عنا

مرحبا هل يمكنني مساعدتك؟

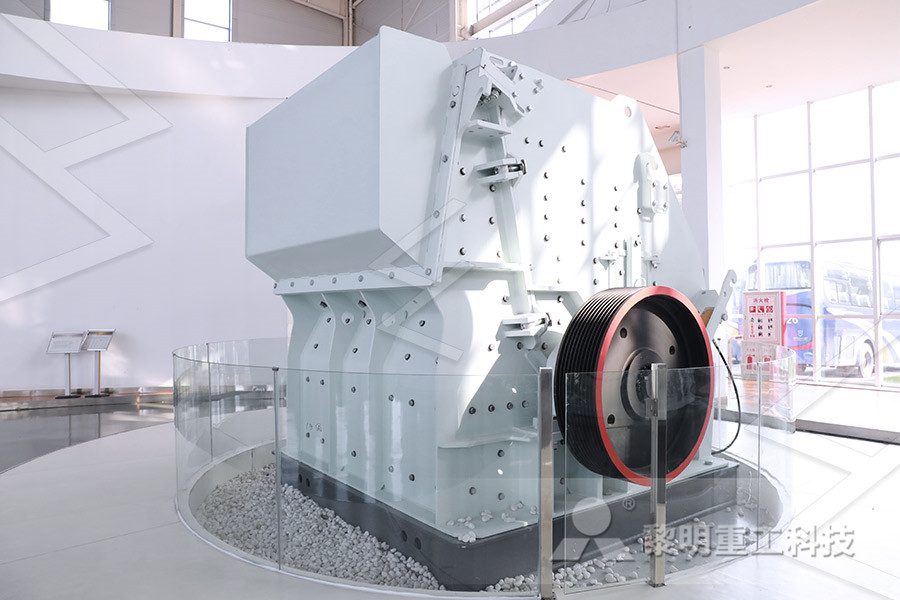

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

magnetic separation in mineral processing

2021-03-27T14:03:05+00:00

Separation in mineral processing Minerallurgy

Magnetic separation is based on the variation in the magnetic susceptibility of minerals in motion through a magnetic field of varying intensity, Separation of paramagnetic and highly magnetic minerals or ferromagnetics, from diamagnetic or weakly magnetic minerals, is achieved by electromagnetic separator Since the development of magnetic separators in the last century, magnetic separation has been regarded as an effective method for mineral recovery With the continuous development of new machines and the continuous improvement of performance, we can now say with certainty that magnetic separation is highly accurateMagnetic Separator Mineral ProcessingApr 02, 2020 Processing plants could capitalize on magnetic separation technologies to reduce their environmental footprint while more efficiently recovering a range of valuable minerals Although the technology has fallen out of favour with some people, there have been advancements in the field of magnetic sorting in the last decadeMagnetic separation – an attractive sorting option

How magnetic separation optimizes sorting and process

Jun 18, 2020 Magnetic separation is one such technology, but give it a second look and you'll see it has many advantages that could improve mineral processing, such as its ability to handle high throughputs and easy operability It’s also relatively low cost and reduces processing footprints downstreamA discussion of magnetic separation techniques for concentrating ilmenite and chromite ores M DOBBINS*, J DOMENICO*, and P DUNN* *Outotec (USA) Inc—Minerals Processing, Physical Separation Magnetic separation has long been used to upgrade and beneficiate a wide variety of industrial mineralsA discussion of magnetic separation techniques for Abstract For many years magnetic separation has been used by the kaolin mineral processing industry on a large scale and it is this industry where magnetic separation using superconducting magnets has stimulated most interest Superconducting magnetic separation has made a number of important technical advances in recent yearsStatus of superconducting magnetic separation in the

Mineral processing metallurgy Britannica

Mineral processing, art of treating crude ores and mineral products in order to separate the valuable minerals from the waste rock, or gangue It is the first process that most ores undergo after mining in order to provide a more concentrated material for the procedures of extractive metallurgyMagnetic separators, of various types, are applied in the concentration of fine iron minerals (taconites ), laundry (black sands ), Wolframite and their separation of Sn (cassiterite), separation of ilmenite or magnetite from Ca phosphate minerals (especially apatite) or other nonmetallic minerals, etcSeparation in mineral processing MinerallurgyThe basic principle of magnetic separation In ore processing, the magnetic method exploits the difference in magnetic susceptibility between minerals For an ore that contains a mixture of particles; the particles which are susceptible to magnetic force and the particles which are not susceptible to the magnetic force; they can be separated Magnetic Separation For Ore Dressing and Metallurgy

Chapter Seven Magnetic Techniques for Mineral Processing

In the field of mineral processing, magnetic separation is mainly used for concentration of magnetic components and for removal of magnetic impurities, under dry or wet conditions Basic Jun 18, 2020 Magnetic separation is also used successfully to separate and recover valuable industrial minerals, as demonstrated by SRC’s Mineral Processing group who have done a lot of work in this area The major cost of mining and recovery of these valuable industrial minerals has already been paid for as these minerals report with the diamonds in the How magnetic separation optimizes sorting and process A discussion of magnetic separation techniques for concentrating ilmenite and chromite ores M DOBBINS*, J DOMENICO*, and P DUNN* *Outotec (USA) Inc—Minerals Processing, Physical Separation Magnetic separation has long been used to upgrade and beneficiate a wide variety of industrial mineralsA discussion of magnetic separation techniques for

