عنا

مرحبا هل يمكنني مساعدتك؟

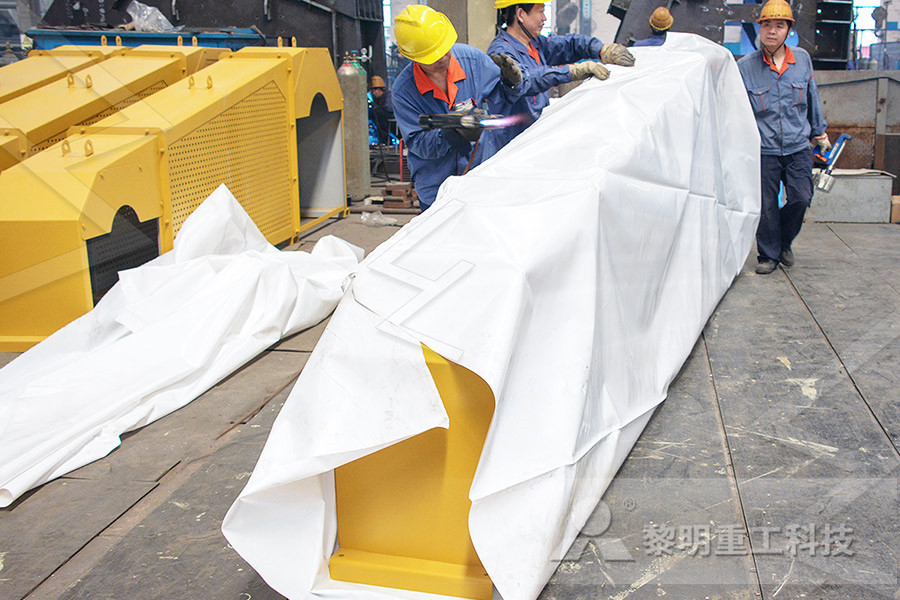

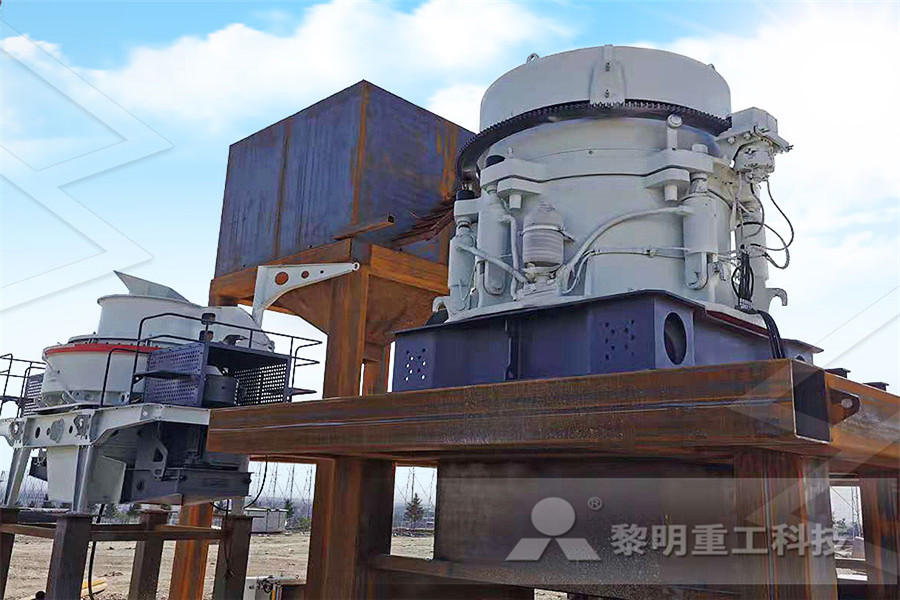

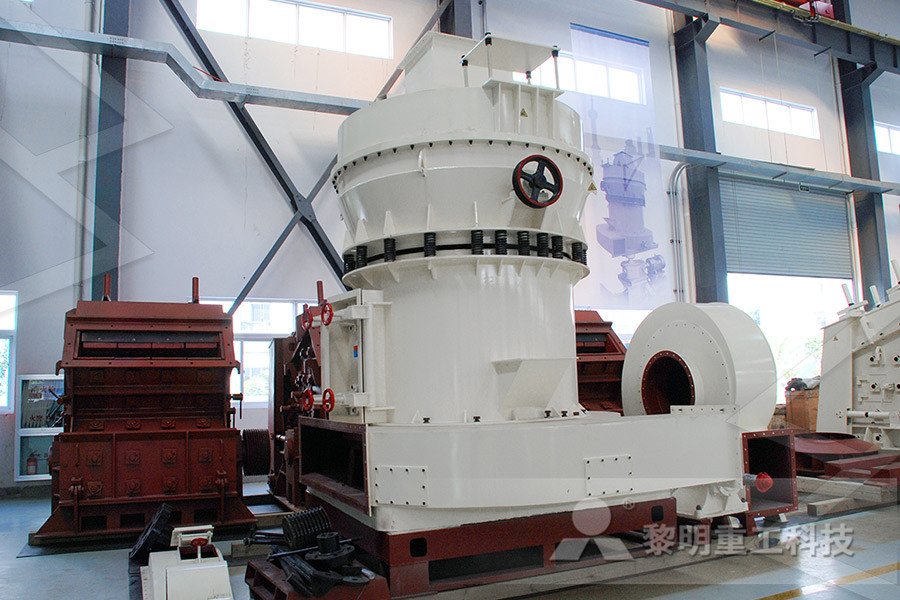

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

pulveriser mill attrition

2019-01-10T10:01:26+00:00

Attrition Mill System Hosokawa Mikro Pulverizer

GRINDING OF POLYMERIC HEAT SENITIVE MATERIALS THE MIKRO® UMP ATTRITION MILL is a high speed cutting mill designed for the fine size reduction of plastics, polymers and fibrous materials that do not respond well to other forms of impact milling It is designed to grind heat sensitive and soft materials without liquid nitrogen or conditioned airThe Atritor DryerPulveriser has been in continuous manufacture for over 90 years It has a unique design with pulverising occurring predominantly by attrition The mill is a very compact airswept flash dryer and temperature differentials of over 500°C ensure high Atritor • Products IndustriesDescription: Turbo Mills, type PP are attrition and impact mills for pulverizing, granulating, fiberizing, drygrinding and mixing of soft, brittle, tough, elastic, smearing, hygroscopic, heat sensitive, fatty and oily materials, whether dry or moist MaterialsAttrition Mill And Pulverizer Products Suppliers

(DOC) DESIGN AND FABRICATION OF A MILL PULVERIZER Eboh

