عنا

مرحبا هل يمكنني مساعدتك؟

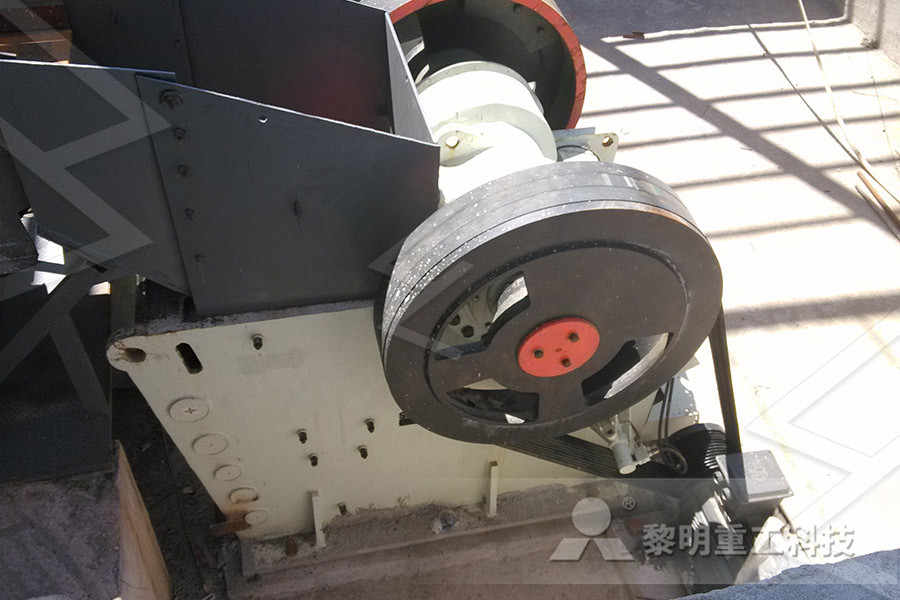

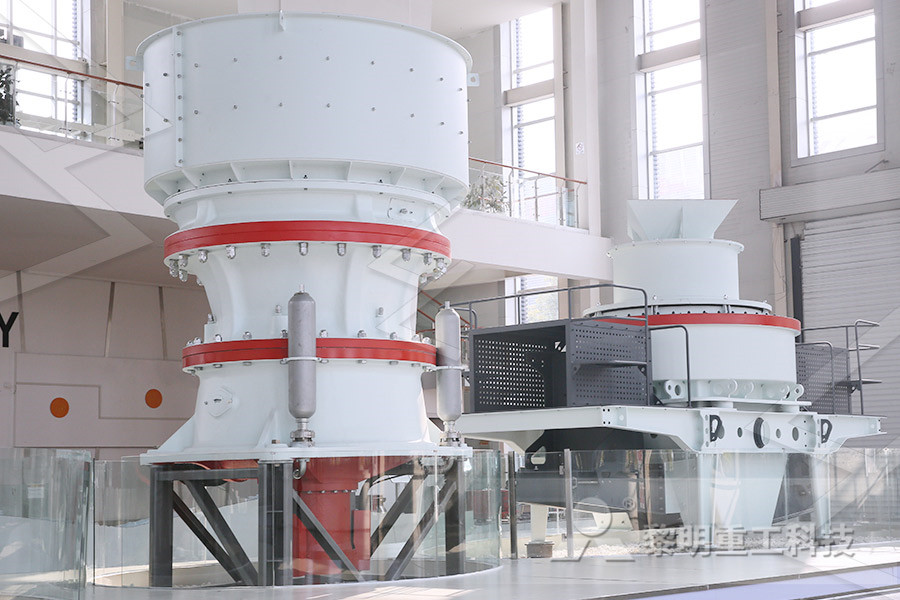

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

pyritic lead zinc sulfide ore flotation

2023-02-09T20:02:13+00:00

DEZINCING OF LEADCOPPER SULPHIDE MINERALS

(2009) conducted differential flotation of leadzinc sulphide ore, where the ore was predominantly contained of sphalerite and pyrite in association with fine sizes of galena, but even the ore was about oxidized condition Using alkyl quinolinebased chelating type collector improved the selectivity of flotation Magdalinovic et al (2004)The first step in oxide minerals and leadzinc carbonate flotation is sulfidization of their surfaces with chemical agents such as sodium sulfide This method is appropriate for lead carbonateSulphidization flotation for recovery of lead and zinc Pyrite Flotation Froth Flotation (Sulphide Oxide) Metallurgist Mineral Processing Engineer Can you list the factors affects the floatability of pyrite from refractory low grade oreI used a Wemco lab flotation cell and aimed on analysing factors like collector dosages (PAX), Activator (Copper sulphate),MIBC , pH and others like pulp Pyrite Flotation Froth Flotation (Sulphide Oxide

