عنا

مرحبا هل يمكنني مساعدتك؟

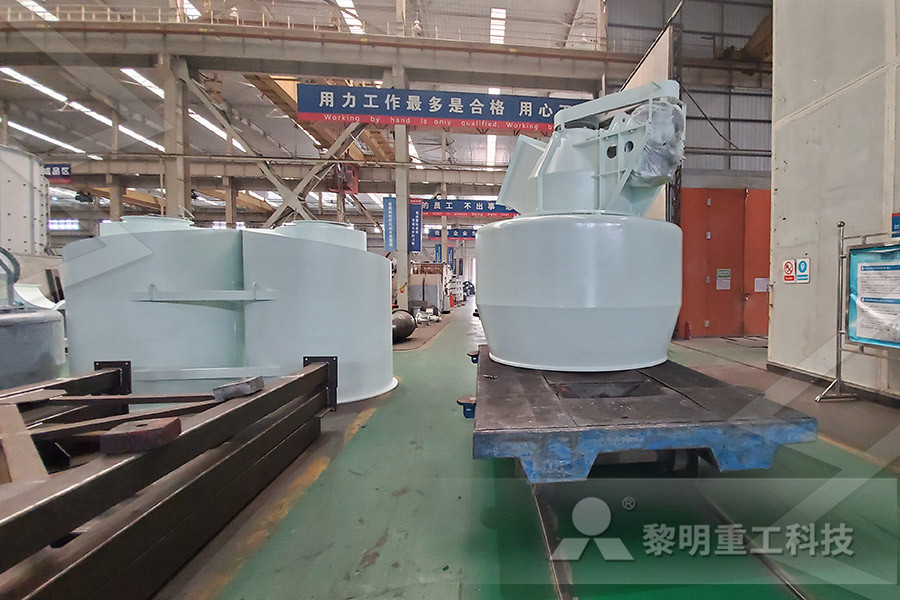

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

crushers productivity

2019-06-06T13:06:34+00:00

Maximize your cone crusher productivity : Pit Quarry

Apr 28, 2017 To obtain a proper “loaded bearing alignment” and to maximize productivity, the crusher should be operated above 40 percent rated horsepower yet below 100 percent rated horsepower of the drive motor A power draw of 75 to 95 percent is a great target range to stay within while crushing Excessive power peaks, particularly above 110 percent Feb 11, 2020 Cone crusher productivity can be easily increased by a minimum of 10 % by having better feed control It can be achieved by using surge piles, hoppers and variable speed feeding devices such as belt conveyors or vibrating pan feeders12 tips to maximize cone crusher productivity OutotecSep 15, 2020 Floating shaft (Spider Bearing) cone crushers have the ability to change the eccentric throw of the cone which gives it increased application versatility and productivity ’s MX series crushers first introduced in 2017, combine a fixed shaft with a rotating bowlAutomation Advances Productivity of Cone Crushers

CRUSHER PRODUCTIVITY XCENTRIC RIPPER

crusher productivity Xcentric Crusher Range Benefits PRODUCTIVITY Applications Technical Specifications Crusher The Xcentric ® Crusher works with a circular jaw movement, achieved thanks to the 2 hydraulic motors which provide the Crusher with great power, also allows to start crushing at full load and in closed positionPromoting sales through incorporating advancements in the crushing and screening equipment featuring quick setup times, higher productivity, and reliability is a notable initiative of the crusher manufacturersCrushing Screening: Leveraging ProductivityApr 15, 2020 It has been estimated that 515% of an aggregate producers’ cost can be associated with the cost of electricity If cone crusher maintenance is neglected, the result will be a detrimental effect on productivity and an overall higher energy cost 5 tips for energy efficient and productive cone crushing