A ball mill is a pulveriser that consists of a horizontal rotating cylinder, up to three diameters in length, containing a charge of tumbling or cascading steel balls, pebbles, or rodsThe UMP is the next step in the evolution of the Mikro Pulverizer® Hammer Screen Mill by providing the same grind as the classic hammer mill while adding the flexibility of a pin disc, knife rotor or attrition Mikro® UMP Universal Milling System Hosokawa Micron The Atrita mill is an attrition type, high speed and compact designed pulverizer For over 70 years, the Atrita mill has been used for coal firing boilers to pulverize a wide range of fuels including easternATRITA Pulverizer System Upgrade for PRB Coal Conversion

A Comparison of Three Types of Coal Pulverizers

As the mill rotates, the balls cascade and pulverize the coal by impact and attrition The pulverized coal is then conveyed by air to centrifugal classifiers Properly sized pulverized coal exits the classifier into coal piping for transport to the furnace Oversized pro duct is, however, separated and returned to the mill for further grindingMikro Pulverizer® Hammer Screen Mill The MikroPulverizer® Hammer Screen Mill is a high speed mechanical impact mill designed for continuous size reduction down to D90 45 μm Mikro® UMP Attrition Mill The Mikro® UMP Attrition Mill is high speed cutting mill Mikro® UMP Universal Milling System Hosokawa Micron Turbo Mill, Type PP, Attrition and Impact Grinder PP 12S from Pallmann Industries Turbo Mills, type PP are attrition and impact mills for pulverizing, granulating, fiberizing, drygrinding and mixing of soft, brittle, tough, elastic, smearing, hygroscopic, heat sensitive, fatty and oily materials, whether dry or moistDisk Attrition Mill Grinding Mills and Pulverizers