Differences and Applications of Magnetic Separation and

Dec 22, 2020 The magnetic separator is the key beneficiation equipment for separating magnetic minerals from nonmagnetic minerals or minerals with magnetic differences The process is based on the different components in the separated materials, which means that in the working magnetic field, the different magnetic field forces and other forces received by Barry A Wills, James A Finch FRSC, FCIM, PEng, in Wills' Mineral Processing Technology (Eighth Edition), 2016 1343 Material Transport in Magnetic Separators Commercial magnetic separators are continuousprocess machines, and separation is carried out on a moving stream of particles passing into and through the magnetic field Close control of the speed of passage of the particles Magnetic Separator an overview ScienceDirect TopicsJun 16, 2013 Magnetic separation 1 A DISCUSSIONONMAGNETIC SEPARATIONPresented By:Gulfam Hussain 2 INTRODUCTION Magnetic separators are used to separateeither valuable minerals from nonmagneticgangue, eg magnetite fromquartz, or magnetic contaminants Or other valuable minerals from the nonmagnetic values All materials are affected in some way whenplaced in a magnetic Magnetic separation SlideShare

Magnetic Separation (Wills' Mineral Processing Technology

Start studying Magnetic Separation (Wills' Mineral Processing Technology, chapter 13, p 353 365) Learn vocabulary, terms, and more with flashcards, games, and other study toolsThe magnetism of nonmagnetic minerals is very small At present, the magnetic separator can not realize mineral processing, so it is called nonmagnetic mineral NOTE: With the development of magnetic separation technology, the boundary between weak magnetic minerals and nonmagnetic minerals will change The lower limit of the magnetization What is Magnetic Minerals How Many Types of Mineral Magnetic separation exploits the different magnetic properties in ore bodies to retrieve target minerals from gangue The process utilises the competition between gravitation, centrifugal and friction forces, magnetic forces, and interparticle attraction or repulsionMagnetic separation : ALS

How magnetic separation optimizes sorting and process

Jun 18, 2020 Magnetic separation is also used successfully to separate and recover valuable industrial minerals, as demonstrated by SRC’s Mineral Processing group who have done a lot of work in this area The major cost of mining and recovery of these valuable industrial minerals has already been paid for as these minerals report with the diamonds in the In the field of mineral processing, magnetic separation is mainly used for concentration of magnetic components and for removal of magnetic impurities, under dry or wet conditions Basic Chapter Seven Magnetic Techniques for Mineral Processing Multotec supplies a complete range of magnetic separation equipment for separating ferromagnetic and paramagnetic particles from dry solids or slurries, or for removing tramp metal Multotec Dry and Wet Drum Separators, WHIMS, Demagnetising Coils and Overbelt Magnets are used in mineral processing plants across the world We can engineer customised magnetic separation solutions for your Magnetic Separation Multotec Mineral Processing

ADVANCES IN MAGNETIC SEPARATION OF ORES

magnetic separation features will be described Dry Magnetic Separation of Nepheline Syenite: The first equipment used in magnetic separation of nepheline syenite is a lowintensity, largediameter drum separator to remove highly magnetic minerals primarily magnetite or mixtures of Jan 04, 2015 1 A DISCUSSION A DISCUSSION ON MAGNETIC SEPARATION ON MAGNETIC SEPARATION 2 INTRODUCTION Magnetic separation is a process in which magnetically susceptible material is extracted from a mixture using a magnetic force Since 19th century magnetic separation processes have been used to concentrate and separate minerals 3Magnetic separation SlideShareAug 07, 2020 Han et al [25, 31, 32] combined seed induced crystallization and magnetic separation, and proposed a novel magnetic seeding and separation process, as shown in Figure 5 Before the iron is precipitated as goethite, finegrained maghemite or magnetite particles are added to the leaching solution to make the goethite precipitate and grow on the Magnetic Separation of Impurities from Hydrometallurgy

Magnetic Separation (Wills' Mineral Processing Technology

Start studying Magnetic Separation (Wills' Mineral Processing Technology, chapter 13, p 353 365) Learn vocabulary, terms, and more with flashcards, games, and other study toolsThe magnetism of nonmagnetic minerals is very small At present, the magnetic separator can not realize mineral processing, so it is called nonmagnetic mineral NOTE: With the development of magnetic separation technology, the boundary between weak magnetic minerals and nonmagnetic minerals will change The lower limit of the magnetization What is Magnetic Minerals How Many Types of Mineral The large peak shown in Fig 13 for centrator the Falcon concentrate displays a diminished magnetic the 094 T magnetic concentrate produced from the Falcon concen Please cite this article in press as: Jordens, A, et al Processing a rare earth mineral deposit using gravity and magnetic separation(PDF) Processing a rare earth mineral deposit using

Chapter 13: Magnetic and Electrical Separation

Magnetic Separation Magnetic separators exploit the difference in magnetic properties between the ore minerals and are used to separate either valuable minerals from nonmagnetic gangue, eg magnetite from quartz, or magnetic contaminants or other valuable minerals from the nonmagnetic The mineral processing industry commonly uses ElectroStatic Separators in conjunction with high intensity magnetic separators such as Bunting’s own Rare Earth Roll Magnetic Separator and Induced Magnetic Roll Separator, it said This combined separation process is used when processing beach sands, for examplemagnetic separation Archives International MiningOct 04, 2018 Magnetic Separation and Iron Ore Beneficiation Magnetic separation is an old technique for the concentration of iron ores and for the removal of tramp iron Since 1849, a number of patents on magnetic separation have been issued in USA, and texts of some of the patents before 1910 describe a variety of magnetic separators for mineral processingMagnetic Separation and Iron Ore Beneficiation – IspatGuru

MAGNETIC SEPARATION YouTube

For more information:7activestudioinfo@7activestudio7activemedical/info@7activemedicalsciencetuts/7activ