عنا

مرحبا هل يمكنني مساعدتك؟

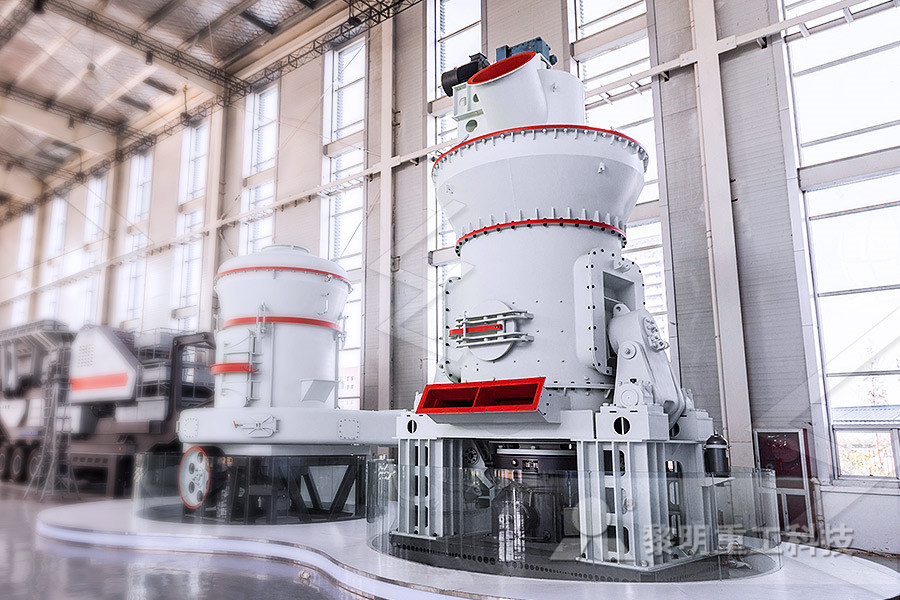

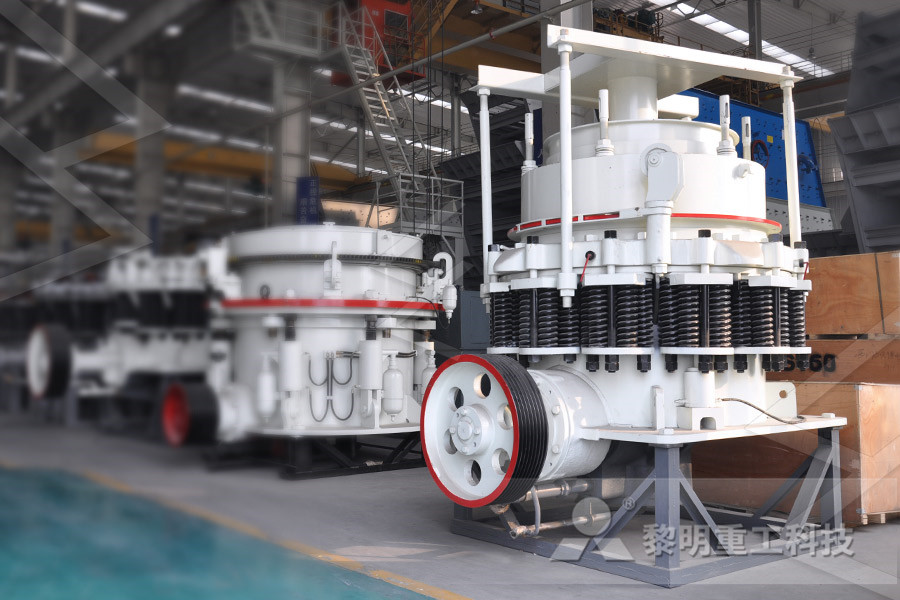

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

designing vibrating screens

2023-08-09T14:08:32+00:00

DESIGN AND FABRICATION OF AN ELECTRIC VIBRATING SCREEN

Highfrequency vibrating screens Circular Vibrating screenThis type of equipment is used for very large particles, sizes that range from pebble size on up to boulder size material It is also designed Jan 08, 2015 SMICO is the leader in custom screening technology In today’s market, no other major screener manufacturer customizes their machines to the level SMICO achiVibrating Screen Design Its Effect on Screen Motion Table of ContentsModel DesignOperating and Control StrategiesResults An analysis of screen design options on the operating efficiency of secondary crushing plants has been conducted using a dynamic computer model The model allows for the simulation of a wide variety of crushing circuits and can be run on either a microcomputer (IBM PC/XT) or a large timesharing mainframe computer Size Vibrating Screen Design Parameters