A study on selective flotation in low and high pyritic

Jun 02, 2016 The effect of chemical reagent configurations was investigated on two different copper sulphide ore types, including high and low pyritic feeds Three different combinations of collectors as isopropylnethyl thionocarbamate (C4132), mixture of mercaptobenzothiazole and butyl sodium dithiphosphate (Flomin 7240) and sodium isopropyl xanthate (Z11) were used in flotation experimentsMost nonconventional hydrometallurgical methods of the processing of complex sulfide ores are based on metals extraction from bulk flotation concentrates (21 12,111 The recovery of zinc, lead and copper by froth flotation, even as a relatively rich concentrate, presents today a rather routine problemProcess Development dggsalaskagovLead and Zinc Lead and zinc ores are usually found together with gold and silver A leadzinc ore may also contain lead sulfide, zinc sulfide, iron sulfide, iron carbonate, and quartz When zinc and lead sulfides are present in profitable amounts they are regarded as ore minerals The remaining rock and minerals are called gangueLead and Zinc Energygov

(PDF) Effect of different depressants on galena flotation

This paper reports the results of flotation tests conducted with a copperleadzinc sulphide ore The major sulphide minerals in the ore are chalcopyrite, galena, sphalerite, marmatite and pyrite LeadZinc sulfide ores branch flotation process The branch flotation process used to the extraction of leadzinc sulfide ores is mainly to float aimed at the quick floated and easy to floated leadzinc ore, while leave the slow floated and difficult to floated leadzinc ore in the subsequent floatation process5 Flotation Processes Used to the Extraction of LeadZinc In the majority of the zinc operations, sphalerite (ZnS) is associated with galena and often sulfides of iron and copper It is therefore essential to arrange the flowsheet not only for recovery of the valuable minerals, but also to selectively separate them into products acceptable to the smelters for ultimate conversion into metal The flowsheet outlined above is typical for the average Lead Zinc Sulfide Separation by Sequential Flotation

Froth Flotation Process Used in the Lead Zinc Sulfide Ore

The most common leadzinc sulfide ore is leadzinc sulfide polymetallic ore The leadzinc sulfide is often associated with a variety of valuable components, such as lead, zinc, copper, sulfur and other useful minerals, whose floatability is obviously different, which determines the different froth flotation process of lead and zinc sulfide This paper reports the results of flotation tests conducted with a copperleadzinc sulphide ore The major sulphide minerals in the ore are chalcopyrite, galena, sphalerite, marmatite and pyrite (PDF) Effect of different depressants on galena flotationFlotation Zinc Activation in Galena Flotation of Finely Disseminated Complex Sulfide Ore; Developing a Selective Flotation Concentration Technique for Polymetallic Ores; The Effect of Grinding Media and Galvanic Interactions upon the Flotation of Sulfide Minerals; Selective Flotation of Different Complex Pyritic OresComplex Sulfides Processing of Ores Concentrates and By

Development of online soft sensors and dynamic fundamental

Aug 01, 2018 Lead–zinc sulfide ores are among the common sulfide ores that use flotation for beneficiation Flotation of these sulfide ores is accomplished using multistage differential flotation Several flotation cells are used to separate and recover galena (lead sulfide, PbS), followed by floating sphalerite (ZnS) in a sequential manner ( Basilio et Silver Lead Zinc Ore Processing Method using Flotation Mar 19, 2017 Sulphide ore of lead and zinc containing considerable silver was A Adjustable Stroke Unit Flotation Cell are incorporated in the Belt Ore Contact US Extraction of a Low Grade Zinc Ore using Gravity and Froth Flotation lead and zinc ore flotation cellThe invention relates to a method for pretreating ore pulp in a lead and zinc oxide flotation process In the method, after a pH regulator, an inhibitor and a collector are added in turn before the rough concentration of lead and zinc oxides, stirring and pulp regulating are performed respectively, pulp regulating is also performed before the concentration of rough concentrate and before the CNA Method for pretreating ore pulp in lead and

Recovery of Gold in Pyritic Sulfide Ores Mine

That appears to leave froth flotation as still the best method of recovering the gold from pyritic ores Sulfide ores, such as chalcopyrite, sphaelerite, galena, and pyrrhotite, and mixtures of these ores have historically been found with micron size gold particles included in themRussian massive rebellious pyritic copperzinc ores are difficulttoprocess For a few decades, the problem connected with the processing and extraction of nonferrous and precious metals remains Abduaziz KAYUMOV Researcher PhD National University The priority froth flotation method is suitable for rich ores with simple mineral composition, high lead and zinc content, and coarse disseminated ores It is also suitable for dense massive sulfide ores with a large number of sulfide ores It has the advantages of easy to control, high concentrate quality, small fluctuation of the flotation How to Select the Froth Flotation Method Used in the

