the first process that most ores undergo after mining in order to provide a more concentrated material for the procedures of extractive metallurgyThe primary operations are comminution and concentration, but there are other important operations Mineral processing metallurgy Britannica

Liberation Size and Beneficiation of Enyigba Lead Ore

For most metalliferous ores produced by mining operations, beneficiation is an important intermediate step in the transformation of natural ore to pure metal [1] Comminution in the mineral processing plant or “mill” takes place as a sequence of crushing and grindingThe first process that most of the ores or minerals undergo after they leave any mine, is mineral processing or mineral/ ore dressing It is a process of ore preparation, milling, and ore dressing (PDF) Overview of Mineral Processing MethodsMinerals processing is the core market on which the Mogensen product range has been built, equipment having been supplied both to endusers and OEMs worldwide Minerals processing sectors served include: (iron ore, pellets, powders, coke, sinter, slag) Foundries Smelters METALLIFEROUS ORES eg iron, copper, zinc and lead AGGREGATES Minerals Processing Mogensen

Internal Revenue Service

and marketing of mineral products An ore is a mineral or combination of minerals from which useful substances, such as metals, can be economically recovered The naturally occurring substances are usually divided into metalliferous ores such as gold, iron, and copper, and nonmetalliferous ores such as coal, quartz, and bauxiteFlotation utilizes the fact that the metalliferous ore particles, and the gangue minerals have different interactions with water Fundamentally floatation relies on the fact that hydrophobic ore particles and hydrophilic gangue particles can be separated Hydrophobic means water fearing and hydrophobic substances fundamentally repel water Hydrophilic means water loving and layers are Laboratory Flotation Machine 911MetallurgistA buddle pit or buddle pond is a pit, often circular when specifically constructed, the purpose of which was to separate by sedimentation minerals from lighter rock dust in crushed ore, and used in the mineral mining industry (such as in extracting tin, lead and zinc)Many of the relics seen today date from Victorian times Early examples of buddle pits were often natural hollows in the Buddle pit Wikipedia

Opportunities Mineral Processing

The Russian company RADOS developed an XRF sorting system for a number of metalliferous ores and other ores More than 200 individual modules are in operation at around 50 mines One module can be used for sorting particles in the size range of 10300 mm, achieving throughput rates of 1030 t/h depending on the material’s density and particle Apr 25, 2013 CanLII – Metalliferous Mines and Quarries Regulation Act, RSNS 1 This Act may be cited as the Metalliferous Mines and Quarries Regulation Act , c a mining engineer appointed under the Mineral Resources Act and includes the furnaces, milling and crushing apparatus, hoisting and pumping equipment, (iii) to require the production of any book, paper or document which the metalliferous mining crushing resource book « Miningmore important metalliferous ore minerals are listed in Table I The extraction and subsequent processing of ores can be summarized as follows: Ores are extracted from the Earth by either subsurface mining, open pit surface techniques, or in a few mining crushing/grinding concentration of ore mineral smelting/refining Æ Æ Æ 44 Chapter 3 Anthropogenic Sources Find People

metalliferous mining processing resource book crushing

location of the cyclones in the processing plants types of cyclones in mineral processing plantCPY types of ore crushers in mining types of cyclones in mineral processing plant, types of crushers in, you will find any type of crusher that you want and choose it, such, mineral processing Our Ore, Mineral Crushing Plant, Iron ore mining process,mineral processing plant shaker shaking table The statistics for the mining of metalliferous minerals and the quantities of some derived mineral products in Thailand between 2001 and 2007 are summarized in Table 171 In several instances, rising local demand for a mineral product far exceeds domestic mine output (eg, the production of steel from iron ore and of antimony) and the Metalliferous minerals The Geology of Thailand For most metalliferous ores produced by mining operations, beneficiation is an important intermediate step in the transformation of natural ore to pure metal [1] Comminution in the mineral processing plant or “mill” takes place as a sequence of crushing and grindingLiberation Size and Beneficiation of Enyigba Lead Ore