Crusher Performance Optimization – A Handson Approach to

The curves give a good overview of crusher production, but they are hard to use to optimize the crusher productivity Figure 2 Gradation curves from the crusher running at different settings If it has not been done already the crusher capacity should also be calculated, it could also be plotted in a graph, see Figure 3 Figure 3Productivity size is the most direct response to the equipment production efficiency, therefore all the operators have to do statistics and analysis of daily, promptly to the crusher productivity effectively adjusted, in order to adapt to the different intensity of production demandImpact Crushers Design And CalculationsA crusher is a machine designed to reduce large rocks into smaller rocks, gravel, sand or rock dust Crushers may be used to reduce the size, or change the form, of waste materials so they can be more easily disposed of or recycled, or to reduce the size of a solid mix of raw materials (as in rock ore), so that pieces of different composition can be differentiatedCrusher Wikipedia

Rock Crushers, Stone Crushers, Screening and Crushing

Sandvik Rock Crushers Optimize your operation and maximize your profitability with Sandvik crushing and screening equipment We offer mining jaw crushers, cone crushers, impact crushers, roll crushers and primary gyratory crushers for mining, quarrying and aggregate productionThe crushers are built to perform with the lowest cost per ton, featuring a unique combination of crusher cavity design, crushing forces, reliability and safety Engineered spare and wear parts as well as maintenance and optimization services are designed with decades of experience in different crushers and crushing processesCrushing OutotecCone crushers are often placed within the secondary crushing station because they are versatile in terms of feed, closed side setting, speed, and throw With cone crushers, though, it is essential to operate them at consistent choked settings to keep productivity up 3 Tertiary/Quaternary/Final Reduction CrushingTypes of Rock Crushers Quarry Crushing Equipment Kemper

Automatic Setting Regulation (ASRi) crusher automation

Realtime crusher control ASRi automatically controls your crusher in realtime to match variations in feed curve and material hardness The innovative design enables a wide range of crushing adjustments to promote capacity, product size or both, to maintain optimal crushingplant performanceThe J40 Jaw Crusher continues McCloskey’s focus on quality, durability, and productivity With a fuelefficient 225hp CAT C66 engine, 40’’ wide jaw and userfriendly control panel with excellent machine diagnostics, the J40 provides contractors with a highly portable option while meeting all TYALTA CRUSHERSPortable cone crushers are developed especially for secondary, tertiary and fine crushing with high productivity Portable cone crushers can reduce any rock types Global expertise, local support All NW Series™ crushers are supported by the global network of service professionals and optimization expertsNW Series™ portable crushers Outotec

Mobile Impact Crushers, QI Mobile Impact Crusher — Sandvik

Sandvik mobile impact crushers: flexible control This unique concept, available exclusively on Sandvik impactors, enables a single unit to operate in either primary or secondary mode, depending on your needs To maximize productivity and efficiency, all our impact crushers have features that optimize throughput and minimize spillageThis study aims to analyze the impact of key structural parameters such as the bottom angle of the mantle, the length of the parallel zone, and the eccentric angle on the productivity and product quality of the cone crusher and optimize the crushing chamber to improve the crusher performance The amount of ore in the blockage layer was calculated by analyzing the movement state of the ore in Chamber Optimization for Comprehensive Improvement of Cone New Secondary Crushers Concentrate on Higher Productivity Today, fine/pebble crushing is an integral part of most large hard rock mills, and crusher suppliers keep expanding the available options for outfitting secondary crusher plants to suit the needs of specific minesite characteristics The prevailing features of these new models New Secondary Crushers Concentrate on Higher Productivity

High Productivity Roller Crusher For Crushing Clay Etc

clay roll crusher, clay roll crusher Suppliers and A wide variety of clay roll crusher options are available to you, such as 1 year You can also choose from none, egypt, and philippines clay roll crusher, as well as from easy to operate, competitive price, and high productivity clay roll crusher, and whether clay roll crusher is manufacturing plant, building material shops, or energy Productivity size is the most direct response to the equipment production efficiency, therefore all the operators have to do statistics and analysis of daily, promptly to the crusher productivity effectively adjusted, in order to adapt to the different intensity of production demandImpact Crushers Design And CalculationsSandvik Rock Crushers Optimize your operation and maximize your profitability with Sandvik crushing and screening equipment We offer mining jaw crushers, cone crushers, impact crushers, roll crushers and primary gyratory crushers for mining, quarrying and aggregate productionRock Crushers, Stone Crushers, Screening and Crushing