CNA Floatation process of complex lead zinc

The present invention relates to a kind of floatation process of complex lead zinc ores, the following technological process of employing: ore grindingplumbum floatation district flotation of leadzinc sulphur mixes constituency flotation zinczinc chats constituency flotation zinc again; The present invention uses plumbous zinc standardsized sheet road etc can float flow process, the power Table of ContentsChemistry of Sodium SulfideSulfidization Sodium Sulfide in Sulfide Minerals Flotation Sodium sulfide is one of the most widely used alkali metal sulfides in the flotation of copper, lead, and zinc minerals in their oxidized form The sulfidization process, developed in the USA in 191520 for oxide copper minerals flotation, is especially suitable for oxidized lead ores in Role of Sodium Sulfide Copper Lead Zinc Ore FlotationThe above four reagents are commonly used conditioners for the flotation of oxidized lead and zinc ore After being sulfurized, and then adjusted according to the nature of the ore, the oxidized lead and zinc ore can be collected according to the collecting principle of sulfide ore with collectors such as xanthateFlotation Conditioners of Oxidized Zinc and Lead Ore

Critical importance of pH and collector type on the

Feb 04, 2021 In both lead and zinc circuits, pyrite is the main sulphide gangue mineral It is critical to decrease the presence of iron (Fe) and Zn in the lead concentrate during the flotation of galenaLeadzinc sulphide ore contains lead sulphide (galena), and zinc sulphide (sphalerite) In the first flotation stage, galena is rendered hydrophobic with an organic collector such as xanthate, while sphalerite is kept from floating by depressants, and in the second flotation stage, activator was used to activated zinc flotationRecycle of Wastewater from LeadZinc Sulfide Ore Flo The most common leadzinc sulfide ore is leadzinc sulfide polymetallic ore The leadzinc sulfide is often associated with a variety of valuable components, such as lead, zinc, copper, sulfur and other useful minerals, whose floatability is obviously different, which determines the different froth flotation process of lead and zinc sulfide Froth Flotation Process Used in the Lead Zinc Sulfide Ore

Complex Sulfides Processing of Ores Concentrates and By

Flotation Zinc Activation in Galena Flotation of Finely Disseminated Complex Sulfide Ore; Developing a Selective Flotation Concentration Technique for Polymetallic Ores; The Effect of Grinding Media and Galvanic Interactions upon the Flotation of Sulfide Minerals; Selective Flotation of Different Complex Pyritic OresFlotation kinetics rates of lead, zinc, and iron The pH values of 6 and 8 were selected as optimum pH for the lead and zinc flotation respectively Lead, zinc, and iron flotation kinetic rates in the lead flotation stage at pH values of 6 and 8 were shown in Fig 10 As it can be seen, there is a sharp increase in the lead recovery in the Critical importance of pH and collector type on the A new flowsheet was developed to recover the valuable minerals from oxide or oxidesulfide ores of lead and zinc The flowsheet consisted of flotation of sulfide minerals, desliming and (PDF) Sulfidization flotation of a low grade oxide PbZn ore

Feasibility Study of Differential Flotation of Cu–Pb–Zn

Aug 28, 2020 In this research, flotation of copper, lead and zinc minerals from a copper oxide–sulfide ore was studied The identification tests showed that the sample is a mixture of quartz, chalcopyrite, galena, cerussite, hemimorphite and iron oxide minerals with 504% CuO, 161% PbO, 207% ZnO and 5640% SiO 2The experimental design methodology (RSM) was conducted to investigate the effect of USA USA USA US A US A US A US A US A US A US A US A US A Authority US United States Prior art keywords flotation ore sulfide zinc cyanide Prior art date Legal status (The legal status is an assumption and is not a legal conclusionUSA Concentration of ores by flotation Google For froth flotation, an aqueous slurrry the ground ore is treated with the frothing agent An example is sodium ethyl xanthate as a collector in the flotation of galena (lead sulfide) to separate it from sphalerite (zinc sulfide) The polar part of xanthate anion attaches to the ore particles and the nonpolar hydrocarbon part forms a Froth flotation Wikipedia

USA Flotation of carbonaceous ores Google Patents

USA USA USA USA US A US A US A US A US A US A US A US A US A US A US A US A Authority US United States Prior art keywords flotation carbonaceous pulp lignin sulphonate tests Prior art date Legal status (The legal status is an assumption and The polymetallic sulfide ores of copper, lead, and zinc are usually processed via flotation, and the concentrates of these three metals and sulfur can be obtained Valuable elements in the ore are recovered by enriching theFlotation experiment research on a polymetallic sulfide ore ofLeadzinc sulphide ore contains lead sulphide (galena), and zinc sulphide (sphalerite) In the first flotation stage, galena is rendered hydrophobic with an organic collector such as xanthate, while sphalerite is kept from floating by depressants, and in the second flotation stage, activator was used to activated zinc flotation Since the organic regent used are different in the two flotation Recycle of Wastewater from LeadZinc Sulfide Ore Flo

1 Froth Flotation – Fundamental Principles

After carrying out a froth flotation separation, the products are as shown in Table 1 Using this data, calculate: (a) Ratio of concentration (b) % Metal Recovery (c) % Metal Loss (d) % Weight Recovery, or % Yield (e) Enrichment Ratio Table 1: Grade/recovery performance of a hypothetical copper ore flotation CopperLeadZinc ores Danafloat CopperLeadZinc ores The CuPbZn separation process is among the most challenging flotation separations primarily because the first step must entail bulkhow to separate zinc ore from lead ore