Construction, Working and Maintenance of Electric

In a vibrating screen, the screening surface with desired screen openings (screening deck) is vibrated by a vibrator assembly/exciter They perform size separations from 300 mm in size down to 45 μm and they are used in a variety of sizing, grading, scalping, dewatering, wet Mar 20, 2010 guidance for designing a vibrating screen I am a final year student of mechanical engineering as a final year project am designing a two deck vibrating screen for separation/ cleaning of puffed rice (puffed rice is really light in weight ), with both screens inclined in opposite direction, using a single shaft eccentric wts on both sides the whole body is suspended on four springs i have Designing a Vibrating Screen bulkonlineTable of ContentsModel DesignOperating and Control StrategiesResults An analysis of screen design options on the operating efficiency of secondary crushing plants has been conducted using a dynamic computer model The model allows for the simulation of a wide variety of crushing circuits and can be run on either a microcomputer (IBM PC/XT) or a large timesharing mainframe computer Size Vibrating Screen Design Parameters

DESIGN AND FABRICATION OF AN ELECTRIC VIBRATING SCREEN

Vibrating screen design parametersAccording to (Denzin and Lincoln,2000) the overall performance of any vibration screen depends on the following general design parameters: Screen surface and open area, wire cloth aperture size and shape, slope of screen deck (for inclined screens), the design parameter are listed below for an aesthetic and Jan 08, 2015 SMICO is the leader in custom screening technology In today’s market, no other major screener manufacturer customizes their machines to the level SMICO achiVibrating Screen Design Its Effect on Screen Motion Sep 01, 2009 Dynamic optimal design of vibrating screen The initial force mainly distributes on the side plate and cross beams when the vibrating screen works Then it makes a rigid motion and elastic deformation which generates a greater dynamic stress on the side plate and leads to fatigue crack of the side plate [11] Adding stiffeners to base structure Dynamic design theory and application of large vibrating

Vibrating Screen Working Principle

Metallurgical ContentScreen Vibration PatternsVibrating Screen DesignScreen CapacityVibrating Screen CapacitySCREENINGVibrating Screen CapacityVibrating Screen SPECIFICATIONSFloating Circle MotionWhat It IsHow It WorksMethods of Fastening Vibrating Screen ClothDouble Deck Vibrating Screen—Floor MountedScreen Frame Sizes and ScaleUp Problems and Fundamentals of Vibrating Screen Abstract—The project deals with the design and analysis of bearing for the vibrating screen of capacity 100 tones per hour transmitting 20 BHP at a speed of 850 rpm The design is based on the standard design procedure In the present work by using the standard design procedure diameter of vibrating screen shaft has been designedDESIGN AND ANALYSIS OF SHAFT AND BEARING FOR By means of MATLAB optimization technology, the optimal mathematical model of linear vibrating screen is establishedOn the basis of the actual design parameters for the 27m2 linear vibrating (PDF) Design and structure optimization of a

Top 10 Vibrating Screens of 2020 Screening Materials

Apr 27, 2020 Rotary vibrating screen principally utilize for the grouping of materials with high screening effectiveness and fine screening precision It features a completely shut structure, no flying powder, no spillage of fluid, no obstructing of work, programmed release, no material stockpiling in the machine, no dead point of matrix structure, expanded screen territory, etcVibrating Screen Handbook PDF SKU: VSMAPDF Revision: {{currentSkuRevision}} {{subscriptionCounter}} The selected variation is not available Product Description Downloadable PDF, in black and white Chapters cover the history of screening, types of screening media, selection of screen size and type, engineering data, problems and solutions Vibrating Screen Handbook PDF AEMGough Co (Engineering) Ltd are a UK Market Leader in the design, supply, installation, commissioning and after sales services of Bucket Elevators, Vibrating Sieves, Feeders, and Conveyors Gough has developed solutions for a vast range of production processes within its market leading sectors of food production, chemicals and Vibratory Sieves, Screens Separators Gough Engineering