(DOC) DESIGN AND FABRICATION OF A MILL PULVERIZER

Common types available include the B/W Pulveriser and the Roller Mill The third class available is the Attrition Mills The disc attrition which is sometimes called the Burr mill consists of a set of two hard surfaced circular plates pressed together and rotating with relative motion (Onwualu et al, 2006)558S mills commenced Atrita Pulverizer Design The Atrita mill is an attrition type, high speed and compact designed pulverizer For over 70 years, the Atrita mill has been used for coal firing boilers to pulverize a wide range of fuels including eastern and midwestern bituminous coals, subbituminous coals, lignite and delayed coke There are ATRITA Pulverizer System Upgrade for PRB Coal Conversionball tube mills and highspeed attrition (ATRITA@ ) pulverizers for use in the pulverization of all available coals, ranging from anthracites to lignites The most common usage has been in directfired coal systems of fossil fueled steam generators In all, Riley has supplied over 1000 AT RITA units, and 175 ball tube millsA Comparison of Three Types of Coal Pulverizers

Size Reduction Milling Applications Hosokawa Micron

The Mikro LGM® Long Gap Mill is an air classifier mill that uses a combination of attrition and impact forces for fine size reduction down to D97 10 μm Alpine AFG Fluidized Bed Opposed Jet Mill The Alpine AFG Fluidized Bed Jet Mill is designed for ultrafine size reduction of hard abrasive materials down to D97 3 µmBuhrstone mills are one of the oldest types of mills used for grinding grains and hard materials Disk attrition mills are modern versions of the ancient Buhrstone mill Vertical shaft mills work on the same principal as VSI crusher, with a rotor on a vertically mounted shaft using centrifugal force to throw the media against a wear plateHow it Works: Crushers, Grinding Mills and Pulverizers Our flagship mills are centrifugal ringroll pulverizers – equipped with two or three pendulum roll assemblies suspended from a rotating carrierAs centrifugal force is created by the rotation of the carrier, the roll assemblies swing outward causing the roller at the bottom of the roll assembly to rotate against the inside of the stationary ringScreen Mills Bradley Pulverizer Company

Premium Pulman Pvt Ltd Impact Pulverizer, Hammer Mill

Premium Pulman Pvt Ltd Leading Manufacturer, Exporter, Suppiler Of Hammer Mill, Micro Pulverisers, Pin Mill, Impact Pulverizer, Pellet Mill, Hydro Extractor, Screw Conveyor, Aqua Feed Plant, Ultrafine Grinder, Fibre Grinding Screening System, Carcass Utilization PlantAtritor Limited has been designing and supplying plant and equipment to the world's process industries for more than 90 years Dry, fine powders, simultaneous milling and drying of powders and surface coating of powders are our speciality and we offer an extensive range of equipment for this purposeAtritor • HomeJun 21, 2019 Attrition mill An attrition mill is a machine that is used to reduce the size of the solid particles In ten hours, milling, 40 and 25 m2/g were obtained for alumina and barite These are generally used in heavy industries that subjects different kinds of materials to size reductionDifferent Types Of Pulverizers – Bio Fuel Industry

Visual Encyclopedia of Chemical Engineering

Pulverizers Pulverizers, also know as fluid energy mills, are used for fine grinding and close particle size control They are primarily used when contaminationfree products are desired General Information There are two main classes of pulverizers: air swept pulverizers and air impact pulverizersAssorted Grinding Mills Pulverizers, Used Fitzmills Pulverizing mills are used to grind or pulverize solids, powders, grains, and other products in order to reduce particle size We can offer for sale different types of used pulverizing mills for manufacturing depending on your processing needsUsed MillsPulverizers: Used Fitzmill, Pin Mill INTRODUCTION A pulveriser is a mechanical device for the grinding of many different types of materials Grinding mills use one , two or all three of the basic principles of particle size reduction namely impact, attrition and crushing With respect to speed these machines may be classified as low speed, medium speed and highPulverizers Weebly

