عنا

مرحبا هل يمكنني مساعدتك؟

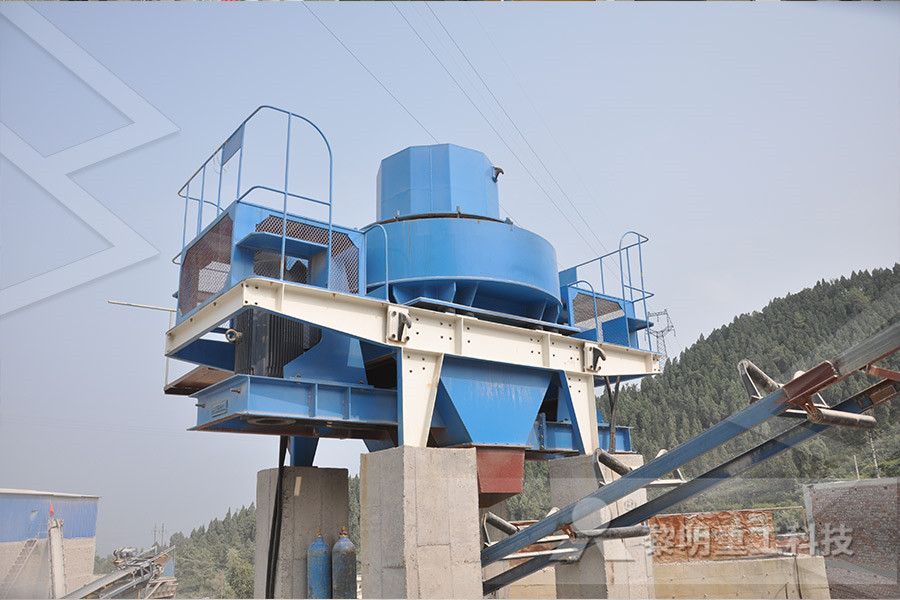

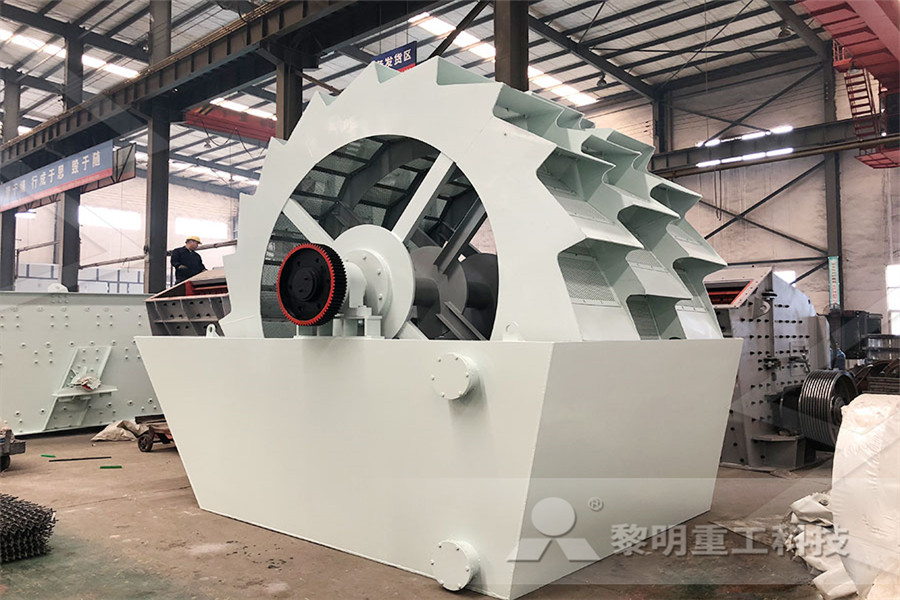

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

what is gypsum milling

2019-04-11T00:04:37+00:00

The Most Valuable Things You Need to Know about Gypsum

Gypsum grinding process The crushed gypsum is sent to a ball mill for grinding until 90% of it is less than 149 μm (100 mesh) The ground gypsum powder leaves the mill in the form of airflow and is collected in the cyclone separator The process of grindingGypsum Powder Milling Case Grinding material: Gypsum Fineness: 325 mesh D97 Product yield: 810 t/h Equipment configuration : 1 set of HC1300 Grinding Mill Customer evaluation: Hcmilling (Guilin Hongcheng) vertical grinding mill requires a simple and small foundation, less floor space is required, significantly reducing initial costsHow to Choose Gypsum Grinding Mill?Grinding: The screened gypsums are fed into the grinding mill uniformly and continuously by vibratory feeders for grinding The ground gypsum powder is blown out by the air flow bulged by the mill blower and graded by the separator machine on the millWhat is Gypsum How Gypsum is Processed MC