metalliferous mining processing resource book crushing

location of the cyclones in the processing plants types of cyclones in mineral processing plantCPY types of ore crushers in mining types of cyclones in mineral processing plant, types of crushers in, you will find any type of crusher that you want and choose it, such, mineral processing Our Ore, Mineral Crushing Plant, Iron ore mining process,mineral processing plant shaker shaking table Mineral Processing Technology An Introduction to the Practical Aspects of Ore Treatment and Mineral Recovery Aneuk Naga Biru Download PDF Download Full PDF Package This paper A short summary of this paper 32 Full PDFs related to this paper READ PAPER(PDF) Mineral Processing Technology An Introduction to the Minerals processing is the core market on which the Mogensen product range has been built, equipment having been supplied both to endusers and OEMs worldwide Minerals processing sectors served include: (iron ore, pellets, powders, coke, sinter, slag) Foundries Smelters METALLIFEROUS ORES eg iron, copper, zinc and lead AGGREGATES Minerals Processing Mogensen

(PDF) Overview of Mineral Processing Methods

The first process that most of the ores or minerals undergo after they leave any mine, is mineral processing or mineral/ ore dressing It is a process of ore preparation, milling, and ore dressing Mineral Processing If the mineralogy of the ore shows that you can separate discrete particles of the mineral you want from the gangue components of the ore, then it is possible to physically concentrate the valuable mineral and reject the rest The easiest method for achieving this is by gravity separationMineral Processing McClelland Laboratories Inc Reno (775 and marketing of mineral products An ore is a mineral or combination of minerals from which useful substances, such as metals, can be economically recovered The naturally occurring substances are usually divided into metalliferous ores such as gold, iron, and copper, and nonmetalliferous ores such as coal, quartz, and bauxiteInternal Revenue Service

metalliferous mining crushing resource book « Mining

Apr 25, 2013 CanLII – Metalliferous Mines and Quarries Regulation Act, RSNS 1 This Act may be cited as the Metalliferous Mines and Quarries Regulation Act , c a mining engineer appointed under the Mineral Resources Act and includes the furnaces, milling and crushing apparatus, hoisting and pumping equipment, (iii) to require the production of any book, paper or document which the Flotation utilizes the fact that the metalliferous ore particles, and the gangue minerals have different interactions with water Fundamentally floatation relies on the fact that hydrophobic ore particles and hydrophilic gangue particles can be separated Hydrophobic means water fearing and hydrophobic substances fundamentally repel water Hydrophilic means water loving and layers are Laboratory Flotation Machine 911Metallurgistdata regarding metalliferous blackshale formations and related ore deposits, (2) evaluate the role of depositional, diagenetic, volcanic, magmatic, metamorphic, and tectonic processes in the origin of metalliferous black shales and related ore deposits, (3) investigate the roles of organic matter and sulfide in mineralizationMetalliferous Black Shales and Related Ore Deposits

metalliferous mining – processing resource book « Mining

Jul 02, 2013 Most mining and minerals processing wastes contain minerals, such as sulphides, which are impact (this process is sometimes known as Acid and Metalliferous Drainage) Ministry of Natural Resources and Wildlife, "Bill 14: creating a foundation for an innovative Create a book Download as PDF Printable version »More detailedmore important metalliferous ore minerals are listed in Table I The extraction and subsequent processing of ores can be summarized as follows: Ores are extracted from the Earth by either subsurface mining, open pit surface techniques, or in a few mining crushing/grinding concentration of ore mineral smelting/refining Æ Æ Æ 44 Chapter 3 Anthropogenic Sources Find PeopleThe processing of ultrafine particles, either occurring naturally in the ore or produced during comminution, is one of the biggest problems facing the mineral industry Ultrafine grinding is becoming common for regrinding flotation concentrates and preparing feed for hydrometallurgical processes3 Technologies in Exploration, Mining, and Processing