DESIGN AND FABRICATION OF AN ELECTRIC VIBRATING SCREEN

Vibrating screen design parametersAccording to (Denzin and Lincoln,2000) the overall performance of any vibration screen depends on the following general design parameters: Screen surface and open area, wire cloth aperture size and shape, slope of screen deck (for inclined screens), the design parameter are listed below for an aesthetic and Sep 01, 2009 Dynamic optimal design of vibrating screen The initial force mainly distributes on the side plate and cross beams when the vibrating screen works Then it makes a rigid motion and elastic deformation which generates a greater dynamic stress on the side plate and leads to fatigue crack of the side plate [11] Adding stiffeners to base structure Dynamic design theory and application of large vibrating By means of MATLAB optimization technology, the optimal mathematical model of linear vibrating screen is establishedOn the basis of the actual design parameters for the 27m2 linear vibrating (PDF) Design and structure optimization of a

Vibrating Screens Kinergy

• Durability: Kinergy Vibrating Screens are built to last with an average of over 20 years of productive use and an availability of 95% or more • Lowering Height: Kinergy’s Vibrating Screens can be installed horizontally or on a slight decline which reduces the height of the needed building or screening towerConstruction cost is reduced and the daily operating expense is less because Parker have been designing and manufacturing vibrating aggregate grading screens for over 50 years and its e range of machines is at the forefront of the need to provide an efficient screen with features ensure good results and effectiveness in the application requiredVibrating Screens Parker PlantVibrating Screen Handbook PDF SKU: VSMAPDF Revision: {{currentSkuRevision}} {{subscriptionCounter}} The selected variation is not available Product Description Downloadable PDF, in black and white Chapters cover the history of screening, types of screening media, selection of screen size and type, engineering data, problems and solutions Vibrating Screen Handbook PDF AEM

Vibrating Screen Consep Engineering Innovation

Consep provides a wide range of screen designs available, for a broad variety of applications ranging from dewatering, sizing, scalping, trash, carbon and gravity feed screens Consep’s Vibrating Screens are unique in their ability to provide custom screen designs to fit clients individual applications or layoutson a linearly vibrating screendeck in science direct in 2010 [4] Su Ronghua, Zhu Liuqing, Peng Chenyu “ CAE applied to dynamic optimal design for largescale vibrating screen” in institute of electrical and electronics engineering in 2010 [5] Frantisek novy, marian cincala, peter kopas, otakarDesign Modification of Failure Mode Effect Analysis of VIBRATING SCREEN – CAPACITY CALCULATIONS Throughput per square foot of screen area is the name of the screen game, and no design engineer wants to be considered short in the area of capacity and efficiency It behooves the buyer/operator to examine and evaluate the data available before committing to any screen type or systemSCREEN CAPACITY CALCULATION VIBFEM

Vibrating Screens Mogensen

The vibrating screen range covers both rotary and linear action drives to accommodate different applications, open or enclosed bodies, single length or double length decks and light to heavy duty design Single to multi deck configurations, wire mesh, polydecks, rubber mats to Nov 01, 2014 Vibrating screens fail at stresses below the fatigue limit in design standards • Evidence from failures has shown that a fatigue limit at 1 × 10 7 or less is incorrect • A design guide is proposed for welded vibrating equipment in the gigacycle regime • In noncorrosive conditions a fatigue limit stress range at 4 × 10 8 is proposedHigh cycle fatigue of welded structures: Design guidelines Nov 25, 2019 In order to cater to the needs of ore crushing and separation industry, the Vibrating Screen Manufacturer has launched a wide variety of vibratory screeners and separators All these equipments and screens are designed using the year of research and development and the advanced level of technology is used for designing the screensVibrating Screen Advantages and Common Design of

VIBRATING SCREENS Hawk Machinery

These vibrating screens can be constructed in either single or a double deck design and used as a heavy duty primary or scalping screen Inclines of these hiscalp vibrating screens range from 1530 degrees and use either singular or double shafted centrifugal circular motion mechanismTARNOS manufactures a very wide range of Vibrating Screens depending on the job to perform, working conditions and other conditionings of the installation All of our vibrating screens are robustly constructed, and their constant improvements on design are enables our machines to solve a greater range of difficult screening problems more effectively and economicallyVibrating screens Dewatering Screens Vibrating Design