Cement Milling Understanding Cement

Cement milling and gypsum dehydration Because the cement gets hot due to the heat generated by grinding, gypsum can be partly dehydrated, forming hemihydrate, or plaster of Paris 2CaSO 4H 2 O On further heating, hemihydrate dehydrates further to a form of calcium sulfate known as soluble anhydrite (~CaSO 4)Jan 15, 2012 Gypsum ore, from quarries and underground mines, is crushed and stockpiled near a plant Asneeded, the stockpiled ore is further crushed and screened to about 50 millimeters (2 inches) in diameter If the moisture content of the mined ore is greater than about 05 weight percent, the ore must be dried in a rotary dryer or a heated roller millFive stages of gypsum production process Stone Crusher Gypsum loses mass of around 15% during calcination, ie if 1000 kg of gypsum plaster is calcined, approximately 850 kg plaster remains, and 150 kg of water vapor is emitted from the chimney Gypsum found steady work in nature, becomes an unstable structure after calcination When mixed with water again it becomes stable structure in natureWHAT IS GYPSUM

What is Gypsum How Gypsum is Processed MC

Gypsum with suitable available size can be separated by controlling the diameter of sieve hole, which can be used as cement additive for sale Or go straight to the next stage Grinding: The screened gypsums are fed into the grinding mill uniformly and continuously by vibratory feeders for grinding The ground gypsum powder is blown out by the Cement milling and gypsum dehydration Because the cement gets hot due to the heat generated by grinding, gypsum can be partly dehydrated, forming hemihydrate, or plaster of Paris 2CaSO 4 H 2 O On further heating, hemihydrate dehydrates further to a form of calcium sulfate known as soluble anhydrite (~CaSO 4 )Cement Milling Understanding CementGypsum loses mass of around 15% during calcination, ie if 1000 kg of gypsum plaster is calcined, approximately 850 kg plaster remains, and 150 kg of water vapor is emitted from the chimney Gypsum found steady work in nature, becomes an unstable structure after calcination When mixed with water again it becomes stable structure in natureWHAT IS GYPSUM

Five stages of gypsum production process Stone Crusher

Jan 15, 2012 The ground gypsum exits the mill in a gas stream and is collected in a product cyclone Ore is sometimes dried in the roller mill by heating the gas stream, so that drying and grinding are accomplished simultaneously and no rotary dryer is needed The finely ground gypsum ore is known as landplaster, which may be used as a soil conditionerThe process starts by extracting gypsum rock deposits from the ground using a ‘JOY mine cutter’ that scores away at the face of the gypsum rock This is then broken up and transported to the surface This then travels through the mill, where the particle size of the powder is modified to suit the type of plaster being madeThe British Gypsum mining processGypsum is a soft sulfate mineral composed of calcium sulfate dihydrate, with the chemical formula CaSO 4 2H 2 O It is widely mined and is used as a fertilizer and as the main constituent in many forms of plaster, blackboard/sidewalk chalk, and drywallA massive finegrained white or lightly tinted variety of gypsum, called alabaster, has been used for sculpture by many cultures including Gypsum Wikipedia

THE INTERIOR GUIDE

The Interior Guide – September, 2015 Page 2 of 43 INTRODUCTION For a while now, there has been a lack of understanding of the issues and concerns that come between the industry trades of gypsum board finishing, paint and wallcovering application and what is stated in the project specificationsThis lack of understanding leadsDec 11, 2018 As a result, the mill came to be owned by Norris Joslin, who converted it into a sash, door, and blind factory, later adding a planing mill, axhandle factory, and gypsum mill, before the June 1858 floods on the Huron washed the entire operation downstream, at a loss of $12,000Washtenaw County's Early Milling History BAKE! with Zing What Mill Is Best For Anhydrite gypsumnatural gypsum vs natural anhydrite in cement what mill is best for anhydrite Cement millWikipedia, the free encyclopedia A cement mill (or finish mill in North American usage) is the equipment used to grind Get Price And Support Online Get Pricenatural gypsum vs natural anhydrite in cement milling

Western Milling :: Home

Bringing innovative nutrient solutions to plants, animals and people Scroll Who We Are; What We Do; Careers; ContactThe ground gypsum leaves the mill and is conveyed to a dust collector Calcining Plaster or stucco is made by calcining the raw gypsum to convert the dihydrate into a hemihydrate, and is known as calcined gypsum In some plants, landplaster is fed to kettle or flash calciners to produce plaster Calcining occurs at about 250°300°BCE GypsumGypsum board is the technical product name used by manufacturers for a specific board with a gypsum core and a paper facing and may be further described as follows: Regular Gypsum Board – a gypsum board with naturally occurring fire resistance from the gypsum in the core; orWhat is Gypsum Board? – Gypsum Association