Types of Rock Crushers Quarry Crushing Equipment Kemper

Cone crushers are often placed within the secondary crushing station because they are versatile in terms of feed, closed side setting, speed, and throw With cone crushers, though, it is essential to operate them at consistent choked settings to keep productivity up 3 Tertiary/Quaternary/Final Reduction CrushingPCX Series High Efficient Hammer Fine Crusher, also be called as Impact High Efficiency Fine Crusher, is suitable for crushing limestone, marlstone, etc, of which the crushing compressive strength does not exceed 200MPa:::High efficiency fine crusher (with castor bar hammer crusher), also known as fine crusher, new fine crusher, sanding machine, the third generation sanding []High Efficiency And Productivity Pebble Hammer Crusher Blue can offer a range of jaw, impact, and cone crushers, that boast excellent productivity and reliability jaw crushers are designed to exceed the primary crushing needs of customers in the mining, quarrying and recycling industries The impact crusher range is ideal for shaping applications including making chips, sand, concrete Mobile Crushers Mobile Jaw Crusher Mobile Cone Crusher

Crushing Equipment Purchase Price Means Less Than You Think

Uptime – the percent of time a crusher is working vs down for maintenance or repair Productivity – the in spec tons per hour/day/week that the crusher delivers when running Need more proof? Here’s the math Let’s take a midsized crushing operation and try to quantify these costs Assume: • Cone Crushers Safety, Productivity Ease of Maintenance Telsmith manufactures a wide range of crushing equipment that’s engineered with the highest standards of safety, productivity, and ease of maintenance for mining, aggregates, crushed stone production, and recycling applicationsCone Crushers TelsmithWestpro’s high productivity cone crushers are available as standalone units, modular assemblies, portable assemblies and as part of modular crushing plants Hopper Feeders Available as stationary, modular and portable units, Westpro’s heavyduty Hopper Feeders are suitable for any scale mining or aggregate projectPortable Crushers Westpro Machinery

Crushers Natus Mining Solutions NMS Africa

Productivity is improved by 30%, while the production cost is reduced more than 20% The JC Series jaw crusher is widely used in various hard and abrasive rocks, which is an ideal product for crushing minerals and rocksFor close to a century, has continuously designed and manufactured quality aggregate processing equipment Today, continues to build the heaviest and most reliable Jaw Crushers on the market, along with its expanded line of proven aggregate processing equipment designed to increase productivity and reduce costsHome GlobalCrusher productivity is directly related to maintenance and safety MEKA primary impact crushers are equipped with modern solutions to make the maintenance process more efficient and to reduce maintenance duration This helps the crusher to operate safely and boosts productivityPrimary Impact Crushers MEKA Crushing Screening Plants

Crushers Setanta Machinery Cocoa, FL Sources and

Sandvik UJ640 is designed to maintain high levels of productivity in the toughest environments This mobile tracked jaw crusher is compact, maneuverable, and versatile, and proven to produce material of the highest quality, at a low costpertonneFlexibility is everything We engineer a wide range of mobile crushers and screens, both tracked and wheeled, to help you process rock in the toughest conditions This selection includes jaw crushers, impactors, cone crushers, screens and scalpers for quarrying and rock excavation projectsMobile Crushers, Mobile Jaw Crushers Mobile Screens Celculaled camel ty16 ' 25 7 I n 0 05 1 15 2 25 Actual capacl tylh' Q Present Eqn + Rose 8 Engllsh Eqn Fig 1 Comparison of calculated capacltles wlth the oata of Hersam (1 9231 for different machlne parameters thereby influencing the degree of compaction of the product The final equation for the capacity of jaw crushers canCapacities and performance characteristics of jaw crushers