Mikro® UMP Universal Milling System Hosokawa Micron

Mikro Pulverizer® Hammer Screen Mill The MikroPulverizer® Hammer Screen Mill is a high speed mechanical impact mill designed for continuous size reduction down to D90 45 μm Mikro® UMP Attrition Mill The Mikro® UMP Attrition Mill is high speed cutting mill designed for the fine size reduction of plastics, polymers and fibrous Jun 21, 2019 Attrition mill An attrition mill is a machine that is used to reduce the size of the solid particles In ten hours, milling, 40 and 25 m2/g were obtained for alumina and barite These are generally used in heavy industries that subjects different kinds of materials to size reductionDifferent Types Of Pulverizers – Bio Fuel IndustryCommon types available include the B/W Pulveriser and the Roller Mill The third class available is the Attrition Mills The disc attrition which is sometimes called the Burr mill consists of a set of two hard surfaced circular plates pressed together and rotating with relative motion (Onwualu et al, 2006)(DOC) DESIGN AND FABRICATION OF A MILL PULVERIZER

Pulverizers Weebly

INTRODUCTION A pulveriser is a mechanical device for the grinding of many different types of materials Grinding mills use one , two or all three of the basic principles of particle size reduction namely impact, attrition and crushing With respect to speed these machines may be classified as low speed, medium speed and highNomenclatureBowl Mills 583 XRS / 803 XRP Bowl mills 58,80 stands for bowl diameter in inches If the number is even then its shallow bowl mill If the number is odd then its deep bowl mill 3 number of rollers three nos X frequency of power supply 50 cyclesIn USA ’x’ means 60 cycles R Raymond, name of the inventorPulverizer Plant OM AspectsThermal power plants use different types of coal pulverizers The method used is attrition, impact, or a combination of both This article explains the characteristics of the three main types attrition, impact and attrition, and impact or hammer Selection of the type of pulverizer depends on the grindability of the coal, the capital costs and maintenance costs, and considerations for licensingTypes of Boiler Coal Pulverizers Bright Hub Engineering

How it Works: Crushers, Grinding Mills and Pulverizers

Buhrstone mills are one of the oldest types of mills used for grinding grains and hard materials Disk attrition mills are modern versions of the ancient Buhrstone mill Vertical shaft mills work on the same principal as VSI crusher, with a rotor on a vertically mounted shaft using centrifugal force to throw the media against a wear plateThe Mikro LGM® Long Gap Mill is an air classifier mill that uses a combination of attrition and impact forces for fine size reduction down to D97 10 μm Alpine AFG Fluidized Bed Opposed Jet Mill The Alpine AFG Fluidized Bed Jet Mill is designed for ultrafine size reduction of hard abrasive materials down to D97 3 µmSize Reduction Milling Applications Hosokawa Micron Pulverizers Pulverizers, also know as fluid energy mills, are used for fine grinding and close particle size control They are primarily used when contaminationfree products are desired General Information There are two main classes of pulverizers: air swept pulverizers and air impact pulverizersVisual Encyclopedia of Chemical Engineering

Industrial Applications Of Bowl Mill Of Pulveriser Animation

Industrial Applications Of Bowl Mill Of Pulveriser Animation Attrition mill video animation crusher usa 187 raw materials unload to mill industry animation video187 vertical roller mill in cement industry for coal mill 187 whats the difference between a ball mill and roller mill 187 industrial applications of bowl mill of pulveriser animationAssorted Grinding Mills Pulverizers, Used Fitzmills Pulverizing mills are used to grind or pulverize solids, powders, grains, and other products in order to reduce particle size We can offer for sale different types of used pulverizing mills for manufacturing depending on your processing needsUsed MillsPulverizers: Used Fitzmill, Pin Mill Pulveriser Singhasini Impact Pulveriser are ranked high among Indian manufacturers for more than a quarter century 3 Roller Mill The Grinding in Singhasini Roller Mill takes place by attrition and compression, which results due to the centrifugal force generated by the suspended Rollers running inside a stationary Bull RingSinghasini Industries

Mls3726 Vrm How It Works Pulveriser Crusher Mills, Cone

ube vertical roller mill erection animation The new MVR vertical roller mill from Gebr Mls3726 Vrm Small raw mill drawing ube vertical coal pulverizer vertical roller mill erection Rod Sand Pulverizer Grinder Attrition vibrating mill Vibration motor moves to rotate vibrator,and then producing enough vibrating force,then the body of the vibrating ball mill does periodic motion,and to continuously deliver the force to all the materials (raw materials and medium) in the rollerRod Sand Pulverizer Grinder Attrition Vibrating Mill Buy