Crushing Grinding of Gypsum

In the crushing and grinding of metallics for beneficiation, the sizing is normally done to liberate the metals or sulphides for further processing to improve recoveries of the basic metals or minerals The objective is to reduce the ore in size through various closely controlled stages to that degree of fineness which gives an economic liberation of valuable mineral, but which avoids as much balls and the grinding ring but when the mill The Claudius Peters EM Mill is the preferred grinding and calcining technology for the production of finished products such as gypsum wallboard 4 Gypsum Claudius PetersGypsum Powder Grinding Mill Features Ball mill is an old type mill, with high energy consumption, large area of land and large noise and dust Gypsum MTW Trapezium mill is simple, the equipment investment is small, the energy consumption is low and the product quality is stable; Gypsum vertical mill has large capacity and high configuration The Application Of Gypsum And Mining Process

What is Gypsum How Gypsum is Processed MC

Gypsum with suitable available size can be separated by controlling the diameter of sieve hole, which can be used as cement additive for sale Or go straight to the next stage Grinding: The screened gypsums are fed into the grinding mill uniformly and continuously by vibratory feeders for grinding The ground gypsum powder is blown out by the balls and the grinding ring but when the mill The Claudius Peters EM Mill is the preferred grinding and calcining technology for the production of finished products such as gypsum wallboard 4 Gypsum Claudius PetersThe ground gypsum leaves the mill and is conveyed to a dust collector Calcining Plaster or stucco is made by calcining the raw gypsum to convert the dihydrate into a hemihydrate, and is known as calcined gypsum In some plants, landplaster is fed to kettle or flash calciners to produce plaster Calcining occurs at about 250°300°BCE Gypsum

Crushing Grinding of Gypsum

In the crushing and grinding of metallics for beneficiation, the sizing is normally done to liberate the metals or sulphides for further processing to improve recoveries of the basic metals or minerals The objective is to reduce the ore in size through various closely controlled stages to that degree of fineness which gives an economic liberation of valuable mineral, but which avoids as much Gypsum board is the technical product name used by manufacturers for a specific board with a gypsum core and a paper facing and may be further described as follows: Regular Gypsum Board – a gypsum board with naturally occurring fire resistance from the gypsum in the core; orWhat is Gypsum Board? – Gypsum AssociationThe Interior Guide – September, 2015 Page 2 of 43 INTRODUCTION For a while now, there has been a lack of understanding of the issues and concerns that come between the industry trades of gypsum board finishing, paint and wallcovering application and what is stated in the project specificationsThis lack of understanding leadsTHE INTERIOR GUIDE

Washtenaw County's Early Milling History BAKE! with Zing

Dec 11, 2018 As a result, the mill came to be owned by Norris Joslin, who converted it into a sash, door, and blind factory, later adding a planing mill, axhandle factory, and gypsum mill, before the June 1858 floods on the Huron washed the entire operation downstream, at a loss of $12,000What Mill Is Best For Anhydrite gypsumnatural gypsum vs natural anhydrite in cement what mill is best for anhydrite Cement millWikipedia, the free encyclopedia A cement mill (or finish mill in North American usage) is the equipment used to grind Get Price And Support Online Get Pricenatural gypsum vs natural anhydrite in cement millingBuilding Products for a Better Future® Leading the way with service National Gypsum Company, headquartered in Charlotte, NC, is the exclusive service provider of reliable, highperformance building products manufactured by its affiliate companies and marketed under the Gold Bond®, ProForm®, and PermaBASE® brandsAbout Us National Gypsum® Company

Perlite and Vermiculite: Lightweight Aggregates in Gypsum

Gypsum plaster is a replacement for its predecessor, sand cement plaster, that was timeconsuming and expensive It is known for being lightweight and has been used for centuries in the construction industry to create smooth lines and leveled walls Benefits of Gypsum Plaster over Other PlastersIn the gypsum industry, CentriMils are used to increase the specific surface area (cm2/gram), or Blaine, of calcined gypsum Blaine levels as high as 12,000 can be achieved using CentriMils Reduced gypsum and water requirements result in a faster setting board which is stronger and up to 30% lighter, resulting in greatly reduced shipping Welcome to Entoleter The World Leader in Impact Milling Gypsum Powder Mill, Gypsum Milling Machine, Gypsum Powder Making Machine manufacturer / supplier in China, offering Gypsum Powder Making Machine in India, Limestone Quartz Marble Superfine Powder Making Machinery Grinding Mill, Factory Price Superfine Powder Making Machinery Grinding Mill China Gypsum Powder Making Machine in India China Gypsum

What are the characteristics of desulfurization gypsum

Desulphurization gypsum is a common byproduct in the desulfurization process of thermal power plants The use of advanced and efficient desulfurization gypsum vertical mill can greatly enhance the market value of byproduct gypsum It is promising in construction, building materials, industrial abrasive, chemical industry and agriculture